OPERATION

[A'WARNING] Risk of electric shock. Do not handle pump or

pump motor with wet hands or when standing on wet or damp

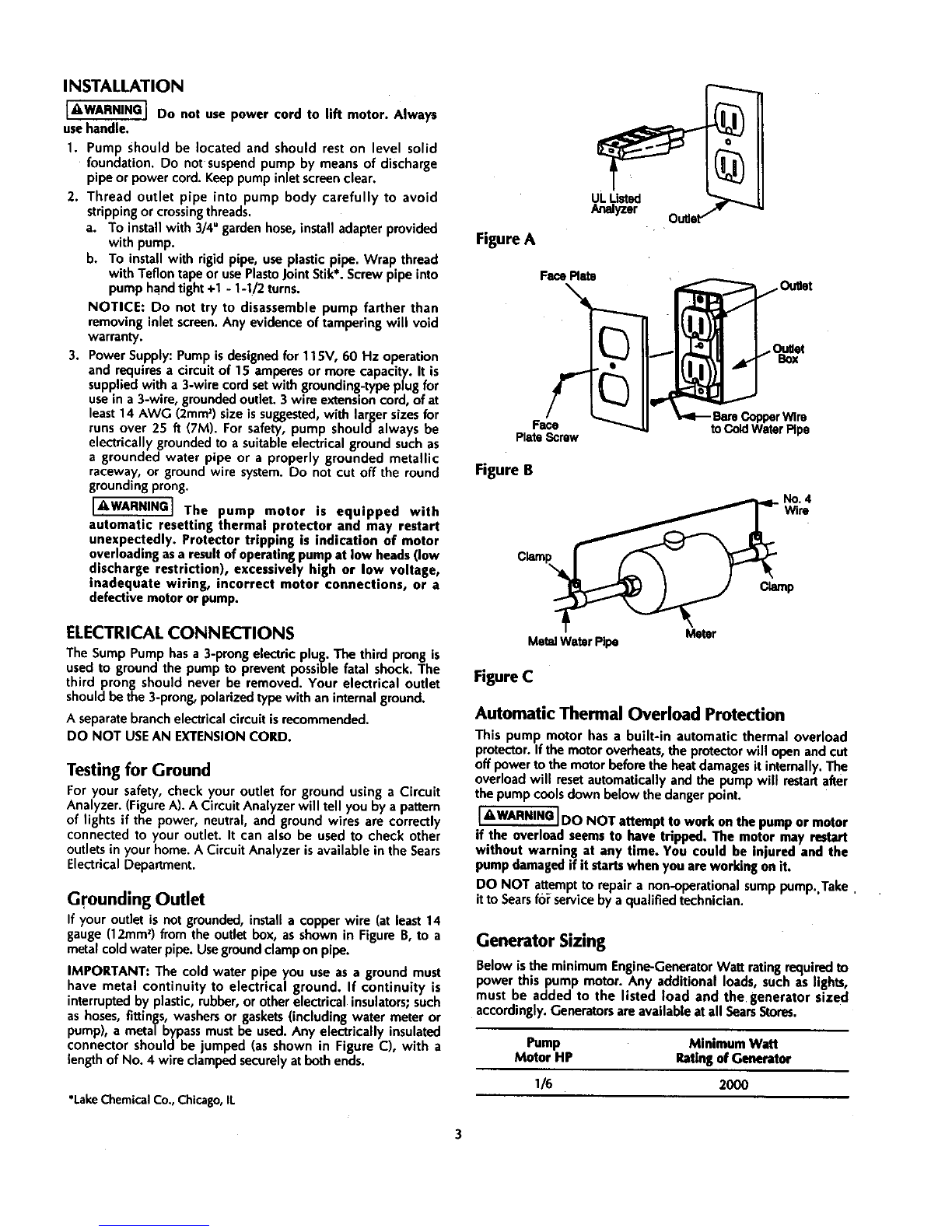

surface, or in water.

1. Shaft seal depends on water for lubrication. Do not operate

pomp unless it is in at least 1/2" (12.7mm) of water as seal

may be damaged if allowed to run dry.

2. Motor isequipped with automatic reset thermal protector. If

temperature in motor should rise unduly, switch will cut off

all power before damage can be done to motor. When

motor hascooled sufficiently, switch will reset automatically

and restartmotor. If protector trips repeatedly, pump should

be checked as to cause of difficulty. Low voltage, long

extension cords, clogged impeller, very low head or lift, etc.,

could causecycling.

3. Pump will pump water down to 3/16" (4.75mm); this means

that it will not remove all water. If unit has been operating

and suddenly no water comes out of discharge hose,shut off

unit immediately. Water level is probably very low and unit

has broken prime. Use mop or squeegee to remove

remaining water.

[_'WARNING] Risk of electric shock. Before attempting to

check why unit has stopped operating, disconnect power

from unit. Do not handle pump with wet hands or when

standing on wet or damp surfaces, or in water. Failure to

follow precaution can result in personal injury and/or

property damage.

Airlocks

When a pump airlocks, it runs but does not move any water. An

airlock will cause the pump to overheat and fail. This pump has

an anti-airlock hole in the bottom of the pump body. If you

suspectan airlock, unplug the pump, clean out the anti-airlock

hole with apaper clip or piece of wire, and restartpump.

IMPORTANT: This hole allows the pump to start priming within

15 seconds in as little as 1/2" of water. NEVER restart pump in

less than 1/2" of water. Leakage from the anti-airlock hole is

normal.

MAINTENANCE

Make certain that the pump is unplugged before attempting to

service or remove any componenL

1. The motor in the unit is sealed in oil. No additional

lubrication is necessary.

2. IMPORTANT: Disassembly of the motor assembly will void

the warranty. It might also cause internal leakage and

damage to the unit. If repairs are required, return the pump

to the dealer from whom it was purchased.

3. Inlet screen should be kept clean and free of all foreign

objects.

Pump Cleaning

NOTICE: Attempting to disassemble motor will void the

warranty.

1. Disconnect power cord from electrical outlet before working

on pump. The volute screen and shield may be removed to

replace impeller or clean pump of mud or debris.

SERVICE

General

[_'WARNING]Risk of electric shock. When servicing pump

always disconnect power to electrical outlet and remove pump

electric cord from outlet.

1. If pump does not operate:

a. Check for looseplug at electric outlet.

b. Check for blown fusesor tripped circuit breakers at fuse

box/circuit breaker box.

c. If a and b above check OK, plug in a light that you know

works. If it lights, take your pump to Searsfor service. If

it doesn't light, the electrical circuit is faulty; consult a

licensed electrician.

2. Pump starts,but blows fuses/tripscircuit breakers:

After disconnecting power to pump, remove the screen and

shield from the bottom of the pump and make sure that the

impeller turns freely. Remove any debris obstructing

impeller. If pump still does not operate correctly, return it to

your nearest SearsService Department for repairs.

3. Pump runs, but does not empty sump:

a. Clean pump intake screen.

b. Water may be entering sump faster than the pump can

discharge it.

c. Be sure vertical distance from pump discharge outlet to

discharge pipe outlet is 15 feet (4.5M) or less.

d. Be sure discharge pipe is not plugged or frozen.

e. Turn off pump for afew seconds, clean out anti-airlock

hole and restart pump.

Performance

Vertical Pumping Distance

3 FT. 5 FT 10 FT 15 FT 20 FT

GPH 1,320 1,250 930 660

Vertical Pumping Distance

0,9M I ,SM 3,0M 4,5M 6,0M

LPH 4995 4730 3520 2495 0

Maximum load amps: 4.4 Amps

Repair Parts - Model 572.826130

Part No. Description Qty.

PS17-54 Power cord 1

FT0013-43 Garden Hose Adapter 1

PSS-24P Impeller 1

PS8-5P Screen 1

PS70-3P Shield 1

F642-9202 Owner's Manual 1

4