CHINT NVF5 Series User manual

NVF5 Series Inverter Preface

Preface

Thank you for choosing Chint NVF5 series Inverter.

NVF5 series Inverter adopts the speed sensorless vector control technology, It has

the features of fast load response, low frequency high torque and strong overload

capability,Realized the precise control of industrial equipments.NVF5 series inverter has

performance of stable voltage output、torque limited、speed track、simple PLC、process

PID etc.Satisfying the requrements of many industrial equipments,such as Drawing

Machine、Textile、Macine Tools、Logistic、packaging、Food、Plastic Cement、Fans and

Pumps.

NVF5 series Inverter are designed with internal EMC circuit to depress

electromagnetic interference and full thinking of EMC、dust、oil pollution of the customer

site.The modular design of NVF5 can reduce dust and oil stains into the machine.All NVF5

series can realize IP22 with optional top protective cover.

NVF5 series Inverter has three levels parameter menus:Simple mode,Customized

mode and Engineering mode.Be able to meet requirement of different users.The simple

mode is easy to learn,is intended for beginners;The custom mode is able to customize

specific parameter menu,is intended for specific equipment debugger;The engineering

mode contains all user parameters,is intended for professional engineers.

The manual is intended for qualified personnel and provided instructions and

features of NVF5, including Product selection, installation and programming, parameter

explanation, etc. To ensure proper use of the inverter, please read this manual carefully

before using. Plase save it for using later.

If having any problems which cannot be solved during use, please contact

corresponding Chint channels or directly contact the Chint technical personnel for help.

(Customer service phone: 400-1177-797)

The company reserves the right to constantly optimize and improve NVF5 series

inverter, information is subject to change without notice.

NVF5 Series User Manual Table of Content

Table of Contents

Chapter 1 Safety Information .................................................................... - 1 -

1.1 Safety Definition...............................................................................................- 1 -

1.2 Safety Precautions...........................................................................................- 1 -

1.3 Precautions for Users.......................................................................................- 3 -

1.4 Notice of Scrap.................................................................................................- 5 -

Chapter 2 Product Overview..................................................................... - 6 -

2.1 Catalog Numbers Description ..........................................................................- 6 -

2.2 Nameplate Description.....................................................................................- 6 -

2.3 Specifications and Models................................................................................- 6 -

2.4 Technical Specifications...................................................................................- 7 -

2.5 ProductAppearance and Diagram...................................................................- 9 -

2.6 Product Dimensions and Weights..................................................................- 10 -

2.7 IP22 Top Protective Cover Description........................................................... - 11 -

Chapter 3 Installation and Wiring ...........................................................- 13 -

3.1 Peripherial Components Description..............................................................- 13 -

3.2 Peripherial Components Selection and Guideline..........................................- 13 -

3.3 Installation......................................................................................................- 16 -

3.4 Description of the cover..................................................................................- 17 -

3.5 Wiring of Power Terminal and I/O Terminal....................................................- 18 -

3.6 I/O Terminal Description.................................................................................- 22 -

3.7 EMC Precautions...........................................................................................- 24 -

Chapter 4 Integral Keypad....................................................................... - 26 -

4.1 Integral Keypad Instructions...........................................................................- 26 -

4.2 Integral Keypad LED Light and Display..........................................................- 27 -

4.3 Parameter Menu Mode...................................................................................- 29 -

4.4 Integral Keypad Lock and Password Setting..................................................- 32 -

Chapter 5 Simple Parameter Menu and Commissioning Process.........- 34 -

5.1 Simple Parameter Menu List..........................................................................- 34 -

5.2 Simple Commissioning Process.....................................................................- 36 -

Chapter 6 Parameter Function Description............................................- 38 -

6.1 Start Source Setting.......................................................................................- 38 -

6.2 Frequency Reference Setting.........................................................................- 42 -

6.3 Start and Stop Setting....................................................................................- 57 -

6.4 Motor Auto Tuning..........................................................................................- 62 -

6.5 V/F Parameters..............................................................................................- 64 -

6.6 Vector Control Parameters.............................................................................- 67 -

6.7 OverCurrent Stall Protection ..........................................................................- 71 -

6.8 OverVoltage Stall Depress.............................................................................- 71 -

6.9 Protective Function ........................................................................................- 72 -

6.10 Monitoring Function......................................................................................- 78 -

6.11 I/O Terminal Parameter Setting ....................................................................- 78 -

6.12 Ride Through Function.................................................................................- 85 -

6.13 Jogging.........................................................................................................- 86 -

- 1 -

NVF5 Series User Manual Table of Content

6.14 Skip Frequency............................................................................................- 87 -

6.15 Forward and Reverse Switch.......................................................................- 87 -

6.16 Regenerative Braking...................................................................................- 88 -

6.17 Frequency Detection Output(FDT)..........................................................- 88 -

6.18 Output Current Zero Point Detection............................................................- 89 -

6.19 Running Timer..............................................................................................- 89 -

6.20 Start At Power Up.........................................................................................- 90 -

6.21 Sleep Wake Mode........................................................................................- 90 -

Chapter 7 Troubleshooting......................................................................- 91 -

7.1 Diagnostic ......................................................................................................- 91 -

7.2 Abnormal Operation and Solution ..................................................................- 95 -

Chapter 8 Maintenance............................................................................ - 97 -

8.1 Maintenance Instructions ...............................................................................- 97 -

8.2 Maintenance Items.........................................................................................- 97 -

8.3 Routine Maintenance.....................................................................................- 98 -

8.4 Regular Maintenance.....................................................................................- 98 -

8.5 Spare Parts Replacement..............................................................................- 99 -

8.6 Storage.........................................................................................................- 100 -

Appendix A RS485-MODBUS Communication Instructions ................- 101 -

A.1 Networking Mode.........................................................................................- 101 -

A.2 Interface Mode.............................................................................................- 101 -

A.3 Communication Mode..................................................................................- 101 -

A.4 Protocol Format...........................................................................................- 102 -

A.5 Protocol Application .....................................................................................- 103 -

A.6 Control Command, State Information and Fault Information........................- 105 -

A.7 Parameter Management..............................................................................- 108 -

A.8 Network Wiring ............................................................................................- 109 -

A.9 Definition of Communication Exception Code..............................................- 109 -

Appendix B Parameter list ....................................................................- 111 -

Appendix C Accessiories ......................................................................- 142 -

Quality Commitment..............................................................................- 143 -

- 2 -

NVF5 Series User Manual Chapter 1 Safety Information

Chapter 1 Safety Information

Before conducting transfer, installation, running and maintenance, please read the

user manual carefully and conform to all safety guidelines for the application. Failue to

comply may result in personal injury and/or equipment damage or even death of people.

In the event of personal injury and equipment damage caused by noncompliance with

the safety guidelines by you or your clients, Chint can not assume any responsibility.

1.1 Safety Definition

1.2 Safety Precautions

1.2.1 Before installation

Attention

Installation is not allowed in case that the nameplate is inconsistent with your order

requirements!

Installation is not allowed in case that material

objects are inconsistent with the packing

list!

1.2.2 Installation

Danger

Installation must be conducted by qualified personnel in case of the danger of electric

shock!

Please install the inverter on the metal equipmen(supplementary enclosure) or

other

non-combustible objects in case of the danger of fire!

It is not permitted to place combustibles nearby in case of the danger of fire!

The products should be installed with either fuses or an input circuit breaker between

the inverter and power supply in case of danger of fire!

!

Sign

Description

Danger

The occasion where death or serious injury may be caused by the

mis-operation.

Attention

The occasion where intermediate or slight injury or property damage may be

caused by mis-operation.

Danger

In case of a damaged inverter or components lack, it is not suggested to conduct

installation or running; otherwise, the danger of fire or injury may be caused!

It is not allowed to contact with the power terminals, the control circuit terminals

,

electronic parts and components of the inverter by hand directly!

!

- 1 -

NVF5 Series User Manual Chapter 1 Safety Information

It is not permitted to install the inverter in an environemnt containing explosive gases in

case of the danger of explosion!

It is not permitted to insall the inverter at a place directly exposed in sunlight in case of

the danger of equipment damage!

It is not permitted to install the inverter on occasions where water splashing in case of

the danger of equipment damage!

1.2.3 Wiring

1.2.4 Running

Attention

In the transfer process, it is not allowed to make the integral keypad and the cover plate

under pressure in case of the danger that they fall off and damage equipment and

person!

Please install the inverter on the place capabel of bearing the weight in case that the

inverter falls off and damages equipment and person!

In the installation process, it is not permitted to leave metal objects in the machine in

case of the danger of fire!

Danger

Wiring must be conducted by qualified personnel in case of the danger of electric

shock!

Wiring

is not allowed to be conducted unless complete disconnection of the input power

is confirmed in case of the danger of electric shock!

The ground terminal of the inverter must be reliably grounded in case of the danger of

electric shock!

The exposed parts

of cables used for main circuit connection must be well wrapped

with insulating tape in case of the danger of electric shock!

It is not allowed to realize short circuit between P and B in case of the danger of fire and

equipment damage!

The main circuit te

rminal and the cable lug must be connected firmly in case of the

danger of equipment damage!

The I/O terminals besides RA, RB and RC are prohibited to wire with AC 23

0V in case

of the danger of equipment damage!

Attention

The voltage withstand test has been finished before leaving the factory; the users no

longer have to conduct the test again, otherwise the improper test could damage the

device!

When the cable length of the motor is greater than 50 meters, output AC reactor is

suggested in case of the danger of equipment damage!

!

!

- 2 -

NVF5 Series User Manual Chapter 1 Safety Information

1.3 Precautions for Users

Danger

The inverter must be covered with the cover plate before power on in case of the

danger of electric shock and explosion!

The inverters which have been stored for more than 2 years must been done

precharge

experiment. When energized, the voltage regulator is used to slowly increase the

voltage in case of the danger of electric shock and explosion!

During power-on, it is not allowed to touch the terminals by hand in case of the danger

of electric shock!

It is not permitted to operate the inverter with a damp hand in case of the danger of

electric shock!

After replacing control boar

ds,the inverter will begin running after parameters are

correctly set in case of the danger of equipment damage!

The products is intended for qualified personnel to test during running in case of the

danger of personal injury or equipment damage!

Please don’t change original factory parameters in case of the danger of equipment

damage!

Attention

Please ensure the power phase and rated voltage are consistent with the nameplate of

the product in case of the danger of equipment damage!

Check connection of the main circuit of the inverter to ensure disappearance of short

circuit and fastened conenction in case of the danger of equipment damage!

It is not permitted to control the inverter start and stop frequently in a power-

on and

power-off mode in case of the danger of equipment damage!

Safety

Information

Description

Compared with

power frequency

running

The inverter is a voltage source type machine and the output

voltage is PWM waves including harmonics. Therefore, the

temperature rise, noise and vibration of the motor will slightly

increase compared with power frequency running.

Constant-torque

low-speed

running

When the inverter drives common AC induction motor to run at a

low speed for a long term, the output torque maybe reduced due to

the heat dissipation effect of the motor. If it is required to run at a

low speed and constant-torque for a long term, a variable frequency

motor must be used.

Electronic thermal

protection value

of motor

When using an adaptive motor, the inverter could perform thermal

protection on the motor. In case that the motor is not matched with

the inverter in rated capacity, the protection threshold value must be

adjusted or other protection must be taken for guaranteeing safe

running of the motor.

Running over

50Hz

In case that the motor runs at the frequency over 50Hz, in addition

to increase of the vibration and noise of the motor, the applied

!

- 3 -

NVF5 Series User Manual Chapter 1 Safety Information

speed range of motor bearings and mechanical devices must be

ensured, please inquiry in advance if having questions.

Lubrication of

mechanical

devices

The gearbox, gears and other mechanical devices needing

lubrication probably be damaged when running at a low speed for a

long term , please inquiry in advance if having questions.

Negative torque

load

For lift load , negative torque is often generated, the inverter may

trip due to overcurrent or overvoltage, and then a appropriate brake

assembly should be selected.

Mechanical

resonance point

of load

Within the output frequency range, the inverter may encounter the

mechanical resonance point of the load, now the skip frequency

shold be selected.

Occasion of

frequently start

and stop

Selecting DI terminals to control the start/stop of the inverter. It is

prohibited to use contactors and other switching devices at the input

side of the inverter for direct and frequent start/stop in case of

equipment damage.

Motor insulation

check before

connection to

inverter

When the motor is used for the first time or before the motor is used

again after being placed for a long time, insulation check shall be

conducted to prevent the effectiveness of insulation of a motor

winding in case of the damage to the inverter. Wiring is shown in the

following figure. In the testing process, it is supposed to adopt a

500V voltage type megger and guarantee that the insulation

resistance is not less than 5MΩ.

Capacitor or

voltage

dependent

component for

improving power

factors

Since the inverter PWM output waveform, fault trip of the inverter or

damage to devices may be caused if a capacitor or an anti-thunder

piezoresistor installed at the inverter output must be removed.

Contactor and

switching devices

installed on the

output of the

inverter

If a contactor and other switching devices will be used between the

output of the inverter and the motor, please ensure that switch

operation is performed on the inverter whitout running; otherwise,

the inverter may be damaged.

Outside rated

voltage

It is not suggested to use the inverter beyond the allowable

operating voltage range, and please use a corresponding voltage

increasing/decreasing device for voltage transformation if needed.

Lightening surge

protection

A surge protection device installed in the inverter.The inverter has

certain self-protection ability to inductive thunder.

Altitude and

In the areas at the altitude exceeding 1000 meters, The inverter can

- 4 -

NVF5 Series User Manual

1.4 Notice of Scrap

derating

application

be used with dreating. The following figure shows a relation curve of

the rated current of the inverter and altitude.

Current

Altitude

100%

90%

80%

1000m 2000m 3000m

Danger

The electrolytic capacitor of the main circuit and the electrolytic capacitor on the printed

board may explode in the burning process.

Plastic parts such as the panel may produce poisonous gases when burning.

Please treat the discarded inverter as industrial waste.

- 5 -

NVF5 Series User Manual Chapter 2 Product Overview

Chapter 2 Product Overview

2.1 Catalog Numbers Description

Applicable

Motor Power

(kW)

T: Universal

Model

Number of

Inverter Input

Phases

D: Single

Phase

S: Three

Phases

Input Voltage

Rating

2:230V

4:380V~ 440V

Brake Unit

B: Standard

Embedded

Blank: No

Embedded

NVF5 0.4 TD 2 B

Product

Model

/

Figure 2-1-1 Products Naming Rules

2.2 Nameplate Description

NOTE:NVF5 Serieal Inverters maintained CE certificate and complied with European Low

Voltage(LVD) Directive and Electromagnetic Compatibility(EMC) Directive.

Figure 2-2-1 Nameplate

2.3 Specifications and Models

1.Product

2.Catalog No.

3.Power Rating

4.Rated Input

5.Rated Output

6.Standard

8.Factory No.

7.CE Certificate

- 6 -

NVF5 Series User Manual Chapter 2 Product Overview

Table 2.1 Inverter Model and Specification

Power

Supply Catalog No. Power

Capacity

kVA

Input

Current

A

Output

Curren

t

A

Adaptiv

e Motor

kW

Brak

e

Unit

Single-Phase

AC 230V

NVF5-0.4/TD2 1.0 5.4 2.5 0.4

Optio

nal(e

mbed

ded)

NVF5-0.4/TD2-B

NVF5-0.75/TD2 1.9 10.3 5 0.75

NVF5-0.75/TD2-B

NVF5-1.5/TD2 2.9 15.5 7.5 1.5

NVF5-1.5/TD2-B

NVF5-2.2/TD2 4.2 20 10 2.2

NVF5-2.2/TD2-B

Three-Phase

AC

380V~440V

NVF5-0.4/TS4-B 0.8 2.3 1.5 0.4

Stan

dard(

embe

dded)

NVF5-0.75/TS4-B 1.5 3.4 2.7 0.75

NVF5-1.5/TS4-B 3.0 5.1 4.2 1.5

NVF5-2.2/TS4-B 4.0 6.6 5.8 2.2

NVF5-3.7/TS4-B 5.9 12.1 10.5 3.7

NVF5-5.5/TS4-B 8.6 13.1 13 5.5

NVF5-7.5/TS4-B 11.0 22.2 17 7.5

2.4 Technical Specifications

Form2.2 Specifications

Item

Description

Input Voltage range Three-phase 380~440V :

380 V

(-15%)

~440 V

(+15%

)

Single-phase 230V:230 V(±15%)

Frequency range (47~63)Hz

Output

Voltage 0~rated input voltage

Frequency (0~400)Hz

Overload capacity 150%of rated current for up to 1 minute,and 180%

of

rated current for up to 2 seconds

Main control

function

Control mode SVC control、V/F control、Torque control

Start torque SVC:150% rated torque at 0.5Hz

V/F:100% rated torque at 1Hz

Carrier frequency

1kHz~15kHz

- 7 -

NVF5 Series User Manual Chapter 2 Product Overview

Speed range

SVC:1:100;V/F:1:50

Speed control

accuracy

±0.5% of peak speed in SVC mode

Frequency

resolution Digital setting:0.01Hz;

Analog setting:Max. frequency×0.5%

V/F curve Linear V/F curve;(2、1.7、1.2、multi-point)power

reduced torque curve

Accel./Decel.curve

4 types of linear Accel./Decel. curve;S-curve

Accel./Decel.

Distinct features

Over-current stall protection, over-voltage stall

protection, torque limit, RPM tracking, simple PLC,

process PID, multi-segment speed control, automatic

slip compensation, automatic torque boost,

pre-excitation function, instant power cut function

Peripheral

interface

Digital input

5 multifunctional digital programmable input (including

1 high-speed pulse input terminal)

Digital output

1 multifunctional digital programmable output (speed

up to 100kHz)

Analog input

2 analog signal input, (0~20)mA, (4~20)mA current

signal input or (0~10)V, (-10~+10)V voltage signal

input can be selected

Analog output

1 analog signal output, (0~20)mA, (4~20)mA current

signal output or (0~10)V, (-10~+10)V voltage signal

output can be selected

Relay output

A pair of N.O. contacts and a pair of N.C. contacts,

contact capacity: 3A/250V

Communication

interface

Standard RS485 communication. External operation

panel can be connected;

Braking function

Embedded braking unit is optional for single-phase

models, and standard for three-phase models.

Operation panel

Display of over 20 parameters including frequency

setting, output frequency, output voltage, and output

current.

Protection function

Protections against over-current, over-voltage,

under-voltage, overheat, overload, input phase loss,

output phase loss, load loss, and motor ground short

circuit.

Environment

Occasion

The occasion is supposed to be indoor, not directly

exposed in sunlight and free of dust, corrosive gas,

combustible gas, oil mist, water vapor, water drops or

saline matter.

Altitude

Without derating below 1000 meters. Above 1000

meters derate 10% for every 1000 meters but shall not

exceed 3000 meters.

Temperature (-10~+45)℃

- 8 -

NVF5 Series User Manual Chapter 2 Product Overview

(Temperature at(45~50)℃,derate 1% for every 1

℃

Humidity (5~95)%RH,non-condensing

Vibration

Vibration accel. speed≤5.8m/s²

Storage (-40~+70)℃

Structure IP level IP20(Standard),IP22 with accessories

Cooling mode

Cooling Fan

Materials

Plastic for all series

Installation mode ≤2.2kW Din rail or screw(Single-phase 2.2kW only

screw);>2.2kW screw

2.5 Product Appearance and Diagram

Figure 2-5-1 NVF5-0.4/TD2~NVF5-2.2/TD2/NVF5-0.4/TS4-B~NVF5-2.2/TS4-B Appearance

Diagram

(The cooling fan of NVF5-2.2/TD2 at the bottom of the Inverter)

- 9 -

NVF5 Series User Manual Chapter 2 Product Overview

Figure 2-5-2 NVF5-3.7/TS4-B~NVF5-7.5/TS4-B Appearance Diagram

2.6 Product Dimensions and Weights

W

H

D

H1

W1

d

63.4

Figure 2-6-1 NVF5-0.4/TD2~NVF5-2.2/TD2/NVF5-0.4/TS4-B~NVF5-2.2/TS4-B Appearance

Diagram

- 10 -

NVF5 Series User Manual Chapter 2 Product Overview

W

H

DW1

H1

d

Figure 2-6-2 NVF5-3.7/TS4-B~NVF5-7.5/TS4-B Appearance Diagram

And Installtion Dimension

Table 2.3Dimensions and Weights(Unit:mm)

2.7 IP22 Top Protective Cover Description

Catalog No. W H D W1 H1

Mounting

hole d

Weight

kg

NVF5-0.4/TD2

75 148 125.2 64 137.5 Φ5.3 1.2

NVF5-0.4/TD2-B

NVF5-0.75/TD2

NVF5-0.75/TD2-B

NVF5-1.5/TD2

NVF5-1.5/TD2-B

NVF5-2.2/TD2 75 148 146.7 64 137.5 Φ5.3 1.25

NVF5-2.2/TD2-B

NVF5-0.4/TS4-B

75 148 125.2 64 137.5 Φ5.3 1.03

NVF5-0.75/TS4-B

NVF5-1.5/TS4-B

NVF5-2.2/TS4-B

NVF5-3.7/TS4-B 89.5 206 149.2 78.5 196.8 Φ5.5 1.79

NVF5-5.5/TS4-B

NVF5-7.5/TS4-B 118 216 163.4 105 205 Φ6 2.78

- 11 -

NVF5 Series User Manual Chapter 2 Product Overview

An optional Top Protective Cover may be selected to realize IP 22 protection level.The Top

Protective Cover consists of two parts:Protective Cover and Bracket.You can refer to the figure 2-6-3

to install(a Installing Bracket ;b InstallingProtective Cover),Apperance after being installed

shown as Figure 2-6-4

Figure 2-6-3 Installing Bracket and Proctive Cover diagram

Figure 2-6-4 Apperance after being installed

- 12 -

NVF5 Series User Manual Chapter 3 Installation and Wiring

Chapter 3 Installation and Wiring

3.1 Peripherial Components Description

3.2 Peripherial Components Selection and Guideline

- 13 -

NVF5 Series User Manual Chapter 3 Installation and Wiring

3.2.1 Input AC Reactor Descriptions

The AC input reactor are used to reduce harmonics and improve impedance.When

the enviroment need higher harmonic requirements,an optional AC input reactor should be

selected.Please refer to the reactor specifications of reactor provider below.

Power

Supply

Catalog No.

Input Current

A

AC input reactor

Three-Phas

e

AC380V~440

V

NVF5-0.4/TS4-B 2.3 ACL-00037-AL8M40-2L

NVF5-0.75/TS4-B 3.3 ACL-00037-AL8M40-2L

NVF5-1.5/TS4-B 5.1 ACL-00050-AL4M20-2L

NVF5-2.2/TS4-B 6.6 ACL-00075-AL3M00-2L

NVF5-3.7/TS4-B 12.1 ACL-0010-AL2M20-2L

NVF5-5.5/TS4-B 13.1 ACL-0015-AL1M42-2L

NVF5-7.5/TS4-B 22.2 ACL-0020-AL1M08-2L

3.2.2 Brake Resistor Description

Table 3.1 Brake Resistor Specifications

Catalog No. Input Current

A

Recommend

ed Circuit

Breaker

A

Recommend

ed

Contactor

A

Cable

Specificatio

n

mm²

NVF5-0.4/TD2 5.4 16 10 2.5

NVF5-0.4/TD2-B

NVF5-0.75/TD2 10.3 25 16 2.5

NVF5-0.75/TD2-B

NVF5-1.5/TD2 15.5 32 25 4

NVF5-1.5/TD2-B

NVF5-2.2/TD2 20 40 32 6

NVF5-2.2/TD2-B

NVF5-0.4/TS4-B 2.3 10 10 2.5

NVF5-0.75/TS4-B 3.3 10 10 2.5

NVF5-1.5/TS4-B 5.1 16 10 2.5

NVF5-2.2/TS4-B 6.6 16 10 4

NVF5-3.7/TS4-B 12.1 25 16 4

NVF5-5.5/TS4-B 13.1 32 25 6

NVF5-7.5/TS4-B 22.2 40 32 6

- 14 -

NVF5 Series User Manual Chapter 3 Installation and Wiring

Power

Supply

V

Catalog No.

Motor

Power

kW

Brake Unit

Resistance

Value

Ω

Power

W

AC

230V

NVF5-0.4/TD2

0.4

Optional

(embedded)

-- --

NVF5-0.4/TD2-B

NVF5-0.75/TD2

0.75 150 80

NVF5-0.75/TD2-B

NVF5-1.5/TD2

1.5 100 150

NVF5-1.5/TD2-B

NVF5-2.2/TD2

2.2 75 250

NVF5-2.2/TD2-B

AC

380V~440V

NVF5-0.4/TS4-B

0.4

Standard

(embedded)

--

--

NVF5-0.75/TS4-B

0.75

800

80

NVF5-1.5/TS4-B

1.5

400

150

NVF5-2.2/TS4-B

2.2

300

250

NVF5-3.7/TS4-B

3.7

200

400

NVF5-5.5/TS4-B

5.5

150

500

NVF5-7.5/TS4-B

7.5

100

800

Note:The usage and working conditions needs to be considered when selecting brake

resistor. The following is a description of brake resistor selection:

(1)Brake Resistor Calculation

When the output current equals half the rated current of the motor, the same braking

torque can be obtained as the rated torque of the motor,so the rough calculation of brake

resistor is:

=

,is brake voltage, is motor rated current,to ensure that the

inverter is not damaged, the minimum value of the brake resistor is when the

current flowing through the brake resistor is motor rated current. When selecting the

resistance of the brake resistor, it must not be less than the below value.

=

According to the above description, the selection range of brake resistor is:

<

(2)Brake Resistor Power Calculation

The power of brake resistor:

=

The brake resistor power is mainly determined by the brake utilization rate ED%.

Because the braking time of the system is relatively short, the temperature rise of the

braking resistor is not enough to achieve a stable temperature rise.So the principle for

determining the brake resistor capacity is to minimize the brake resistor capacity if the

temperature rise of the brake resistor does not exceed its allowable value (i.e. the rated

temperature rise),The rough algorithm is as follows:

= % =

%,

= 1 ||

is brake resistor derating coefficient(Normally select

)。

- 15 -

NVF5 Series User Manual Chapter 3 Installation and Wiring

R is actual brake resistor resistance,P

is brake resistor power.

3.2.3 Output AC Reactor Descriptions

The cable between Inverter and Motor should not be too long.If the cable is too long,the

distributed capacitance will be large, the harmonic current will be generated easily.

The outputAC reactor should be selected when the motor cable is too long.Please refer

to the table below:

Catalog No.

Input

Current

A

Min.Cable Length

(m)AC output reactor

NVF5-0.4/TS4-B 1.5 50

OCL-00030-ALU2100-1L

NVF5-0.75/TS4-B 2.7 50

OCL-00030-ALU2100-1L

NVF5-1.5/TS4-B 4.2 50

OCL-00050-ALU2000-1L

NVF5-2.2/TS4-B 5.8 50

OCL-00065-ALU1500-1L

NVF5-3.7/TS4-B 10.5 50

OCL-0011-ALU1200-1L

NVF5-5.5/TS4-B 13 70

OCL-0016-ALU900-1L

NVF5-7.5/TS4-B 17 100

OCL-0020-ALU700-1L

3.3 Installation

The inverter shall be installed at an indoor place ,good in ventilation and generally in a

vertical mode. When using inverter, please pay attention to installation distance

requirement. The following are examples of multiple side-by-side installations and multiple

vertical installations.

(1)multiple side-by-side installations

Figure 3-3-1 Side-by-side Installatio Diagram

- 16 -

Other manuals for NVF5 Series

1

This manual suits for next models

15

Table of contents

Other CHINT Inverter manuals

Popular Inverter manuals by other brands

Solax

Solax X1 Series Quick installation guide

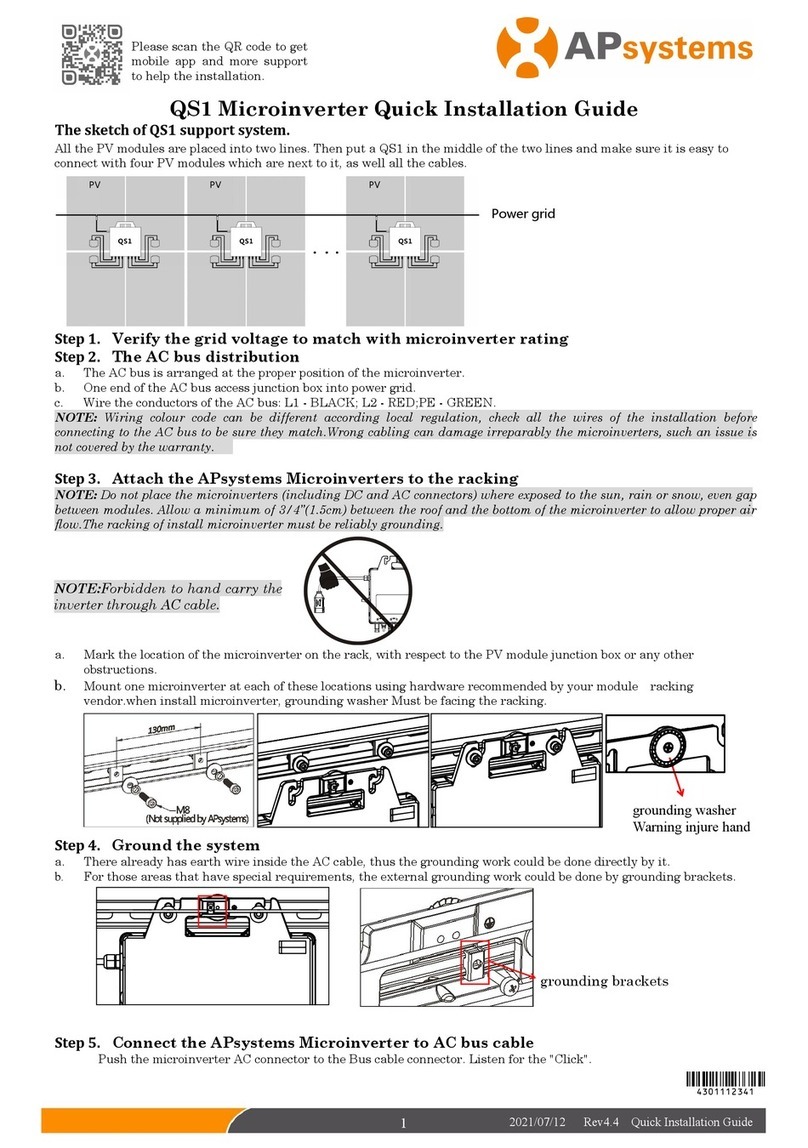

APsystems

APsystems QS1 Quick installation guide

SUNBEAMsystem

SUNBEAMsystem MOONRAY Series user manual

MAC3

MAC3 E-Power user manual

Hoymiles

Hoymiles HYS-3.0LV-EUG1 Quick installation guide

Analytic Systems

Analytic Systems Pure Sine 300 Installation and operation manual