3 of 64CORRADI S.R.L. - INSTALLATION MANUAL - PERGOTENDA ® MAESTROREV.1 - 11.2019

CONTENTS

Dear installer,

In this manual you will nd all recommendations for a fast and precise installation of the components.

Sure of your expertise in the use of our products, we recommend you to strictly respect our indications.

We are also willing to accept suggestions and useful information on possible improvements both in

installation techniques and form of this manual.

We would like to remind you to always consider the installation conditions by checking with the most

attention the conformity of the chosen materials with the environmental conditions.

It is also a good rule to issue a nal declaration of correct installation according to the specications

provided for in this manual, beside the mandatory declarations of conformity required by law, where

requested.

MAESTRO is a product by CORRADI S.r.l.

Any technical operation necessary during the installation must be carried out exclusively by skilled and

authorised personnel.

Any personal operation (tampering with, technical changes, etc.) performed during the warranty period

voids the warranty immediately.

CORRADI S.r.l. reserves the right to apply technical changes to the components or the product,

except for the main features, at any time and without notice.

INSTALLATION MANUAL

TRANSLATION OF THE ORIGINAL INSTRUCTIONS CONTENTS

SYMBOLS.......................................................................................................................................................................................................................................... 4

CONTROLS AND VERSIONS ................................................................................................................................................................................................. 6

MATERIAL CHECK, UNPACKING AND PREPARATION.......................................................................................................................................... 7

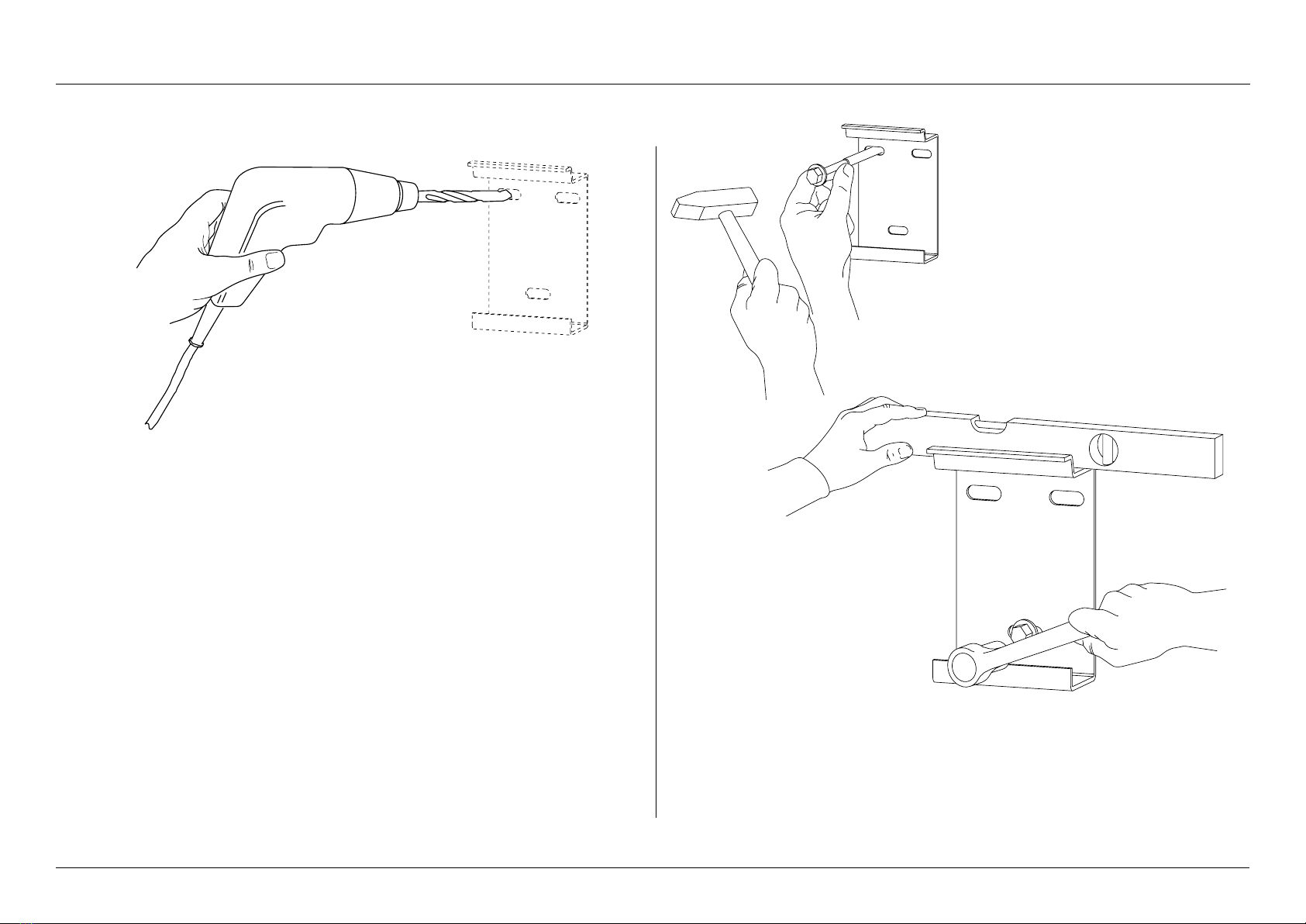

1 WALL INSTALLATION............................................................................................................................................................................................................ 8

2 PILLAR INSTALLATION......................................................................................................................................................................................................... 12

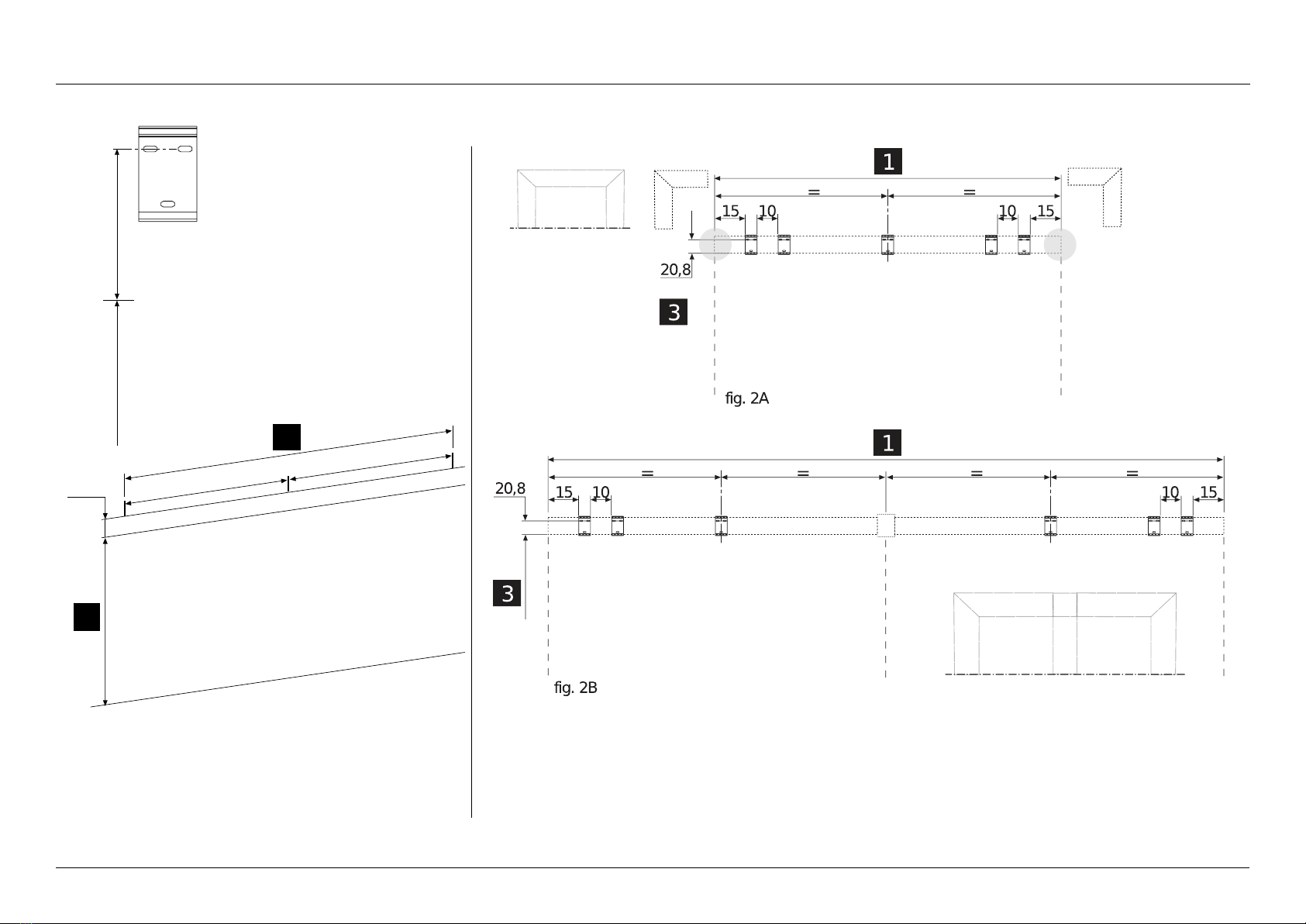

3 CROSSBEAM INSTALLATION ........................................................................................................................................................................................... 17

4 RUNNER INSTALLATION..................................................................................................................................................................................................... 26

5 CENTRAL RUNNER INSTALLATION OF A THREERUNNER STRUCTURE.............................................................................................. 27

6 TRANSMISSION SHAFT INSTALLATION.................................................................................................................................................................... 28

7 CONTROL UNIT INSTALLATION..................................................................................................................................................................................... 30

8 IMPACT AWNING CANVAS INSTALLATION ............................................................................................................................................................ 31

9 MOTOR CABLE INLET COVER CASING...................................................................................................................................................................... 32

10 MOBILE GUTTER................................................................................................................................................................................................................... 34

11 GUTTER PROFILE INSTALLATION .............................................................................................................................................................................. 38

12 SUPPORTING PROFILE INSTALLATION .................................................................................................................................................................. 40

13 SUPPLEMENTARY PILLAR............................................................................................................................................................................................... 41

14 SCREEN INSTALLATION.................................................................................................................................................................................................... 42

15 SLIDING GLASS DOORS INSTALLATION ............................................................................................................................................................... 45

16 DRIP GUARD PLATE INSTALLATION......................................................................................................................................................................... 46

17 CASING INSTALLATION.................................................................................................................................................................................................... 46

18 WALLMOUNTED OPTION WITH PILLARS........................................................................................................................................................... 50

19 WALLMOUNTED OPTION WITHOUT PILLARS................................................................................................................................................. 51

20 SILICONE APPLICATION AREAS.................................................................................................................................................................................. 52

21 ANGLE PLATE INSTALLATION ...................................................................................................................................................................................... 53

22 ANTIREBOUND SYSTEM INSTALLATION............................................................................................................................................................. 54

ELECTRIC SYSTEM...................................................................................................................................................................................................................... 61

TABLES ............................................................................................................................................................................................................................................... 62

EXAMPLE DETERMINATION OF THE WIND RESISTANCE ACCORDING TO THE LOADS AND THE DOWELS .............. 64