2

CAUTION

We advise the user to verify that the installation of the equipment be performed in a

proper way; the manufacturer cannot be held responsible for damages resulting from

incorrect installation, poor maintenance or incorrect use.

Before using the oven carefully read the instructions for use. The manufacturer

cannot be held responsible if the requirements indicated in this manual are not observed.

All installation, maintenance or repair operations must be carried out exclusively by

authorized and qualified personnel.

INSTRUCTIONS FOR THE INSTALLER

POSITIONING THE OVEN

Position the equipment on a horizontal surface, well-balanced. The distance between the

back and side walls of the oven must be of at least 50 cm.

INSTALLATION

Remove the plastic film before starting up the oven. Clean all glue residues carefully

without using abrasive substances.

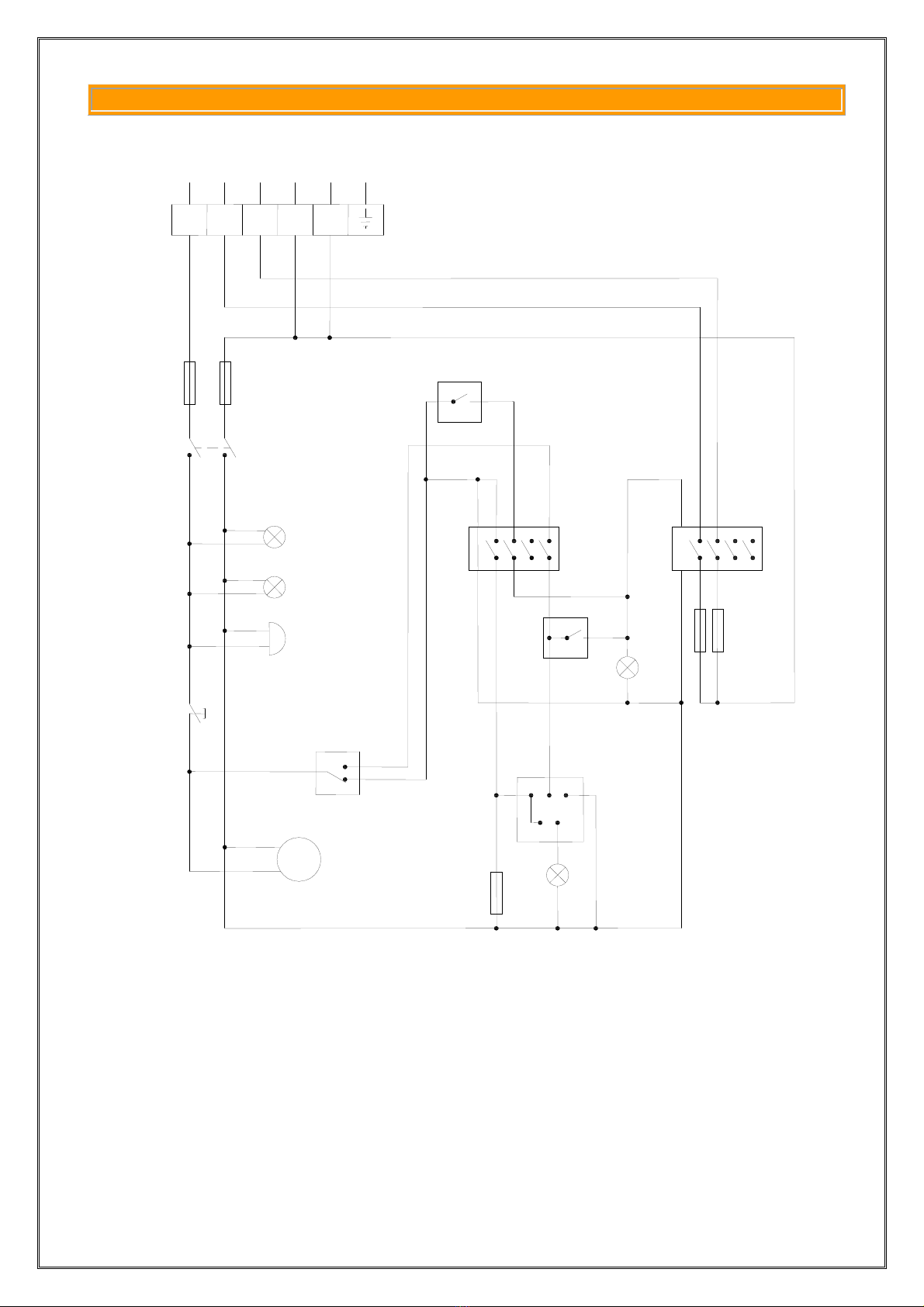

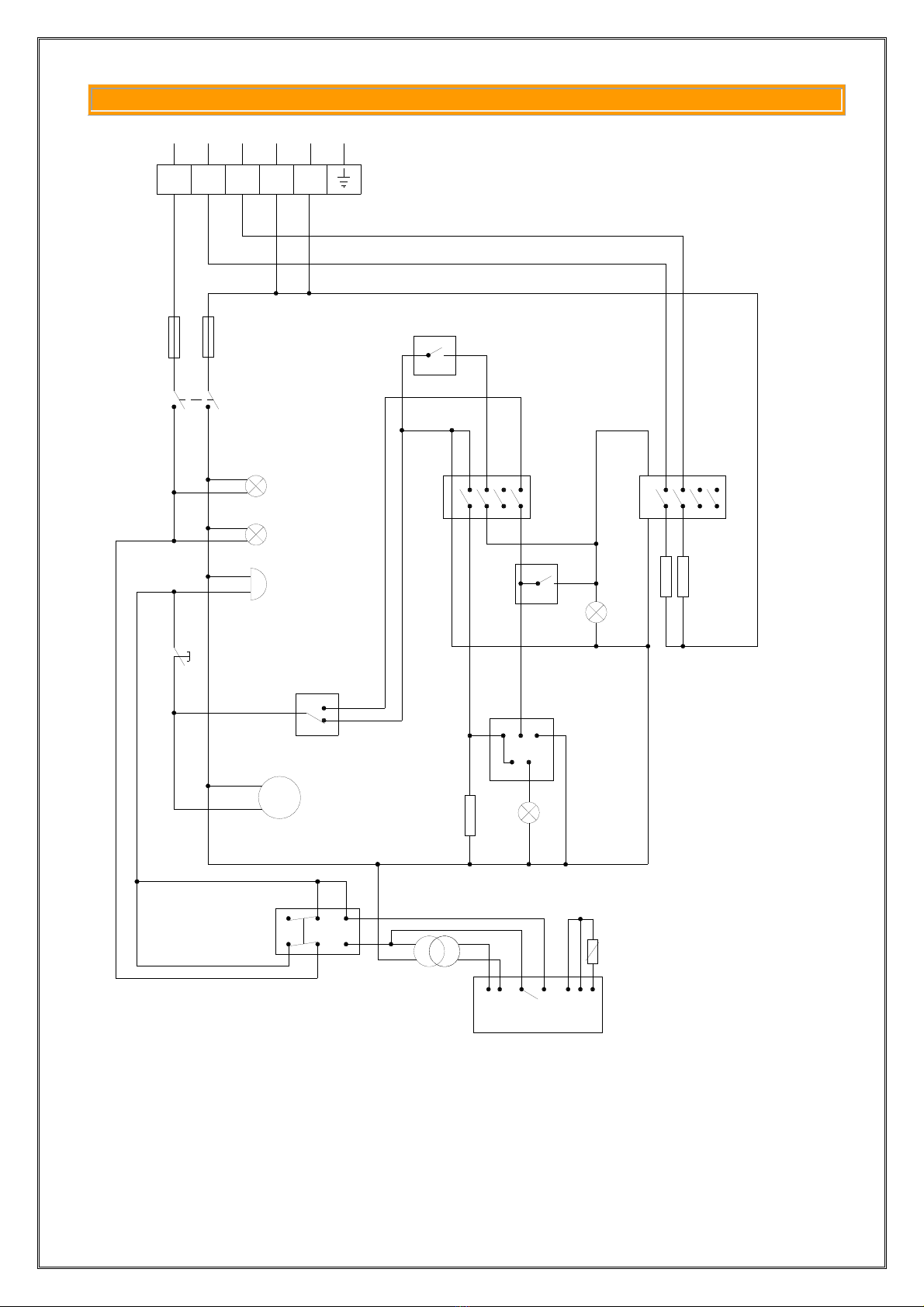

ELECTRICAL CONNECTION

This oven is manufactured to operate at the voltage indicated on the relevant label. To

access the connector board, remove the right side of the unit by removing the fastening

screws.

The flexible wire for connection to the mains must not have characteristics lower than the

ones with rubber insulation model H07RN – F and the section must be the one indicated in

the table “TECHNICAL DATA”.

Connection to the electric line must be made by inserting an automatic switch with

adequate capacity with an opening distance between the contacts of at least 3 mm.

Furthermore, during operation, power supply must not be very different from the value of

the rated voltage ± 10%.

The unit must be connected to a ground outlet. Inside the unit, in the connector board,

there is a terminal with the symbol which the ground wire must be connected to.