CONTENTS

CONTENTS ...........................................................................................................................................................2

TABLE OF FIGURES ............................................................................................................................................... 4

1. GETTING STARTED......................................................................................................................................... 5

2. SAFETY..........................................................................................................................................................5

3. COMPONENTS INCLUDED WITH EMMA..........................................................................................................6

4. COMPONENTS THE INSTALLER NEEDS TO SUPPLY...........................................................................................7

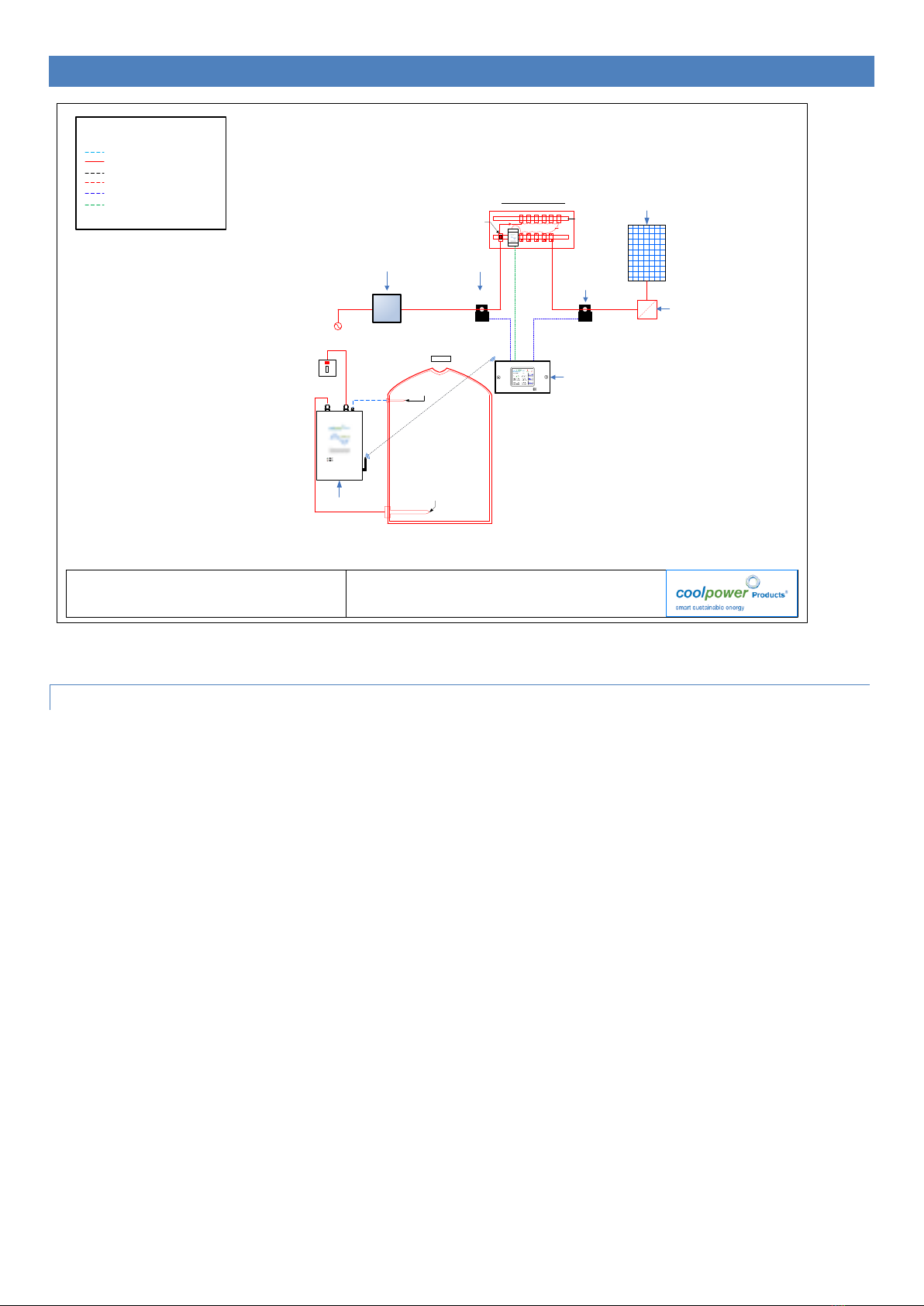

INSTALL OVERVIEW..............................................................................................................................................8

Description of basic operation................................................................................................................................... 8

5. ELITE INSTALLATION......................................................................................................................................9

ELITE WALL MOUNTING ...................................................................................................................................................... 9

Procedure................................................................................................................................................................... 9

CABLE ENTRIES .................................................................................................................................................................. 9

Procedure:.................................................................................................................................................................. 9

POWER SUPPLY TO THE ELITE ............................................................................................................................................... 9

Procedure................................................................................................................................................................... 9

POWER SUPPLY TO THE ELITE ............................................................................................................................................. 10

Procedure:................................................................................................................................................................10

FIT IMPORT EXPORT CT PROCEDURE ...................................................................................................................................10

Procedure:................................................................................................................................................................10

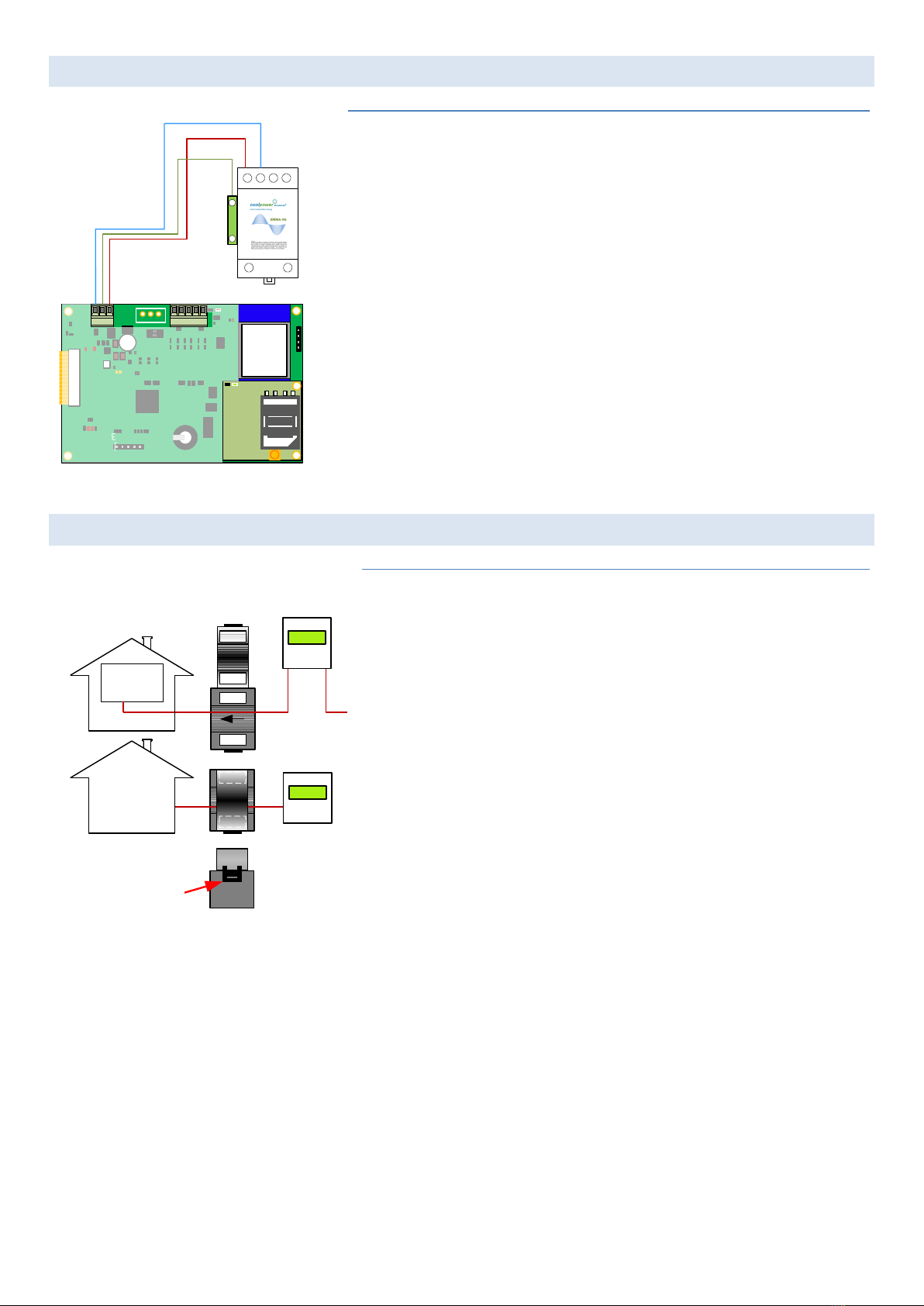

IMPORT EXPORT CT WIRING.............................................................................................................................................. 11

Procedure:................................................................................................................................................................11

FIT GENERATION CT.........................................................................................................................................................11

Procedure:................................................................................................................................................................11

GENERATION CT WIRING ..................................................................................................................................................11

Procedure................................................................................................................................................................. 11

CONNECT EARTH .............................................................................................................................................................12

Procedure................................................................................................................................................................. 12

ATTACH FACEPLATE TO BACKPLATE .....................................................................................................................................12

Procedure................................................................................................................................................................. 12

POWER THROTTLE INSTALLATION ...................................................................................................................... 13

POWER THROTTLE WALL MOUNTING ..................................................................................................................................13

Power Throttle Lid Screws........................................................................................................................................ 13

Power Throttle keyhole mounting slots ...................................................................................................................13

POWER THROTTLE MAINS WIRING ......................................................................................................................................14

POWER THROTTLE TEMP SENSOR WIRING.............................................................................................................................15

Extended Earth incoming lead with ring terminal termination to screw connection. .............................................15

Power Input from Mains ..........................................................................................................................................15

Power output to load...............................................................................................................................................15

TEMPERATURE SENSORS....................................................................................................................................................16