Kendall SCD™

700 Series Controller

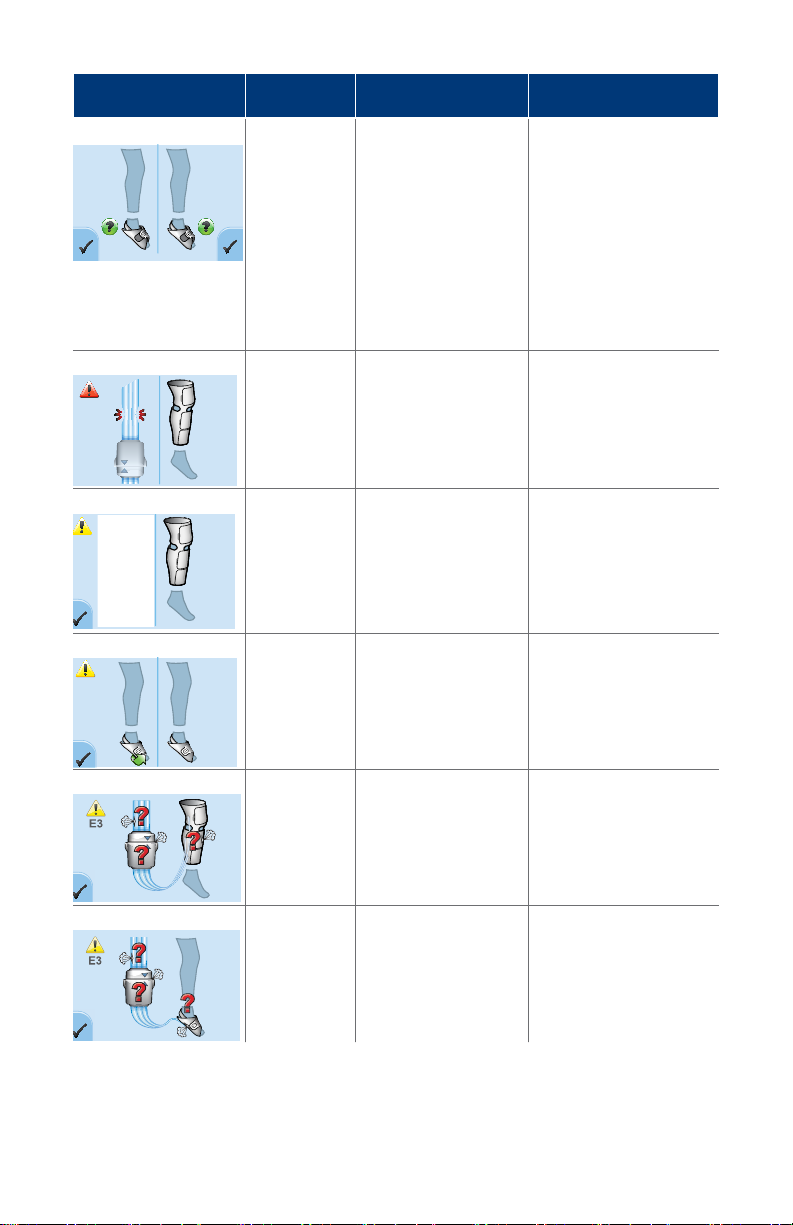

error Key

When the microprocessor detects a fault condition, it interrupts the

normal operation of the controller, deactivates all valves to vent the air

from the garment(s), displays a fault code, and sounds an audible error.

Errors can be reset once the user confirms the cause of the error and

remedies the problem. If a Garment Mismatch error is triggered, the

user may remedy the problem by pressing the corresponding A and B

Button(s). Some errors will remain active until the controller is turned

off or the battery runs out of charge (if operating on battery power).

The Kendall SCD™700 series controller has three error types:

User Resettable, Manual Reset Required and Service Required.

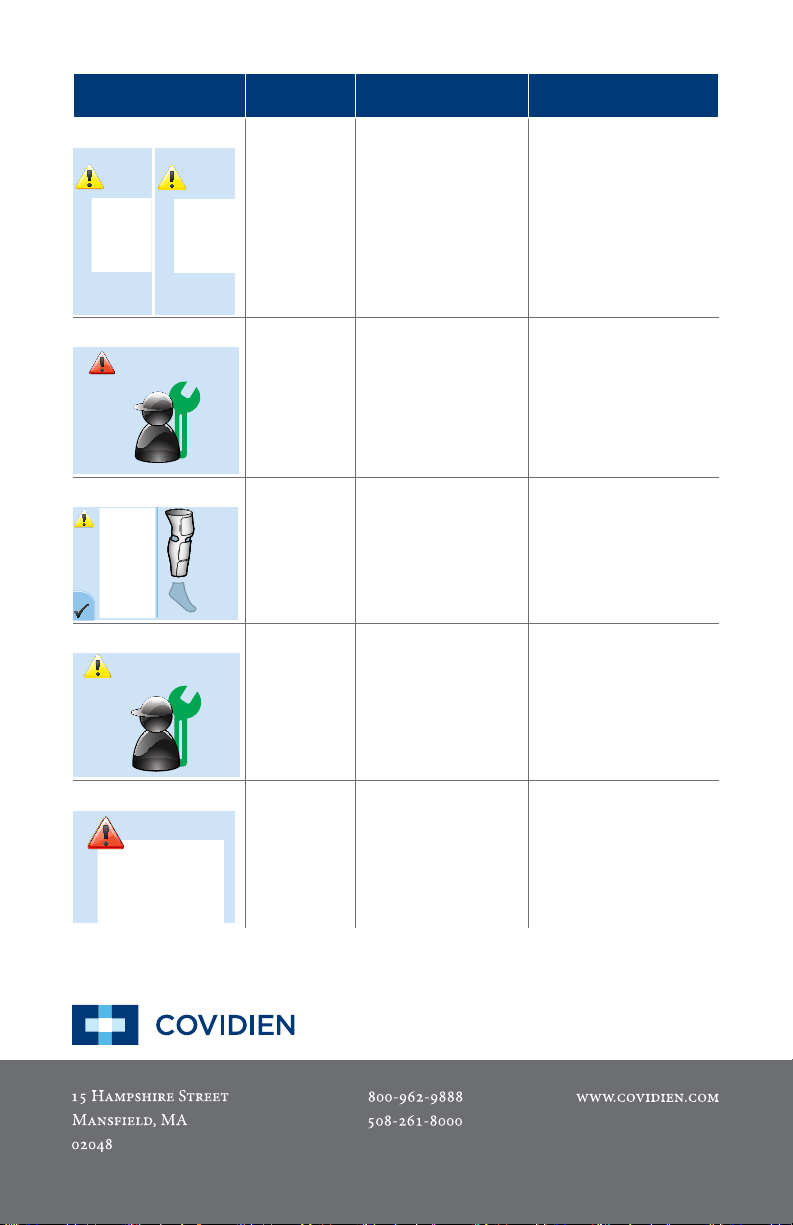

User Resettable

This type of error allows the user to remedy the issue and resume operation by

pressing the A and B button(s) corresponding with the port affected without

powering the unit down. For this type of error, a check mark will be shown

indicating which port is the area of concern. A yellow triangle indicates a low

concern error. If the triangle is red it is indicative of an error related to abnormally

high pressure. If the error persists, then the controller requires service.

Manual Reset Required

An error that can be corrected by the user but requires the device to be

powered off and on. If the error persists, then the controller requires service.

Service Required

Error code is present because of a failed internal component.

It cannot be addressed by the user.