3

GENERAL INFORMATION

To The Purchaser:

Congratulations! You are the owner of one of the finest

pumps on the market today. These pumps are products

engineered and manufactured of high quality components.

With years of pump building experience along with a con-

tinuing quality assurance program combine to produce a

pump which will stand up to the toughest applications.

Check local codes and requirements before installation.

Servicing should be performed by knowledgeable pump

service contractors or authorized service stations.

Receiving:

Upon receiving the pump, it should be inspected for dam-

age or shortages. If damage has occurred, file a claim

immediately with the company that delivered the pump.

If the manual is removed from the crating, do not lose or

misplace.

Storage:

Short Term - Pumps are manufactured for efficient

performance following long inoperative periods in storage.

For best results, pumps can be retained in storage, as

factory assembled, in a dry atmosphere with constant

temperatures for up to six (6) months.

Long Term - Any length of time exceeding six (6) months,

but not more than twenty four (24) months. The units

should be stored in a temperature controlled area, a roofed

over walled enclosure that provides protection from the

elements (rain, snow, wind blown dust, etc..), and whose

temperature can be maintained between +40 deg. F and

+120 deg. F. Pump should be stored in its original shipping

container and before initial start up, rotate impeller by hand

to assure seal and impeller rotate freely.

Service Centers:

For the location of the nearest Weinman Service Center,

check your Weinman representative or Crane Pumps &

Systems, Inc., Service Department in Piqua, Ohio, telephone

(937) 778-8947 or Crane Pumps & Systems Canada, Inc.,

Bramton, Ontario, (905) 457-6223.

INSTALLATION

FOUNDATION

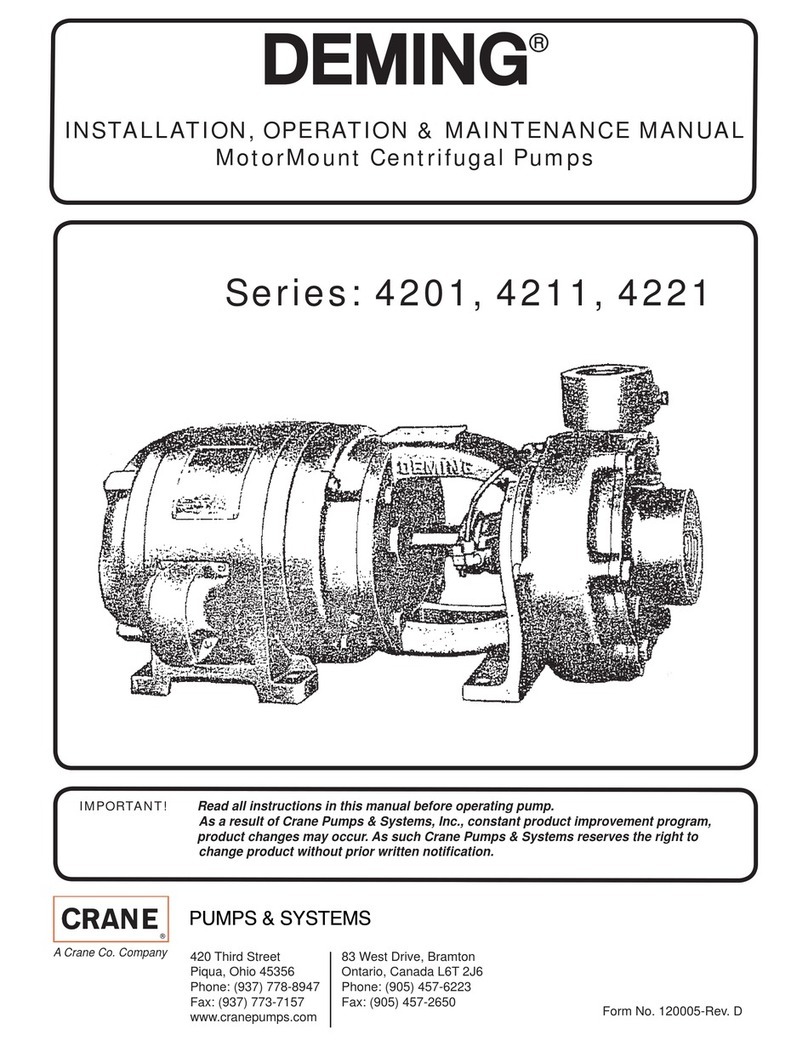

Weinman Motor-Mount Pumps can be installed on any

sufficientlysolidfoundationsincepumpand motor are rigidly

aligned. The unit may be installed on a concrete foundation

with anchor bolts set in place or securely mounted on a wall

in either a horizontal or vertical position with motor above

pump. The pump should be located as near the source

of supply as possible with a minimum of suction pipe and

elbows.

PIPING

A foot valve and strainer must be installed on the lower end

of the suction pipe to keep pump completely filled with liquid

whenthepump isusedunder suctionliftconditions.Connect

suction pipe to pump, making certain that all connections

are airtight. When a foot valve and a strainer are used, it is

necessary to install a check valve in the discharge line near

the pump to prevent possible casing damage due to line

shock or surge when the pump stops. A gate valve should

also be installed in the discharge line. Connect discharge

pipe to pump casing.

It is important that the suction and discharge pipes “line up”

naturally with the pump. Do not “pull” pipes into position

with flange bolts or fittings. Support pipes independently of

the pump to eliminate any strain on the pump. Turn shaft to

see that it rotates freely. If rotor binds, it indicates a strain on

the casing, which must be corrected before operating pump.

It may be necessary to shim motor at foundation to assist

piping connection line-up.

WIRING/ROTATION

Check motor name plate for electrical characteristics. Be

sure they are the same as the rating of the electric power

available. Connect power lines to motor in accordance with

the wiring diagram on the motor. Test rotation by jogging

motor. Shaft must rotate in the direction indicated by arrow

cast on pump casing.

OPERATION

PRIOR TO STARTING

Be sure the following important items are checked before

starting.

1. Pump and driver bolted securely.

2. Piping complete.

3. Motor properly lubricated. Follow the recommendations

found in the Maintenance Section of this manual.

4. Open the seal flush valve, if used.

5. Shaft turns freely.

6. Rotation is correct. The pump must rotate in the

direction of the arrow on the casing.

7. Discharge valve. A high or medium head centrifugal

pump operating at full speed with the discharge valve

closed, requires much less power than when operating

at its rated head and capacity with the discharge valve

open. For this reason, it is usually best to have the

discharge valve only partially open when starting the

pump.

WARNING !

Operating the pump with a closed or partially open

discharge valve can result in excessive heat buildup.

Such operation should be limited to the shortest

practical duration. Operating the pump at or near shut-

off head places greater loads on the shaft and motor

than operation at the designed flow rate and head,

8. Suction valve, if used, must be fully open. Do not use

suction valve as a throttling device