Cleaning your keg:

Copper Tun Cold Water Cleaner / Detergent

is a powerful cleaner, removing dirt, stains and

undesirable micro-organisms, restoring surfaces

to original condition.

• Release any pressure in the keg by operating

the pressure relief valve. Remove the lid and

rinse out any remaining beer from the previous

batch.

• Fill the keg with 5L of cold water and add a

sachet of Cleaner Detergent. Use this solution

to thoroughly wash the inside of the keg. For

stubborn stains use a brush..

• Top the keg up until it’s full and leave to stand

for 10 minutes.

• Empty the keg and rinse with cold water to

remove detergent residue.

Sterilizing your keg:

Copper Tun No Rinse Sterilizer effectively

sterilizes your equipment with active oxygen

and breaks down to leave only oxygen, water

and minerals found naturally in water. No Rinse

Sterilizer is different to conventional alkaline

powdered sterilizers as it requires no rinsing off

after sterilizing.

• Fill the keg with 5L of Water and add a sachet

of No Rinse Sterilizer. Stir thoroughly to ensure

all dissolved. Top up with water to within 25 mm

of the gas inlet tube (approximately 19 litres).

Let stand for 10 minutes.

• Fit the hatch cover and connect up the gas

connect to the IN post and the tap to the OUT

post.

• Adjust the pressure to 70kpa (10psi) and open

the tap to run some sterilizer through the beer

line and out the tap.

• Let stand for 5 minutes and repeat process to

sterilize the inside of the beer line. Disconnect

the gas inlet and release the pressure from

inside the keg.

• Disconnect the gas and empty out the keg.

TRANSFERRING YOUR BEER TO THE KEG:

Fit a length of sterilised tubing to your fermenter

tap. This tubing should be long enough to reach

the bottom of the keg so that you ll the keg

from the bottom without splashing the beer.

You will notice that there is a tube in the keg

running from the top of the keg to the centre

at the bottom. This is called the Dip Tube and

is used to draw the beer from the keg. There is

also another tube that is quite short in length.

This is the CO2 inlet, where the CO2 is injected

into the beer.

Your keg should be lled to approximately 12-

25 mm (1/2 to 1 inch) from the bottom of this

tube. Any remaining beer can be bottled using

2 Brewcraft Carbonation Drops for each 750 ml

bottle, making sure to seal the bottle securely.

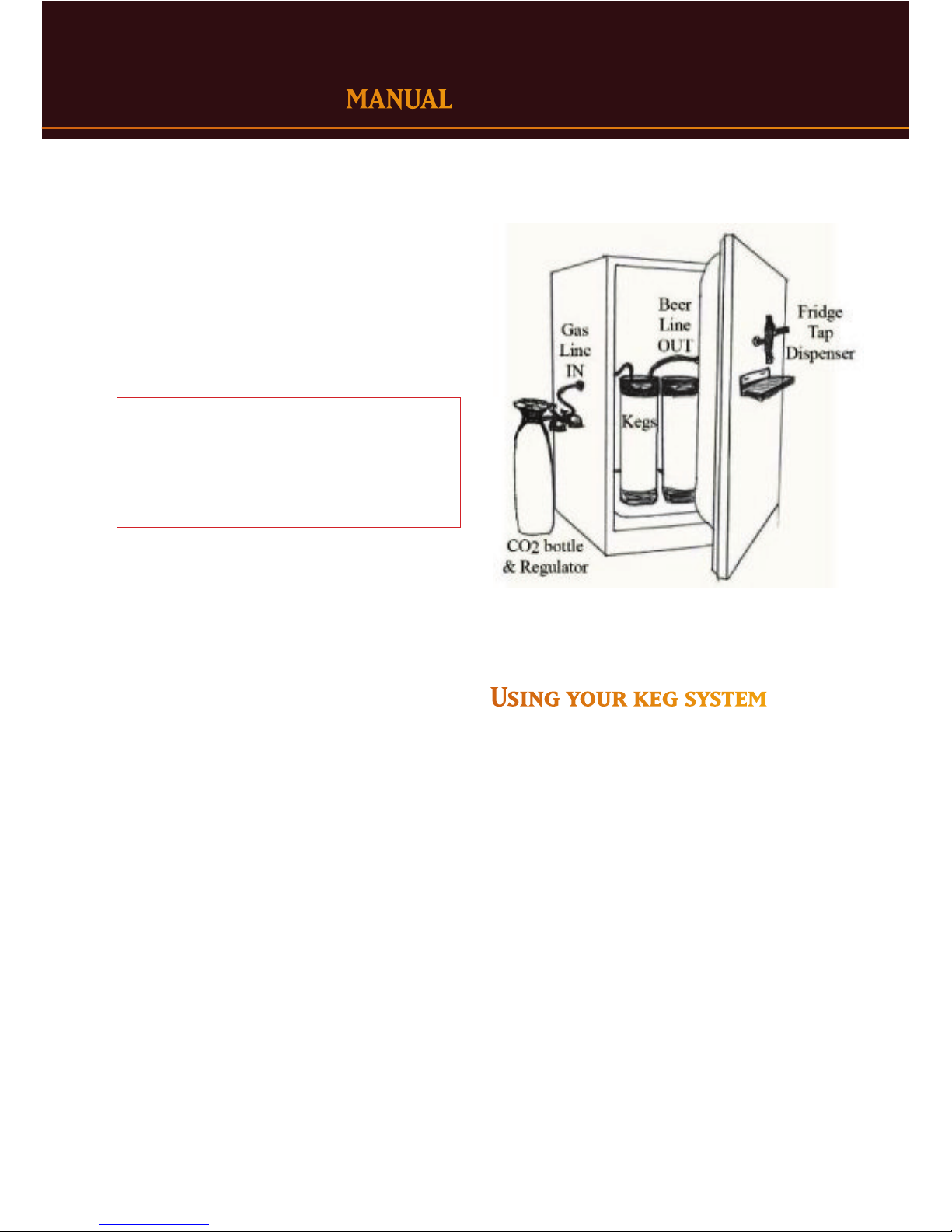

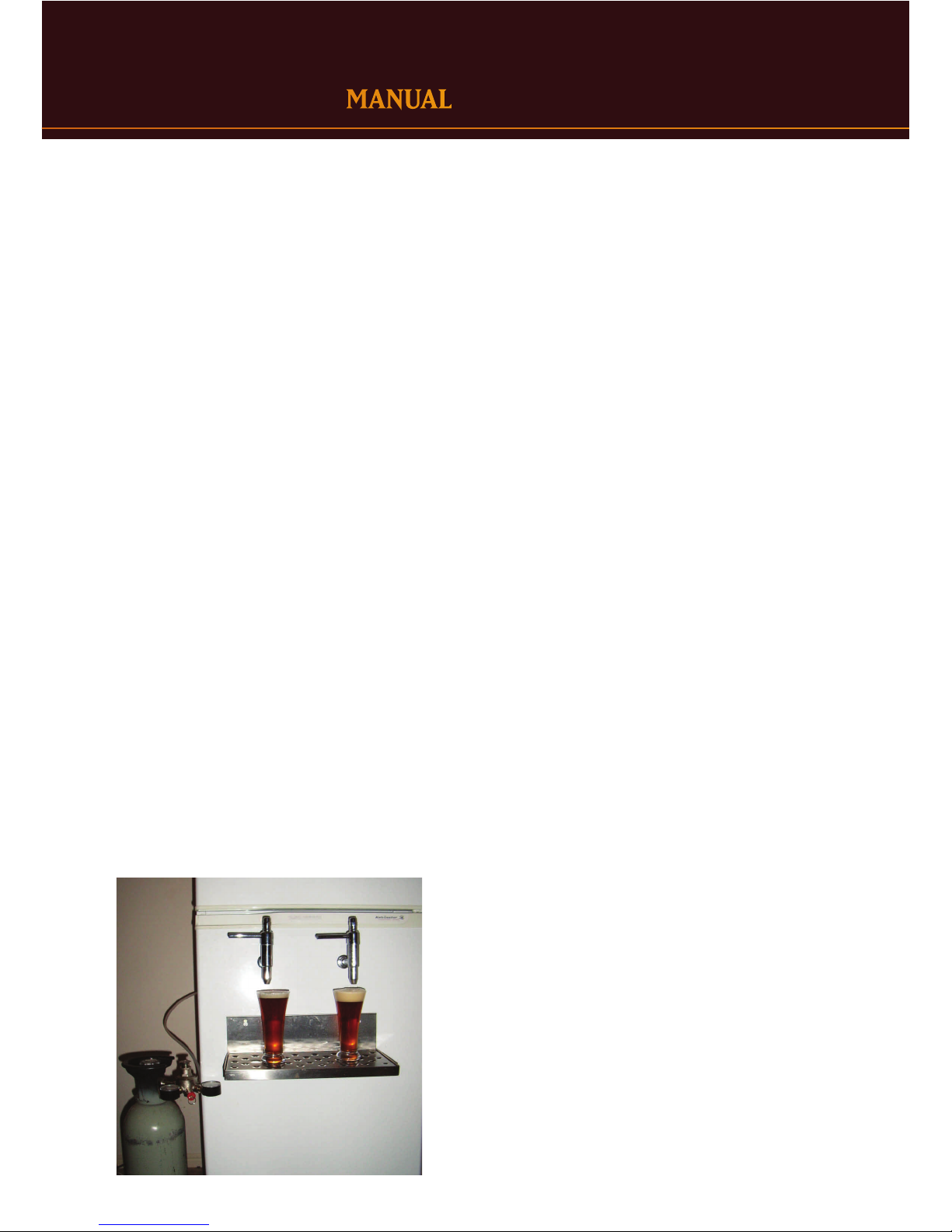

Once the keg is full, replace the hatch cover and

move keg to the prepared fridge. Assuming

your gas line was cut to length it should be

long enough to reach outside the fridge so you

can connect it to the gas bottle. Turn the gas

bottle on and set the pressure on the regulator

to between 70 and 100 kpa (10 - 15 psi) and

connect the gas line to the keg.

PRIMING THE KEG WITH CO2:

You need to purge the headspace of the keg of

any oxygen to protect the beer from oxidisation.

By releasing the pressure release valve, the

CO2 will ow into the keg and the air will ow

out through this valve. This is called burping the

keg and is best done in three short bursts.

CARBONATING:

The absorption of the CO2 into your beer can

depend on many things, most particularly the

temperature of the beer, the pressure at which

it is applied and the length of time pressure is

applied.

The CO2 will be absorbed at a faster rate when

the beer is cold (the beer will not absorb gas

at room temperature) so if you apply 230kpa