Table of contents YHC 700

Table of contents

Warnings.....................................................................................................................4

1. General characteristics ..........................................................................................5

2. Technical specifications ........................................................................................5

2.1 Hardware..................................................................................................................................5

2.2 Mechanical features.................................................................................................................5

2.3 Electrical features.....................................................................................................................5

2.4 Supported devices ...................................................................................................................6

2.4.1 Devices on bus RS485 #1 (remote control)..........................................................................6

2.4.2 Devices on bus RS485 #2 (monitoring)................................................................................6

2.5 Accessories..............................................................................................................................6

3. Electrical installation..............................................................................................7

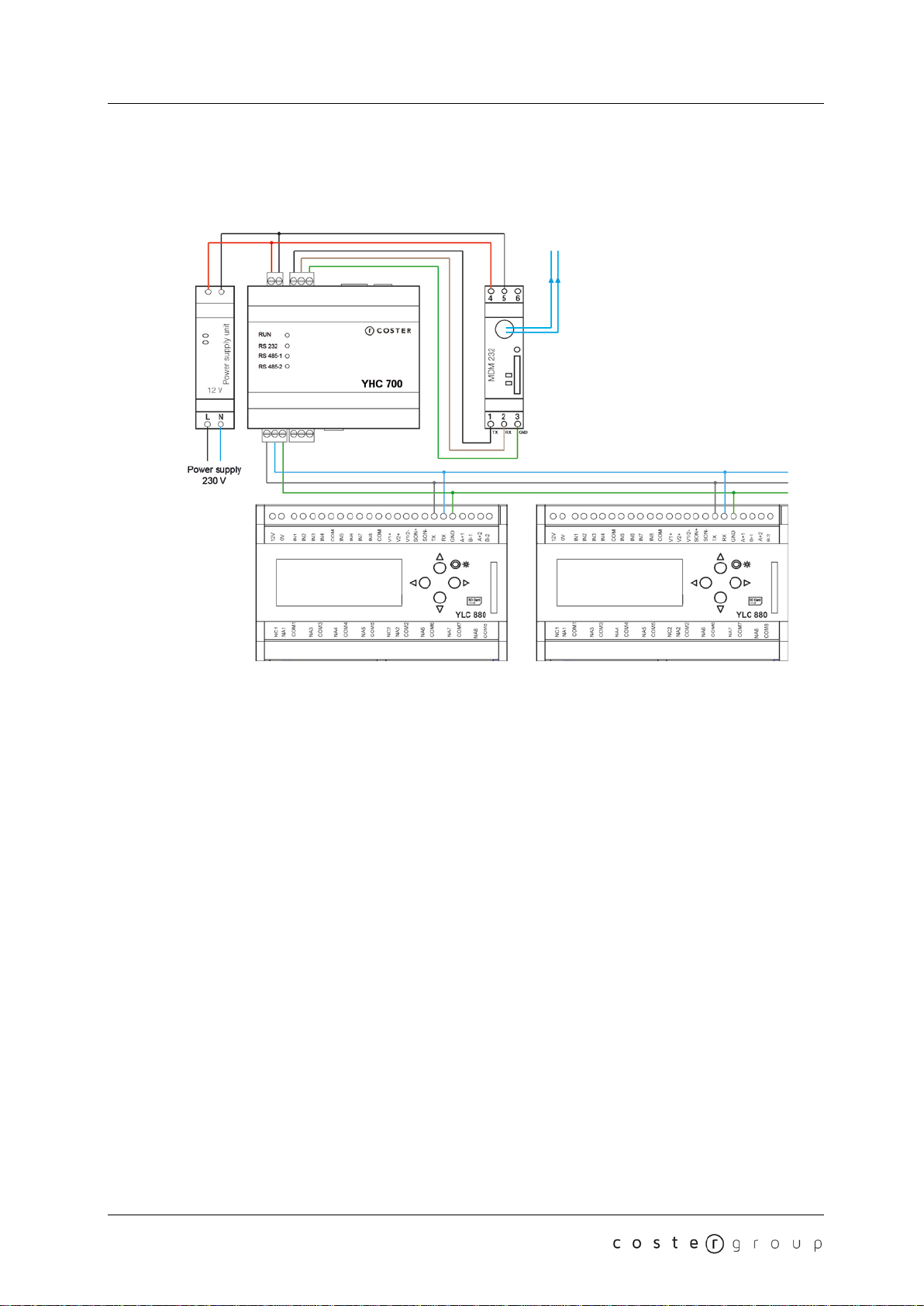

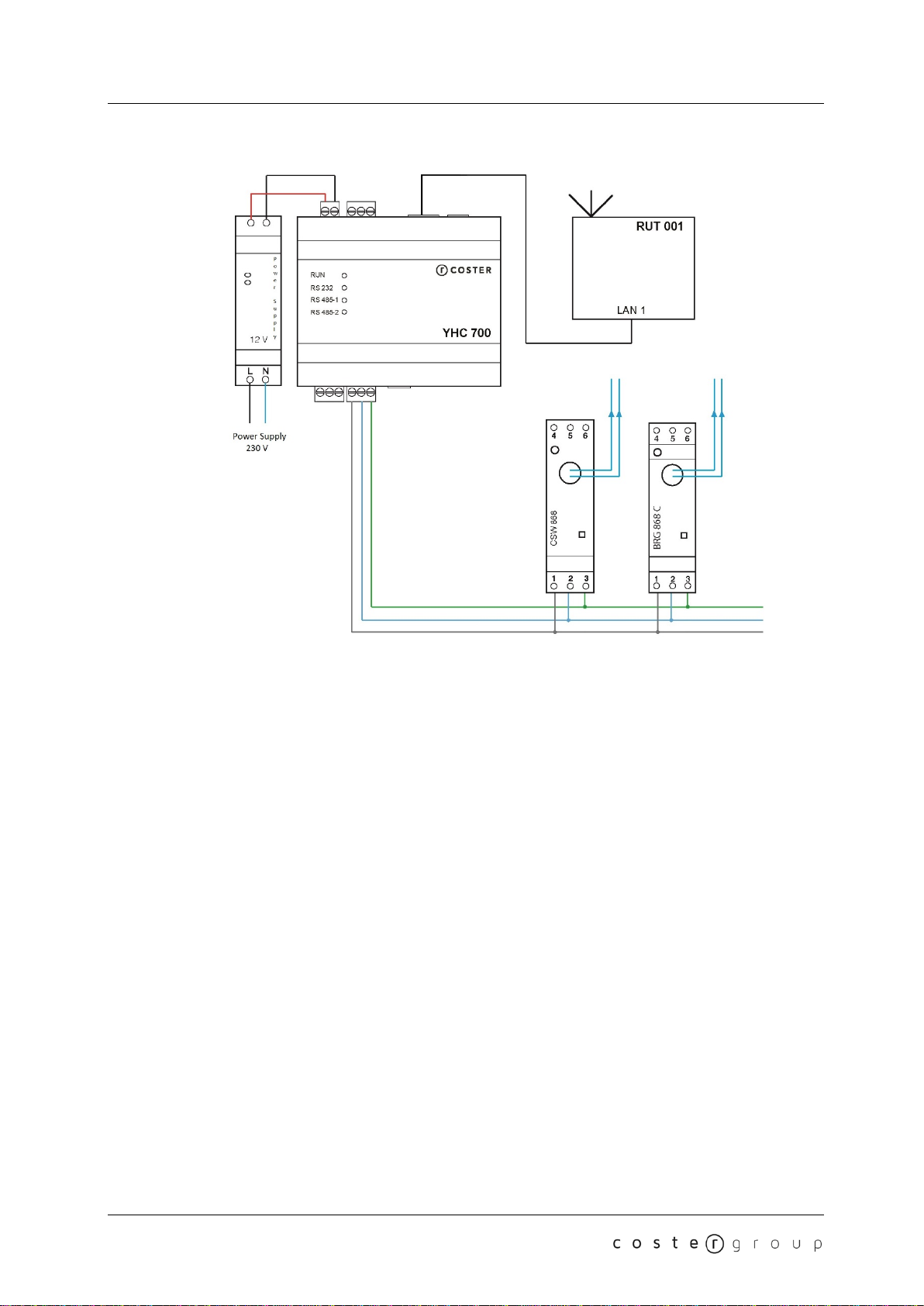

3.1 Electrical connections ..............................................................................................................7

3.2 Connection examples...............................................................................................................8

4. LEDs......................................................................................................................12

5. Main features.........................................................................................................13

5.1 Communication with a supervisor..........................................................................................13

5.2 Communication with field devices..........................................................................................13

5.3 Bridging between YLC controllers..........................................................................................14

5.4 Data logging (instantaneous data logger)..............................................................................14

5.5 YLC data caching...................................................................................................................14

5.6 Sending alarms......................................................................................................................14

5.6.1 Sending alarms via e-mail...................................................................................................14

5.6.2 Sending alarms via HTTP/HTTPs.......................................................................................14

5.6.3 Sending alarms using the MDM 232 modem......................................................................15

5.7 Monitoring data reading .........................................................................................................15

5.8 Datalogging dei dati di monitoraggio......................................................................................15

5.9 M-BUS devices integration.....................................................................................................15

5.10 Sending data to the Cloud ...................................................................................................16

5.10.1 Sending data via the Ethernet port ...................................................................................16

5.10.2 Sending data to the cloud using the MDM 232 modem....................................................16

5.11 Sending date and time.........................................................................................................16

5.12 Software reset......................................................................................................................17

6. Remote management............................................................................................17

7. YHC Configuration................................................................................................17

7.1 Connecting to YHC ................................................................................................................17

2