Cleco

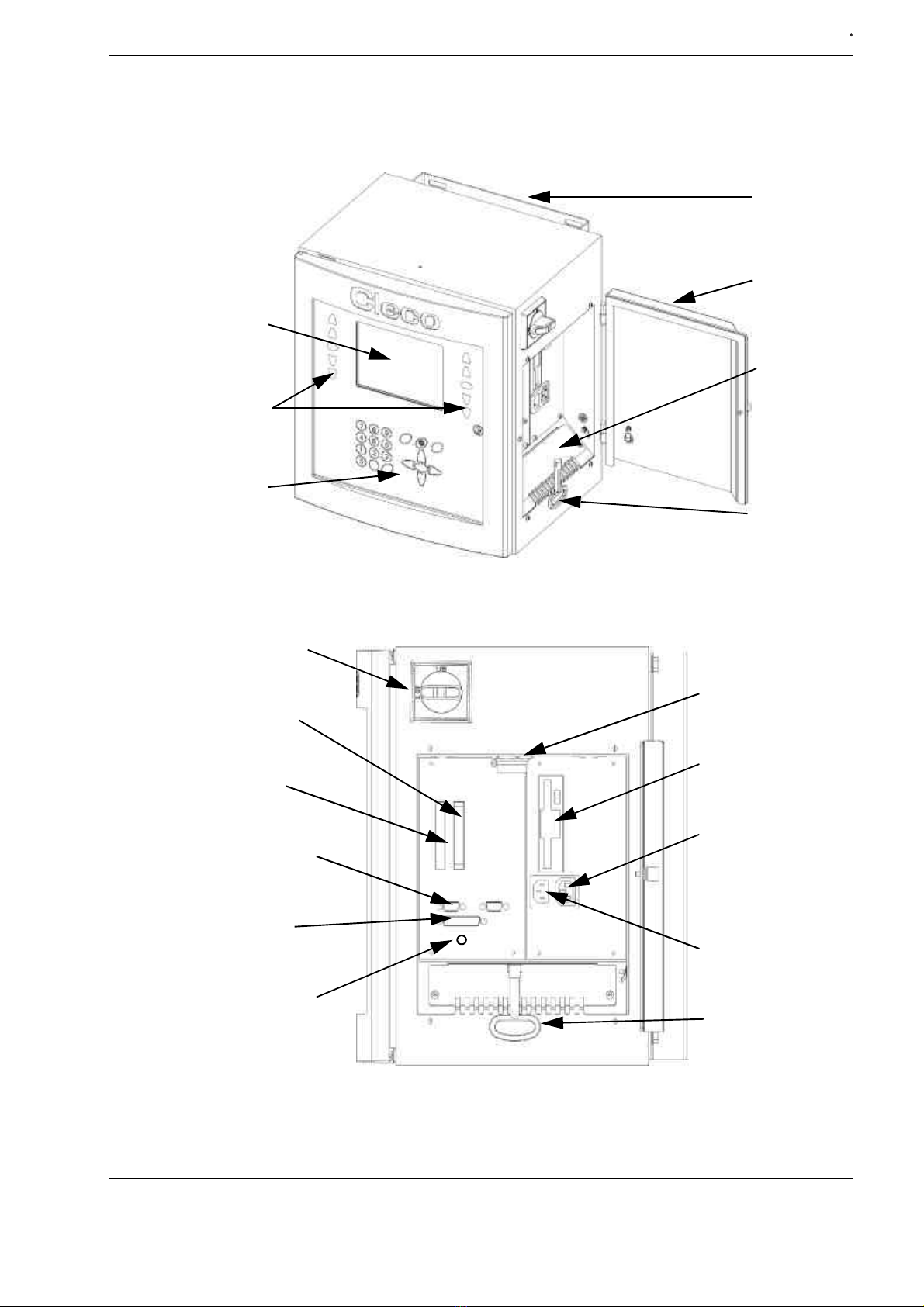

Electric Tool Control TME-100 Series

4 PL12-1300 12/00 end14IVZ.fm, 30.01.2001

3.3.4 Standard Application Builder / Advanced Parameters ........................ 31

3.3.5 Advanced Application Builder / Application Matrix .............................. 32

3.3.6 Advanced Application Builder / Inputs................................................. 33

3.3.7 Advanced Application Builder / Outputs.............................................. 34

3.3.8 Advanced / System Settings ............................................................... 36

3.4 RUN Screen ........................................................................................ 36

3.5 Oscilloscope........................................................................................ 37

3.6 Communication ................................................................................... 38

3.6.1 Communications / Printer.................................................................... 38

3.6.2 Communications / Serial Data Transmission ...................................... 39

3.7 Tool Setup ........................................................................................... 40

3.8 Tool Library.......................................................................................... 41

3.8.1 Tool Library.......................................................................................... 41

3.8.2 Tool Library / Custom .......................................................................... 42

3.9 Statistics .............................................................................................. 43

3.9.1 Statistics / Summary............................................................................ 43

3.9.2 Statistics / Chronological History......................................................... 43

3.10 Diagnostics.......................................................................................... 44

3.10.1 Inputs / Outputs................................................................................... 44

3.10.2 Tool / Calibration ................................................................................. 45

3.10.3 Tool / Voltages..................................................................................... 46

3.10.4 Tool / Angle Encoder ........................................................................... 47

3.10.5 Tool / TQ Measurement....................................................................... 48

3.10.6 Tool / Speed ........................................................................................ 48

3.10.7 Arcnet / Map........................................................................................ 49

3.10.8 Arcnet / Statistic .................................................................................. 50

3.10.9 Serial ................................................................................................... 52

3.11 Utilities................................................................................................. 53

3.11.1 Utilities / Update Software................................................................... 53

3.12 Administration ..................................................................................... 54

3.12.1 Administration / Load/Save ................................................................. 54

3.12.2 Administration / Print ........................................................................... 55

3.12.3 Administration / Password................................................................... 55

3.12.4 Administration / Date & Time .............................................................. 56

4 Statistics 57

4.1 Understanding Statistics...................................................................... 57

4.1.1 The Nature of Variation ....................................................................... 57

4.1.2 The Normal Curve............................................................................... 57

4.1.3 The Procedure .................................................................................... 58

4.1.4 System Improvement .......................................................................... 62

4.2 Statistic Symbols ................................................................................. 63

5 Glossary 65

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com