107-B00 Page 10/16

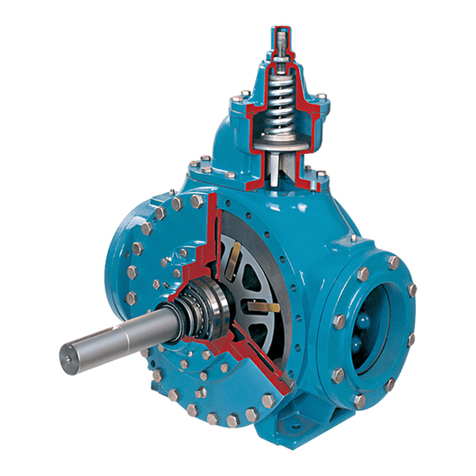

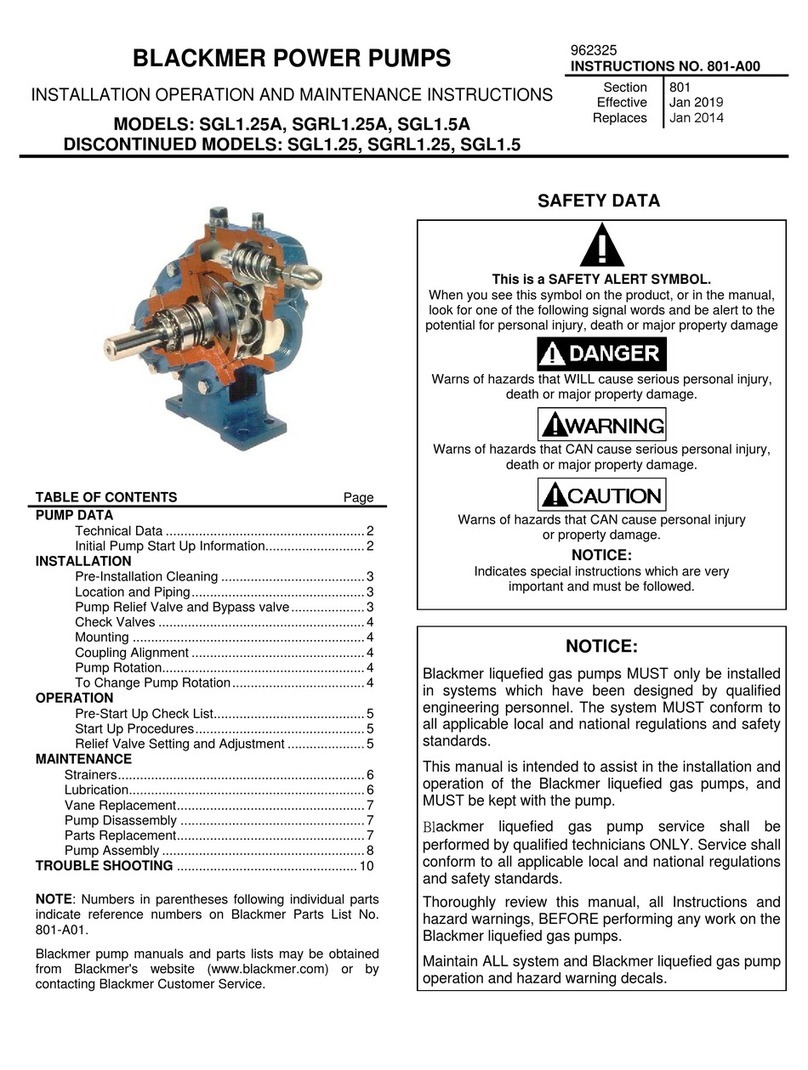

f. Position the disc relief hole so that when the head is

mounted on the pump with the “Blackmer” name in

an upright position, the disc hole will be towards the

INTAKE side of the pump. See Figure 7.

g. Install the disc machine screws (71A) and

lockwashers (71B).

Figure 7 – Disc Relief Hole Location (4-inch Models)

10. Install a new head O-ring (72) in the groove on the inside

face of the head. Lay the O-ring flat and start in on one

side of the groove, stretching ahead with the fingers, as

shown in Figure 7.

Figure 7 – Head O-Ring Installation

11. Carefully install the head assembly (20) over the shaft.

Do not contact the end of the shaft with the mechanical

seal. Position the head with the small weep hole towards

the bottom of the pump. Install and partially tighten four

head capscrews (21) 90° apart. The remaining capscrews

will be installed in step 18.

On 4-inch models, make sure the head is mounted with

the “Blackmer” name upright and the disc relief hole

towards the intake side of the pump. The seal jacket drive

tangs must be engaged in the rotor slots.

12. Hand pack the ball bearing (24) with grease. Refer to the

"Lubrication" section for the recommended grease.

13. Install the bearing into the head recess. The bearing balls

should face outward, with the grease shield (ref. 123, 2”

models only) inward. The bearing must be fully and

squarely seated in the head.

14. Turn the pump casing around and remove the outboard

head and disc previously installed.

15. Install the mechanical seal and disc in the outboard head

as instructed in steps 7 through 8 for the 2 and 3-inch

models or step 9 for the 4-inch models.

16. Finish assembling the outboard side of the pump as

instructed in steps 10 through 13.

17. Rotate the shaft by hand to engage the mechanical seal

drive tangs, and to test for binding or tight spots. If the

rotor does not turn freely, lightly tap the rims of the heads

with a soft faced mallet until the correct position is found.

18. Install and partially tighten the remaining head capscrews

19. Uniformly torque the head capscrews to 30 lbs ft (40.7

Nm), alternating between one side of the head and the

other. Frequently check that the shaft still turns freely. If

tight, loosen the capscrews and repeat the procedure. If

the shaft continues to bind, check for grease or dirt on the

mechanical seal faces.

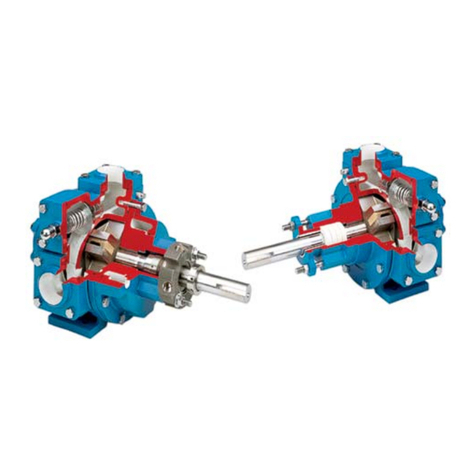

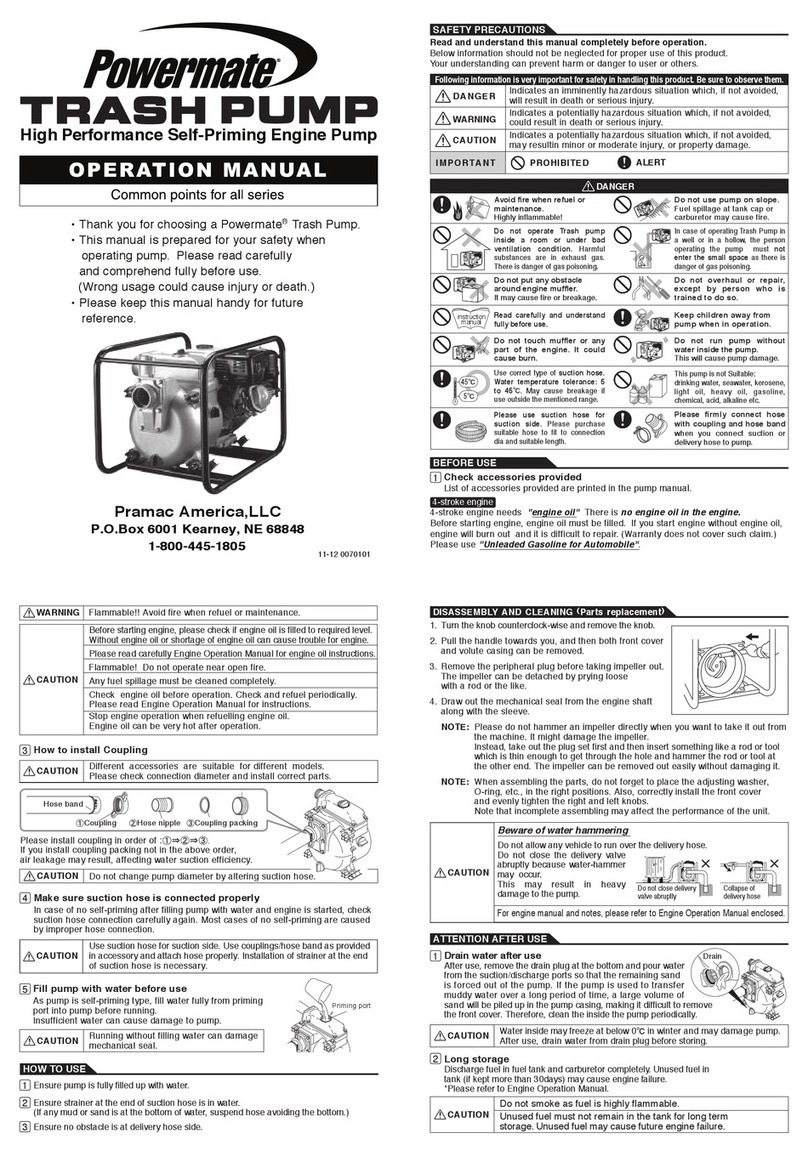

Figure 8 – Locknut Assembly

20. LOCKNUT ADJUSTMENT

It is important that the bearing locknuts (24A) and

lockwashers (24B) be installed and adjusted properly.

Overtightening locknuts can cause bearing failure or a

broken lockwasher tang. Loose locknuts will allow the

rotor to shift against the discs, causing wear. See Fig. 8.

a. On both ends of the pump shaft, install a lockwasher

(24B) with the tangs facing outward, followed by a

locknut (24A) with the tapered end inward. Ensure the

inner tang "A" of the lockwasher is located in the slot

in the shaft threads, bending it slightly, if necessary.

b. Tighten both locknuts to ensure that the bearings are

bottomed in the head recess. DO NOT overtighten

and bend or shear the lockwasher inner tang.

c. Loosen both locknuts one complete turn.

d. Tighten one locknut until a slight rotor drag is felt

when turning the shaft by hand.

e. Back off the nut the width of one lockwasher tang "B".

Secure the nut by bending the closest aligned

lockwasher tang into the slot in the locknut. The pump

should turn freely when rotated by hand.

f. Tighten the opposite locknut by hand until it is snug

against the bearing. Then, using a spanner wrench,

tighten the nut the width of one lockwasher tang “B”.

Tighten just past the desired tang, then back off the

nut to align the tang with the locknut slot. Secure the

nut by bending the aligned lockwasher tang into the

slot in the locknut. The pump should continue to turn

freely when rotated by hand.

g. To check adjustment, grasp the nut and washer with

fingers and rotate back and forth. If this cannot be

done, one or both locknuts are too tight and should be

alternately loosened one stop at a time 0.001"

(0.025mm). Begin by loosening the locknut adjusted

last.

21. Inspect the grease seal (104) for wear or damage and

replace as required. Grease the outside diameter of the

grease seal and push it into the inboard bearing cover

(27A) with the lip of the seal inward (towards the pump).

22. Attach a new bearing cover gasket (26) and the inboard

bearing cover (27A) to the inboard head. Install the

outboard bearing cover (27) and a new gasket to the

outboard head. Make sure the grease fittings (76) on the

bearing covers are accessible. Install and torque the

bearing cover capscrews (28) to 30 lbs ft (40.7 Nm).