Table of contents

General information .......................... 1

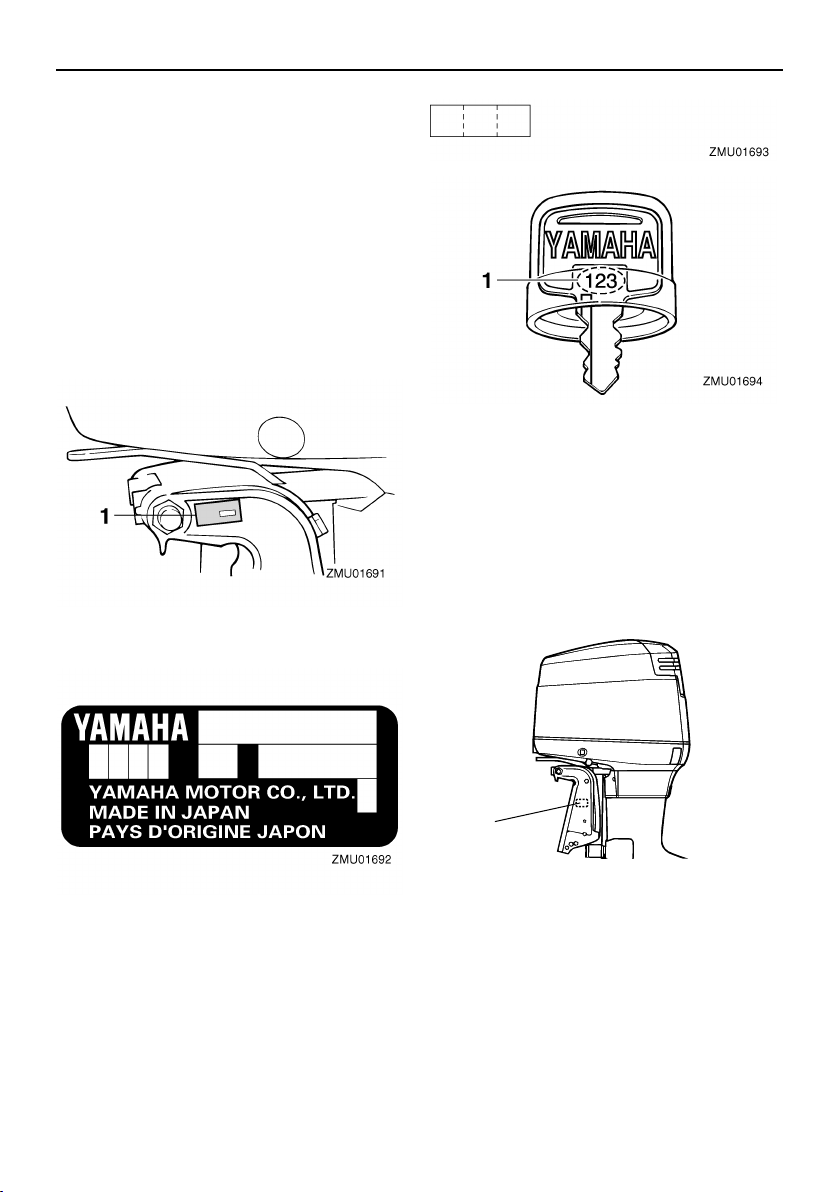

Identification numbers record.......... 1

Outboard motor serial number .......... 1

Key number....................................... 1

EC label........................................... 1

Safety information ........................... 2

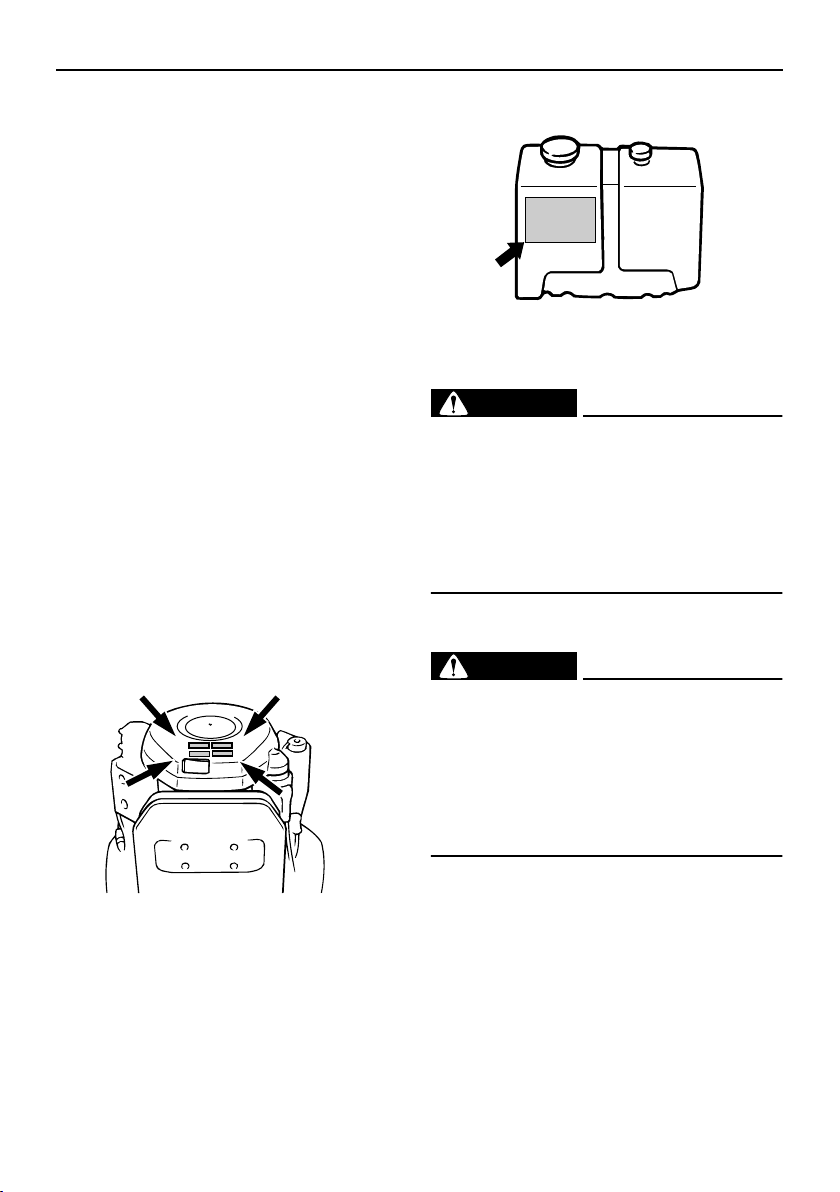

Important labels............................... 3

Warning labels .................................. 3

Fueling instructions ......................... 4

Gasoline............................................ 4

Engine oil .......................................... 4

Battery requirement......................... 4

Battery specifications ........................ 4

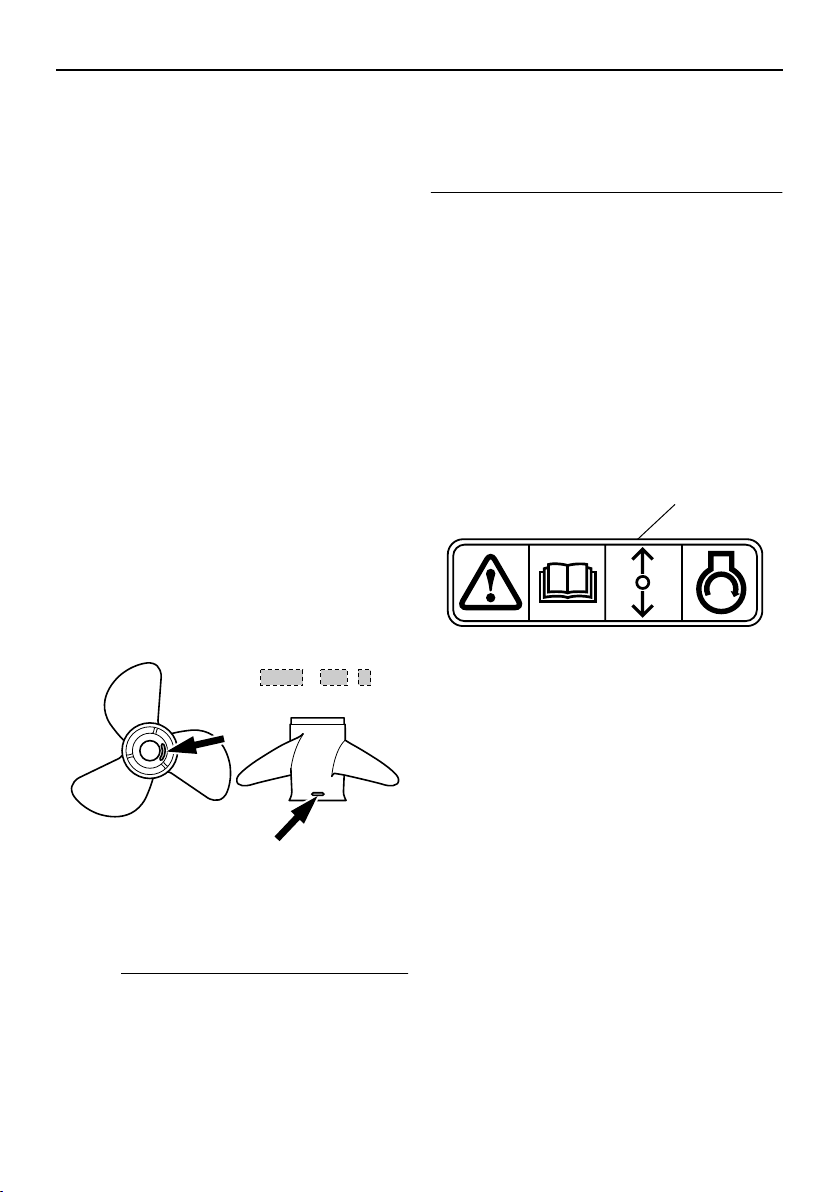

Propeller selection........................... 4

Start-in-gear protection ................... 5

Basic components ............................ 6

Main components............................ 6

Fuel tank ........................................... 6

Fuel joint ........................................... 7

Fuel gauge ........................................ 7

Fuel tank cap .................................... 7

Air vent screw ................................... 7

Remote control.................................. 7

Remote control lever......................... 7

Neutral interlock trigger..................... 8

Neutral throttle lever.......................... 8

Choke switch..................................... 8

Free accelerator................................ 9

Throttle friction adjuster..................... 9

Engine stop lanyard switch ............. 10

Choke knob for pull type ................. 11

Main switch ..................................... 11

Power trim and tilt switch on

remote control or tiller handle ....... 11

Power trim and tilt switch on bottom

engine cowling .............................. 11

Power trim and tilt switches (twin

binnacle type) ............................... 12

Trim tab with anode ........................ 12

Tilt support lever for power trim and

tilt or hydro tilt model..................... 13

Top cowling lock lever

(pull up type) ................................. 13

Digital tachometer ........................... 14

Oil level indicator (digital type) ........ 14

Overheat warning indicator (digital

type) .............................................. 14

Speedometer (digital type) .............. 15

Trim meter (digital type) .................. 15

Hour meter (digital type)..................16

Trip meter ........................................ 16

Clock ............................................... 16

Fuel gauge ...................................... 17

Fuel warning indicator ..................... 17

Low battery voltage warning

indicator ........................................ 17

Fuel management meter ................. 18

Fuel flow meter................................18

Fuel consumption meter..................19

Fuel economy.................................. 19

Twin-engine speed synchronizer ....19

Water separator warning

indicator ........................................ 20

Warning system ............................ 20

Overheat warning (twin engines) ....20

Oil level warning and oil filter

clogging warning ........................... 21

Operation ......................................... 23

Installation..................................... 23

Mounting the outboard motor .......... 23

Breaking in engine ........................ 24

Gasoline and engine oil mixing

chart (50:1).................................... 25

Procedure for oil injection models ... 25

Preoperation checks ..................... 25

Fuel ................................................. 25

Oil .................................................... 25

Controls ........................................... 26

Engine ............................................. 26

Operation after long period of

storage .......................................... 26

Filling fuel and engine oil .............. 26

Filling fuel for models without a

fuel joint......................................... 26

Filling oil for oil injection models...... 26

Oil level indicator operation............. 28

Operating engine .......................... 29

Feeding fuel (portable tank) ............ 29

Feeding fuel .................................... 29

Starting engine ................................ 30