CONTENTS

PRODUCT ........................................................................................................................................ 1

1 PRODUCT LIST ........................................................................................................................................ 1

2 NOMENCLATURE..................................................................................................................................... 2

2.1 Nomenclature of outdoor units.................................................................................................................. 2

3 PRODUCT FEATURES............................................................................................................................. 2

3.1 General introduction..................................................................................................................................... 2

3.2 Features............................................................................................................................................................ 2

4 SPECIFICATIONS..................................................................................................................................... 3

4.1 Specifications................................................................................................................................................. 3

4.2 Operation range ............................................................................................................................................. 4

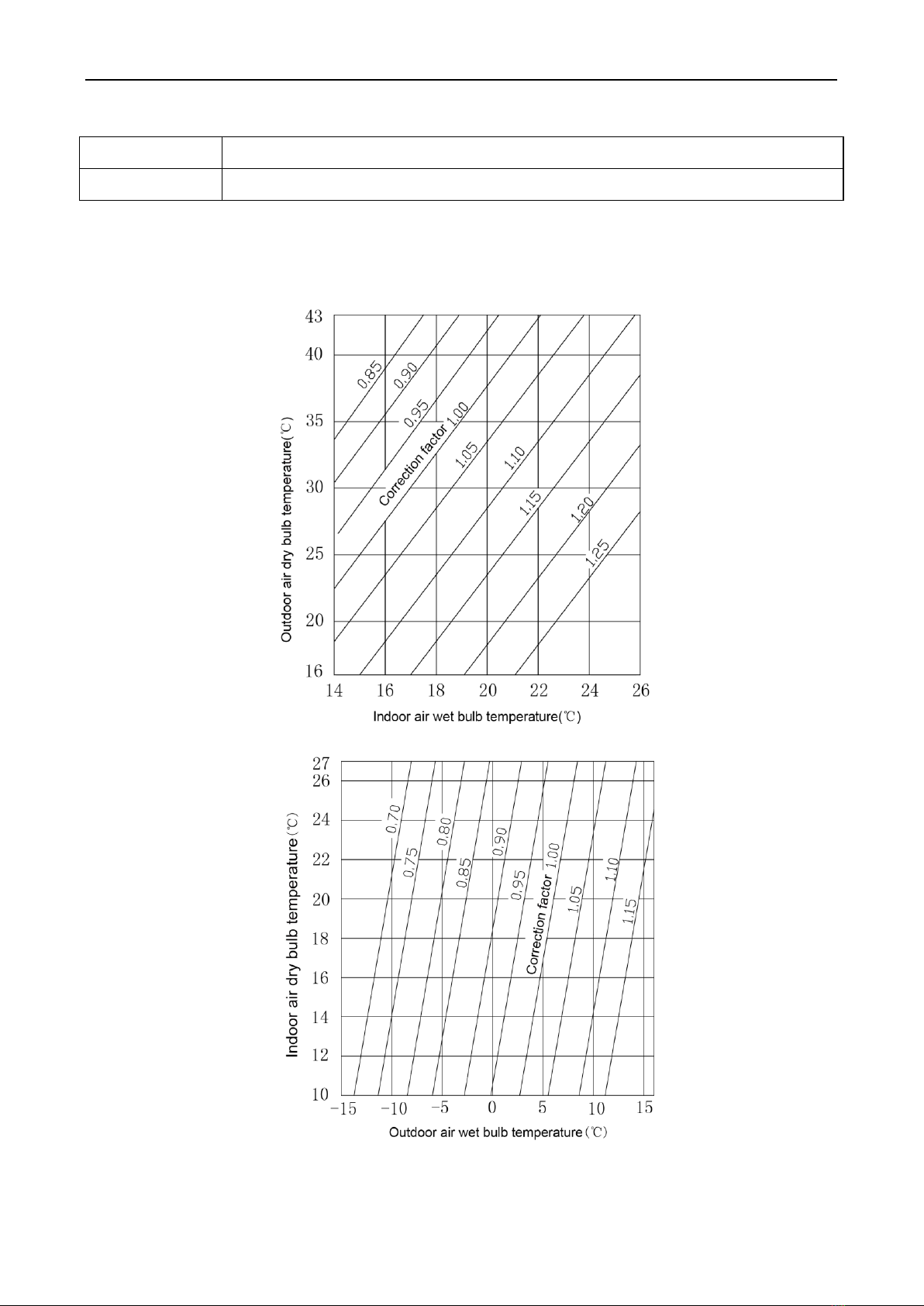

5 PRODUCT CAPACITY CORRECTION..................................................................................................... 4

5.1Correction factor of indoor and outdoor temperature .......................................................................... 4

5.2 Correction factor of pipe length and height difference........................................................................ 5

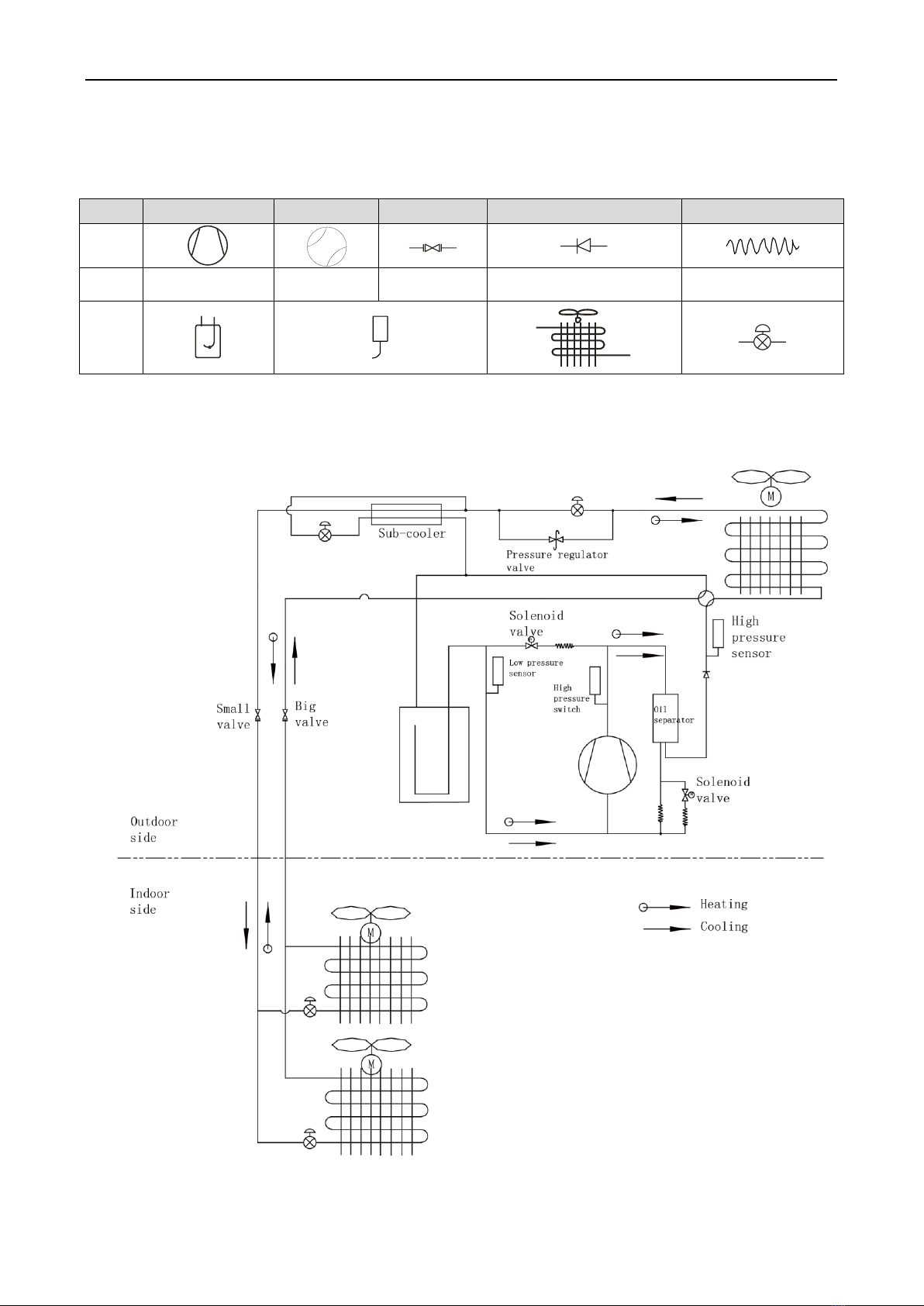

6 PRINCIPAL OF OPERATION.................................................................................................................... 6

CONTROL ........................................................................................................................................ 9

1UNITS’ CONTROL.................................................................................................................................... 9

1.1 Schematic diagram of units’ control ......................................................................................................... 9

1.2 Interpretation on the schematic diagram................................................................................................. 9

2REMOTE MONITORING SYSTEM .......................................................................................................... 9

2.1 General introduction..................................................................................................................................... 9

3MONITORING SOFTWARE................................................................................................................... 10

3.1 Function introduction................................................................................................................................. 10

3.2 Connection of computer and units.......................................................................................................... 10

3.3 Parts introduction........................................................................................................................................ 11

INSTALLATION .............................................................................................................................. 55

1 ENGINEERING INSTALLATION PREPARATION AND NOTICE .......................................................... 55

1.1 Installation notice ........................................................................................................................................ 55

1.2 Installation key points and importance.................................................................................................. 55

2 INSTALLATION MATERIALS SELECTION............................................................................................ 56

2.1 Refrigerant piping........................................................................................................................................ 56

2.2 Condensate water pipe............................................................................................................................... 57

2.3 Insulation material....................................................................................................................................... 57

2.4 Communication cable and control cable............................................................................................... 57

2.5 Power cable................................................................................................................................................... 58

2.6 Hanger rod and support............................................................................................................................. 58

3 INSTALLATION OF OUTDOOR UNIT.................................................................................................... 58

3.1 Check before installation........................................................................................................................... 58

3.2 Selection of installation site...................................................................................................................... 58

3.3 Carrying and installing outdoor unit....................................................................................................... 58

3.4 Installation notices...................................................................................................................................... 59

3.5 Fixing and damping of unit ....................................................................................................................... 59

3.6 Outline dimension and position of installation hole........................................................................... 59

3.7 Installation space requirement................................................................................................................. 60

DEBUGGING &MAINTENANCE.................................................................................................... 61

1 DEBUGGING OF UNIT........................................................................................................................... 62

1.1 Preparation for debugging......................................................................................................................... 6 2

1.2 Debugging of unit........................................................................................................................................ 63

1.3 Parameters reference value for the normal operation of unit.......................................................... 67

2 MALFUNCTION LIST.............................................................................................................................. 69

2.1 Malfunction list for the wired controller................................................................................................. 69

2.2 Status display table for indicators on main board of outdoor unit................................................. 70

3 TROUBLESHOOTING ............................................................................................................................ 78

4 POWER DISTRIBUTION OF UNIT......................................................................................................... 88

4.1 Power distribution of unit.......................................................................................................................... 88

4.2 Main electric parts ....................................................................................................................................... 88

4.3 Circuit diagram............................................................................................................................................. 89