ii

1593

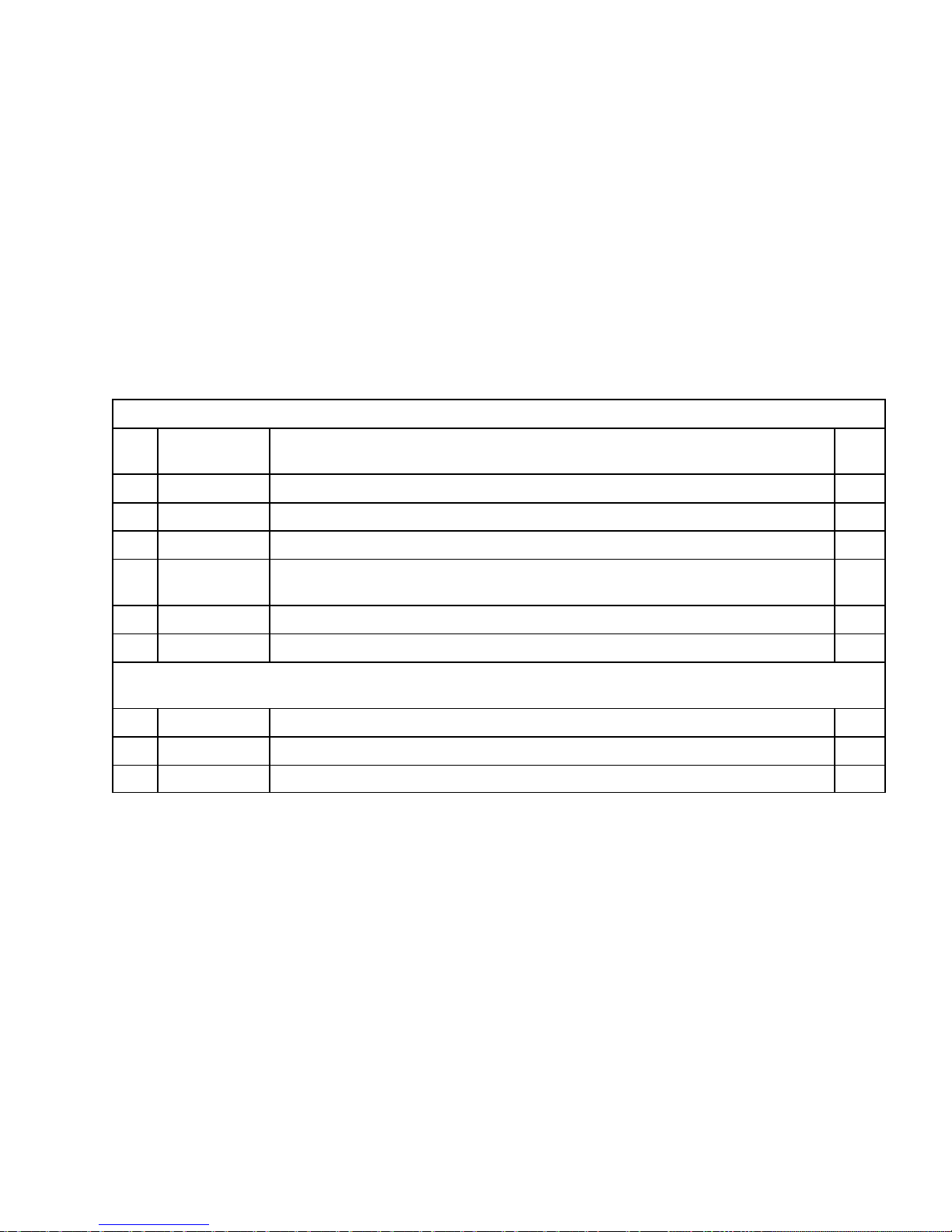

TABLEOFCONTENTS(cont’d)

Page

COOLINGUNITREFRIGERATIONPOWERSWITCH 15.................

COOLINGUNITCARBONATORMOTORS SWITCH 15...................

COOLINGUNITCIRCULATINGMOTORSWITCH 15.....................

REFRIGERATIONSYSTEMTEMPERATURE SENSINGDEVICE AND

HIGH--PRESSURECUTOUTSWITCH 15...................................

COOLINGUNITWITHINTERNALCONDENSER COILAND FAN

ASSEMBLY15.......................................................

COOLINGUNITCONNECTEDTOREMOTECONDENSER COILAND

FANASSEMBLY16..................................................

DAILY PRE--OPERATION CHECK16.......................................

ADJUSTMENTS16.......................................................

ADJUSTINGCO2REGULATORS16...................................

ADJUSTINGDISPENSINGVALVES WATERFLOWRATE16.............

ADJUSTINGWATER--TO--SYRUP‘‘RATIO’’ OFDISPENSEDPRODUCT16.

ADJUSTINGSIZEOFDRINKDISPENSED16...........................

REPLENISHINGCO2SUPPLY16..........................................

REPLENISHINGSYRUP SUPPLY16.......................................

CLEANINGAND SANITIZING17...........................................

DAILYCLEANING17.................................................

SANITIZINGSYRUP SYSTEMS17.....................................

COOLINGUNITMAINTENANCE17........................................

COOLINGUNITEQUIPPEDWITH CONDENSER COILAND AIR

INTAKE FILTERS17..................................................

COOLINGUNITCARBONATORMAINTENANCE17.....................

COOLINGUNITCARBONATEDWATER CIRCULATINGPUMPMOTOR

LUBRICATION17....................................................

REMOTECONDENSER COILAND FANASS’Y(IFAPPLICABLE)

MAINTENANCE18.......................................................

CLEANINGCO2GAS CHECK VALVES 18..................................

SERVICEAND MAINTENANCE19.............................................

PREPARINGCOOLINGUNIT FORSHIPPING,STORING,OR RELOCATING19

PERIODICINSPECTION19...............................................

REMOTECONDENSER COILAND FANASSEMBLYMAINTENANCE19.......

COOLINGUNITMAINTENANCE20........................................

CLEANINGCOOLINGUNITAIRINTAKE FILTERS20....................

CHECKINGICEWATERBATH20......................................

CHANGINGICEWATERBATH20.....................................

WATERPUMP YEARLYMAINTENANCE(ORAFTERWATERSYSTEM

DISRUPTIONS)23...................................................

ADJUSTMENTS24.......................................................

PRIMARYCO2REGULATOR26.......................................

SECONDARYCO2REGULATORS26..................................

WATERFLOWRATE26..............................................

WATER--TO--SYRUP‘‘RATIO’’ OFDISPENSEDPRODUCT26.............

CLEANINGAND SANITIZING26...........................................

DAILYCLEANING OFUNIT26........................................