i312021002

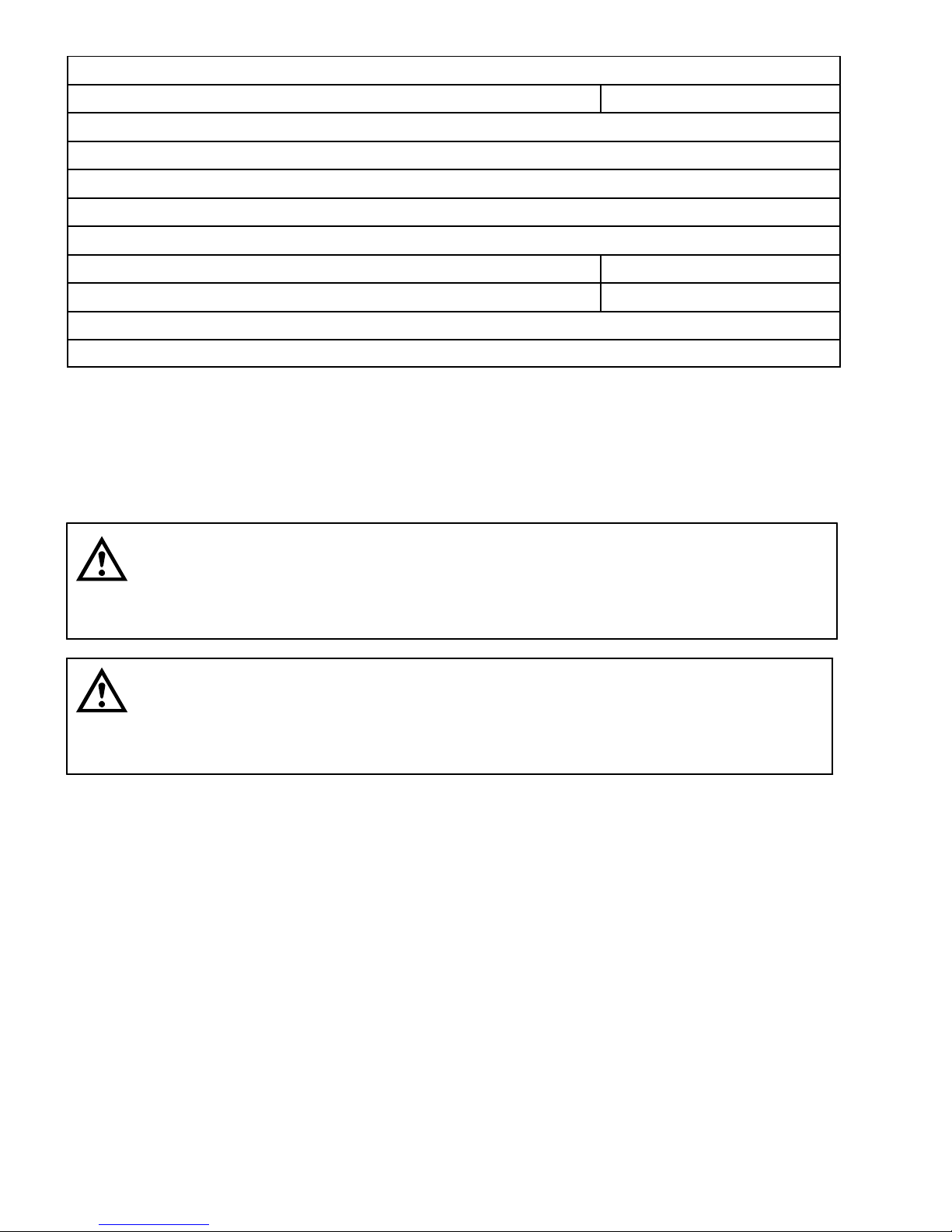

TABLEOFCONTENTS

Page

SAFETYINFORMATION1....................................................

RECOGNIZE SAFETYINFORMATION1...............................

UNDERSTAND SIGNALWORDS1....................................

FOLLOWSAFETYINSTRUCTIONS1.................................

CO2(CARBON DIOXIDE)WARNING1................................

SHIPPING,STORING,OR RELOCATINGUNIT1.......................

GENERALINFORMATION3..................................................

CLAIMSINSTRUCTIONS3...............................................

WARRANTYREFERENCEINFORMATION3...............................

DESIGN DATA3........................................................

DESCRIPTION4........................................................

THEORYOFOPERATION5..............................................

PARTSIDENTIFICATION7...................................................

OWNER’SRECOMMENDEDMAINTENANCE9.................................

OPERATORSINSTRUCTIONS11..............................................

OPERATINGCONTROLS11..............................................

COOLINGUNITPOWERSWITCH 11..................................

COOLINGUNITCIRCULATINGPUMP POWERSWITCH 11..............

COOLINGUNITCARBONATORMOTORPOWERSWITCH 11............

DAILY PRE-OPERATION CHECK11........................................

GENERALMAINTENANCE13.................................................

ADJUSTMENTS13.......................................................

ADJUSTINGCO2REGULATORS13...................................

ADJUSTINGCARBONATORWATERTANKLIQUIDLEVEL 13............

SANITIZINGSYRUP SYSTEMS13.........................................

CHECKINGICEWATERBATH13..........................................

CLEANINGCONDENSER COIL 14.........................................

CARBONATORWATERPUMPMAINTENANCE(ORAFTERWATER

SYSTEMDISRUPTION)14................................................

REPLENISHINGCO2SUPPLY14..........................................

REPLENISHINGSYRUP SUPPLY15.......................................

PERIODIC CLEANING OFCOOLINGUNIT15...............................

CLEANINGAND SANITIZING15...........................................

DAILYCLEANING OFUNIT15........................................

SANITIZINGPOST-MIX SYRUP SYSTEMS15..........................

TROUBLESHOOTING19......................................................

DISPENSEDPRODUCTCARBONATIONTOO LOW.19......................

ONLY SYRUPDISPENSED.19............................................

WARMPRODUCTBEINGDISPENSED19..................................

WATERPUMPWILL NOTOPERATE19....................................

WATERPUMPMOTOROPERATES BUTWATERPUMPDOES NOTPUMP

WATER.19..............................................................

WATERPUMPCAPACITYTOO LOW.19...................................