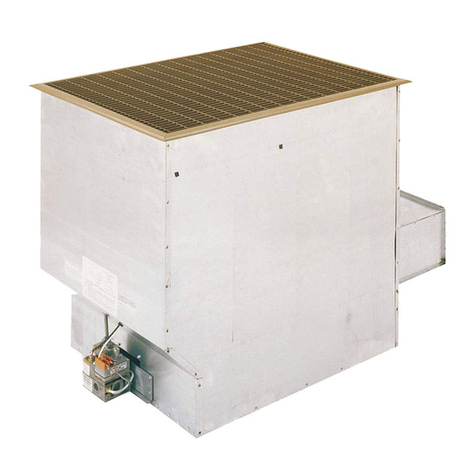

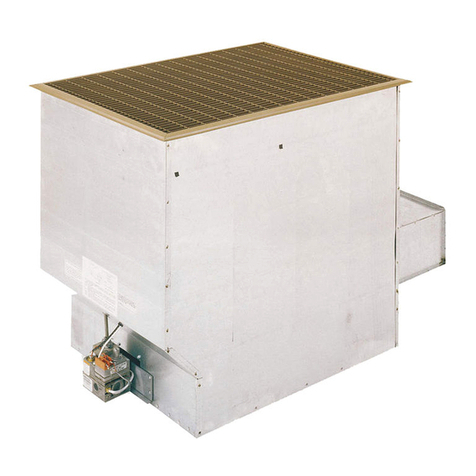

6GAS FIRED VENTED FLOOR FURNACES

INTRODUCTION

THIS IS A GAS-FIRED, GRAVITY VENTED FLOOR

FURNACE THAT WILL OPERATE SAFELY AND PROVIDE

AN EFFICIENT SOURCE OF HEAT WHEN INSTALLED,

OPERATED AND MAINTAINED AS RECOMMENDED IN

THESE INSTALLATION AND OPERATING INSTRUCTIONS.

READ THESE INSTRUCTIONS THOROUGHLY BEFORE

INSTALLING, SERVICING, OR USING THE APPLIANCE.

IF YOU DO NOT UNDERSTAND ANY PART OF THESE

INSTRUCTIONS, CONSULT LOCAL AUTHORITIES, OTHER

QUALIFIED INSTALLERS, SERVICE TECHNICIANS, THE

GAS SUPPLIER OR THE MANUFACTURER.

HELPFUL INSTALLATION INFORMATION HELPFUL

INSTALLATION INFORMATION

Do not attempt to heat through more than one doorway

in any direction to adjoining rooms.

Always over-estimate the amount of heat required rather

than under-estimate it. Always use the next size floor

furnace above your actual heating requirements.

Seal all cracks around windows, doors, and attic access

doors or significant heat loss will occur.

INSTALLATION REQUIREMENTS

Listed below are steps that are part of a floor furnace

installation. You must see that each step is followed

closely so that the floor furnace will provide maximum

efficiency with safe operation.

YOU MUST:

1. Locate the floor furnace in the best

available space for safe and efficient

operation.

2. Provide fresh air for combustion and

venting.

3. Cut and frame the floor opening so that

the floor furnace fits properly.

4. Attach the draft hood and connect the

vent pipe in compliance with applicable

codes.

5. Connect an adequate gas supply to the

floor furnace.

6. Select the best location for the

thermostat.

7. Check and adjust the floor furnace for safe

and efficient operation.

If you have any doubts about the correct way to install a

floor furnace, contact local authorities or agency, or your

gas supplier. If local or state codes require that your floor

furnace installation be inspected by local authorities, do

so after the floor furnace is installed and before it is put

into service.

SAFETY

1. WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause property

damage, personal injury or loss of life. Installation and

service must be performed by a qualified installer,

service agency or the gas supplier keep burner and

control compartment clean. See installation and

operating instructions accompanying appliance. Due

to high surface temperatures keep children, clothing

and furniture away.

2. Follow all applicable codes and ordinances. If

there are none, follow the installation standards,

latest edition of NFPA54ANSI.Z223.1. A copy may

be obtained from the National Fire Protection

Association, 1 Batterymarch Park; Quincy, MA, 02269.

3. DO NOT install this floor furnace in a recreational

vehicle, trailer or mobile home.

4. DO NOT operate this floor furnace unless it is

connected to aproperly installed and maintained

vent system. Do not exhaust flue gases under the

floor for any reason.

5. Be sure this floor furnace is equipped for the type gas

you intend to use.

6. Locate the thermostat in a room or space that cannot

be separated by adoor or other means from the room

or space in which the floor furnace grill is installed.

7. Never use a match, candle, flame or other source of

ignition to check for gas leaks. Use only soapy water

or liquid detergent.

8. Adequate air for combustion and venting must be

provided.

9. If it is suspected that rising water or seepage may

enter the floor furnace, turn off the gas immediately.

Do not use this floor furnace if any part has been

under water. Immediately call a qualified service

technician to inspect the floor furnace and to replace

any part of the control system and any gas control

which has been under water.

10. Have your floor furnace and vent system inspected

before using and at least annually by a qualified

service technician.

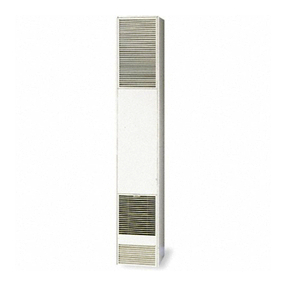

11. The grill becomes hot when the floor furnace is in

operation. Children must be closely supervised when

in the presence of any heating appliance. Contact

with bare skin may result in severe burns. Keep

children off the grill.

12. Before cleaning or servicing the floor furnace, turn off

the gas and allow it to cool. This will prevent burns.

13. Always leave the grill in place except when cleaning

or servicing the floor furnace.

14. Never operate the floor furnace without the sight

glass assembly in place, or with the glass broken

or missing.