COX CXO300 User manual

INSTALLATION

GUIDE

–––

CXO300 – designed for

purpose

coxmarine.com

TABLE OF CONTENTS

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

11.0

12.0

13.0

14.0

INTRODUCTION

INSPECTION OF OUTBOARD

REMOVAL OF OUTBOARD ENGINE FROM THE CRATE

MOUNTING THE OUTBOARD ONTO THE TRANSOM

RIGGING INSTALLATION

STEERING

RIGGING TUBE INSTALLATION

FUEL SYSTEM INSTALLATION

POWER SUPPLY

WIRING HARNESS INSTALLATION

HELM CONTROL INSTALLATION

OUTBOARD OIL FILL

APPLYING GREASE TO THE PTT

INSTALLING THE TOP COWL

4

5

6

10

16

27

31

34

38

41

48

55

57

59

4CXO300 INSTALLATION MANUAL

1.0 INTRODUCTION

1.0 INTRODUCTION

1.1 INTRODUCTION

The purpose of this document is to define the procedures or steps that are required to be done in order

to do a safe and correct installation of a CXO300 outboard engine(s).

The different systems of the outboard(s) are designed to work together continuously to provide a safe

and reliable boating experience.

Any modifications to the outboard(s) or deviation to installing the units to as described in the procedures

of this document, is likely to affect safety, legality and longevity and should be expressly avoided.

1.2 EMISSIONS-RELATED INSTALLATION INSTRUCTION (USA)

In order to ensure emissions compliance of the installed outboard(s), it is essential that the processes

and requirements detailed in ‘Section 8.0.0’ of the document are adhered to.

Failing to follow these instructions when installing a certified engine in a vessel violates federal law

(40 CFR 1068.105(b)), subject to fines or other penalties as described in the Clean Air Act.

This product is EPA Tier 3 compliant and can be used on US flagged vessels. To support US registered

vessels to operate internationally, this marine engine is also certified to IMO Annex VI Tier II

standards, and may therefore be limited to use on new and/or non-exempt vessels that meet one of

the following criteria:

1 Recreational vessels < 24 meters in length under Annex VI Regulation 13.5.2.1

2 Vessels with a Tier III exemption for combined nameplate of <750kW due to ships design or

construction limitations under Annex VI Regulation 13.5.2.2

3 Recreational vessels of >24m with gross tons < 500, and a keel laid date < January 1, 2021, per

Annex VI Regulation 13.5.2.3

If you install the engine in a way that makes the engine’s emission control information label hard to

read during normal engine maintenance, you must place a duplicate label on the vessel, as described

in 40 CFR 1068.105.

5

CXO300 INSTALLATION MANUAL 2.0 INSPECTION OF OUTBOARD

INSPECTION OF OUTBOARD 2.0

2.1 INSPECTION OF OUTBOARD AFTER DELIVERY AT INSTALLATION LOCATION

2.1.0 Before you remove the outboard from the packaging, make sure that you inspect the packaging

for damage(s) during shipping and storage.

2.2.0 Make sure that you do a check for damage on the outer packaging.

2.3.0 Remove the packaging straps and outer packaging.

2.4.0 Make sure that the outboard is mounted safely and the Power Tilt and Trim (PTT) lock is on.

2.5.0 Make sure that the outboard specification (color, leg length and gear ratio) is correct.

2.6.0 Make sure that you do a check for damage on the outboard cover.

2.7.0 Remove the outboard cover and make sure that you do a check for damage on the outboard

cover again.

2.8.0 Make sure you speak to your distributor or local Cox service provider for aid if:

2.8.1 Damages can be seen on the outboard, outboard cover and packaging.

2.8.2 Outboard specification is not correct.

2.8.3 Outboard is not mounted safely, and the PTT lock is not on.

6CXO300 INSTALLATION MANUAL

3.0 REMOVAL OF OUTBOARD ENGINE

3.0 REMOVAL OF OUTBOARD ENGINE FROM THE CRATE

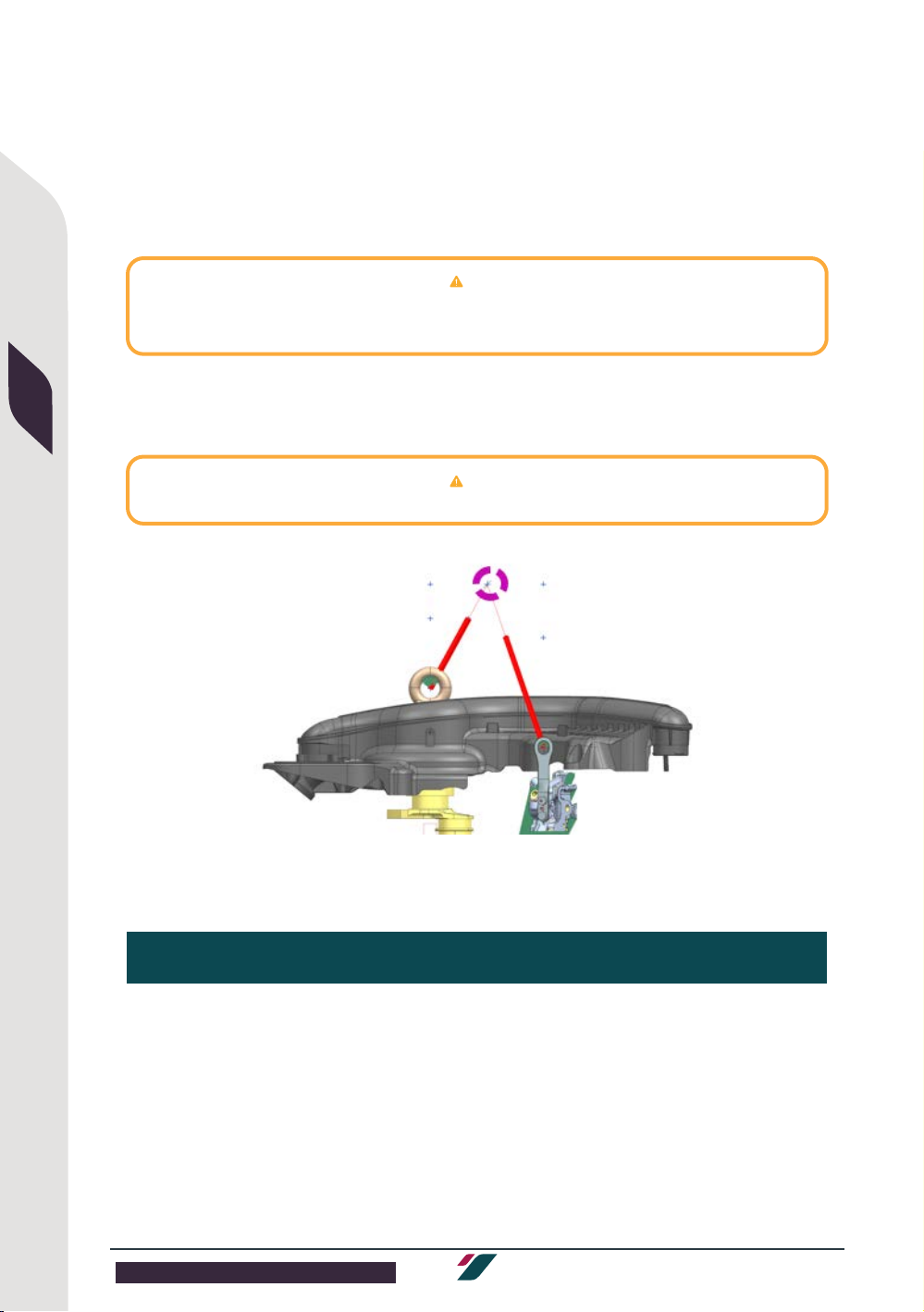

3.1.0 Attach the applicable straps or chains to the correct points on the metal transportation crate

(Figure 3.1a)

Figure 3.1a. Points for attaching straps and steps for lifting the metal transportation crate with

outboard to a vertical position.

3.2.0 Using a gantry crane (or A-frame gantry crane) lift the crate to a vertical position.

3.3.0 Remove the straps or chains from the crate.

3.4.0 Remove the propeller shaft steady bar.

3.5.0 Remove the two long vertical rails.

3.6.0 Remove the top frame from the crate.

3.7 REMOVAL OF OUTBOARD TOP COWL

3.7.1 Open the three latches that hold the top cowl to the outboard.

3.7.2 Remove the outboard top cowl and stow it safely; if working on multiple outboard, ensure cowls

are labeled.

3.7.3 Close the three latches that hold the top cowl onto the outboard.

3.8.0 Remove the lifting eye cover from the top cover.

3.8.1 Use the applicable torx drive to remove the torx screws (2).

WARNING

If you are working on multiple outboards, make sure each cowl is marked for install to its initial outboard.

CAUTION

If you use an incorrect torx driver, it will damage the torx screw head.

7

CXO300 INSTALLATION MANUAL 3.0 REMOVAL OF OUTBOARD ENGINE

3.9.0 Remove the crank pulley cover.

3.9.2 Use 14mm hex driver or Allen key to remove the crank pully cover.

3.10.0 Install the centre lifting eye and sleeve (Kit No. 909427) . Hand tight only.

3.10.1 When the centre lifting eye is tight, if the eye orientation is not within 45° of the centre line of the

outboard, bar over the engine until it is in the correct orientation as shown.

3.11.0 Install the right hand lifting eye (909441) to the starboard/right cylinder head (Figure3.11) and

torque the two fasteners (029355) to 23Nm.

Figure 3.11 Lift hooks and lifting eyes positions on the outboard.

8CXO300 INSTALLATION MANUAL

3.0 REMOVAL OF OUTBOARD ENGINE

3.0 REMOVAL OF OUTBOARD ENGINE FROM THE CRATE

3.12.0 Install the left hand lifting eye (909440) to the port/left cylinder head (Figure 3.11) and torque

the two fasteners (029355) to 23Nm.

3.13.0 Attach the three point lifting frame to the lifting eyes or attach three straps of length detailed

in the table below. Make sure that you apply equal tension to all the straps for vertical lifting of

the outboard.

Minimum strop lengths for lifting the outboard are detailed in the table below. Using a longer strop length

with result in a greater angle than 25°.

3.14.0 Remove the bolts that hold the PTT to the crate.

3.15.0 Move the outboard to a safe position.

Minimum strop length required at 25° to the vertical (mm)

Centre Lifting Eye 420

Left-hand Lifting Eye - Port 590

Right-hand Lifting Eye - Starboard 590

NOTE

Unequal loading of straps may result in damage to outboard during lifting.

NOTE

Working load limit (WLL) for left-hand lifting eye (909440) and right-hand lifting eye (909441):

Vertical outboard lift WLL = 500kg 25° vertical outboard lift WWL = 96kg

9

CXO300 INSTALLATION MANUAL 3.0 REMOVAL OF OUTBOARD ENGINE

3.16.0 Assemble the crate again.

3.17.0 Keep or send the crate back to Cox.

CAUTION

Do not reuse any fasteners from the shipping crate for the installation of the outboard to a vessel -

the fasteners are for shipping purposes only. Use only components from the supplier rigging kits for

installation to vessel.

10 CXO300 INSTALLATION MANUAL

4.0 MOUNTING THE OUTBOARD

4.0 MOUNTING THE OUTBOARD ONTO THE TRANSOM

4.1.0 Before you drill the mounting holes, make sure that:

4.1.1 The outboard is appropriate for the vessel.

4.1.2 The mounting hole positions are identified correctly.

4.2.0 Make sure that the vessel is rated for the power output of the outboard(s).

4.3.0 Make sure that the vessel transom is sufficiently strong to mount the outboard.

4.4.0 Make sure that there is sufficient clearance to steer and trim the outboard engine(s).

4.5.0 Make sure that you use an applicable method to identify the correct center line of the

outboard. For example:

4.5.1 Identify the center point between two chines and draw a line down the centric-V of the vessel,

as shown on Figure 4.5.

4.5.2 If you are not sure about the center line position, speak to the boat builder for aid.

4.6.0 Make sure that you use the center line mark as the datum (the fixed starting point to measure

the distance from the center line) for installing multiple outboards.

4.6.1 Use the table in figure 4.6 to determine the distance between centers and any applicable

steering system limits.

D

D

C

C

B

B

A

A

Figure 4.5. Vessel

with center line from

the transom to the

center-V.

Figure 4.4 Vessel displaying center lines on the vessel and on the outboards

A - 30°B - 337mm C - 565.6mm D - see figure4.6

11

CXO300 INSTALLATION MANUAL 4.0 MOUNTING THE OUTBOARD

4.6 Outboard steering angle relationship

4.7.0 Make sure the mounting position marks are at the correct height for the outboard(s).

CXO300 Outboard Install Guide (based on current Cox steering systems)

Between centres

724 [28.5] 762 [30] 784 [30.9]

Single

Install

Twin Install Triple

Install

Quad

Install

Twin Install Triple

Install

Quad

Install

Twin

Install

Triple

Install

Quad

Install

Parallel Asymmetric Parallel Asymmetric

Maximum

Envelope

(mm [in])

1131

[44.5276}

1652

[65.0394]

1885

[73.0315]

2376

[93.5433]

3100

[122.0472]

1836

[72.5276]

1893

[74 .5276 ]

2598

[102. 28 35]

3360

[132.2835]

1915

[75.3937]

2699

[106. 2598]

3483

[137.126]

Maximum steering angle (°)

Port turn

Angle A 30 17 30 17 17 26 30 26 26 30 30 30

Angle B 17 20 17 17 26 27 26 26 30 30 30

Angle C 17 17 26 26 30 30

Angle D 17 26 30

Starboard turn

Angle E 30 17 20 17 17 26 27 26 26 30 30 30

Angle F 17 30 17 17 26 30 26 26 30 30 30

Angle G 17 17 26 26 30 30

Angle H 17 26 30

12 CXO300 INSTALLATION MANUAL

4.0 MOUNTING THE OUTBOARD

4.0 MOUNTING THE OUTBOARD ONTO THE TRANSOM

4.7.1 Make sure the positioning of the anti-ventilation plate is in line with the bottom

of the hull directly in front of it.

4.7.2 Make sure that the anti-ventilation plate and the water line is at the correct height. Cox

offer 3 outboard leg lengths (25”, 30” and 35”) to make sure that the outboard operates

correctly with the vessel.

4.7.3 Make sure that you use the dimensions in Figure 4.8 to select the correct outboard leg length

for the vessel.

Figure 4.7 Information about the three leg lengths of the outboard engine. Units mm (in)

25”

A 609 (24)

B 1997 (78.6)

C 141 (5.6)

D 1241 (47.8)

E R1286 (50.7)

F 918 (36.1)

G 853 (33.58)

30”

A 732 (29)

B 2124 (83.6)

C 268 (10.5)

D 1341 (52.8)

E R1413 (55.6)

F 1045 (41.1)

G 853 (33.58)

35”

A 863 (34)

B 2251 (88.6)

C 395 (15.6)

D 1468 (57.8)

E R1540 (60.7)

F 1172 (46.1)

G 853 (33.58)

13

CXO300 INSTALLATION MANUAL 4.0 MOUNTING THE OUTBOARD

4.8.0 Make sure that the water line of the vessel is between the lines which are shown on the

outboard in Figure 4.9.

Figure 4.8. Minimum and maximum water lines on the outboard engine.

4.9.0 Make sure that you read the information of the different leg lengths on multiple outboard

installs in Figure 4.9. It will help you put the PTT mountings in the correct position for

the correct steering geometry.

Figure 4.9 Different leg lengths on multiple outboard installations

4.10.0 When the positions for the center line(s) and height(s) are found.

4.10.1 Make marks at the positions of the six holes for the outboard(s).

4.10.2 Make sure that you use the supplied template (Servicing Kit No: 037023, figure 4.10) to get

the correct positions of the mounting holes.

4.10.3 Make sure that you use two bolts on each side for the six top holes.

4.10.4 Make sure that you use one bolt on each side for the bottom hole.

Max water line - make

sure that the exhaust

idle vent is out of the

water

Min water line - make

sure that the water

pump is covered for

correct operation

14 CXO300 INSTALLATION MANUAL

4.0 MOUNTING THE OUTBOARD

4.0 MOUNTING THE OUTBOARD ONTO THE TRANSOM

4 .11.0 Make sure that you use a 6 mm pilot drill to make initial holes in the transom. Make sure that

the drill is always at 90 degrees to the transom when drilling the holes.

4.12.0 Make sure that you use a clearance drill to finish the holes for the 12 mm bolts (M12).

4.13.0 Make sure that you use the correct specification bolts, nuts and washers (M12 x 1.75mm

Stainless Steel grade A4-80) to attach the outboard to the transom.

4.13.1 Make sure that the length of the bolts are long enough to go through the PTT, transom , the

lock nut and all washers.

4.13.2 Make sure two full threads of the bolts are showing through the nyloc nuts.

4.14.0 Make sure that you apply marine sealant (Sikaflex 291i or equivalent) to the areas around the

mounting holes on the PTT and to transom face.

4.15.0 Make sure that you use a gantry crane (A-frame) to move the outboard into position and mount

to transom.

4.16.0 Make sure that you apply marine sealant (sikaflex 291i or equivalent) to the bolts. Torque the

fasteners to 80 Nm.

BB

A

A

CC

D

E

H

F

G

Figure 4.10

Engineering

drawing showing

the PTT-Transom

layout - mm (in).

A 13 (0.51)

B 163.5 (6.44)

C 125.4 (4.94)

D 95.2 (3.75)

E 318.5 (12.54)

F 92.5 (3.64)

G 115.3 (4.54)

H 18.5 (0.73)

15

CXO300 INSTALLATION MANUAL 4.0 MOUNTING THE OUTBOARD

4.17.0 Remove the lifting straps or chains from the outboard and move the crane to a safe area.

4.18.0 If you are doing a multiple installation, repeat steps 4.15.0 through 4.18.0 for each outboard to

be installed.

4.19.0 Remove the lifting eyes (3) and install the crank pulley cover. Torque the crank pulley cover to

9-11 Nm.

4.20.0 Place the lifting eye cover on the top cover. Torque the torx screws (2) to 3 Nm.

16 CXO300 INSTALLATION MANUAL

5.0 RIGGING INSTALLATION

5.0 RIGGING INSTALLATION

5.1. RIGGING KITS

5.1.1 Make sure that you use the applicable rigging kits. There are different rigging kits for different

vessel or outboard configuration.

5.1.2 Make sure that the contents of the rigging kits are correct before you start the rigging

installation.

Single Install Twin Install Triple Install Quad Install Quintuple Install Sextuple Install

Components Part Number Without Steering

SK-000103 With Steering SK-000097 Without Steering

SK-000080 With Steering SK-000081 Without Steering

SK-000082 With Steering SK-000078 Without Steering

SK-000079 With Steering SK-000083 Without Steering

SK-000084

Without Steering

SK-000085

Seastar Control Head, Single Lever 034392 ●/1 ●/1 -- -- -- -- -- -- -- --

Seastar Control Head, Dual Lever 034391 -- -- ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1

Coastkey, Start Panel 033979 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1

Coastkey, 2 button fob 033980 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1

Coastkey, CECU Eng 1 033981 ●/1 ●/1 -- -- -- -- -- -- -- --

Coastkey, CECU Eng 1-2 033982 -- -- ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1

Coastkey, CECU Eng 3 033983 -- -- -- -- ●/1 ●/1 -- -- -- --

Coastkey, CECU Eng 3-4 033984 -- -- -- -- -- -- ●/1 ●/1 ●/1 ●/1

Coastkey, CECU Eng 5-6 033985 -- -- -- -- -- -- -- -- ●/1 ●/1

Fuel Lift Pump Unit 037236 ●/1 ●/1 ●/2 ●/2 ●/3 ●/3 ●/4 ●/4 ●/5 ●/6

Outboard to Vessel CAN Harness 033870 ●/1 ●/1 ●/2 ●/2 ●/3 ●/3 ●/4 ●/4 ●/5 ●/6

Outboard to Vessel Controls Harness 033871 ●/1 ●/1 ●/2 ●/2 ●/3 ●/3 ●/4 ●/4 ●/5 ●/6

CAN T Piece 034393 ●/4 ●/6 ●/6 ●/8 ●/8 ●/10 ●/10 ●/12 ●/12 ●/14

CAN Terminating Resistor Female 034394 ●/2 ●/2 ●/3 ●/3 ●/4 ●/4 ●/5 ●/5 ●/6 ●/7

CAN Terminating Resistor Male 034395 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1

Trim Panel, Twin Install 033939 -- -- ●/1 ●/1 -- -- ●/1 ●/1 -- --

Trim Panel, Triple Install 0 33 749 -- -- -- -- ●/1 ●/1 -- -- ●/1 ●/1

CAN connector cover Female 034986 ●/1 ●/1 ●/2 ●/2 ●/3 ●/3 ●/4 ●/4 ●/5 ●/6

Flush Adaptor 034363 ●/1 ●/1 ●/2 ●/2 ●/3 ●/3 ●/4 ●/4 ●/5 ●/6

ECU power harness 036484 ●/1 ●/1 ●/2 ●/2 ●/3 ●/3 ●/4 ●/4 ●/5 ●/6

Outboard to vessel fuel lines 031164 ●/1 ●/1 ●/2 ●/2 ●/3 ●/3 ●/4 ●/4 ●/5 ●/6

Outboard busbar nut 025599 ●/2 ●/2 ●/4 ●/4 ●/6 ●/6 ●/8 ●/8 ●/10 ●/12

Seastar Optimus EPS Core Pack, Single Install 027834 -- ●/1 -- -- -- -- -- -- -- --

Seastar Optimus EPS Core Pack, Twin Install 027166 -- -- -- ●/1 -- ●/1 -- ●/1 -- --

Seastar Steering Smart Cylinder, Tournament Series, Standard 027168 -- ●/1 -- ●/2 -- ●/1 -- -- -- --

Seastar Steering Smart Cylinder, Tournament Series, with Starboard-side Tie Bar Bracket 034385 -- -- -- -- -- ●/1 -- ●/1 -- --

Seastar Tie Bar, Tournament Series, Large 034386 -- -- -- -- -- ●/1 -- ●/2 -- --

Seastar Tie Bar Hardware Kit 034387 -- -- -- -- -- ●/1 -- ●/2 -- --

Seastar Optimus EPS Front-Mount Helm Unit 027169 -- ●/1 -- ●/1 -- ●/1 -- ●/1 -- --

Seastar Optimus EPS CAN1 Harness, 30ft 027170 -- ●/1 -- ●/1 -- ●/1 -- ●/1 -- --

Seastar Pro Hydraulic Steering Hose Kit, 10ft 027172 -- ●/1 -- ●/2 -- ●/2 -- ●/2 -- --

Seastar Optimus EPS CAN3 Harness, 3ft 027173 -- ●/1 -- ●/1 -- ●/1 -- ●/1 -- --

KIT, Steering Cylinder Spacer SK-000100 -- ●/1 ●/2 ●/2 ●/2 ●/2 ●/2 ●/2 ●/2 ●/2

Extension Harness Part Number

CAN Vessel Harness 1m 033872 ○/1 ○/1 ○/1 ○/1 ○/1 ○/1

CAN Vessel Harness 4m 033873 ○/1 ○/1 ○/1 ○/1 ○/1 ○/1

CAN Vessel Harness 6m 03 3874 ○/1 ○/1 ○/1 ○/1 ○/1 ○/1

CAN Vessel Harness 8m 033875 ○/1 ○/1 ○/1 ○/1 ○/1 ○/1

Vessel Helm Control Harness 4m 033876 ○/1 ○/2 ○/3 ○/4 ○/5 ○/6

Vessel Helm Control Harness 6m 033877 ○/1 ○/2 ○/3 ○/4 ○/5 ○/6

Vessel Helm Control Harness 8m 033878 ○/1 ○/2 ○/3 ○/4 ○/5 ○/6

Helm Screen Kits Part Number

Murphy PV450 4” Screen Kit SK-000134 ○/1 ○/1 ○/1 ○/1 ○/1 ○/1

Murphy PV780B 7” Screen Kit SK-000135 ○/1 ○/1 ○/1 ○/1 ○/1 ○/1

Murphy PV1200 12” Screen Kit SK-000136 ○/1 ○/1 ○/1 ○/1 ○/1 ○/1

Helm Screen Kits Part Number

Victron Energy Orion-Tr 12/12-30A (360W) Isolated DC-DC Converter 038206 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1

Voltage Sensing Battery Combiner (Not Supplied by Cox) - ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1

KEY: STANDARD/QUANTITY

●/1

INSTALLATION-SPECIFIC/QUANTITY

○/1

MAX EXTENSIONS (m)

17

CXO300 INSTALLATION MANUAL 5.0 RIGGING INSTALLATION

5.1.3 There are three lengths (4m, 6m and 8m) of vessel CAN and Helm controls harnesses

that are provided in the rigging kit. If a vessel harness which is longer than 8m is necessary,

make sure you speak to your Cox service provider about it. The rigging kits are as follows:

Figure 5.1 Rigging Kit Contents

Single Install Twin Install Triple Install Quad Install Quintuple Install Sextuple Install

Components Part Number Without Steering

SK-000103 With Steering SK-000097 Without Steering

SK-000080 With Steering SK-000081 Without Steering

SK-000082 With Steering SK-000078 Without Steering

SK-000079 With Steering SK-000083 Without Steering

SK-000084

Without Steering

SK-000085

Seastar Control Head, Single Lever 034392 ●/1 ●/1 -- -- -- -- -- -- -- --

Seastar Control Head, Dual Lever 034391 -- -- ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1

Coastkey, Start Panel 033979 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1

Coastkey, 2 button fob 033980 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1

Coastkey, CECU Eng 1 033981 ●/1 ●/1 -- -- -- -- -- -- -- --

Coastkey, CECU Eng 1-2 033982 -- -- ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1

Coastkey, CECU Eng 3 033983 -- -- -- -- ●/1 ●/1 -- -- -- --

Coastkey, CECU Eng 3-4 033984 -- -- -- -- -- -- ●/1 ●/1 ●/1 ●/1

Coastkey, CECU Eng 5-6 033985 -- -- -- -- -- -- -- -- ●/1 ●/1

Fuel Lift Pump Unit 037236 ●/1 ●/1 ●/2 ●/2 ●/3 ●/3 ●/4 ●/4 ●/5 ●/6

Outboard to Vessel CAN Harness 033870 ●/1 ●/1 ●/2 ●/2 ●/3 ●/3 ●/4 ●/4 ●/5 ●/6

Outboard to Vessel Controls Harness 033871 ●/1 ●/1 ●/2 ●/2 ●/3 ●/3 ●/4 ●/4 ●/5 ●/6

CAN T Piece 034393 ●/4 ●/6 ●/6 ●/8 ●/8 ●/10 ●/10 ●/12 ●/12 ●/14

CAN Terminating Resistor Female 034394 ●/2 ●/2 ●/3 ●/3 ●/4 ●/4 ●/5 ●/5 ●/6 ●/7

CAN Terminating Resistor Male 034395 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1

Trim Panel, Twin Install 033939 -- -- ●/1 ●/1 -- -- ●/1 ●/1 -- --

Trim Panel, Triple Install 0 33 749 -- -- -- -- ●/1 ●/1 -- -- ●/1 ●/1

CAN connector cover Female 034986 ●/1 ●/1 ●/2 ●/2 ●/3 ●/3 ●/4 ●/4 ●/5 ●/6

Flush Adaptor 034363 ●/1 ●/1 ●/2 ●/2 ●/3 ●/3 ●/4 ●/4 ●/5 ●/6

ECU power harness 036484 ●/1 ●/1 ●/2 ●/2 ●/3 ●/3 ●/4 ●/4 ●/5 ●/6

Outboard to vessel fuel lines 031164 ●/1 ●/1 ●/2 ●/2 ●/3 ●/3 ●/4 ●/4 ●/5 ●/6

Outboard busbar nut 025599 ●/2 ●/2 ●/4 ●/4 ●/6 ●/6 ●/8 ●/8 ●/10 ●/12

Seastar Optimus EPS Core Pack, Single Install 027834 -- ●/1 -- -- -- -- -- -- -- --

Seastar Optimus EPS Core Pack, Twin Install 027166 -- -- -- ●/1 -- ●/1 -- ●/1 -- --

Seastar Steering Smart Cylinder, Tournament Series, Standard 027168 -- ●/1 -- ●/2 -- ●/1 -- -- -- --

Seastar Steering Smart Cylinder, Tournament Series, with Starboard-side Tie Bar Bracket 034385 -- -- -- -- -- ●/1 -- ●/1 -- --

Seastar Tie Bar, Tournament Series, Large 034386 -- -- -- -- -- ●/1 -- ●/2 -- --

Seastar Tie Bar Hardware Kit 034387 -- -- -- -- -- ●/1 -- ●/2 -- --

Seastar Optimus EPS Front-Mount Helm Unit 027169 -- ●/1 -- ●/1 -- ●/1 -- ●/1 -- --

Seastar Optimus EPS CAN1 Harness, 30ft 027170 -- ●/1 -- ●/1 -- ●/1 -- ●/1 -- --

Seastar Pro Hydraulic Steering Hose Kit, 10ft 027172 -- ●/1 -- ●/2 -- ●/2 -- ●/2 -- --

Seastar Optimus EPS CAN3 Harness, 3ft 027173 -- ●/1 -- ●/1 -- ●/1 -- ●/1 -- --

KIT, Steering Cylinder Spacer SK-000100 -- ●/1 ●/2 ●/2 ●/2 ●/2 ●/2 ●/2 ●/2 ●/2

Extension Harness Part Number

CAN Vessel Harness 1m 033872 ○/1 ○/1 ○/1 ○/1 ○/1 ○/1

CAN Vessel Harness 4m 033873 ○/1 ○/1 ○/1 ○/1 ○/1 ○/1

CAN Vessel Harness 6m 03 3874 ○/1 ○/1 ○/1 ○/1 ○/1 ○/1

CAN Vessel Harness 8m 033875 ○/1 ○/1 ○/1 ○/1 ○/1 ○/1

Vessel Helm Control Harness 4m 033876 ○/1 ○/2 ○/3 ○/4 ○/5 ○/6

Vessel Helm Control Harness 6m 033877 ○/1 ○/2 ○/3 ○/4 ○/5 ○/6

Vessel Helm Control Harness 8m 033878 ○/1 ○/2 ○/3 ○/4 ○/5 ○/6

Helm Screen Kits Part Number

Murphy PV450 4” Screen Kit SK-000134 ○/1 ○/1 ○/1 ○/1 ○/1 ○/1

Murphy PV780B 7” Screen Kit SK-000135 ○/1 ○/1 ○/1 ○/1 ○/1 ○/1

Murphy PV1200 12” Screen Kit SK-000136 ○/1 ○/1 ○/1 ○/1 ○/1 ○/1

Helm Screen Kits Part Number

Victron Energy Orion-Tr 12/12-30A (360W) Isolated DC-DC Converter 038206 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1

Voltage Sensing Battery Combiner (Not Supplied by Cox) - ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1 ●/1

KEY: STANDARD/QUANTITY

●/1

INSTALLATION-SPECIFIC/QUANTITY

○/1

MAX EXTENSIONS (m)

18 CXO300 INSTALLATION MANUAL

5.0 RIGGING INSTALLATION

5.0 RIGGING INSTALLATION

*

i

ii

B

Rigging Component Part Number

Vessel Helm Control Harness 8m (One

per outboard) 033878

Key

CAN Harness

Helm Controls Harness

12v switched ignition feed

CoastKey Connection

PTT Connection

Fuel Level Sensor

12v Positive

12v Negative

Dometic CAN1

Dometic CAN3

Breaker

Battery Switch

Service Tool Connection

CAN T-Piece

CAN Terminating Resistor

Second Station Extension #

Engine Battery

CoastKey Start Panel

CoastKey ECU

Lift Pump

Fuel Pump

Water In Fuel Sensor

4 inch Screen

7 inch Screen

12 inch Screen

Trim Panel - 2 Switch

Trim Panel - 3 Switch

Fuse

Single Control Head

Double Control Head

5.2.0 ELECTRONIC RIGGING GUIDE

5.2.1 Make sure that you read the information in this section which contains component

information, schematic keys and electronic rigging schematics. The rigging schematics

(Figure 5.2a through Figure 5.2g) are as follows:

Figure 5.2a. Rigging components with their related part numbers and schematic key

Rigging Component Part Number

Murphy PV450 4” Screen Kit SK-000134

Murphy PV780B 7” Screen Kit SK-000135

Murphy PV1200 12” Screen Kit SK-000136

DTM Control Head - Dual 034391

STM Control Head - Single 034392

CoastKey - Start Panel 033979

Coastkey - 2 Button Fob 033980

CoastKey - Additional Fob 033980

CoastKey - CECU - Engine 1 033981

CoastKey - CECU - Engine 1-2 033982

CoastKey - CECU - Engine 3 033983

CoastKey - CECU - Engine 3-4 033984

CoastKey - CECU - Engine 5-6 033985

Lift Pump 037236

Outboard to Vessel Harness CAN 033870

Outboard to Vessel Harness Controls 033871

ECU Power Harness 036484

CAN T-piece 034393

CAN Terminating Resistor Female 034394

CAN Terminating Resistor Male 034395

CAN Female Connector Cover 034986

Dometic CAN1 027170

Dometic CAN3 027173

Trim Panel 2 Switch 033939

Trim Panel 3 Switch 033749

CAN Vessel Harness 1m (One per vessel) 033872

CAN Vessel Harness 4m (One per vessel) 033873

CAN Vessel harness 6m (One per

outboard) 0 03874

CAN Vessel Harness 8m (One per vessel) 033875

Vessel Helm Control Harness 4m (One

per outboard) 033876

Vessel Helm Control Harness 6m (One

per outboard) 033877

F

19

CXO300 INSTALLATION MANUAL 5.0 RIGGING INSTALLATION

Figure 5.2b. CXO300 single installation schematic

1-Vessel Busbar

2-Fuse box

3-Fuel Level

4-Connect to Battery Breaker

via a 10amp fuse

5-Victon Energy DC-DC

Converter

6-Vessel Battery Integration

20 CXO300 INSTALLATION MANUAL

5.0 RIGGING INSTALLATION

5.0 RIGGING INSTALLATION

Figure 5.2c. CXO300 twin installation schematic

1-Vessel Busbar

2-Fuse box

3-Fuel Level

4-Connect to Battery Breaker

via a 10amp fuse

5-Victon Energy DC-DC

Converter

6-Vessel Battery Integration

Other manuals for CXO300

2

Table of contents

Other COX Outboard Motor manuals