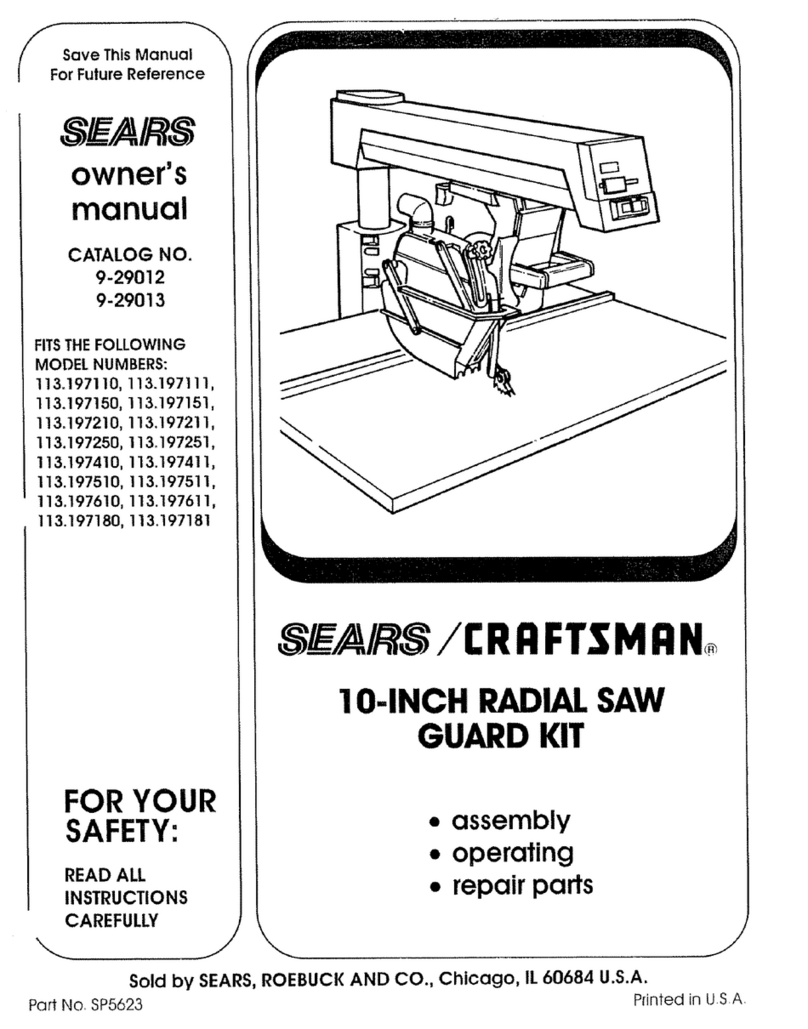

Instructions for Assembling

Un©rafing

Your C_man Bu_der's Saw is shipped complete

(less motor) in one crate, with a carton for miscellaneous

parts inside the crate. Remove nails around sides 'at

bottom d crate. The top and sldes can then be lihed

off. Remove bol_ in legs from bottom of the crate

and lift saw off. h_tructlous for removing are also

printed on the crate. The carton between the legs cou-

talns the rip fence, lah-hand miter, right-hand miter,

saw guard_ splitter, dust bag, switch, pulleys and bdu,

and an envdope with the necessary small parts such as

nu_, etc., needed for assembly.

Assembly

Your Builder's Saw has been assembled, operated,

and inspected at the factory. The saw carriage has been

fastened securely for shipment. There is a pin attached

with a chain to the leh-hand side dthe carriage that

locks the carriage for ripping and dado purpeees at

three points. The carriage Is now locked and fastened.

Open side door removing pin and fastening, so car-

riage can be moved. Mount your motor on the motor

support plate with the motor shah and saw spindle

lined up so that the saw is turning TOWARD the

operator. We have supplied slots in the motor support

plate that will accommodate the holes in most motor

bases. However if they do not fit your motor base,

use the ones that do agree and drill any others that

are necessary° For efficient operation use a 3450 R.PoM.

motor of not less than _ HiP. Any difference in the_

R.P.M. of your motor can be taken care of by usingr

different slz_ of pulleys in accordance with the fol-

lowing table:

Saw Spin_© Motor Motor Appl_ox.

Dia. PuUcy PuUcy R.P,M. Spin.g.P.M.

82V2 3gz 3450 48O0

8 2½ 6_ 1750 48O0

10 2V2 3 3450 4200

I0 2_/2 6 1750 42O0

-- --- 7

SRW

Travel

17Y2

17Yz

15½

15½

2¼

2¼

3¼

3¼

Motor should have a _/_-inch shaft with a 3/16-inch key-

way. After mounting the motor, fasten the 3-inch or

doublesheavepulleyson themotor shaftand puton the

two brits.Ifthebritsfurnishedarenotthe fightlength

you can probablyget the lengthyou need at your

nearest Sears Retail or Mail Order Store. Length of

belt is determined by measuring over the OUTSIDE

diameter of the pulley after iustallation. An adjustment

for tightening brits will be found at the rear of the

motor support plate. Do not have the balls too tight.

The switch is mounted withtwo screws to the front

panel. The following data should be followed for de.

retraining the size of wire recommended for the proper

operation d motor:

MOTOR

H.P.

1

1

1½

MOTOR

VOLTAGE

115

230

115

230

115

230

D]STANCE FROM OUTLET

TO MOTOR

50-feet

No. 14

No. 14

No. 14

No. 14

No. 12.

No. 14

100-f_ 150-feet

No. 12 No. 10

No, 14, No. 14

No. I0 No. 8

No. 14 No. 12

No. 8 No. 6

No. 14 No. 12

and Operatin8 Your Saw

Bolt the splitter angle bracket part No. 7027 to the rear

of the dust chute. Drop the splitter blade, with handl_

over the saw, through the saw slot in the top of the

table. Bolt it with the splitter retaining plate part No.

7125 to the angle bracket part No. 7027. The splitter

blade must be directly in llne with the saw blade. Bolt

guard to the spliRerblade.

The six-inch hand wheel at the front will raise and

lowerthe entire assembly, consisting of saw blade, split°

ter, guard, and handle, to the required height above the

table. The guard should not be more than _ inch

above the work passing _gh saw blade.

The fence guide bar part No. 7121 should be checked

to be sure it has not ja_ed out of llne in shipment. If

so,line up paralidwiththe tabletop and tightenthe

sk mounting screws. For attaching the rip _ence to the

table top, pull out on the small pinion gear knob No.

7235, and slide the fence overthe gmda bar. The fence

may now be moved back and forth by hand. For fin_

adjus_nent engage the piniongear with fence guide bar

by pushing in the knob. The fence can be locked _ront

and back by pushing down on lever No. 7239. If clamp-

ing action is not as tight as desired it may be adjusted

by the jam nuts on the rear end of the tie rod that

runs through the complete fence.

Cumin9 Capa¢i

The depth of cut is controlled by raising and lower-

ing the saw blade using the hand wheel located on

the front panel. The saw can be set to cut thicknesses

from "0" to 3¼ inches. The maximum saw carriage

t_avd is 15_ inches.

Lubrication

Greesin_

The spindle bearings are lubricated at the [ac_

and will' give you approximately 1000 hours of use be-

fore they need to be lubricated. In the housing

the spindlebearings there is a Zerk type fitting which

may be reached from the lab-hand door. Use a ha_

type grease gun, with any high-pressure chassis gun

grease. Do not PACK bearings.

Oi|in_

The followlng parts should be oiled frequently with

No. 20 or No. 30 _utomobile engine oil:

1. Saw raising screw and _,

2. The miter gear sha_ part No. 7063.

3. The hexagon sha_ part No. 7045.

4. Oil poin_ where there is f_ic_io_

between two ormore moving sm_ces

or when a slipfitisnec_sary such

as where the fence _lidas, etc.

To preventsaw table and saw from _th_g, keep

them covered with a film of oll when not in we a_

wipe off before using.

5