CONTENTS

hmoduction ................................................ 2

Specifications .............................................. 2

Safety Rules................................................. 3

Clemances .................................................... 3

Controls ........................................................ 3

Combustion & Ventilation Air................... 4

Venting .......................................................... 5,6

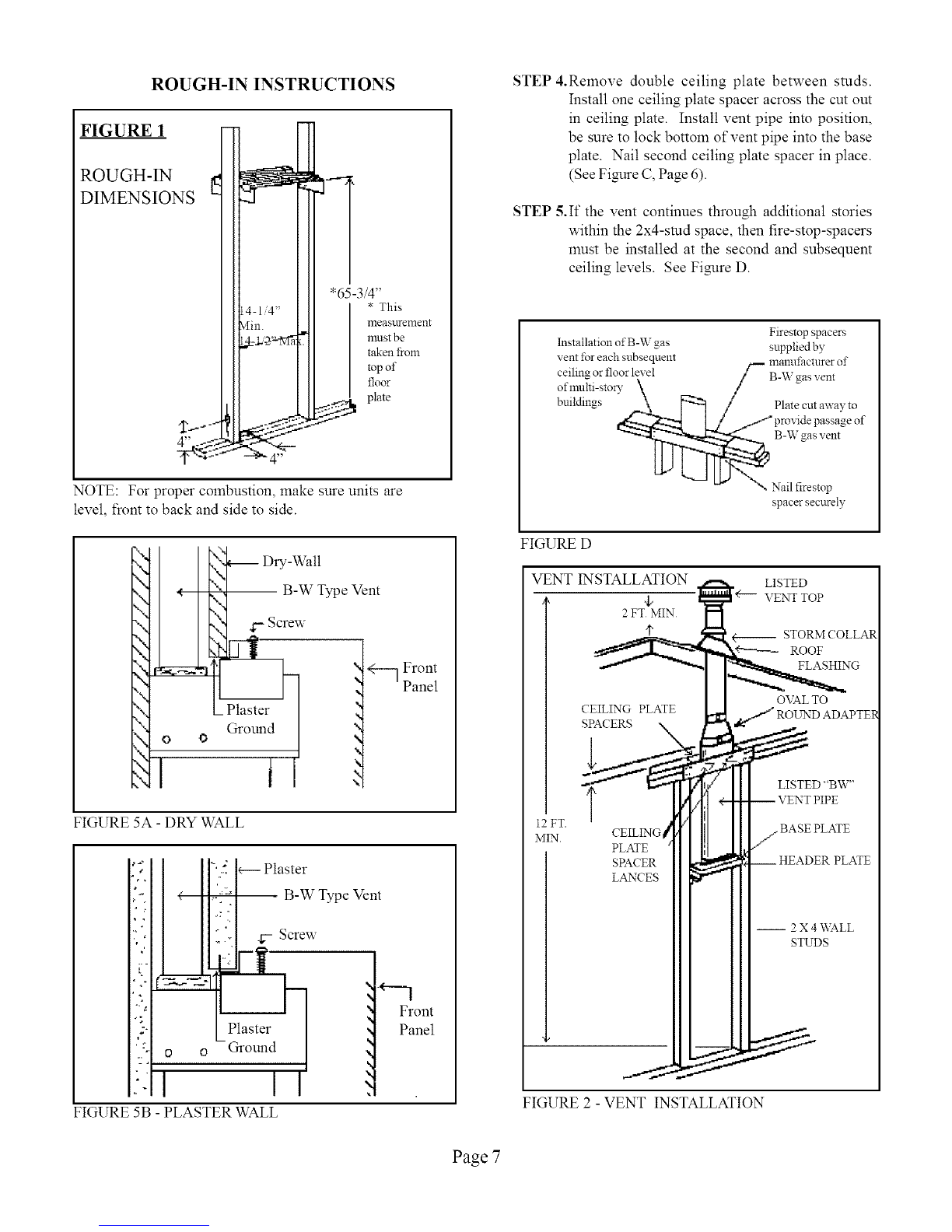

Rough-In Instructions ................................ 6

Installation .................................................... 8

Wiring Instructions ..................................... 9

Rear Register Kit Instructions .................................... 9

Lighting Instructions ................................................... 10!11

Pilot Adjustment ........................................................... 12

Burner Flame Adjustment ............................................ 12

Maintenance Instructions ........................................... 12

WFF81 Fro1Instructions .............................................. 13/14

Trouble Shoothlg Chart................................................ 15/16

Parts Drawing ................................................................ 17

Parts List........................................................................ 18

Warranty. ....................................................................... 20

READ CAREFULLY BEFORE INSTALLING UNIT

These installation instructions are a general guide, and do not supersede applicable local codes and ordinances. Before planning or

making the installation, be sure it complies with all phases of the local heating codes. Or, in the absence of local codes, with the latest

edition of the National Fuel Gas Code, ANSI.Z223.1. In Canada, see the current installation code CAN1-B 149.

The appliance, when installed, must be electrically _ounded in accordance with local codes or, in the absence of local codes, with

the latest edition of the National Electrical Code ANSI/NFPA No. 70. In Canada, see the current Canadian Electrical Code

C5AC22.1.

The ANSI standards are available from the American Gas Association, 1515 Wilson Blvd., Arlington, Virginia 22209.

The NFPA standards are available from the National Fire Protection Association, Batterymarch Park, Quincy, MA. 02269.

Canadian standards are available fiom International Approval SelaTices,178 Rexdale Blvd.,Etobicoke,Ontario, Canada M9W IR3.

NOTE: If optional rear register kit is to be used, see supplemental installation instructions (No. 84504) and section marked

"Special Instructions for Rear Register Kit Application" prior to installation of Rough-In.

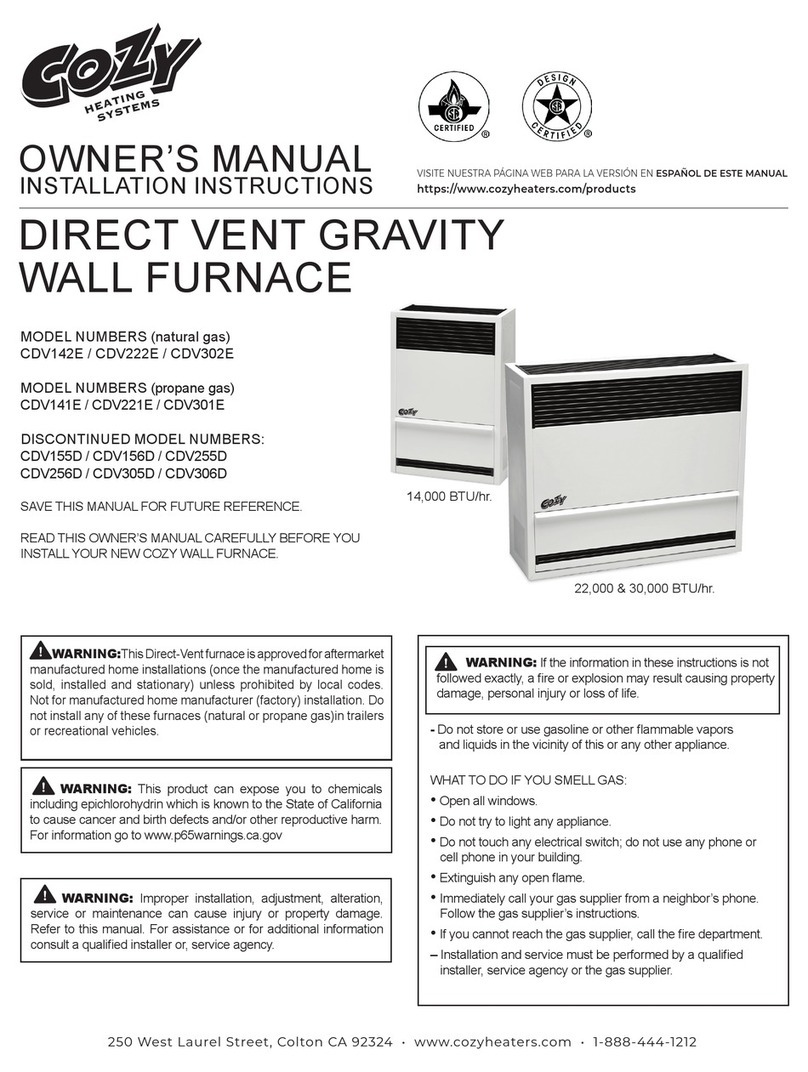

INTRODUCTION

THIS IS A GAS-FIRED, GRAVITY VENTED WALL FURNACE THAT WILL OPERATE SAFELY AND PROVIDE AN

EFFICIENT SOURCE OF HEAT WHEN INSTALLED, OPERATED AND MAINTAINED AS RECOMMENDED IN THESE

INSTALLATION AND OPERATING INSTRUCTIONS. READ THESE INSTRUCTIONS THOROUGHLY BEFORE

INSTALLING, SERVICING, OR USING THE APPLIANCE. IF YOU DO NOT UNDERSTAND ANY PART OF THESE

INSTRUCTIONS, CONSULT LOCAL AUTHORITIES, OTHER QUALIFIED INSTALLERS, SERVICE AGENCIES, THE GAS

SUPPLIER OR THE MANUFACTURER. SPECIFICATIONS

Your vented wall furnace comes packed in a single carton. (For wall thermostat models that includes the thermostat, thermostat

wire, and insulated staples). Before installing the wall furnace check the rating plate to verify that the Model Nmnber is correct

and that the wall furnace is equipped for the type gas you intend to use.

Model Type _pe BTUiHr. \_m Gas Shpg.

No. Collffol Gas Input Size Inlet FINISHED DIMENSIONS \Vt.

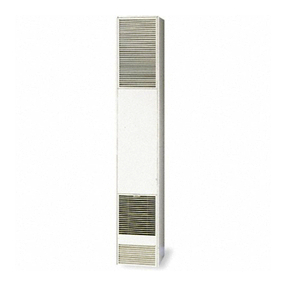

SINGLE _I__LL FURNACE

1/2' 16-1/2' Wx68"Hx6-1i2"D 90 Lbs.

1/2" 16-1i2"Wx68"Hx6-1i2"D 90 Lbs.

1/2" 16-1i2"Wx68"Hx6-1i2"D 90 Lbs.

1/2" 16-1i2"Wx68"Hx6-1i2"D 90 Lbs.

W251F Snap Bulb Nat. 25.000 4"

W255F \Vall Star Nat. 25.000 4"

W252F Snap Bulb L.P. 25,000 4"

W256F \Vall Star L.P. 25,000 4"

W351F Snap Bulb Nat. 35.000 4"

W355F \Vall Star Nat. 35.000 4"

W352F Snap Bulb L.P. 35,000 4"

W356F \Vall Star L.P. 35.000 4"

W501F Snap Bulb Nat. 50,000 4"

W505F Wall Star Nat. 50,000 4"

W502F Snap Bulb L.P. 50,000 4"

W506F Wall Stat L.P. 50,000 4"

One or two fan kits may be used on dual-wall furnace.

1/2" 16-1 i2"Wx68"Hx6-1/2"D 90 Lbs.

1/2" 16-1i2"Wx68"Hx6-1/2"D 90 Lbs.

1/2" 16-1i2"Wx68"Hx6-1i2"D 90 Lbs.

1/2" 16-1i2"Wx68"Hx6-1i2"D 90 Lbs.

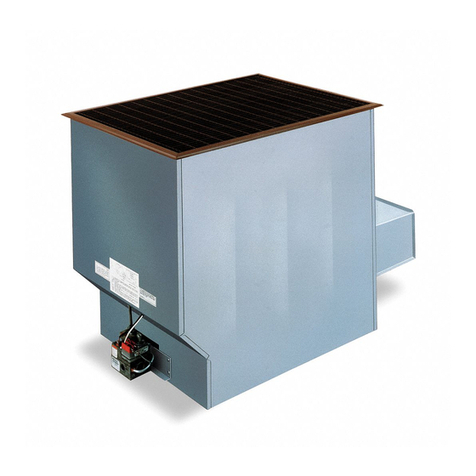

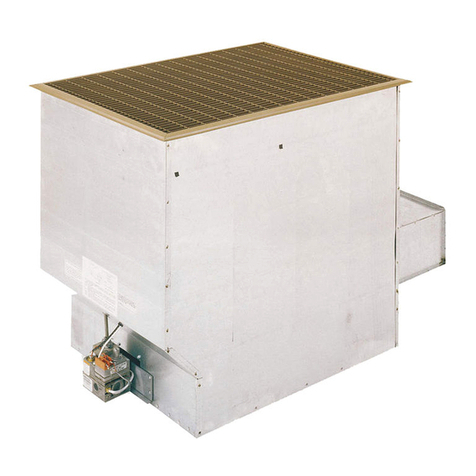

DUAL V_LL FUI_NACE

1/2" 16-1i2"Wx68"Hx6-1i2"D 134 Lbs

1/2" 16-1i2"Wx68"Hx6-1i2"D 134 Lbs

1/2" 16-1i2"Wx68"Hx6-1i2"D 134 Lbs

1/2" 16-1i2"Wx68"Hx6-1i2"D 134 Lbs

REAR REG. KIT

Model \Veidlt

40542 5 Lbs.

40542 5 Lbs.

40542 5 Lbs.

40542 5 Lbs.

40542 5 Lbs.

40542 5 Lbs.

40542 5Lbs.

40542 5Lbs.

Page 2

NiA NiA

NiA NiA

NiA NiA

NiA NiA

FANKIT

Model \Vt.

\tTF81 10 Ibs

\\,TF81 10 Ibs

V_TF81 101bs

\tTF81 10 Ibs

WFF81 10 Ibs

WFFS1 10 Ibs

WFF81 10 Ibs

V_TF81 101bs

\,_TF81 101bs

\,_TF81 101bs

\,_TF81 101bs

\,_TF81 101bs