installation manual TWIN 80 EN

10

1.5. Condensing boiler

The concentric air inlet and exhaust outlet need to be

connected with one of the adapter sets.

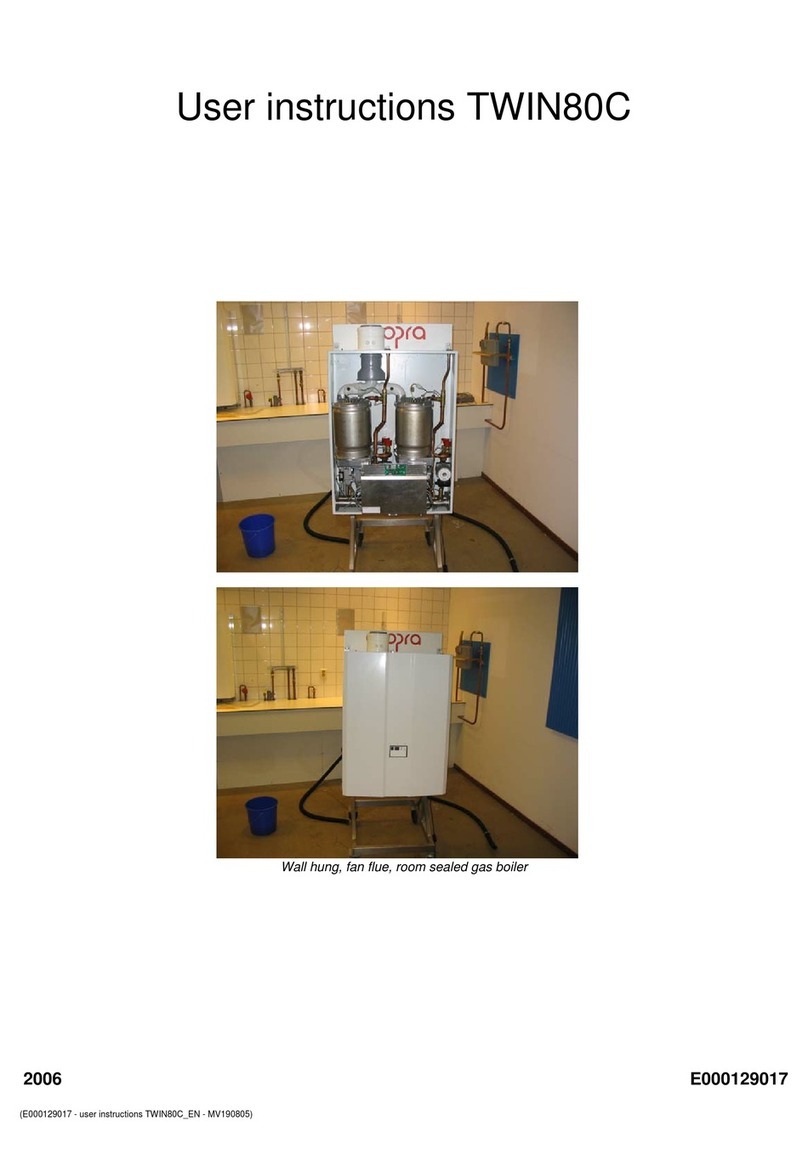

The TWIN 80C is a wall hung, fan flue, room sealed, high

efficiency condensing gas boiler for central heating and / or

under floor heating systems.

The type plate, which specifies the type of gas etc. to be used, for

which the unit is set, is on the left side of the unit.

1.6. Operation

The appliance is equipped with pre-set gas/air ratio regulators.

The purpose of this regulator is to keep the gas/air ratio in the

burner as optimal as possible at all times e.g. when modulating.

This ensures clean and reliable combustion across the entire

load range. In addition it achieves high part-load efficiency.

The TWIN 80C incorporates 2x type 40C heat units (existing of

2x heat exchanger, 2x premix burner, 2x fan, 2x gas valve, 2x

venturi, 2x circulation pump, 2x printed circuit board). Each heat

burner works independently, cascade controlled by two printed

circuit boards.

A fan sucks the air required for the combustion through the air

feed canal (A). Because the combustion air in the venturi sucks

an under pressure, the correct amount of gas (G) is

automatically added to the combustion air.

The flammable gas/air mixture thus obtained is fed to the

burner(s), via a mixing chamber, to be ignited at the surface of

the burner(s) by a ceramic glow plug. The hot combustion gases

are efficiently fed through the heat exchanger(s), where they

give their heat to the system water. The flue gases are fed

outdoor, through the flue tube (F), into a combined flue tube

exhaust canal.

The formed condensation water (H2O) is discharged through the

waste trap.

1.6.1. Display

The display operates for both printed circuit boards.

Open the door in front of the jacket for operating and reading the

codes on the display, - The boiler of this picture is in the

stand-by mode, because the display

shows a continuous 0.

- The actual water temperature of

the flow sensor is 19‘C.

1.6.2. Master – Left hand side printed circuit board.

The Master is the leading board, calculates and divides the

necessary power over both units. Therefore the regulation

controls will always be connected to the Master.

•Room thermostat 24 Volt default

•Outdoor temperature sensor default

•OpenTherm regulation default

•Room thermostat 230 Volt optional

•Direct control 0-10 Volt optional

Note: Spare part boards are set for SLAVE.

If needed, make SLAVE (A=1) into MASTER (A=0).

1.6.3. Slave –right hand side printed circuit board.

In case of a lock-out of the Master printed circuit board the Slave

is still able to operate correctly.

1.7. LED indication

Two LED’s have been placed under the appliance informing the

user the status of each unit individually.

The left hand side LED (L) is indicating the actual status of the

Left hand side heating unit.

•LED is ON = burner concerned is ON

•LED is OFF = burner concerned is OFF

•LED is FLASHING = unit concerned is LOCK-OUT

The right hand side LED (r) is indicating the actual status of the

right hand side heating unit.

•LED is ON = burner concerned is ON

•LED is OFF = burner concerned is OFF

•LED is FLASHING = unit concerned is LOCK-OUT

Concentric

100/150 mm

N00M990080

Concentric

110/150 mm

N00M990082

or

or