8

D-3.3) Pump-Down Test:

After the pump has been properly wired and lowered into the

basin, sump or lift station, it is advisable to check the system

by filling with liquid and allowing the pump to operate through

its pumping cycle. The time needed to empty the system, or

pump-down time along with the volume of water, should be

recorded on the start-up report.

SECTION E: PREVENTATIVE MAINTENANCE

As the motor is oil filled, no lubrication or other maintenance

is required, and generally Barnes Pumps will give very

reliable service and can be expected to operate for years on

normal sewage pumping without failing. However as with any

mechanical piece of equipment a preventive maintenance

program is recommended and suggested to include the

following checks:

1) Inspect motor chamber for oil level and contamination and

repair as required per section F-1.

2) Inspect impeller and body for excessive build-up or

clogging and repair as required per section F-2.

3) Inspect motor, bearings and shaft seal for wear or leakage,

replace as required per section F-3.

SECTION F: SERVICE AND REPAIR

NOTE: All item numbers in ( ) refer to Figures 9 & 10,

3450RPM and Figures 11 & 12 , 1750RPM.

F-1) Lubrication:

Anytime the pump is removed from operation the cooling oil

in the motor housing (2) must be checked visually for oil level

and contamination.

F-1.1) Checking Oil:

Motor Housing - To check oil, set unit upright. Remove cap

screws (6) and lockwashers (4), lift conduit box assembly (10)

from motor housing (2) but DO NOT disconnect conduit box

wiring from motor leads. With a flashlight, visually inspect the

oil in the motor housing (2) to make sure it is clean, clear and

that oil level is above all internal componentry.

F-1.2) Testing Oil:

1. Place pump on it’s side, remove cap screws (6) and

lockwashers (4), lift conduit box assembly (10) from motor

housing (2) and drain oil into a clean, dry container.

2. Check oil for contamination using an oil tester with a range

to 30 Kilovolts breakdown.

3. If oil is found to be clean and uncontaminated (measure

above 15 KV. breakdown), refill the motor housing as per

section F-1.3.

4. If oil is found to be dirty or contaminated (or measures

below 15 KV. breakdown), the the pump must be carefully

inspected for leaks at the shaft seal (46), conduit box

assembly (10), O-rings (11) and (42) pipe plug (5) before

refilling with oil. To locate the leak, perform a pressure

test as per section F-1.4. After leak is repaired, refill with

new oil as per section F-1.3.

F-1.3) Replacing Oil:

Motor Housing - Drain all oil from motor housing and dispose

of properly. Refill with (see parts list for amount) new cooling

oil as per Table 1. An air space must remain in the top of

the motor housing to compensate for oil expansion (see

Fig. 9 or 11). Set unit upright and fill only until the motor,

as viewed through the conduit box opening, is just covered

and no more. Reassemble the O-ring (11), conduit box

assembly (10), cap screws (6) and lockwashers (4), apply

thread locking compound to each cap screw (6) thread before

installing. Torque cap screws (6) to 15 ft, lb.

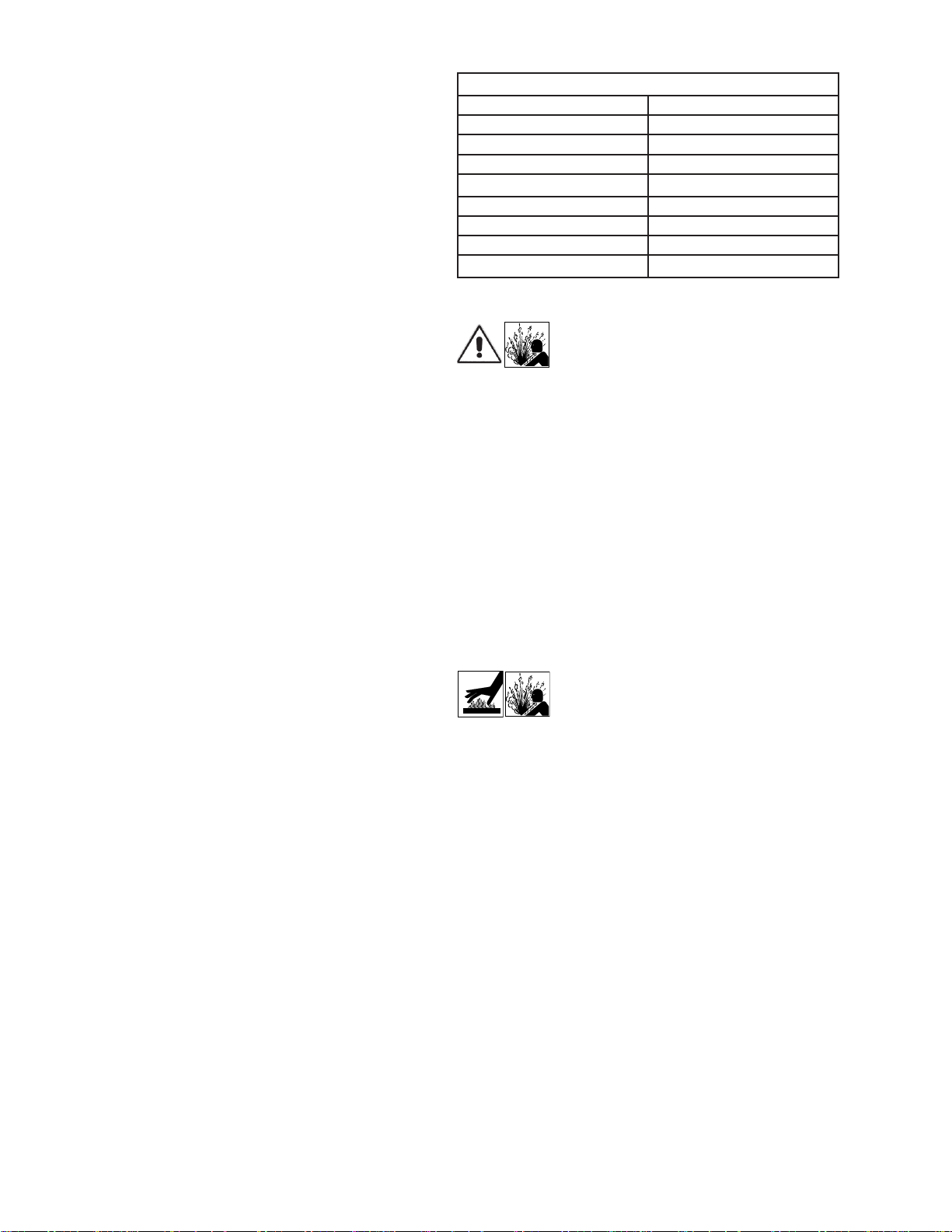

TABLE 1 - COOLING OIL - Dielectric

SUPPLIER GRADE

BP Enerpar SE100

Conoco Pale Paraffin 22

Mobile D.T.E. Oil Light

G & G Oil Circulating 22

Imperial Oil Voltesso-35

Shell Canada Transformer-10

Texaco Diala-Oil-AX

Woco Premium 100

Important! - Do not overfill oil. Overfilling

of motor housing with oil can create

excessive and dangerous hydraulic

pressure which can destroy the pump

and create a hazard. Overfilling oil voids

warranty.

F-1.4) Pressure Test:

Motor Housing - Before checking the pump for leaks around

the shaft seal, o-rings, and cord inlet, the oil level should be

full as described in section F-1.3. Remove pipe plug (5) and

lifting handle (7) from motor housing (2). Apply pipe sealant

to pressure gauge assembly and tighten into pipe plug hole

(see Figure 2). Pressurize motor housing to 10 P.S.I. Use a

soap solution around the sealed areas and inspect joints for

“air bubbles”. If, after five minutes, the pressure is still holding

constant, and no “bubbles” are observed, slowly bleed the

pressure and remove the gauge assembly. Replace the pipe

plug using a sealant. If the pressure does not hold, then the

leak must be located.

Caution! - Pressure builds up extremely

fast, increase pressure by “tapping” air

nozzle. Too much pressure will damage

seal. Do Not exceed 10 P.S.I. in motor

housing.

F-2) Impeller and Volute Service:

F-2.1) Disassembly and Inspection:

To clean out volute (26), disconnect power, remove hex

nuts (20) and lockwashers (19), vertically lift motor and seal

assembly from volute (26). Clean out body if necessary.

Clean and examine impeller (28) for pitting or wear, replace

if required. Inspect square ring (42) and replace if cut or

damaged. If impeller (28) requires replacing, remove jam

nut (34) and washer (35), by placing a flat screwdriver in the

slot of the end of the shaft to hold the shaft stationary while

unscrewing the impeller (28). Once impeller (28) is removed,

remove pull washer (16) and exclusion seal (17) if damaged

or cut.

F-2.2) Reassembly:

Position exclusion seal (17) on shaft until it seats against the

stationary portion of seal (46). Place pull washer (16) on shaft

until it seats against exclusion seal (17). To install impeller

(28), clean the threads with loctite cleaner and screw impeller

(28) onto the shaft hand tight. Apply thread locking compound

to shaft threads and install washer (35) and jam nut (34).

Torque to 40 ft. lbs. Rotate impeller to check for binding.

Position o-ring (42) on volute flange and position impeller

and motor housing assembly over studs and onto volute (26).