TABLE OF CONTENTS

viii Bravo™ Preventive Maintenance Guide Rev. 2

Chapter 2: Technical Data

Section A: Facility Requirements and Specifications

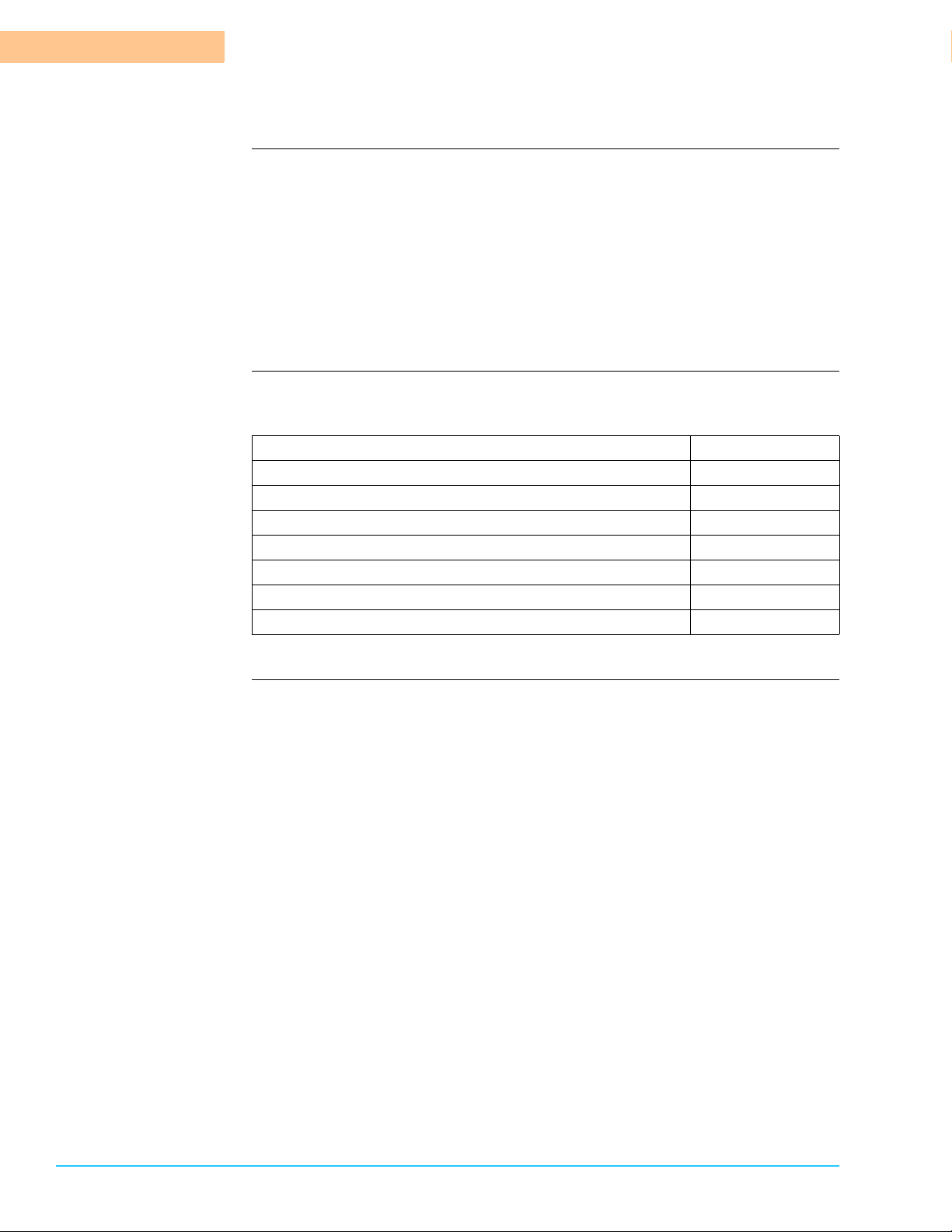

Exhaust Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ElectricalInformation. .. . . . .. . . . .. . . .. . . . .. . . . .. . . . .. . . . .. . . . .. 19

Standard Power Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Start Up Power Requirements Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Process Ready Power Requirements Table. . . . . . . . . . . . . . . . . . . . . . . . . . . 19

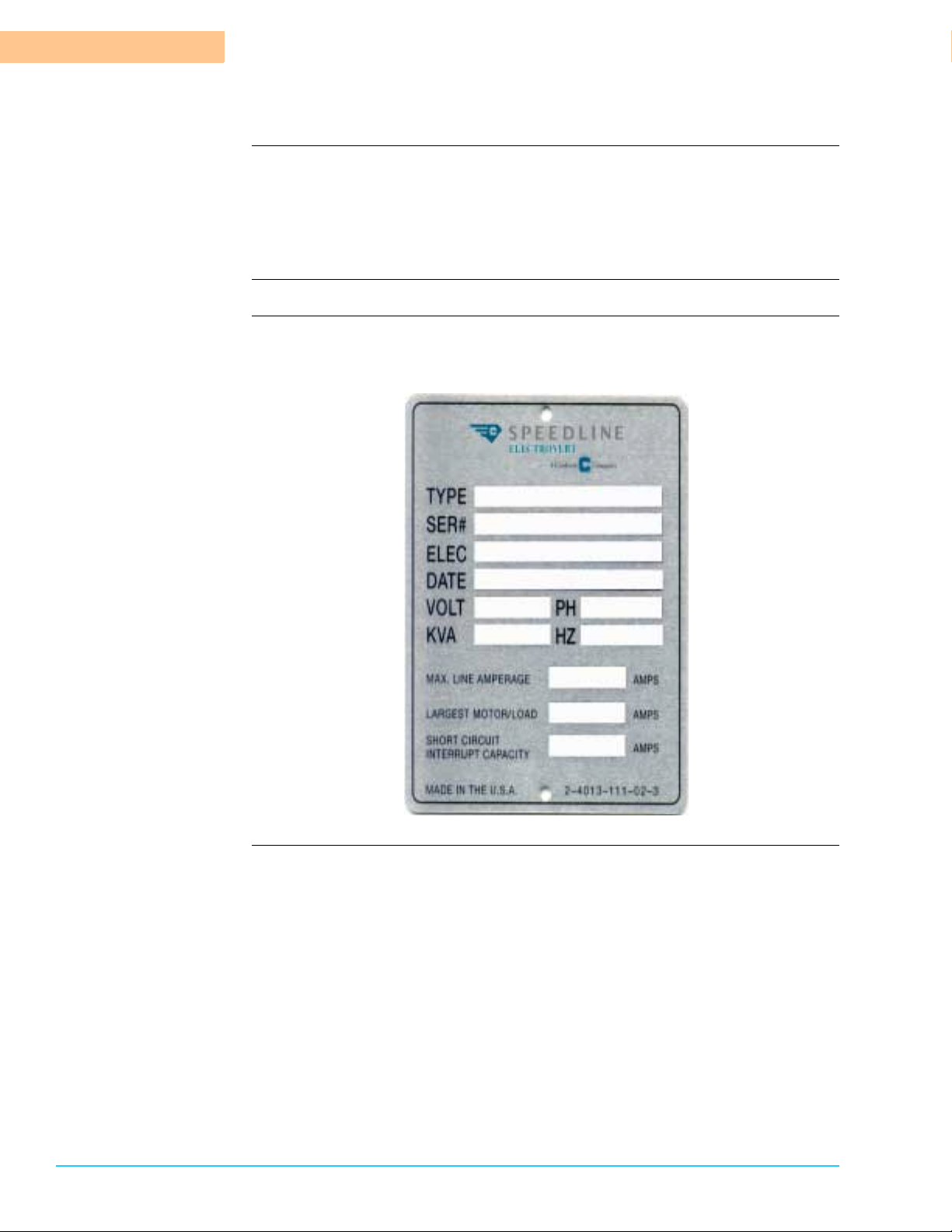

Electrical Codes and Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Underwriters Laboratory (UL). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

CE Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

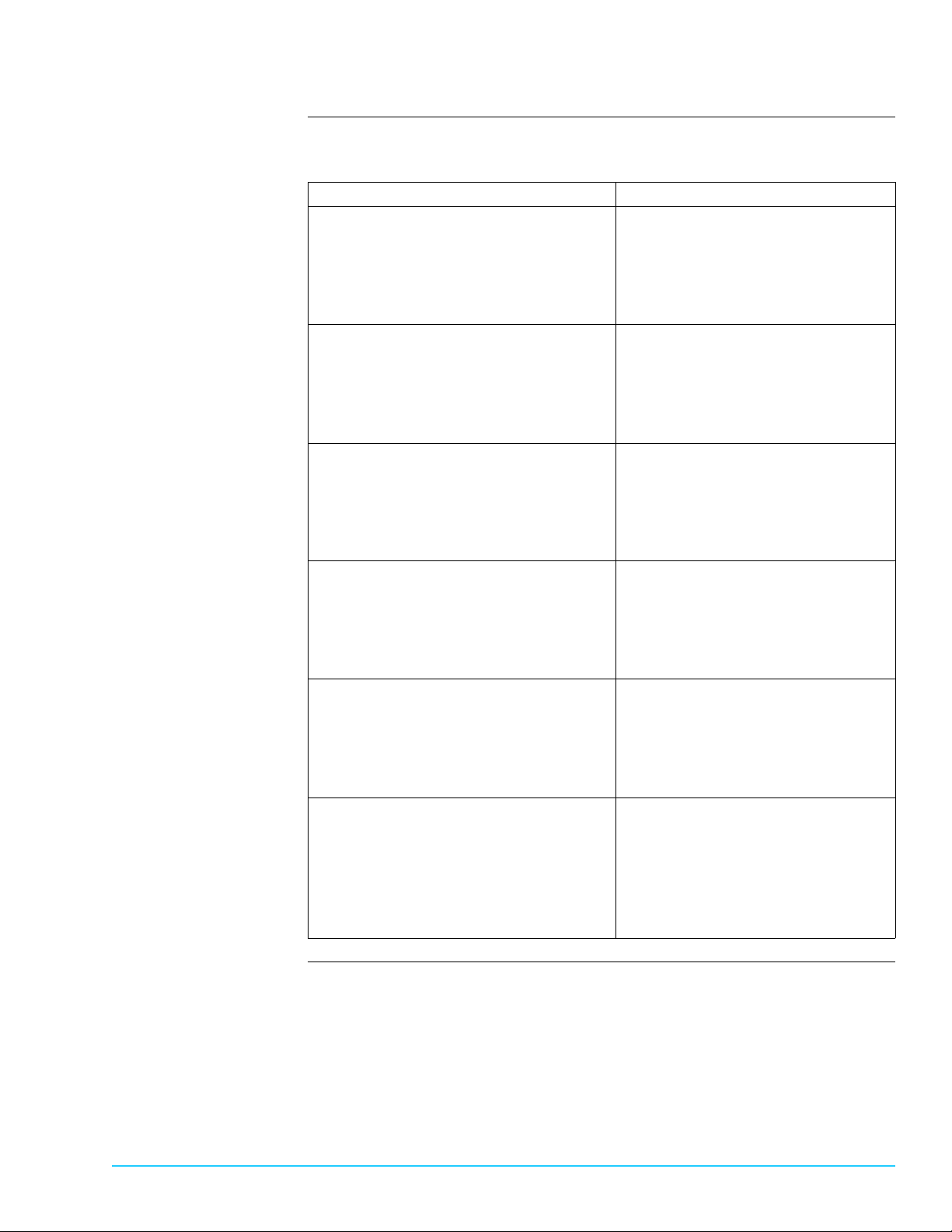

Section B: Machine Components

Forced Convection Heating Module Table . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Convection Blower Specifications Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Forced Convection Air Cooling Module Table . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cooling Blower Specifications Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Conveyor Module Standard Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Conveyor Module Options Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Conveyor Specifications Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Section C: System Dimensions

Physical Characteristics Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Chapter 3: Preventive Maintenance Schedule

Safety Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Section B: Weekly PM Schedule

Weekly PM Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Section C: Monthly PM Schedule

Monthly PM Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Section D: Quarterly, Semi–Annual and Annual Maintenance PM Tables

Quarterly, Semi–Annual and Annual Maintenance PM Tables . . . . . . . . . . . . . . . 31

Quarterly Maintenance Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Semi–Annual Maintenance Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Annual Maintenance Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Chapter 4: Weekly Preventive Maintenance Procedures

Rail Width Limit Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Limit Switch Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Analog Transducer Wire Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Photocell(s) Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Chapter 5: Monthly Preventive Maintenance Procedures

Electrical Cabinet Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Vacuum Hood Exhaust Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Cleaning Machine Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Inspect Chamber Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Blower Inspection and Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Exhaust Vent Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45