CSA VSM User manual

CSA treated water line

Direct acting upstream pressure

relief-sustaining valve

Mod. VSM

Direct acting PSV Mod. VSM

2

For further information please consult us at: www.comeval.es

Personnel involved in the installation or maintenance of valves should always be alert

to potential emission of water and pipeline material, and take the necessary safety

precautions. Always wear the suitable protection like helmets, gloves, googles, when

dealing and handling hazardous pipelines and valves.

Introduction

This manual will provide you with the information to properly install and maintain CSA direct acting

pressure relief/sustaining valves Mod. VSM. The contents and the procedure are intended for

technicians in charge of CSA valves only, prior to a theoretical and practical training by CSA

qualified or authorized personnel.

Safety

All safety messages in the instruction manual are flagged with the following symbol meaning

danger, caution and warning. This means and makes reference to procedures that may lead to

equipment and system damage and to severe injury or death for the personnel involved.

Inspection

Your valve VSM has been packaged to provide protection during shipment, however it can be

damaged during transport. Please carefully inspect the unit for damages or discrepancies with the

order upon arrival and report a claim immediately before unloading the goods.

Parts

Recommended spare parts are listed on the assembly drawing depicted on page 8.These parts

should be stocked to minimize delays in case of malfunction. When ordering spare parts please

make reference to the assembly drawing and identification plate present on the valve.

Direct acting PSV Mod. VSM

3

For further information please consult us at: www.comeval.es

Contents

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Handling and storage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Fusion/Powder coated valves- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6

Set up - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Drawings- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7

Troubleshooting- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8

Disassembly- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Direct acting PSV Mod. VSM

4

For further information please consult us at: www.comeval.es

Valves with fusion/powder coated exterior paint require flat washers to be installed

under the flange nuts when installing the valve to the pipeline flange, to prevent the

paint from cracking or chipping.

Personnel involved in the installation or maintenance of valves should be constantly

alert to possible damages caused by an improper handling of the valve.

Description

The automatic direct acting PSV Mod. VSM consists of a upstream pressure balanced single seat

globe pattern valve, piston actuated, and equipped with a spring located in the cover to impart the

force necessary for the proper working. The operating principle is explained in detail on the

technical catalogue, for further explanations please contact us. The VSM will automatically throttle

and modulate the water supply to maintain a preset and adjustable upstream pressure, regardless

of upstream pressure fluctuations, . The special design of CSA with built in self cleaning piston

technology guarantees long lasting performances with a dramatic reduction of the maintenance

time, minimizing the risk of friction and malfunctioning.

Handling and Storage

Lifting the valve improperly may damage it. Lift the valve with slings, chains or cables fastened

around the valve body or eyebolts if present, or fastened to bolts or rods through bolt holes in the

flanges. Do never lift the valve by the adjusting screw. If installation will be delayed, place valve

indoors in secure, weather tight storage. If temporary outside storage is unavoidable, make sure a

vermin proof rain cover is secured around/over the valve to keep off rain and mud. Skid and set the

assembly on a flat, solid, and well drained surface for protection from ground moisture, runoff and

pooled rain water. Do not leave the valve exposed to high humidity and excessive temperature

conditions.

Fusion/Powder Coated Valves

Direct acting PSV Mod. VSM

5

For further information please consult us at: www.comeval.es

The difference in pressure generated by the valve when closed or during modulation

will produce a thrust proportional to the pressure itself.

Anchorage blocks and way of preventing valve’s movement or shifting need to be

taken into account.

Installation

The pressure relief/sustaining valve should always be installed in a horizontal position, meaning

the axis of the valve versus the ground level. Vertical installation is allowed up to the DN 100 mm

prior to consult with us. The valve has to be installed between two sectioning devices, one

upstream and one downstream to allow for maintenance, with a filter upstream of it to prevent dirt

from creating malfunctioning. For the recommended flow rate and differential pressure please refer

to the sizing information displayed in the catalogue or contact us, sending the project, data for

further assistance and valve sizing.

Before installation, remove foreign material such as weld spatter, oil, grease, and dirt from

the pipeline.

Prepare pipe ends and install valves in accordance with the pipe manufacture’s instructions

for the joint used.

Tighten the flange bolts or studs in a crisscross pattern and minimum of four stages.

Place the valve in the right direction following the arrow moulded on the body

If not included in the order install a pressure gauge upstream to check both the value in

dynamic conditions and the maximum static pressure. reached during closing. and make

sure it doesn’t exceed the valve’s design pressure

Note to Engineer: The direct acting pressure relief/sustaining valve VSM will regulate and

maintain an upstream pressure value according to the force of the spring, located inside the

cover, supplied with two different range (standard version):

Upstream pressure regulation from 1.5 to 6 bar (blue spring, standard)

Upstream pressure regulation from 5 to 12 bar (red spring, standard)

The spring range is indicated on the stainless steel identification plate and on the order

confirmation, should the pressure needed be different or outside of the range please

contact us for an immediate replacement of the spring, do not exert excessive torque on the

spring or relief it completely

Direct acting PSV Mod. VSM

6

For further information please consult us at: www.comeval.es

When the valve reacts to modulate, in sustaining the upstream, pressure, the effective pressure

variation on the line depends on the length of the entire system and part of the network subject to the

VSM. This could take sometimes minutes, therefore allow for it before acting on the spring.

The flow rate is an effect of the pressure controlled by the VSM for that specific system. An inlet

pressure value, maintained for an instance at 3 bar, wouldn’t produce the same flow rate everywhere

as it depends on the headloss between the valve itself and the final boundary conditions.

Maintenance

The pressure relief/sustaining valve VSM is sturdy and reliable, and it was designed to minimize

maintenance. A semi-annual visual inspection for the proper movement of the piston and the

cleaning of the compensation chamber is recommended. A routine maintenance for gasket,

control, o-rings and if needed replacements is recommended every 4 years and explained on page

10 ref picture 1 on page 7. A possible malfunction can be identified by a leakage through the seat,

normally caused by dirt accumulated inside the body, or seeping through the shaft and leaking

through to the cover, hunting and excessive variation of the upstream pressure.

Set up

Before the start-up of the valve make sure the instructions provided on the maintenance

section “Installation” on page 5 were properly followed and understood.

Operate very slowly on the following procedure to avoid stresses on the valve and

unexpected pressure surges.

The valve is initially isolated from the main line by means of the sectioning devices

upstream and downstream.

Open the downstream gate valve by 30%, then open slowly the upstream sectioning device

to generate some flow through the valve. Make sure the maximum nominal pressure is not

exceeded during this operation.

Unless the valve has been ordered with a specific setting turn the adjusting screw (9)

anticlockwise to relief the spring (not completely), make sure VSM will respond with a

smooth modulation by reducing the upstream pressure increasing the flow.

Open completely the downstream gate valve.

Let VSM work and modulate according to the demand, act on the adjusting screw (9) by

turning it clockwise to increase the upstream pressure, anticlockwise to decrease and

check the pressure gauges for further reference.

Allow for enough time for the system to balance.

By means a pressure gauge upstream and a flow meter make sure that both the flow rate

and difference in pressure, in dynamic condition, don’t exceed the recommended values

displayed in the catalogue.

Be sure to allow for at least 5 mt increase in the set pressure occurring between dynamic

Direct acting PSV Mod. VSM

7

For further information please consult us at: www.comeval.es

and static (no flow) conditions

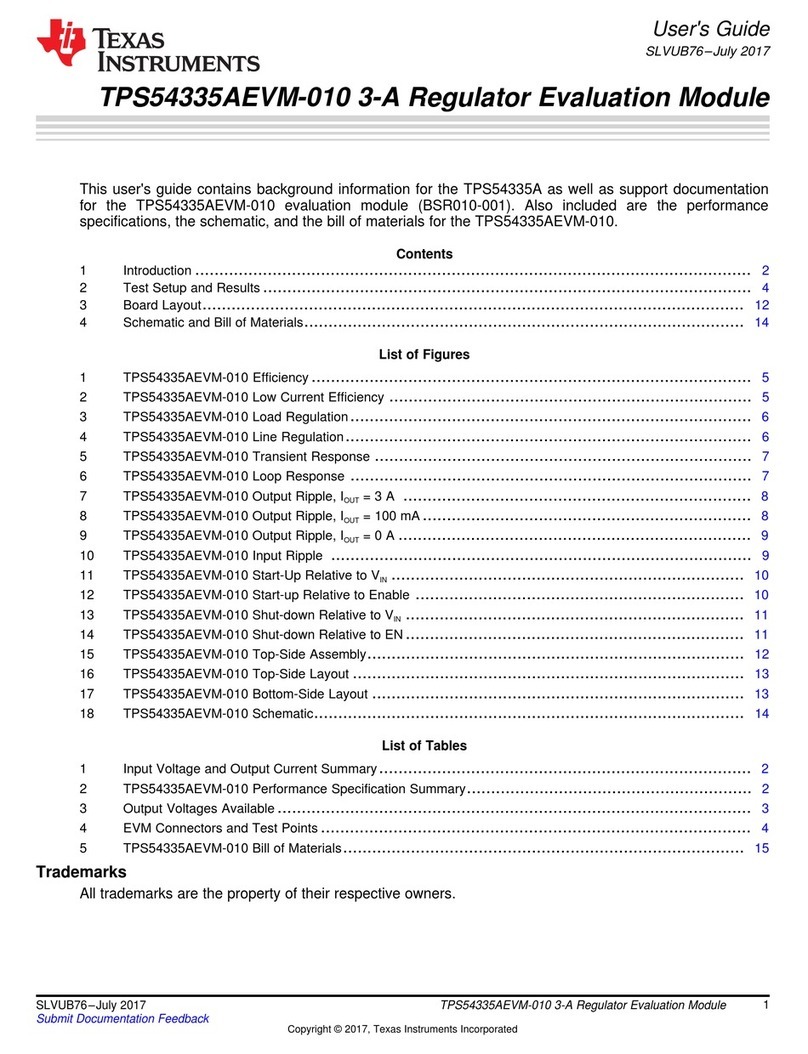

Drawings

Picture 1

Recommended Spare parts nr: 13-21-22-23-24-25-26-27-28-30-32

9

8

7

4

14

5

21

10

11

25

20

28

23

29

15 24

1

19

12

22

27

18

30

17

16

13

3

6

2

26

31

32

Direct acting PSV Mod. VSM

8

For further information please consult us at: www.comeval.es

Problems solving

Condition

Possible Cause

Corrective Action

Valve leaks at flange joint.

Loose flange bolting.

Tighten flange bolting.

Blown flange gasket.

Replace flange gasket.

Miss-alignment or damage

to field piping and supports.

Adjust miss-alignment or

repair piping or supports.

Damaged flange face/s or

improper flange

connections.

Repair flange, replace

valve body or adjust flange

connections.

Direct acting PSV Mod. VSM

9

For further information please consult us at: www.comeval.es

Problems solving

Problem

Cause

Solution

The valve

doesn’t close

There is dirt accumulated between

the obturator and the seat

Remove the valve and clean it inside to

remove dirt

The pressure upstream is above

the set point

Check the pressure and adjust the

screw acting on the spring turning it

clock wise

There is dirt inside causing friction

to the piston

Check the movement of the piston and

remove dirt or foreign materials

The plane gasket of the obturator/

seat and / body is damaged due

cavitation and the valve can’t

assure a watertight sealing any

more

Check the difference in pressure,

operating cycles of the valve, flow rate.

Make sure they don’t exceed the advised

values from us technical literature

The

valve

doesn’t

open

The pressure upstream is below

the set point

Check the pressure and adjust the

screw acting on the spring by turning it

anti clockwise

There is dirt accumulated between

the obturator and the body

Remove the valve and clean it inside to

remove dirt

There is dirt causing friction to the

piston during its movement

Check the movement of the piston and

remove dirt or foreign materials

Direct acting PSV Mod. VSM

10

For further information please consult us at: www.comeval.es

Do not remove the nuts (17) holding the cover without having completely relieved the spring by

turning the screw (9) anticlockwise. Failing in doing so may cause severe damages and injuries

to the personnel .

Disassembly (toproceedwith itisnecessarytohave therequiredsparekeysandtools)

In order to carry out the proper maintenance of VRCD proceed as follows, ref drawing picture 1 on

page 7, for further info consult us :

1. slowly close the upstream and downstream gate valves;

2. if the VSM is installed in a location not suitable for maintenance, please remove it from

the pipe ;

3. turn the screw (9) anticlockwise to relief the spring (4)

4. remove the nuts holding the cover (17) and take out the cover (2) and spring (4)

5. be sure not to loose the spring guide (7) when the spring is removed

6. remove the driving tap (15) the hexagonal part of the main shaft (11) will be visible

7. push the mobile block from the shaft (11) downwards

8. set the hexagonal part with a wrench and keep it steady while unscrewing the first nut

(6) holding the piston tight

9. unscrew the upper ring (5) pulling it out along with the upper and lower piston (3 and

14) which do not have to be separated

10. Push the piston out of the ring paying attention not to damage the lip gasket (21), o-ring

(26) and the guiding PTFE ring (13)

11. Check the surface of the piston, clean it if necessary

12. Unscrew the lower ring (18) paying attention not to damage the o-ring (27)

13. Extract from above the spacer (12) and the o-ring (25)

14. Pull out the obturator block (20-28-29) paying attention not to damage the o-ring (32)

15. Check the surface of the plane gasket (28), replace if it necessary

16. check the downstream side of the reducer for possible sign of cavitation, holes

1) Reassembly

In order to carry out the proper reassembly of VRCD follow the instruction explained above on

page in reverse. Pay attention to:

1) use a proper grease on the piston, lip gaskets to allow for the proper movement of the

mobile block.

2) Once the valve has been fully assembled, prior to place the cover, check for the proper

movement of the mobile block making sure there are not sign of friction or any other

element affecting it.

Direct acting PSV Mod. VSM

11

For further information please consult us at: www.comeval.es

We reserve the right to incorporate our latest design and material changes without notice or obligation.

Design features, materials of construction and dimensional data, as described in this manual, are provided for your information only.

Table of contents

Other CSA Control Unit manuals

Popular Control Unit manuals by other brands

schmersal

schmersal PROTECT-PE operating instructions

urmet domus

urmet domus sinthesi steel 1083 manual

SCHNERZINGER

SCHNERZINGER COMPONENT GUARD quick start guide

schmersal

schmersal SRB 211LT/CC operating instructions

jbc

jbc DDE-B Series manual

Texas Instruments

Texas Instruments TPS54335AEVM-010 user guide