Crafstman 944.5291 81 User manual

SRMS

OWNER'S

MANUAL

C-ILDEL

NO.

944.5291

81

Caution:

Read and follow

all Safety Rules

and Instructions

Before Operating

This Equipment

1150

SERIES B&S

ENGINE

27"

TI-.-0-STAGE

POWER-PROPELLED

SNOW TkB70WER

Assembly

Operation

Maintenance

Service and Adjustments

Repair Parts

Sears Canada, Inc., Toronto, Ontario

M5B

288

IMPORTANT

Safe Operation Practicesfor Walk-Behind Snow Throwers

This snow thrower is capable of amputatinghands and feet and throwingobjects.

Failureto observethe followingsafety instructionscould result in serious injury.

WARNING: Snow throwers have ex-

posed rotatingparts,which can cause

severeinjuryfromcontact,orfromma-

terialthrownfromthedischargechute.

Keepthe area of operation clear of all

persons,small children and petsat all

times includingstartup.

CAUTION: Muffler and other engine

parts become extremely hot during

operation and remainhot after engine

hasstopped.To avoidsevereburnson

WARNING: This snow thrower is for contact, stay away from these areas.

useonsidewalks,drivewaysandother

groundlevelsurfaces. Cautionshould

beexercisedwhileusingonslopingsur-

faces. Do not use snow thrower on

surfaces above ground level such as cals known to the State of California

roofsof residences, garages, porches to cause cancer and birth defects or

or other such structures or buildings.

Training

1.

Read, understand and follow all instructions on the (f) Keepthe nozzle incontactwith the rimof thefuel

machine and in the manual(s) before operating this tankorcontaineropeningatalltimes, untilrefueling

unit. Be thoroughly familiar with the controls and the iscomplete. Donotuseanozzlelock-opendevice.

proper use of the equipment. Know how to stop the

unit and disengagethe controls quickly. (g) Replacegasolinecapsecurelyandwipeupspilled

fuel.

2.

Neverallow childrento operatethe equipment. Never

allow adults to operate the equipment without proper (h) If fuel is spilled on clothing, change clothing im-

instruction. mediately.

3.

Keep the area of operation clear of all persons, par-

5.

Use extensioncords and receptaclesas specified by

titularly

small children. themanufacturerfor allunitswithelectricdrivemotors

or electricstarting motors.

4-

Exercisecaution to avoid slipping orfalling, especially

6.

Adjust the collector housing height to clear gravel or

when operatingthe snow thrower in reverse. crushed rock surface.

Preparation

7.

Never attempt to make any adjustments while the

engine (motor) is running (except when specifically

1.

Thoroughly inspectthe area where the equipment is recommendedby manufacturer).

to be used and remove all doormats, sleds, boards,

wires, and otherforeign objects.

8.

Always wear safety glasses or eyeshieldsduringop-

erationor while performingan adjustmentor repair to

2.

Disengage all clutches and shift into neutral before protecteyes fromforeignobjectsthat may bethrown

startingthe engine (motor). from the machine.

Donotoperatetheequipmentwithoutwearingadequate

winter garments. Avoid loosefitting clothing that can

get caught in moving parts. Wear footwear that will

improvefooting on slippery surfaces.

Handlefuel with care; it is highlyflammable

(a) Use an approvedfuel container.

(b) Neveradd fuel to a runningengineor hot engine.

(c) Fillfueltankoutdoorswith extremecare. Neverfill

fuel tank indoors.

(d) Neverfill containersinside avehicle or on atruck

or trailer bed with a plastic liner. Always place

containersontheground,awayfromyourvehicle,

beforefilling.

(e)

When

praclical.

remove

gas-powered

equipment

from

lhe

truck

or

trailer

and

refuel

it

on

theground.

If

this

is

not

possible,then

refuel

such equipment

on

a

trailer

with

a

portable

container, rather than

from

a

gasoline

dispenser

nozzle.

Operation

1.

Do not put handsor feet nearor under rotatingparts.

Keepclear of the dischargeopeningat all times.

2.

Exerciseextremecautionwhenoperatingonorcross-

inggraveldrives,walks,or roads. Stayalertfor hidden

hazardsor traffic.

3.

After

striking

a

foreign

object,

stop

the

engine (motor),

remove the wire from

the

spark

plug,

disconnectthe

cord

on

electric motors,thoroughly inspect the snow

throwerfor

any

damage,

andrepairthe

damage

before

restarting

and

operatingthe snow thrower.

4.

If the

unil

should

start

to

vibrate abnormally,

stop

the

engine (motor)

and

check immediately for the cause.

Vibration

is

generally

a

warning of trouble.

5.

Stop

the

engine(motor)whenever

you

leave

the

oper-

ating

position,beforeuncloggingthe collector/impeller

hous~ng

or discharge

chute,

and

when making

any

repairs,

adjustments

or inspections.

6.

Whencleaning,repairingorinspectingthesnowthrower,

Clearing a Clogged DischargeChute

stopthe engine and makecertainthe collector/impel-

ler

and all

moving

parts

have

stopped. Disconnect

Handcontactwiththerotatingimpellerinsidethedischarge

the spark plug wire and keepthe

wire

away

from

the chute-isthe mostCOh7mOn cause of injury associatedwith

plugto preventsomeonefrom accidentallystartingthe

S~-IOW

thr~wers.Never useyour handto clean out the dis-

engine. charge chute. To clear the chute:

-

7.

Do not run the engine indoors, except when starting

SHUT

THE

ENGINE

OFF!

the engineandfortransportingthe snowthrower inor

2.

Wait 10seconds to be sure the impeller blades have

out of the building. Open the outside doors; exhaust stopped rotating.

fumes are dangerous. 3. Always use a clean-out tool, not your hands.

8.

Exerciseextreme caution when operating on slopes.

9.

Neveroperatethesnowthrowerwithout properguards,

andother safety protectivedevices inplaceandwork-

ing.

10. Never direct the discharge toward people or areas

where propertydamage canoccur. Keepchildrenand

others away.

11. Do not overload the machine capacity by attempting

to clear snow at too fast a rate.

12.

Never operate the machine at high transport speeds

on slippery surfaces. Look behindand use care when

operating in reverse.

13. Disengagepowerto the collector/impellerwhen snow

thrower is transported or not in use.

14. Use only attachments and accessories approved by

the manufacturerof the snow thrower (such as wheel

weights, counterweights,or cabs).

15. Neveroperatethe snowthrowerwithoutgoodvisibility

or light.Always besure of yourfooting,andkeepafirm

holdon the handles.Walk; never run.

16. Nevertouch a hot engine or muffler.

CONGRATULATIONS

on your purchase of a new snow

thrower. It has been designed, engineeredand manufac-

turedtogivebestpossibledependabilityandperformance.

Should you experience any problem you cannot easily

remedy, please contact your nearest authorized service

center. We have competent,well-trained technicians and

the proper tools to service or repairthis unit.

Please readand retain this manual. The instructions will

enable you to assemble and maintainyour snow thrower

properly. Always observethe "SAFETY RULES".

PUMBER:

I

THE

MODEL

AND

SERIAL

NUMBERS

WILL

BE

FOUND^

ON

ADECALATACHEDTOTHE REAROFTHESNOW1

THROWER

HOUSING.

YOU SHOULD RECORDBOTHSERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

Maintenanceand Storage

1. Checkshear boltsandotherboltsat frequent intervals

for propertightnessto besuretheequipmentisinsafe

working condition.

2.

Never store the machine with fuel in the fuel tank

inside a buildingwhere ignition sources are present

such as hot water heaters, space heaters,or clothes

dryers. Allow the engine to cool before storing in any

enclosure.

3. Alwaysreferto operator'smanualfor importantdetails

if the snow thrower is to be stored for an extended

period.

4. Maintain or replace safety and instruction labels, as

necessary.

5. Run the machine a few minutes after throwing snow

to preventfreeze-up of the collector/impeller.

PRODUCT

-

SPECIFICATIONS

-

GasolineCapacity

3.0 Quarts (2,83Liters)

I

and Type:

UnleadedRegularonly

Oil Type

SAE 5W-30 or 10W-30

(API SG-SL):

SyntheticSAE 5W-30

[oil Capacity:

18Ounces (0,5 Liters)

I

Spark Plug:

Champion RJ19LM

Gap:

0.030"(0,762 mm)

-

CUSTOMER RESPONSIBILITIES

Readand observethe safety rules.

Follow a regular schedule in maintaining, caring for

and usingyour snow thrower.

Followthe instructionsunder"Maintenance"and"Stor-

age" sections of this owner's manual.

TABLE

OF

CONTENTS

........................................................

SAFETY RULES

2-3

PRODUCTSPECIFICATIONS

......................................

3

................................

CUSTOMER RESPONSIBILITIES

3

WARRANTY

..................................................................

4

ASSEMBLY

/

PRE-OPERATION

...............................

5-7

OPERATION

............................................................

8-1

3

MAINTENANCE SCHEDULE

.....................................

14

MAINTENANCE

.....................................................

14-1

5

...........................

SERVICEAND ADJUSTMENTS 16-18

...................................................................

STORAGE 19

................................................

TROUBLESHOOTING

20

REPAIR PARTS

.....................................................

22-42

3.l.

-~VL

L!

+

v

!W

.-

)-hi'

rc.

-ar&mQm

L

qm!

a

'

A

IT-

-

d

-

~..-lkhm

*'-

ICJI'BS~~!!T

-

-,

ps-F-

-.

!

%wd,q

m

I

%?T

'

coverage underthis warranty.

REPAIRS:

Repairshavea 90 day warranty. If the defectiveproductisstillwithinthe Warranty Period,then the new warranty is

90

days from the date of repairor to the end of the originalWarranty Period, whichever periodis longer.

DISCLAIMERS:

THE WARRANTIES AND REMEDIESCONTAINEDHEREINARE EXCLUSIVEAND IN LIEUOF ALL OTHER

WARRANTIES, WHETHER ORALOR WRllTEN (OTHER THAN AS STATED HEREIN), AND WHETHER EXPRESS, IMPLIED

OR STATUTORY, INCLUDINGBUT NOT LIMITEDTO ANY. THlSWARRANTY GIVESYOU SPECIFIC LEGAL RIGHTS, WHICH

MAY VARY FROM PROVINCETO PROVINCE.

INNO EVENTSHALL SEARS BE LIABLE FOR ANY INCIDENTAL,SPECIAL, INDIRECTOR CONSEQUENTIALDAMAGES,

WHETHER RESULTING FROM THE USE, MISUSE OR INABILITY TO USE THE PRODUCT OR FROM DEFECTS INTHE

PRODUCT. THE EXCLUSIONS INTHlS PARAGRAPHSHALL NOT APPLY INJURlSDlCATlONSWHERE APPLICABLELAW

DOES NOT ALLOW FOR THE EXCLUSIONOF INCIDENTALOR CONSEQUENTIALDAMAGES. INSUCH JURISDICTIONS,

THlS PARAGRAPHSHALL NOTAPPLY, BUTTHE REMAINING PROVISIONSOFTHlS DOCUMENTSHALL REMAINVALID.

SEARS retainsthe exclusive ri ht to repair or replacethe product or offer a full refundof the purchasepriceat its sole discretion.

SUCH

REMEDY

SHALL BE

Y~UR

SOLE

AND

EXCLUSIVE

REMEDY

FOR

ANY

BREACH

OF

WARRANTY.

T

In additional to complying with all suggested maintenance guidelines and instructions,

customers' obligations shall include but shall not be limitedto: operating the product in accordance with the owner's manual or

any additionalinstructionsor informationprovidedat the time of purchaseor insubsequent communicationstothe purchaserfrom

time to time, exhibit reasonablecare inthe use, operation, maintenance, general upkeep and storage of the product. Failureto

comply with these requirementswill void any applicable warranty.

I

T

I-:

The followinglistcontainsthe applicableWarranty Periodfor yourCraftsmanproduct

and isbased on a combinationof thetype of productor component andthe intendedandactual useof the productor component:

1.

90

DAYS:

Craftsman productsintendedfor use or actually used for commercial, institutional, professional or income-

,

producingpurposes

2. 2

YEARS:

Craftsman riding lawn mowers, yard and garden tractors, walk behind mowers, tillers, brush cutters,

snow blowers, handheld blowers, backpack blowers, hedge trimmers and electrical products for noncommercial,

nonprofessronal, non-institutronal,or non-income-producinguse, except for those componentswhich are part of engine

systems manufactured by third party engine manufacturersfor which the purchase has received an separate warranty

with product information suppliedat the time of purchase.

3.

1

YEAR:

Craftsman power cutters, stump grinders, pole pruners, gas chain saws, electric chain saws, trimmer

attachments, baggersandpolesaws for noncommercial, nonprofessional, non-institutional,or non-income-producinguse.

4.

90

DAYS:

All defective batteries,which will be replacedduring this 90-day Warranty Period.

5.

60

DAYS:

AdditionalWarranty Periodof 60 days will apply to adjustmentsand worn productsor componentsBUT DOES

NOT INCLUDE WEAR OR ADJUSTMENTS for products used for commercial, institutional, professional or income-

producing purposes. Wear items include but are not limitedto: belts, blades, tires, spark plugs, air filters, chains, shear

bolts, skid plates, scraper bars, drift cutters, ropes, tlnes, collection bagsand pulleys.

As the Warranty Periodrunsfrom the dateof purchaseand NOTfrom the datethat a product

IS

delivered,opened, assembledor

first used, please ensure duringthis time periodthat your roduct or component has been assembled and tested for correction

8

ally use it. laimsmadeaftertheWarranty Periodhas expiredwill not be honored.

Warranty coverage is conditioned uponthe originalpurchaser furnishing SEARS

rovider if applicable,with the originalsales receipt or other adequate written proof

n

of the product. In the event that the original purchaser is unable to provide a

company of the originalsales receipt,SEARS CANADA Inc. reservesthe rightto determine in its sole discretionwhat other written

proof of the originalpurchasedate and identificationof the product isacceptable.

1

a

PARTS PACKED SEPARATELY

IN

CARTON

(198563)

I

(1)

DISCHARGECHUTE

-------.----

I

---

SAFTEY IGNITION KEY

(S)

I

(193071)

(1)

LOCKNUT

318

1

(73800600)

,,,,,,----_I

--------------

1

1'

DCTRA

SHEAR

BOLTSAND

NVrs

I

I

(2)

SHEAR BOLTS

1/4-20

x

1-314 (2)

LOCKNUTS

I

I

(192090) 1/4-20

(73800400)

1

L--------------

,

(2)

FLAT WASHERS

1

(2)

CARRIAGE BOLTS

3/8-16

x

2.25

I

I

L

(2)

HANDLE KNOBS

ASSEMBLY

/

PRE-OPERATION

Readthese instructionsandthis manualinitsentirety

beforeyou attempt to assemble or operate your new

snowthrower. Readingtheentiremanualwill familiar-

izeyou with the unit,which willassistyou inassembly,

operation and maintenanceof the product.

Your newsnowthrower hasbeenassembledatthefactory

withthe exceptionof thosepartsleftunassembledforship-

pingpurposes.All partssuch as nuts,washers, bolts,etc.,

necessaryto completethe assembly have beenplaced in

the partsbag.To ensuresafeandproperoperationof your

snow thrower, all parts and hardwareyou assemble must

betightened securely. Usethe correct tools as necessary

to ensure proper tightness.

REMOVESNOW THROWER FROM CARTON

1.

Remove all accessible loose parts and parts boxes

from carton.

2.

Cutdown allfour cornersof carton and lay panelsflat.

3.

Removethetwo

(2)

screwssecuringtheaugerhousing

to the pallet.

4.

Removeallpackingmaterialsexceptplastictie

holding^

speed control rodto lower handle.

5.

Remove the two

(2)

plastic ties securing the upper

handleto the pallet.

6.

Remove snow thrower from carton and check carton

thoroughly for additional loose parts.

HOW TO SET UP YOUR SNOW THROWER

TOOL

BOX

(See Fig.

10)

A

toolbox is providedonyour snowthrower.Thetoolbox

is

locatedontopof the beltcover. Storetheextrashear bolts,

nutsandmulti-wrenchprovidedinpartsbaginthetoolbox.

5

ASSEMBLY

1

PRE-OPERATION

NOTE:

The multi-wrenchmay beusedfor assemblyof the

chuterotatorheadtosnowthrowerandmakingadjustments

to the skid plates.

UNFOLD UPPER HANDLE

.

Raise upper handle to the operating position and

tighten handle knobs securely. Additional carriage

bolts, washers and handle knobsare in bag of parts.

Use to secure upper handle to lower handle. Install

in lower holes in handles.

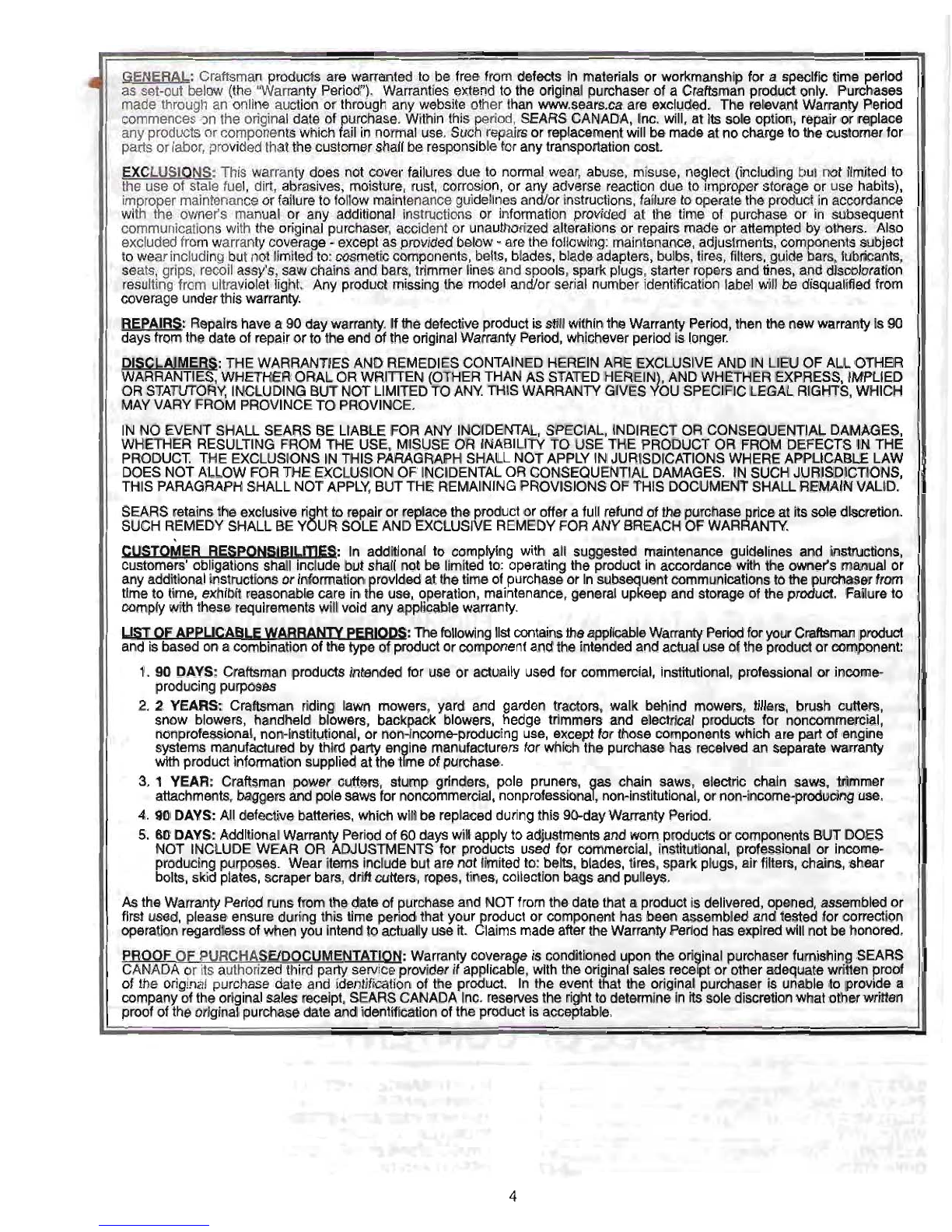

INSTALL SPEED CONTROL ROD (See Figs.

1

and

2)

1.

Removeplastic tie securing rodto lower handle.

2.

Insert rod into speed control bracketand secure witk,

retainer spring.

INSTALLTRACTION DRIVECONTROL ROD

(SeeFigs.

3

and

4)

The traction drive control rod is installed on the snow

thrower.

1.

Remove plastictie securing rodto lowerhandle.

2.

Withtop endof rodpositionedunderleftsideof control

panel,pushroddownandinserttopendof rodintohole

indrive control bracket. Secure with retainerspring.

PLASTICTIE

FIG.

3

FIG.

1

FIG. 4

r

ASSEMBLY

/

PRE-OPERATION

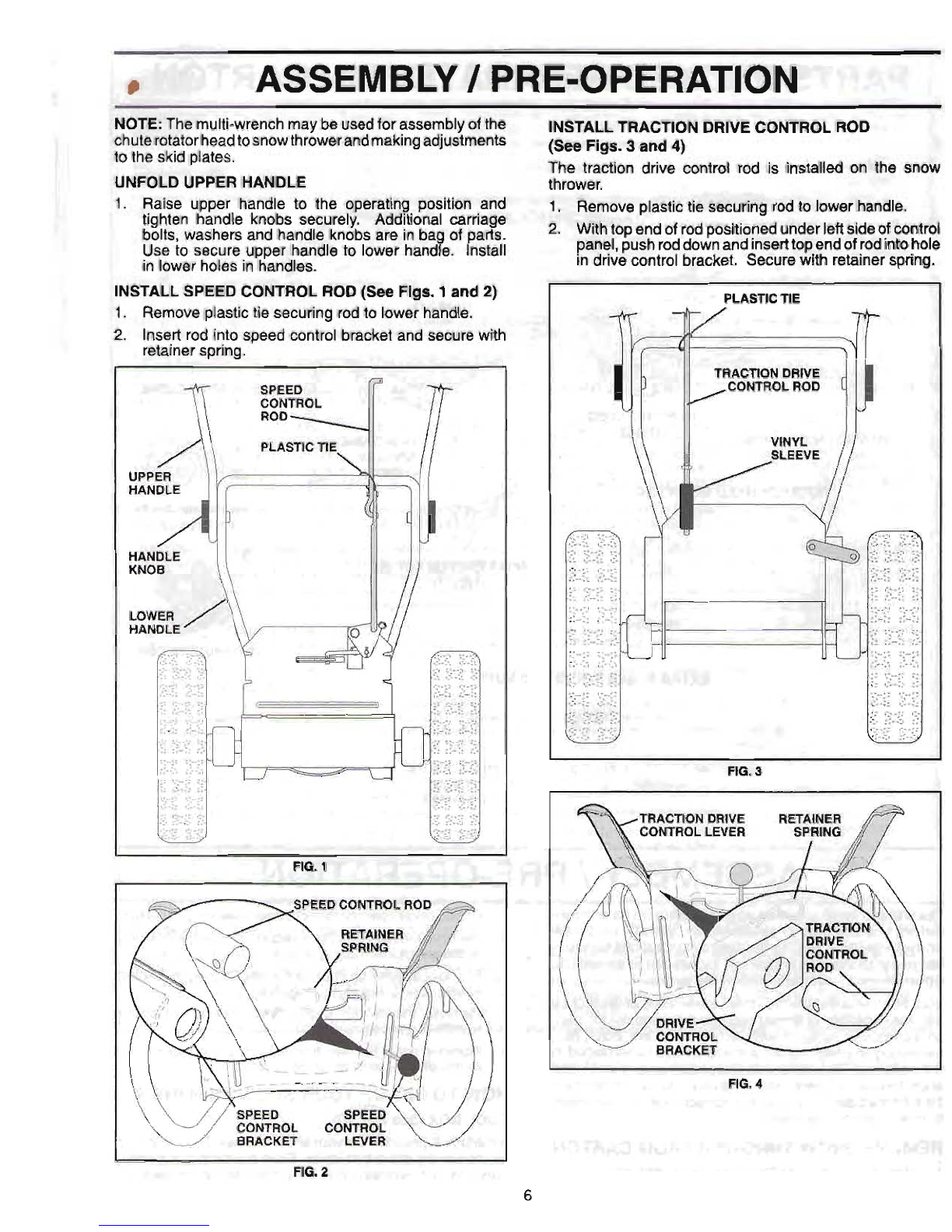

INSTALLAUGER CONTROL ROD (See

Figs.

5

and

6)

1. Retrievevinylsleeveandspringfrom bagof partsand

retrievethe auger control rod from carton chute tray.

Slide straight rod end through the small hole in the

vinyl sleeve. Hook spring in hole in rodend.

2.

Hookend of springintocontrolarmwith loopopening

up as shown. (See Fig.

5)

3.

With top end of rod positioned under right side of

controlpanel, pushdownon rodand insert endof rod

intoholeinaugercontrolbracket. Securewithretainer

spring.

FIG.

5

INSTALL DISCHARGE CHUTE

/

CHUTE ROTATER

HEAD(See

Fig.

7)

NOTE:

The multi-wrenchprovidedin your parts bag may

be usedto installthe chute rotater head.

1. Placedischargechuteassemblyon top of chute base

with discharge opening toward front of snow thrower.

2.

Positionchuterotaterheadoverchutebracket. Ifneces-

sary,rotatechuteassemblytoalignsquareandpinonun-

dersideofchuterotaterheadwithholesinchutebracket.

3.

With chute rotater head and chute bracket aligned,

positionchute rotater headon pin and threadedstud

of mountingbracket.

4. Install

318

washer and locknut on threaded stud and

tighten securely.

ROTATER

HEAD

CHUTE

/

ALIGN BEFORE

MOUNTING

BRACKET TIGHTENING LOCKNUT

BRACm

FIG.

7

CHECK TIRE PRESSURE

Thetiresonyoursnowthrowerwereoverinflatedatthefac-

toryforshippingpurposes. Correctandequaltirepressure

is importantfor bestsnow throwingperformance.

Reducetire pressure to 14-17PSI.

FIG.

6

DANGER

ENGINE

:

t

a

A+j

,

FA&

OR WARNING

ON

1!1

-~

.d

--...

.

SLOW CHOKE

PRIMER

:

READAND FOLLOW

ALL-SAFETY

INFORMATION

AND INSTRUCTIONSBEFORE

USE

OFTHIS PRODUCT.

-

.

OIL

FOR WAR^

REVERSE

KEEP

THESE

INSTRUCTIQNS

FW

FUTURE

REFERENCE

I

y

-

ILOCKAGES !MUST NOT BE

:LEARER OUT~NTIL THE ENGINE

IS SHUT

OFF^

AND THE CLEAN

OUT

TOOL MUST BE USED.

IGNITION

KEY.

INSERT

TO

START

.r

:.,

,

2

51-x.12

*

ANDRUN,

3

l~t**

,

.

.

,

-,

.!,-,,I,-

NEVER

ALLOW

CHILDREN

TO

OPERATE

SNOWTHROWERS.

KEEP 411SHIELDS AND GUAR

S

IN

PLACE

WHILE

OPERATING.

i

SHUT

OFF

ENGINE

AND

REMAI~

BEHIND

HANDLES UNTIL ALL MOVlG

ARTS

HAVE

STOPPED BEFORE UNCLOGGI

OR

SERVICING

UNIT.

It;

i

L

ENGAGED

SNOW

DISCHARGE TRACTION

DRIVE

CONTROL

.

.I.

-A

*

.

Our snow throwersconformto the standards of theAmerican NationalStandards lnstitrllo

Toolbox

-

used to store spgle shear bolts, locknuts and

ON

I

OFF

swltch

-

used

to

STOP

the engine.

wrench.

Drive speed control lever

-

used to select fdiatdor

Safety ignltlon key

-

must be insertedfor the engine to reversemotion and speed of snow thrower.

and

when

is

mactlondrivecontmilever.

usedto engagepower~m-

Electric

start

button

-

usedfor stattingstheengim

rn@~t~~

d.wwthrower.

Oe~oll(auxiliary) starter handle

-

usedfor sta&ng the

engine.

Primer

-

pumps additionalfuelfrom the carburetwto

the

Dlscha

cylinderfor usewhen startinga cold engine,

0.

*

*.

Chokecontrol

-

usedfor startinga cold engine.

Skldplate

-

used%

&just

height

af

sbabrer.bar

from

tk

ground.

T&xtp&rdon

Of

my

arrtruvthrow~rcan-~t~rrsult TheDIRECTIONInwMchsnowis

k

be

thrown

is

cantrolled

infareignobi- thrownintotheeym, which

bry

tha

dischwge

ah&

controllever.

can

resultinsevereeyedamage*

Always

wear

.

safety

glasses

or ayeahiekkwhileoperatin$

your snowtivower or pe*rming any adjust-

:ala,

mentsor repairs.We recommendstandardsafelyglasses

.

;

or

a

wideviaion safety mask worn over spwtacles.

HOW

TO

mE

YOUR

SNOW THROWER

Know

how

to

operate

all

controls before adding fuel

W-I

attemptingto starttheengine.

I-

STOPPlNOl

-

<

,=

*_

TRACTION DRIVE

-4

.

,{

-&a>-:

ReleasetractiondrivecontrolIw~rtostapthefowal'$

-

or reversemovernantof the snow thrower+

AUGER

-.

Releasetheaugercontral'M8wtwbMgsnow&.

F;

ENQINE

-.

4$,

n

@,',I,

Ir

Move ON

/

OFF

switch

to

'OFP-~WPI,

I

a:::

Remove (do not turn)

Wty

ignw

hy

to

pm~t

unauthorizedus$.

+,?

Ti,

FIG.

10

.

.t+

.

The DT$TANCE that snow isthroWn

b

cantmlfsd

by

the

-

NOTE:

Never usechoketo stop eng!mg

~$1

.

4'

position of the chute deflector. Set the deflector low to

4:.

&.&

throw snow

a

short distance; set the deflector higher

to

TO

USE CHOKE CONTROL

(8-

Fig,

9r-

'-

throw snow farther.

Thechokecontrolislocated

m

theerrgine, Usetheohoh

aontrol whenever you am starthg

a

cold

errgsne.

Do

not

u&eto

start

a

warm engine.

r-2

.

-

E

+*

To engagechoke, turn

knob

countcsrcl6bbiee.Slowly

turn

knah

clook~~Lato dldqw,

FIG,

9

'!

TO CONTROL SNOW DISCHARGE

(&XI

Figs.

10

81

11)

WARNING:

Snow

thr~m

have

ex-

flm

lncludlng

startup,

WARNlNG: If

tha

cffmhq

@h&e

or

auger

beuomecl

ge$,

8hWetsglrre

fi

~d~U~.Hm~~artstostop.

UY

the

clmn-outtoal, N

T

YQUR

HANDS,

to

unclog

the

chute

and#=

auger.

,

*

Tochangethedefl

-

flector to desired

. .

..

.

'

_1

.

..

.

.:

-

.

.

.

.'.-

.

+'

.,

.

.

...i;

i

'

:.

'.

,

2

<

;$~j,!?.$

.

.-

,

3-.

"'

'I.

_?

.

-

:

'

.!!,?*$

-

.

Y-

-

'

.,.

-

.

,.

!

/yr

:

s

..

.

'

.

2

:,.&.-

'

.

,'.

.j.

.

;.>:-

.$,

&-.

+'::>&?)

~2

-

+,':

.

-,=

,.'

.

.

,

?

.

>

.

..li

. .

-

1

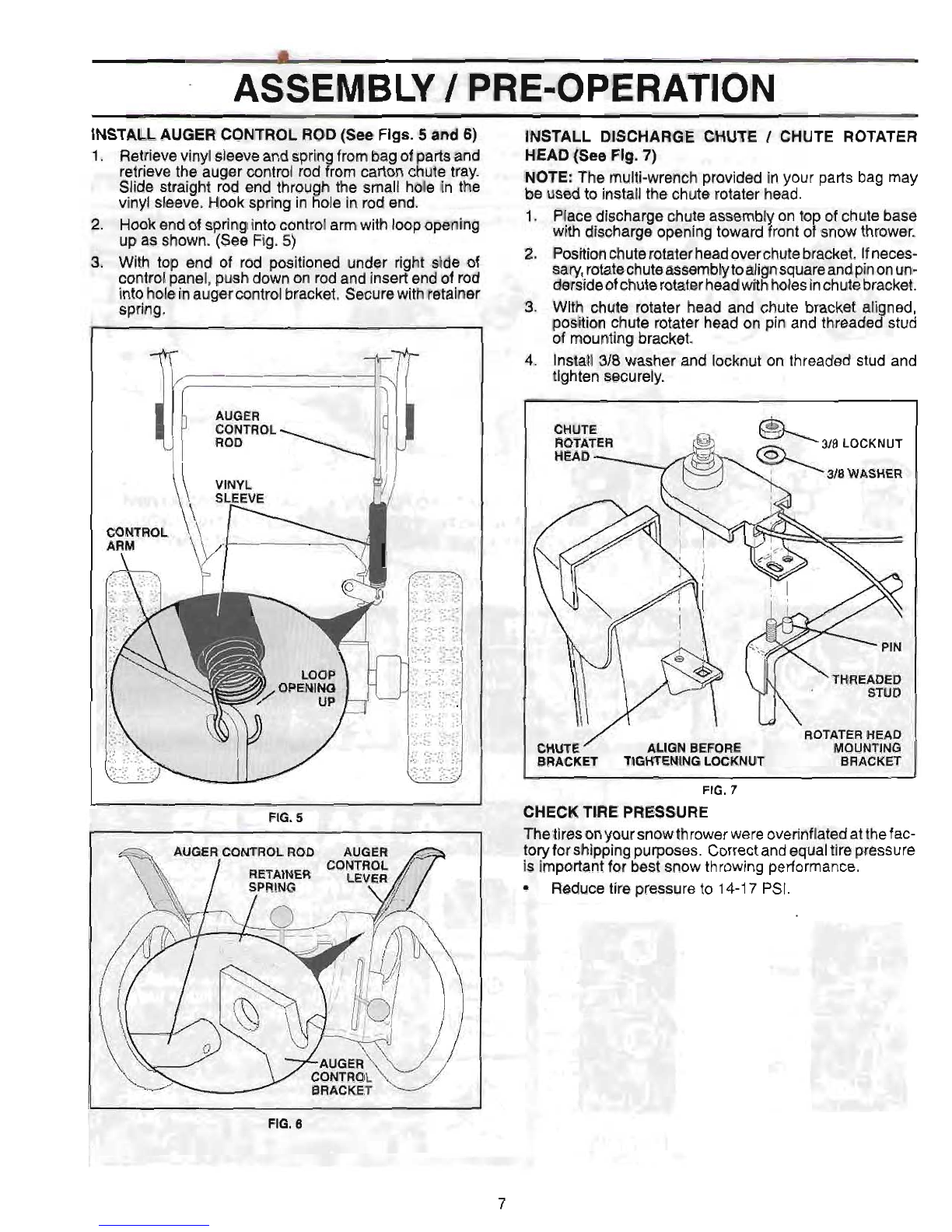

OPERATION

TO

THROW

SNOW

(See

mg.

I*=-)-

31;.

i3

The auger rotationiscontrolled

by

the auger eonfrollever

locatedon the rightside handle.

eeze auger controllever to handleto engagethe

er andthrow snow,

eleas ease

theaugercontrol

leverto

stop

throwingsnow.

WINO

TIlE

CLEANOUT

TOOL

(See

Flg.

13g:

In

mWBiM

snow

mndIrion~,

the dischargechute

may

be-

fame

GEpggeEcl

with

&!

and snow. Usethe clean-out tool

to

dislodge

this

blmkage.

Removetheclean-buttoolfromit'smnting

clip.

Grasp

thetool

firmly

by

the

handle

and

pushandtwistthetool

into

the

cfkclxGg8

chute

to,dlslddge

the

bbckqp.

~8~~~~6tf~1"1~bexn

dl

Jadg;ed,

Wumthed~n-

Out

WoI

b

k'L

mounting

clip

by

pushingit

Enta

theclip.

~wlr~~WtWq~-chuta'is

in*

in

asafe

die@

tion

(nevehwes,

buibgBI

pmpCkothwabliects

are

?ptha

dirtsc-th~af

dlmharga]

beSam

m&artlngsngine.

IbsWrt

&@

einginei

then

squwe

tba

auger'wntrol

lever

U

tlwhgndh&

clew

mew

%!;am

augpr

haws-

bg

and

the

dihatgs

chute.

-

FIG.

13

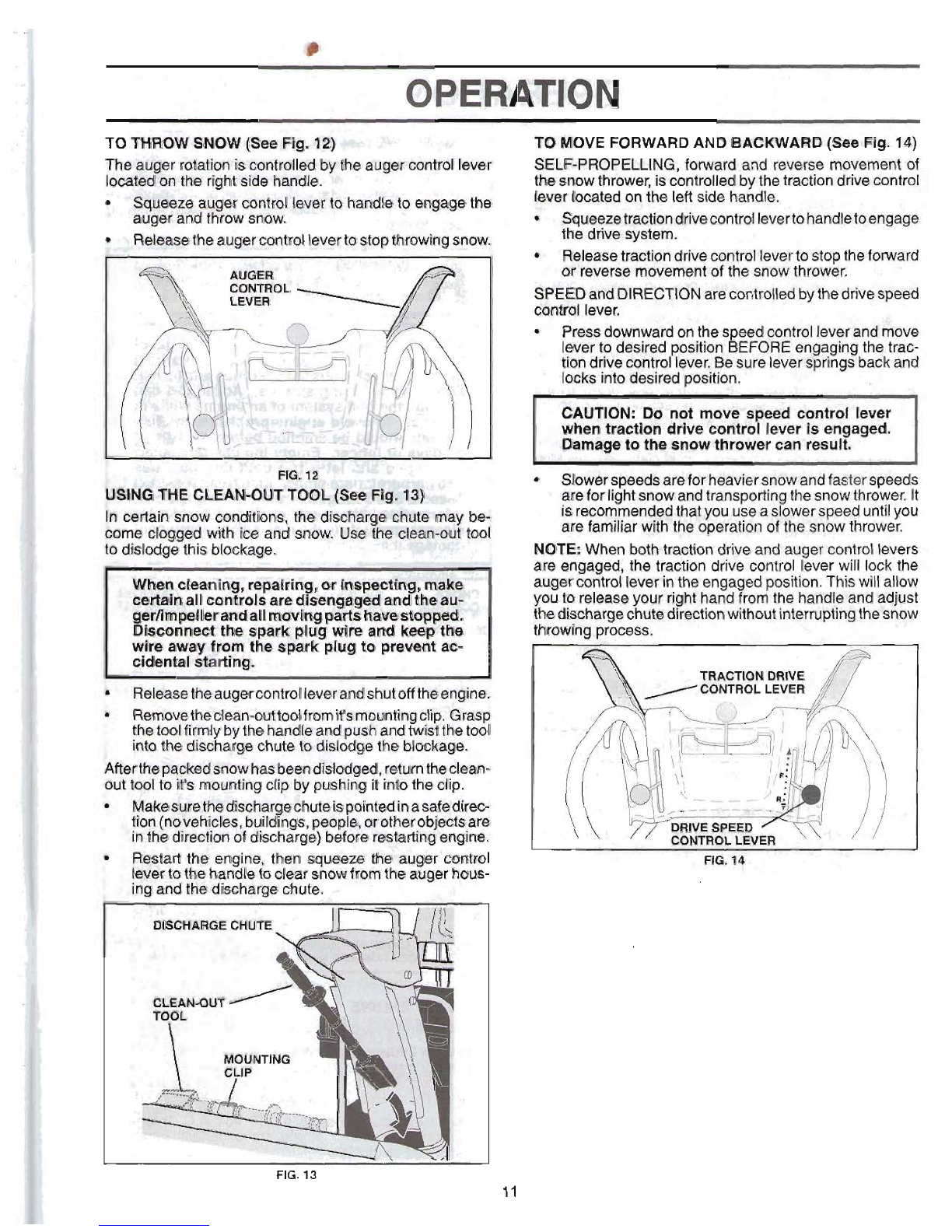

TO MOVE FORWARDAND BACKWARD (See

Flg.

14)

SELF-PROPELLING, forward and reverse movement of

thesnowthrower,iscontrolledbythetractiondrivecontrol

bverlocatedon the left side handle.

.

&queezetractiondrivecontrollevertohandletoengage

.

the drive system.

,

'Releasetractiondrivecontrollevertostoptheforward

arreverse movementof the snow thrower;

..

'

EDandDIRECTIONarecontrolledbythedrivespeed

Pressdownwardonthespeedcontrolleverand

m'W

leverto desired position

BEFORE

engagingthe trac-

tiondrivecontrollever.Besureleverspringsbackand

locks into desiredposition.

I

CAUTION: Do not move speed control lever

when tractlon drive coritrrrl lever is engaged.

Damageto the snow thrower can result.

Slowbrspeedsareforheaviersnowandfasterspeeds

arefor lightsnowandtransportingthesnowthrower. It

.Isrecommendedthatyou useaslowerspeeduntilyou

are familiar with the operationof the snow thrower.

NOTE:

When bothtraction drive and auger control levers

are engaged, the traction drive control lever will lock the

augercontrolleverintheengagedposition.Thiswill allow

you to releaseyour right handfrom the handleand adjust

thedischargechutedlrwtianwithoutiflsaxrupang

the

WQW

throwing process.

FIG.

-

.

..

\,

'

~

.

$

*.',

..

-

t.',;!.''

-

T:

.

iY'

.

. .

.

,

.

:\

,.

,

.

3.

:<.

/.

.

,

.I

:

.

..

.,

'.

.

+,

.

<,

,

:,.

-

1

.

.

.

1

,

..,<

~.

I;'

.

..i;

,

r

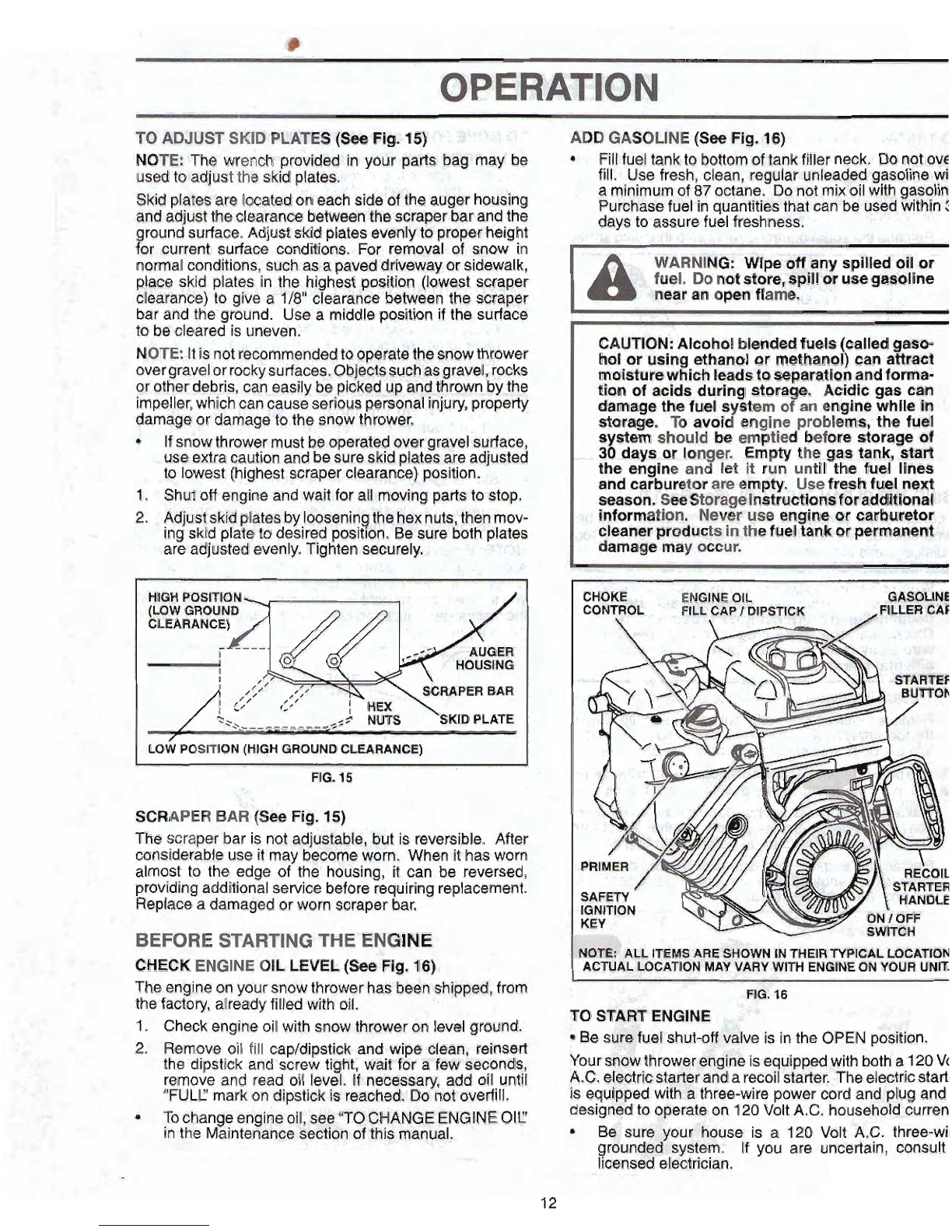

T6

AWWT

lMPl

PLATE@

FEg.

18)

3'-"'.

5

-

NOT&

Tha

wmflch

prov4#ad in your

p@rt$:

bag

rn@y

be

&&aJ

ta&]ust the skidphtaw

1-

..

,<

d

lldd

plat@

are locatedan

ea66'sid6;o?he

ad

'er

howlng

thecfmmmb@Wmn

soraper

%,

r

md

the

Adjust skidplates

f4~nly

to

properheight

gturrcant surfam ~~~fldition8,Far removal of onaw in

nsrmttll

conditbna, eu~h

arr

a

pavd

drlway

Br sidewalk,

plaoe skid plates in the hi hest poeition (bwest scraper

P

cler%ranoe)to give

a

118"

ceararrcebeweem thr acmpar

bar and the ground. Use

a

middle positionif

the

surface

io

becleared is uneven.

NOTE:

Itfsnotmcommenderd

b

oprratethesnowthrower

overgravelor rockysurfaces,Qbjectssuch

tar

gravt~l,rock8

other debris, can easily

be

pioked

up

and

thrownbythe

gpeller, whichcancauseseriouspcmonpl.iflljyry,

,.

propell)!

~mw@or damageto the snow thmwst'

mi,_

,

~,

-

;

:

If

@nowthrawer mustbeopmrad~~cmrgravel

ourtaw,

.are@

extraoautisn

md

besurer

rrksd

ptsatw

ara

adjuls-tsld

,

,

@

lowest (hiqhe~tscraper.

.

elerwanoe) pasition.

t,

@hutoffengine

ad

*Wail

mavinqpartsta$top.

P.

;

hdjustskidplatmby loownln

the

hex

nu$, lhenmov-

Ingskid pl& to deslrad

pmlt

9

on.

8e

sure both plates

me

adiusttad

ewnty*

Tiitgn

setcursrly,

-

.

..

).

')

'b

:-

.

i

.

,?

[

LOW

POSITION(HUHGROUND CLEARANCE)

I

P.

PIC%

tQ

SCRAPER BAR

(See

tsrg,

In

The scraper bar is not adjustable, But

is

reversible. ARer

considerable use it may b~c~mgtworn. When it has

warn

almost

to

the edge of the housing,

it

can be reversed,

providingadditionalservice beforerequiringreplammmt.

Replace

a

damaged or warn scraper bar.

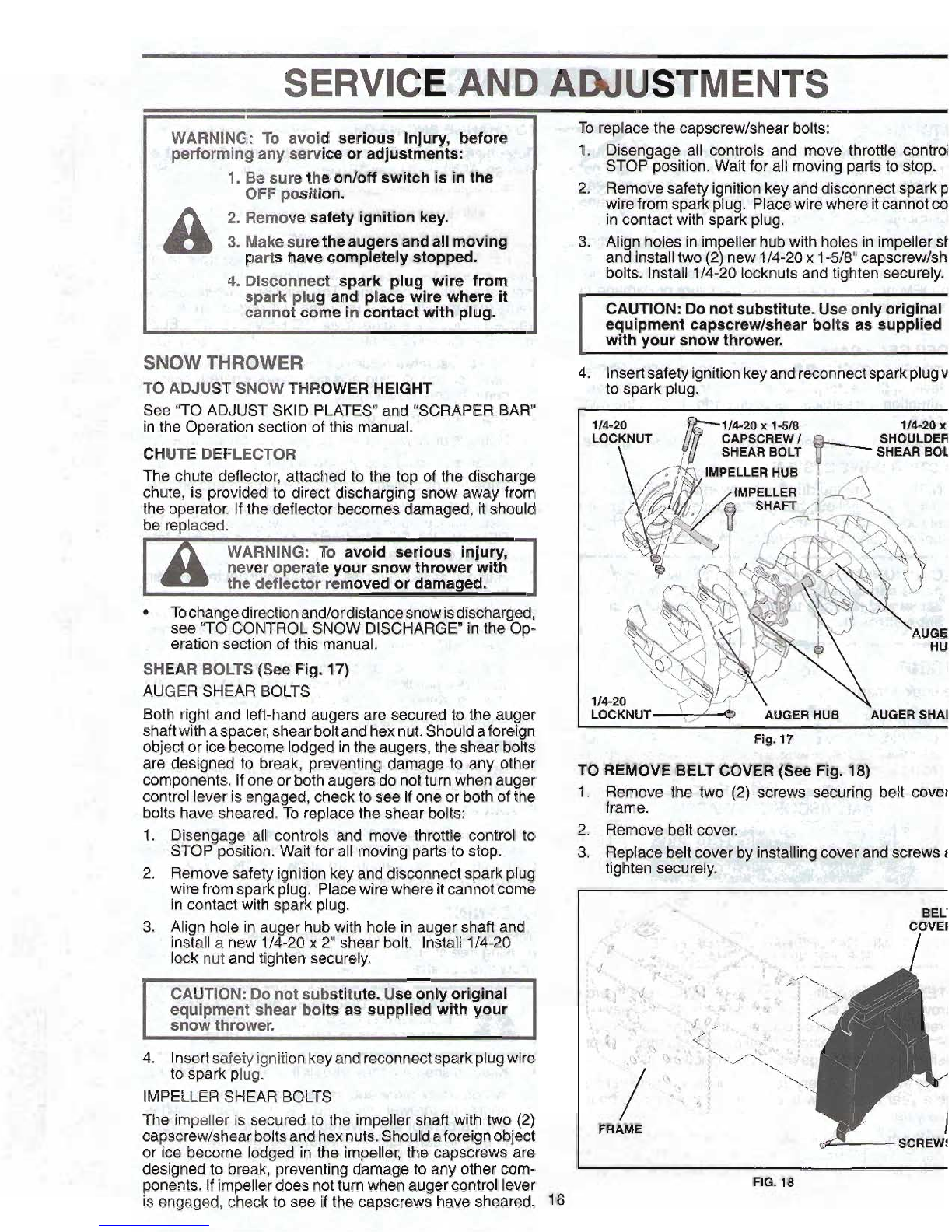

BEFORE

8TARTlNG

THE

EElalJVE

CHECK

ENE;IiUE

QIL

LEVEL

($tm

Fig.

18)

The engineon your snow thrower hu,

b&shipp.&

horn

theOctary, alreadyfilledwith oil.

1.

Checkengine oilwith snow

thwww

on levelground.

2.

Remove oil

fill

cap/dipertick

Blnd

wipe

dm,

&met

the

dipstick and screw tight,

wait

for a

few

smmd$,

moveand read oil lavel.

It

rgr,

add

oil

until

"FUU

markon dipsdek

Is

m*d.

Ds

natov@flll.

Ta changeengineoil,

sea

TO

C.HANG€ENGINE011"

Sn

the Maintenance~srsettonof

this

manual.

ADD

GASOLINE

(8-

Fig.

16)

.

.

,

;:<

:

Q::

:

Fill

fueltankto bottom

of

tankfiller neckh-Donotover

fill.

Usefresh, clean, regular unleadedgasoline wi

aminimumof

87

octane. Do notmixoilwith gasalln

Purchasefuel inquantitiesthat can be usedwithin

f

daysto assurefuel freshness.

,,,.

,

,

.%

%.

&Lbd--

.J'%!

~!f*U;~i%3~-

*

a

WARNINO: Wipe off any spilledoilOK

fuel. Donotstore,spillorusegamline

nearan openflame.

CAUTION:

Alcoholblendedfuels(celled aso-

holor usingethanolor methanol)can a

?t

raot

moisturewhichleadstoseparationandforma-

tion of aclds during stora e. Acidic gas can

damage thefuel s stem o an enginewhlle in

J

P

storage. To avos engine problems, the fuel

system should beemptied beforestorage of

30

days or Ion er. Empty the gas tank, start

.-

the englne an

!

let

it

run until the fuel lines

andcarburetor are empty.

Use

fresh

fuel next.

season. Seestoragelnstructlons

for

additional68

information.

Never useengine or carbu~tor,,~

claraner productsinthefueltankorpermanen&@

damage may occur.

MQJEh

ALL

ITEMS

ARESHOWN INTHEIR TYPICAL LOCATION

ACTUAL LOCATIONMAY

VARY

WITH ENGINE

ON

YOUR UNIT.

I

--

-

---

-

-

-

---.+

!

-

~*

.>,

a,

.

~ra5a

TO

STAR7

ENGlM

-

..

..-

,

!

JC

4

Be

sure

fuel shut-offvalw is inthe

OPEN

position.

Your snowthrowerengineisequippedwith botha 120Vc

A.C.

electricstarterandarecoilstarter, Theelectricstart(

Is

equippedwith athree-wirepower cord and plug and

designedto operate on 120Volt

A.C.

householdcurrenj

Be sure your house is a 120 Volt

A.C.

threewi~

rounded spteim,

Lf

yau

are

uncertain, consult

knsed

-

electrician.

WARM

@CART

r

REWL

t3TMf3

kww

mhQke

tn

the

'GFP

the primesr.

OEWRR

8-TQPPINQ

Runthe csn@ne"forafwminutesto helpdry off any mois-

@WIT

-

ELECTRIC

STARTER

ture onthe engine.

"

.I

<

$..

ItataeH

Wt?lty

ignition

key

@kid

ta recoilstartcord into

IF

RE~~XJIL

STAR^

WA;S

~Q=N

R

ii

'OPY

'lot

*

me

key.

11

the recoil

ahulsr

RBs

Rmen

andwill notturntheengine,

'

t e

e&ra

sr%f@tyignitionk@y inamfeplace, pmceed

es

bIlows:

'&

L

Pieroe

ON

/

OFF swftch in "ONnposiiian.

1.

Graspthe recoilstarker handle

qnsl

gd~wlypullas muoh

S

Rota&

choke controlto "FULL"position. ropeoutof

the

starter

as wwiblei.

4

G?nmthe pawer

cord

ta

the

engine.

5. ~lq,lh.'&hwend

dlh,

power

cord

into

athnbhole

,

gt%m

t

ZO

&#

A.C,

#QTEt

Po net

me

primer

hen

staQg

gnginewith thrs

erlecttb

@tartar.

8.

Diwnmtthe

pow^

card

Qrdm

th@

r

WR

from

tbEmglina.

~u&the

o heto

wMn

u for

a

few

minutes.

&

HI

opt

tbwd~p

"B

uIIpweruntl

It

ha&remherdnorr&

oprat~

Rg

tomp~~.

P

WARM

START

-

ELECTRICSTARER

FollDW

$he

st@pe

abauja,

ka~ping

the choke cop1tml inthe

"OFF"

gosition,

COW

&ART

FEGQlL

STARTER

I.

Inaart

s-%If&&

igir1Itaon key to rwilstart Dord into

I

nitinnslot

unlit

Midcs.

O

NOTturn

th@M@.

AEtp

R

b

t ee~trafsclfityignirlan

by

in

a

FF

wbh

In'ON" pition.

mtmlto "FUUpatinn.

4.

Pursh

.tkQ

liRn@r

four

4)

timm

l

thr

ttmpembre is

6

blow

Ipfor

two

12)

mu

ntanprwstumta

between

1

5'

and

!if0

F.

Iftb~ratura

F8

abm

60aE

primhais

riot

rrmmry.

NOTE

Q&$;ptfmin-g'may

mum

flmdhg, pre\renBn@the

enghefrom

aath'lg

If

you

do

fbod

tbengin&,wait

r

ft?w

miinurn

hbre.&mmg

&I

&at

and

DCI

NOTpush the

Drirner.

b

F%iI

wl

starhw handls quicMy. Do not allow

$tartw

roper

ta

snap tmk.

6$

%

When

theenginestwts,W~~therecoi3~st@erh~ndls

:

ansl'slawly-methe choke controlto the

"(CZFF

pmb

-tian,

AllwT176m

*

crl

trx

warm upfor

a

few

minutehp.

Enghet

will

not

d

!$I

paweruntilit

has

n&hed

normalopera-

ingtcamgwatun.

2.

~ileasathe

rerwrv

starter.handie

and

let

it

snap beck

klgainstthe.%tartar.

If the(swi~(~i~Mill

hib

ta

start,

repeat me abwst.eps or

wr

th8:elmtri~$tarter.

SNOW

mmwi~lcz

nps

AJwaw.operate the sngWthmw@f With the engine at

fullthrc%lo.Fullthrottle offers

bad

perrfomanlc9.

h3Wsnow.

ummo

th

ro

,

to

adjust speed.

It

is

wiesand mreefficientto remove snow imme-

&ally ahr

iZ

1"alls.

th61bwttimet~re~av~~sntrw

k

theeiarly morning.

At

thistlme t& anow

IS

usudiljly

dry

and

ha&

nat

been

ex-

pwd

to

ffier

dimct sun and

warnu'ng

bmprsmtures.

SiigS1tIy overlap each succwsh path ta cs;nBufe

dl

snow will be removwl,

Ailjusttheskidplates

to

m

&r

h&i

htformrr&ntsnow

w~dttiono.

TO

&SST

d~

PLATE@

inthis

don

of

this

manual.

-

parextremelyheavy

srlaw,

revduQe

the,

width

of snow

lwt'mxd

by

cm~Mappimg

~~(IIV~Q~BP.

path and moving

sJuwly.

*

engtfio

rlm

andclear

of

snow duringuse.

This

wiU

Rip

air

fib*

and

exteMengine life.

Afbr~nawthmMng

15 cbmpWd,Jl~wanginato

run

for

afew minutedto meltsnow

md,

off.

Me

engine.

&m

the entire snow thrcrwr th@roughlyafter

each

use and wipe4

dry

so

it

is

ready

far

nequse.

WARNSPIIQ:

Do

nd

aperate

snow

a

thraww

kfwmth&rmndiBarmImpair

vls-

Iblllty.

Throwlng snow

during

;a-htmvy,

winds

e~ow8trom

an

Wind

yau

and

be

hazardmus

t~

the

mj&

opemtl~n

of

the

enow

thlawtar.

-

-

FILL

IN

DATES

GENERAL

REEOMIVIZWDATIONS

"'""

.

ti',

,

The warranty on this snow thrower does not cover items

thathavebeensubjectedtoo eratorabuseornegligence.

To receive full value from

8

e

warranty, operator must

maintainsnowthroweras instructedinthismanual. Some

adjustmentswill needto be made periodically

to

properly

maintainyour snow thrower.

1

.I

At least once a season, checkto

s&

i(

you'dh.$u~dmake

any of the adjuetmentsdescriiedin

the

Senrice

and Ad-

justment@

~sxl

of this manwal..

,.:

!

,?;

.

At leastonceayear, youdo&! replacethe+rk lug

your engine run better and last longer.

I:

and check belts for wear. A new spark plugwilt elp

Followthe maintenanceschedule

'in

this manual.

NOTE:

UseonlyOriginalEquipmentManufacturer(OEM)

partstosewicethisunit. FailuretodoSt5

can

musethe unit

todfuncticm

and

pmgt

a

rkk

Qf

injury

tothe opeatar.

'BJ

t,

1

"

.

,%:

L.

1

+$,*

USE.

.-

if-

A

*

1.

Check engine

OH

ImB

2.

Checkfor loosefastek&rs.

.

.I

YI

,

*

.

.i

J

r

.

',

.

-

,I

i

.

,

1..

;I

SNOW

THROWER

.

.

,.I'

Always observe

the

&&y

rule@ JprformiB$j any

*i

.Keep

tires

frw

af

maintenance.

.,I

:a

rubber.

"I{

,:T,

df

I

>.

TIRES

;

8

NOTE:

To seal

fire

punctures and prevent flat tires

dr

*

Maintainpro er air prmisure

in

bothtlrm to slow leaks, tire sealant may be purchased from yo

(1

4-1

7

RS.I!~'.

local parts deafer. Tire sealant also prevents tire dry

r

and corrosion.

.

,

.+

=-

-

..

?

BELTS

1

._

&

-

3.

-

:,

.%Ik,<..

*

-.

-

$0

CHANGE ENGINE

OIL

Checkbeltsfor deteriorationandwearafter every50hours Determinetemperature range an'licipated before ned

oil

of operation and replace

if

necessary. The belts are not change,AlloilmustmeetAPIserviceclassificationSG-SL.

adjustable. Replace belts

if

they begin to slip from wear.

Be

sure

snow

thrower

is

on

suhce.

(See

YO

REMOVE BELT COVER".in the Service and

Adjustments section of this manual)r Oilwill drain morefreely when warm

*

-

Thebeltson your snowthrowerareof specialconstruction

'

Catchoil ina suitable ~Qt~tainer.

2

andshouldbereplacedbyoriginalequipmentmanufacturer

NOTE:

The left side wheel may be removed f&$ !$now

(OEM)beltsavailablefromyournearestdealer.Usingother thrower for ~asieraccew to the oil drain plugand placeiz

than OEM beltscan cause persona or damage to ment

of

asuitable container,

The

unittllted, restingon the

the snow thfmar.

.

-

<.

frame with the left wheel removed, will help drain any oil

,I

+

r

trappedinsidethe engine. (See"TO REMOVEWHEELS*

inthe ServiceandAdjustments section of this manual).

1.

Removesafetyignitionkey anddiscmnedsparkplug

wire from spark plug and place wirewhere it cannot

come incontactwith plug.

2.

Clean areaaround drainplan

El3

#"lQrease. 3. Removedrainpluganddrainoilinasuitablecontainer.

..

4.

Installdrain plugand tightensecurely.

snow

5.

Wipe

off

anyspilladoilfromsnowthrower

and

engine.

on

$.

Installleftwheel(ifremovedfor drainingoil). Besureto

installklick ininto roperholeinwheelaxle(See

"TO

-REMOVE HEEL

!

"

inthqfienrlce

and

Adjustments

sectidn of this manual).

7.

Removeoilfillcap/dipstick.

~6

to

entertheenginer

--

8.

Reff

ll

engine withWIl9+1mugh"

st1

wkk'cW;,Four

slawly. Do not overfill. For ap roximatecapacity see

"PRODUCTsPEGIFIcATIoN~~sectionofthlsmanual.

ENGINE

on oil fill cap/elipstick for chwking level.

See engine manual. stickcap

Cs

ti htenedsecurely for accurate

oil at "FU

C'

lineon dipstick.

LUBRICATION

'

'

I

t@,'Wiie

off any spilled oil.

a

Useonly highquality de"tbr~eW

dl

rated

W~~API

se9%&

,

,

.

,

.

i

'

_,I-

..

classification SG-SL. Selecttheoil's SAEviscositygrade

.

>

accordingto your expectedoperatingtemperature. Insped

dd

replacecorroded'

.&

d

fire hazardandor damaga

,

.

SPARK

PLUGi:

Replacespark

plu~dthe

bagh-mingofeach

seas~n

oraRer

every

100

hoursof operation,whichey~rac~ursfirst. Spark

plug type and

gap

setting are show

[n

the "PRODUCT

SPECIFICATIONS"sectionof this mnuai.

CLEANING

'

,

.

*

IMPORTANT

Forbest perf~rm&tcrl;-

!keep

snow thrower

housingfree of any dirtor trash. CleanShe outsideof your

snow throwerafter each use.

NOTE

Alfhowgh multi-viscosityoils (5W30,

1

OW30

etc.)

improve

shfftrrg

in

coldweather, these multi-viscosityoils

will result

in

irrereasedoilconsumptionwhen usedabove

32°F.

Che* yausmgineoillevelmorefrequentlytoavoid

possWe

lengiw

damagefrom runninglawon oil.

Changethe

ujt

ef€er

every25 hours

of

operationor at least Keepfinishedsurfaces/wheelafreeofgasoline,oil,etc.

once a year if the smwthrower is not usedfor

25

hours We do not tw~mhendUdhg

a

gar-

to dean

inone year. yoursnowthrowerunlesstheelectricalsystem,muffler

and carburetorare covered

to

keep

water out. Water

Checkthecmkcaseoillevelbeforestarthgtheengine

and

h

engine can result in shortened

engin%-li%e,

aftereach ffve

(5)

hoursof continuoususe. Tighten oil

fill

$,

Cap

I

dipsticksecurely each

time

you

check

ttre

oii

tevd.

-

-

-,

.

_

a

t-

:

.

A.

.

WARNING:

Disconnect

spark

plug

wke

from

sparkplug

and

placewire

Here

it

cannot

came

In

contact

with

plug.

SERVICE

AND

AWUSTMENTS

To

replacethecapscrewlshearbolts:

.

%

WARNlNGi: To avoid serious Injury, before

:-:I

!

performingany mrvtceor adjustmsnts:

p

3-

.t

1.

Disengage all controls and move throffle cbnirol

.

,

.

STOP position.Wait for all movingpartsto stop.

1.

Be

surethe

OM

swltch Istn thew

OFF position.

AIP

Removesafetyignitionkeyanddisconnectspark

p

.

wirefromsparkplug. Placewirewhere itcannotco

A

2.

Remove safety Ignitl~R%&y:~.

o'r'V

incontactwith spark plug.

-

-

.

;a.t,ir,.

yc.

1

1

3.

Makesuretheaugers

and

allmsvin$

.

,

parts havecompletelystopped.

!

I

4.

Disconnect spark plug wire

from';

;'

-I

spark plug and placewire where

#,

"

1

. cannot come

In

contactwith plug.

,

$'-

SNOWTHROWER

--

.

>,+~*.--~,a

i

TO ADJUST SNOW THRO

&&m

:

4.

fr

See TOADJUST SKID PLATES" and "SCRAPE?$.BAR"

inthe Operationsection of this manual.

..

.

,

,,

rCa

CHUTE DEFLECTOR

The chute deflector, attachedto the top of the discharge

chute, is provided to direct discharging snow away from

theoperator. If

the

deflector becomesdamaged,

it

should

.

,

be replaced.

WARNING: To avold serlous

tnju

the deflector removed or damaged.

3

never operateyour snow thrower wit

..

To changedirectionand/ordistancssnow

b

discharge&

-

-seeTOCONTROLSNOW DISCHARGE" inthe Op-

erationsection of this manual.

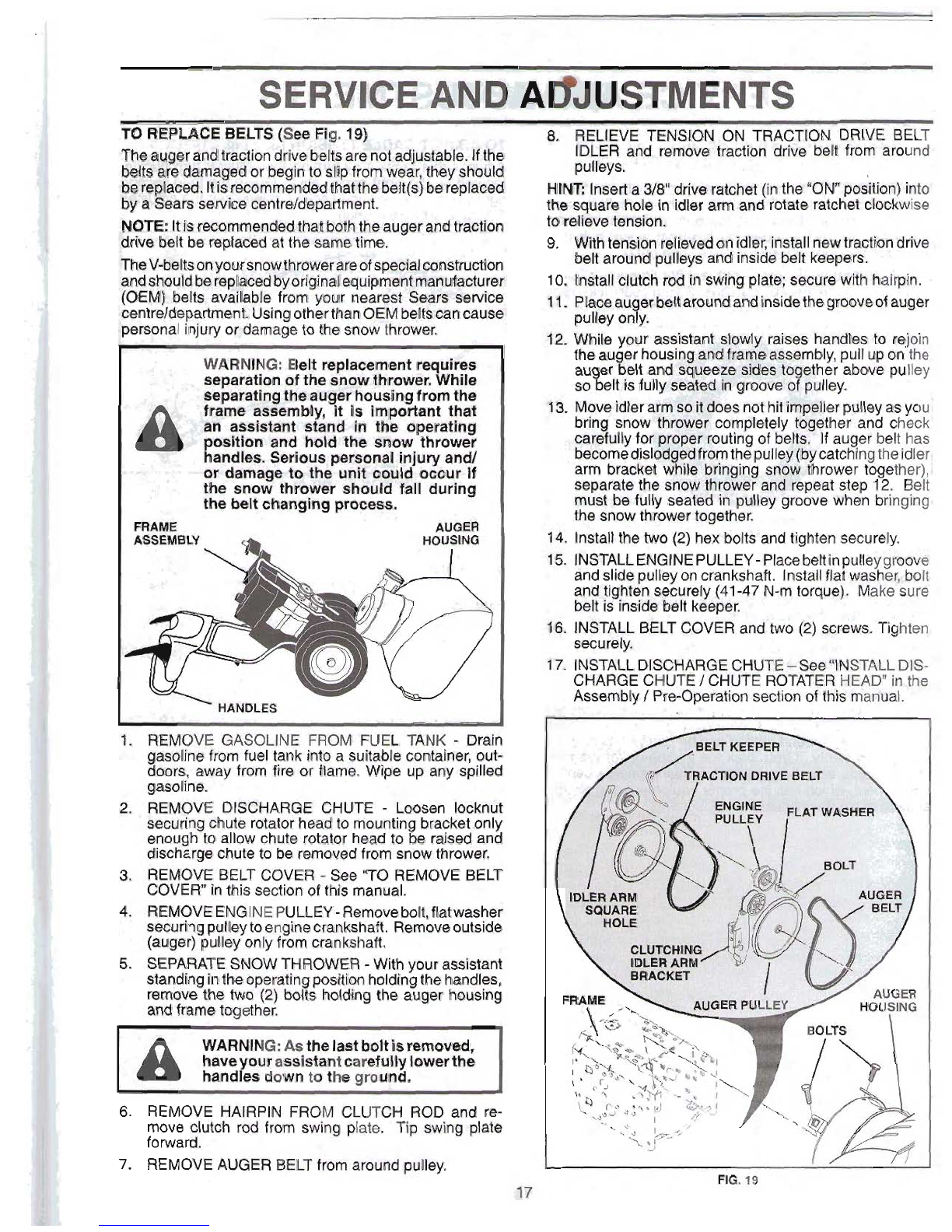

SHEAR BOLTS (See Fig.

17)

,

AUGER SHEAR BOLTS

4'.

,

.

Both right and left-handaugers are securedto the auger

shaftwithaspacer,shearboltandhexnut.Shouldaforeign

objector ice becomelodgedinthe augers,the shearbolts

are designed to break, preventing damage to any other

components. If one or bothaugersdo notturnwhen auger

controlleverisengaged,check to see if one or bothof the

bolts have sheared. To replacethe shear bolts:

1.

Disengage all controls and move throttle control

ta

STOP position.Wait for all movingpartsto stop..

*

2. Removesafety

i

nitionkeyanddisconnectsparkplui

wirefromsparkp

9

ug. Placewirewhere itcannotcoma

incontact with spark plug.

3.

Align holeinauger hub with holeinauger shaft andl

'

installa new 1/4-20

x

2" shear bolt. Install1/4-20

.

-

lock nut and tighten securely.

CAUTION: Do notsubstitute.Useonlyoriginal

equipment shear bolts as supplied with your

snaw thrower.

-

4. Insertsafetyignitionkeyandreconnectsparkplug

wtm

to

sparkplug.

lMPmSHEARBOLm

dig

'+'*;

'

%

-

.

i

The impelleris secured to theimpdkr

ahan

with two

(2)

capscrewiehearWts

4

hex

nub.

ShW

a

foreignobject

or ice become lodgedIn

the

impeller,

the capscrewsare

designedto bxeak, preventingdamage

to

any other com-

ponents. Ifimpellerdoesnotturnwhen augercontrollever

isengaged, check to see if the capscrews havesheared.

1'6

,.-$i-:

Align holesinim eller hub

~+KJ&S

fi~

-

andinstalltwo

(2y

new 1/4-20x

1

bolts. Install1/4-20locknutsam?

CAUTION: Do notsubstitute.

Use

only

ortginal

equipment capscfewlshear

bolts

as supplied

wRh your snow thrower.

4. In%erY~a1&yignNbn

key

and

reaxmeet

sparkplug

v

to spark plug.

,.-.

f

.I

.

.;

:

--

c:f

@.@crews securing belt

cowl

-

-

-<

.

2. Removebelt

-

A=,'

.+

*

3.

Replacebeltcover

by

installingcover andscrews

t

tightensecurely.

-w$

-

'*

RO.

18

SERVKE

AND-N$JUSTMENTS

,

WARNING: Belt replacementr ulres

,

separation

of

thesnow throwe%hile

:'I

1

separating

theauger

houslngfromthe

frame assembly,

It

Is important that

1

an assistant stand

in

the operating

e

asMan mdhold the snow thrower

.

andlea. Serious

personal

Injuryandl

4

I.

*,-

,

or damage to the

unit

muld

occur if

.)

I

the snow thrower should fall during

the belt changingprocess.

FRAM~

Aum

HOUStffi

-,

+

?'

4

TO

REPLACE BELTS

(See

Fig.

19)

:fie'

T

.

,d:ii~t

8.

RELIEVE TENSION ON TRACTION DRIVE BELT

Theaygerandtractiondrivebeltsarenotadjustable. Ifth$ IDLER and remove traction drive belt from around

beltsate

damagedor beginto slipfromwear, they shoukl pulleys.

Ire

replaoed.I1isrecommendedthatthebelt(s)bereplmdd

HINT

Inserta318" drive ratchet

(in

the

"ON

po~ition)~~

bha $ears service dentreldepartment.

'

"!I

the quarehole in idler arm and rotateratchet

clocWi

NOTE:

Itisrecommendedthatboththeaugerandtraction

raltevs

.

1

drivebeltbe replacedat thesametime.

8.

With

tensionrelieved

bn

Mer,ih€lgllne~Wac~kytWbe

TheV-beltsonyoursnowthrowerareofspet3Bl~truction beltaroundpulleysand inside belt keepers.

andshouldbereplacedbyoriginalequipmentmanufacturer

10,

Installclutch rodinwingplate; secure with hairpin.

(OEM) belts available from Your nearest Seat'S service 11. Placeau erbeltaroundandinsidethegrooveofauger

centreldepartment.UsingotherthanOEMbeltscancause pulley ony.

gersonalinjury ordamage to the snow thrower.

7

12. While your asl5-iant tslowly raises handles

to

rejoin

theau er housingandfmmts assbmbly,pullup on the

au er eltand squeeza

rides

to @herabove pulley

so

%

e12 isfully set~bd

in

grooveo

r

pulley.

13. Moveidlerarmso itgoesnothitirflprllerpmeyas

you!

bring snow thrwer completely together and check

carefullyfor praper routingof belts.

If

auger belt has

becomedislo edfromthepulleyfb catchingtheidler,

$,

\

arm bracket

w

Ele b'PinpingsnBw t rower together),;

separate the snwthrower and repeat step

12.

Beit

must be fully seated in

pullw

groove %hen bringiags

.

the snow throwertogether.

1.

REMOVE GASOLINE FROM FUEL TANK

-

Drain

gasoline from fuel tank into a suitable container, out-

doors, away from fire or flame. Wipe up any spilled

gasoline.

8.

,

REMOVE DISCHARGE CHUTE

-

Loosen locknd~

securingchute rotatorheadto mountingbracket only

enough

to

allow chute rotator headto be raised and

discharge chuteto be removedfrom snow thrower.

3. REMOVE BELT COVER

-

See "TO REMOVE BELT

COVER" inthis sectionof this manual.

4.

REMOVEENGINEPULLEY

-

Removebolt,flatwasher

securingpulleytoenginecrankshaft. Removeoutside

;

(auger) pulleyonly from crankshaft.

5.

SEPARATE SNOW THROWER

-

Withyour assistant

standingintheoperatingpositionholdingthehandles,

remove the two

(2)

bolts holding the auger housing

and frame together.

WARNING: As thelastboltisremoved,

our assistantcarefullylowerthe

down to the ground.

.

'6.

REMOVE HAIRPIN FROM CLUTCH ROD and re-

move clutch rod from swing plate. Tip swing plate

forward.

7.

REMOVE AUGER BELT

from

mud

m

FIG

19

SERVICE

AND

AbJUSTllTINTS

.

,

.

.

-4q

.&

TO

REMOVE

WHEELS

(Sm

Fig.

29&&

L',,.

ic

3fi

TO

ADJUST

CABLE

TENSION

Cfbe

Fig.

21)

I*

JS~

Removethe klik pinand removewheel from

axle.

.

Aqd

caMs

tension

by

turning

the

adjusterturn

hue

IMPORT&NT

Wheninstallingwheel, besure

to

use

the

Fa-

baa^

on

the

dmt hand

cahl@.

QrW

Ihe

long

nermostholeinaxleandthewheelhubhole. To disengage *gh*

and

turn

the short -On

to

lengthen

drivesystem from

the

wheels (for pushingartramporting

Adiustunt[l

cable

is

snug.

the snow thrower), remove klik pin from wheel hub and

insertpin intothe outermost hole in

axle

only.

NOTE:

To seal puncturesor preventflat tiree due to stow

leaks,tiresealant maybepurchasedfromyour localparts

dealer.Tiresealantalsoprevents

tire

dry

rot

andcorrosion.

KLlk

PEN

-

W'FeR

HOLE

I

i

HOLE

.

-

(;

3-

3

wHeeL

r

-.i;'

""

'"'

'

'

,

WHEELHUB

-

.

AG.20

.

-

'1-1

1

,

:q

:

.

ENGINE

t

r,

.,

,,

;.

.

+

br-

w-.

I

CARBURETOR

.

'"

'

.

+

,

,

.

.,

-

Your carburetor is not adjustabie. Engine performance

should not beaffectedat altitudes up to

2,134

meters. If

your engine does not operate properlydue

to

suspected

carburetor problems, take your snow throwm to

a

Sears

servlcecenter/department.

..

el

'

ENGlNE

SPEED.

I..

I

..~

-.

2%

Nevertamperwiththeenginegovernor,whichisfactoryset

for properenginespeed. Overspeedlngthe engineabove

the factory highspeed settingcan bedangerous and will

void the warranty. If you think the engine-governed high

speed needs adjudng,

contad

a

Sears service center1

department,which has the proper equipment

and

experi-

enceto make any necessatyadiustments.

Immedlatety prepare your snow thrower for storage at

Empty

the

fueltdnk

by

startingthe engineand

le$C:

theend of the season or if the unitwill not be usedfor

30

it

run

Clntil the fuellines and carburetorare empb

'

days or more.

,..

.

.

2

+

qv-j,

-

,

Never uee engimior barbuntor cleaner produ&hl

'

-

ltm

fueltank or permanentdamage may occur.

..

1-7

WARNING: Never store the snow

throwerwith gasolineInthetankinside

Usefreshfuelnext seasorr:e

a

a

buildingwhere fumee may reach an

&T€:

Fuelstabtlizerisanacceptablealternative in

mb

openflame, spark or pllot lightasona

imitingtheformationof fuel gum depositsduringstorage.

furnace, water heater,clothesdryer or

Addstabilizerto gasolineinfusltank or storagecontainer.

gasappliance. Allowtheenginetocool

Always follaw the mix ratiofound on stabilizer container.

beforestoring inany enclosure.

Run engine at least

10

minutes after adding stabilizer

to

I

allowthe stabilizer to reachthe carburetor. Do not empty

the gas tank and carburetor if usingfuel stabilizer.

ENGINE

OIL

.

-

Drainoil(withenginewarm) andreplacewithcleanBngine

oil. (See "ENGINE.

in4hel

,Maintenance section of

this

manual).

.(I

.

-

4

-

CYLINDER

X

.

._

4.

I

1.

Removespark plug.

I

t

,

2.

Pour oneounce

(29

ml)<of

bil

throughsparkplug

hob

intocylinder.

"'

,

,

uc

i?.

-

3:

Pullrecoilstad& handieslowly8fewtimestodistribute

,.*

L!-

'

!

'

,tCL

--**I

:jd

,.:I

UII.

:

4.

Replapyj~,~vysparkplug.

t"

OT'HER

'

6#

7,

.

.;is

Removesariignltlon'f&y'; stdie itina

$&

$a+

>:

st..

>I'

,

,

,

'

,

-

,

,

DOnot store gasolinefrom one ssasonto another.

ENGINE

;

-

--

-

I.

I

.

1-

-

-

.I

Replace our gasoline can

if

your cbn starts to

rust.

See engine manudl;~

:

.

...

.

,..&,

...

...

I

.

j:.f.

Rustan

dY

or dirt inyour gasolinewill cause problems.

FUEL SYSTEM

Ifpossible,storeyoursnow throwerindoorsandcover

it

to

protect itfrom dust and dirt.

IMPORTANT:

Itisimportantto preventgumdepositsfrom

.

,.

Cover

your

snow

thrower

with

a

suitable

pmtectiw

formingin essentialfuel system partssuch as carburetor

fuel

hose, or tank during storage,

AISO,

alcohol

blende&l-

'1

1

coverthatdoesnot retainmoisture.DOnot useplastia

fuels (called gasohol or using ethanol or methanol) can

,

Plasticcannot breathe, which allows condensation

to

attract moisturewhich leads to separation and formatior7 form and

will

cause your snow throwerto rust:

of acids during storage. Acidic gas can damage the fuel.

.

.,

IMPORTANT:

Nevercover snowthrowerwhilesagikexC

system of an engine while

in

storage, haustarea is still warm.

See

aaPrQ)~tWesectionInmanualunlessdirectedto a

SmiYrr

&milea

mflmant.

-

CAUSE

C0RRE;CPION

1.

Fuelshut-offvalve (if so

1.

Turn fuel shut-off

valve

to OPENposition.

equipped) inOFFpition.

2. Safety ignitionkey

2.

Insert

safety

mitionkey.

isnot inserted.

3.

Out of fuel.

3,

Fillfueltank with

fv;mh,

dam

gmdine.

4.

ThrottleinSTOPposition

4.

Movethrmleto

PAST

p68Mon

(or

ONDFFswitch is

OFF).

(or ONIOFF switch

ta

ON pmltion).

5. Choke

in

OFFpositi~n.

5.

Moveto

FULL

position.

6.

Primernotdepressed.

6.

Primeas instructedinthe Operation

s@Im

d

this maud

7. Engineisflooded. 7. Wait a few minutesbefore restar%'ng,DO NOTprime,

8.

Spark plugwire is

8.

Connectwire to spark plug.

disconneded,

9.

Badspark plug.

9.

Replacespark plug.

10.

Stalefuel.

10.

Emptyfuel tank

&

carburetor, refillwith fresh, clem@boEis

11.

Water infuel.

11.

Emptyfuel tank

&

carburetor, refillwith fresh, clean gawlir

Lossof power

1.

Spark plugwire loose.

2.

Throwingtoo much snow.

3.

Fueltank cap iscovered

with iceor snow.

4.

Dirtyor doggedmuffler.

1.

Reconnectspark plugwire.

2. Reducespeed and width of swath.

3.

Removeiceand snow on andaroundfueltank cap.

1

4.

Cleanor replacemuffler.

Engine idlesor

runsroughly

1.

Chokeisin FULLposition.

2.

Blockageinfuel Itne.

3.

Stale fuel.

4.

Waterinfuel.

5. Carburetorisinneedof

adjustment

~7

omrhaul.

1.

Movechoke to OFF position.

2.

Cleanfuel line.

3.

Emptyfuel tank

&

carburetor, refillwlth fresh, clean

gasdr

4.

Emptyfuel tank

&

carburetor, refillwith freeh, cleang$$oIi~

5. Contact aSearsservicecenterldepartment.

ExtxmsIve

1.

Lomeparkordamaged

1.

Tighten allfasteners. Replacedamagdparts.

If

vibratiof

vlbtation

augerscrr impeller. remains, contacta Sears service center/department.

Recoilstarter

Lossof traction

drlve

/

slowing

of drive speed

1.

Frozenrecoilstarter.

1.

See "IF RECOILSTARTER

HAS

FROZENn

inthe Opefationsectionof

Ws

manual.

1.

Drivebeltisworn.

1.

Check

/

replacedrive belt.

2.

Drivebelt isoff of pulley.

2.

Check

/

reinstalldrive belt.

3.

Frictiondrivewheel isworn.

3.

Contact a Sears servicecenter/department.

Auger beltisoff of pulley.

1.

Check

/

reinstallauger belt.

Auger belt isworn.

2.

Check

/

replaceauger belt.

3.

Cloggeddischargechute.

3.

Clean snow chute.

Augers

/

impellerjammed.

4.

Removedebris or foreign objectfrom augers

/

impeller.