Craycle Hobby Ranger Sport User manual

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

www.craycle.com

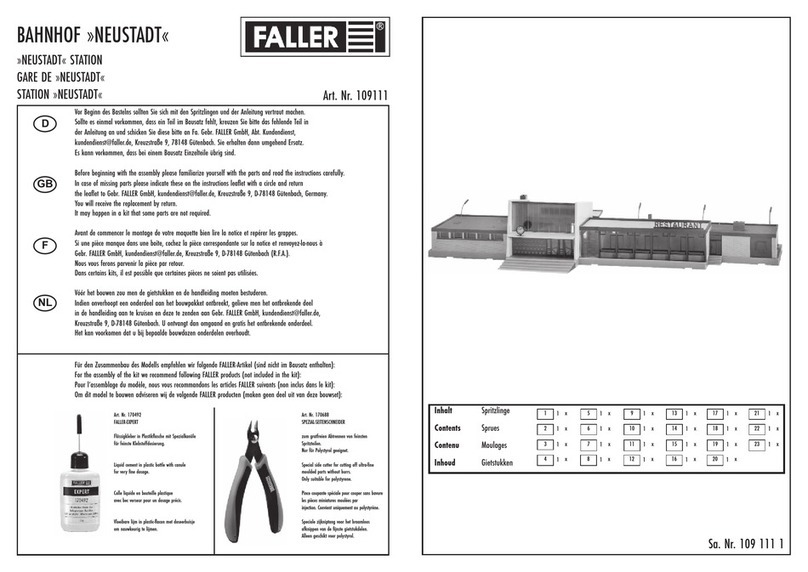

Ranger Sport

User Guide

Model Designed By: Cemal ÖZÇELİK

Model Version: 2.0

Release Date: 18.10.2022

Recommended Setup

Motor

Propeller

ESC

Servo

Battery

Analog/DJI/Vista FPV systems

: 2204/5/6 1500/2500 kv

: 5” - 2/3/4 Blade

: 15-30A

: 4 X 9 g

: 3s 850-2500 mAh

General Specifications

Length

Wingspan

Print Weight

Flying Weight

Wing Area

Wing Loading

Airfoil

23.4 inches

31.5 inches

11 oz.

17.6-22.9 oz.

: 575 mm

: 800 mm

: 311 g

: 500-650 g

: 11.1 dm2

: 49,4 g/dm2

: NACA 2412

Maker Skill

Pilot Skill

150*150*180 mm

Min. Printer Size

PLA - PetG - TPU

Filament

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Equipments

www.craycle.com

Optional EquipmentsNecessary Equipments

• Minimum 3ch Transmitter and Receiver.

• 2205 2300Kv Motor.

• 30A ESC.

• 4pcs 9grams Servo.

• 1500mAh 3S Lipo.

• 5” Propeller - 3 or 2 Blade.

• Medium CA Glue.

• Y cable for Aileron servos.

• 2pcs 2 mm screws for Motor mounting.

• M4x20 Imbus bolt and m4 nut for wing.

• Ø4x250 mm Carbon Rod.

• 2pcs 400, 2pcs 100xØ1,2mm Pushrods.

• PLA - TPU - PetG Filaments.

• Lazer Blade to clear printed parts.

• Adjustable Pushrod connectors.

• Strong Pliers to prepare landing gear.

• Z bend tool.

• Wheel Stoppers.

• Aileron Angle Meter

• Servo Tester.

• Servo Plug Connectors.

• Screw Driver set.

• Sprey Paint.

• Fiber Tape for leading edge of wings.

• Model stand.

• Lipo Bag.

• Lipo Alarm.

• Digital or Analog FPV System.

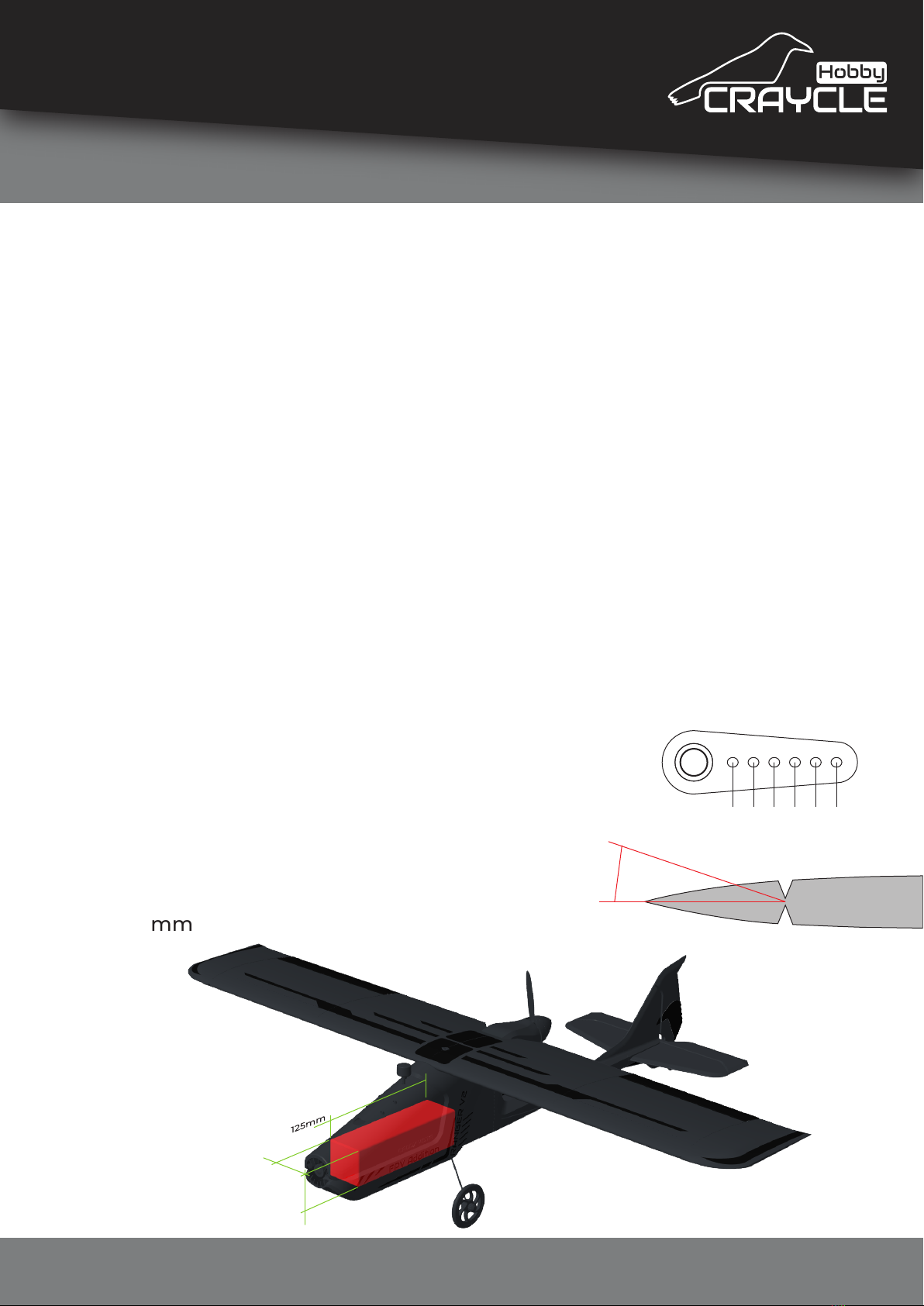

CG position

34,5mm from the Leading Edge. Middle of the filament tunnel.

Pushrods

You can use 1, 1.2 or 1.3mm spring wire or piano wire as well.

Ailerons: 100mm / Elevator: 400mm / Rudder: 400mm

Servo Horn Connection Holes ->

Ailerons: 5. hole / Elevator: 3. hole / Rudder: 3. hole

Flap Movements (X)

Ailerons: 9mm / Elevator: 13mm / Rudder: 6mm

Lipo House Dimensions

42x42x125mm

1 2 3 4 5 6

x

42mm

42mm

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

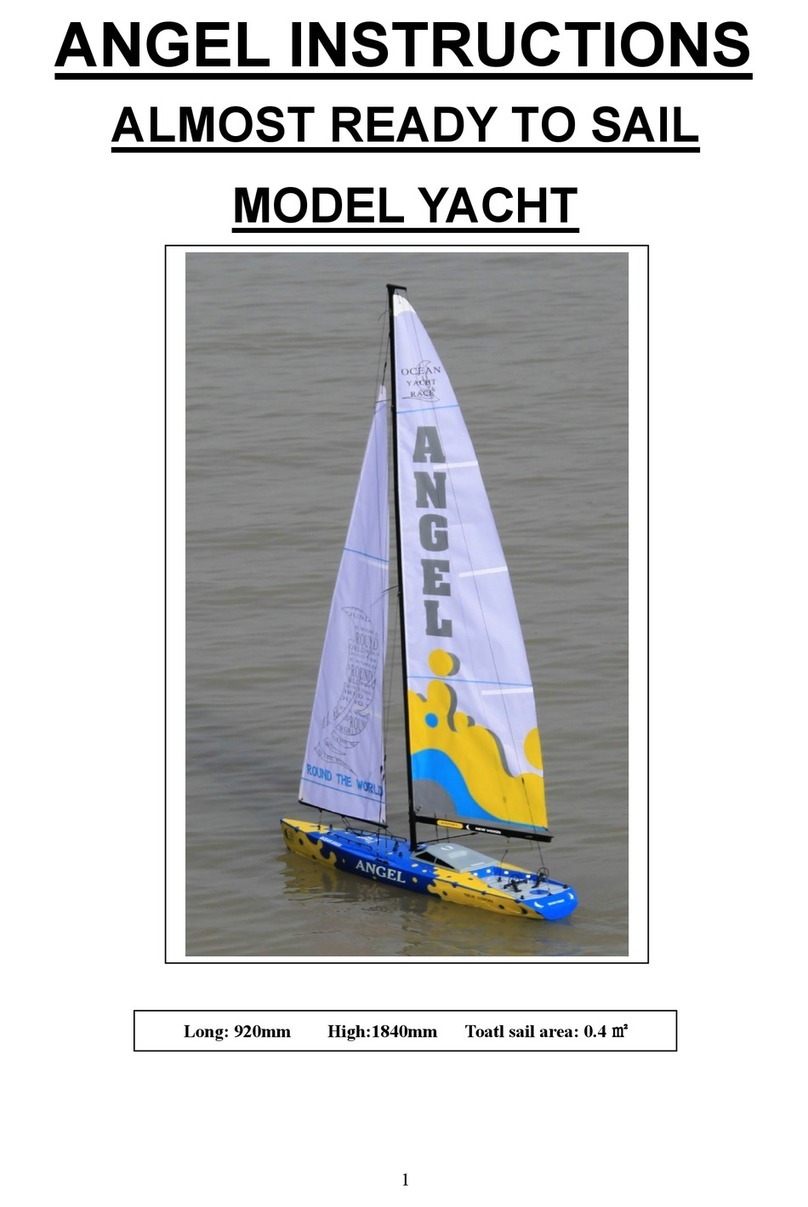

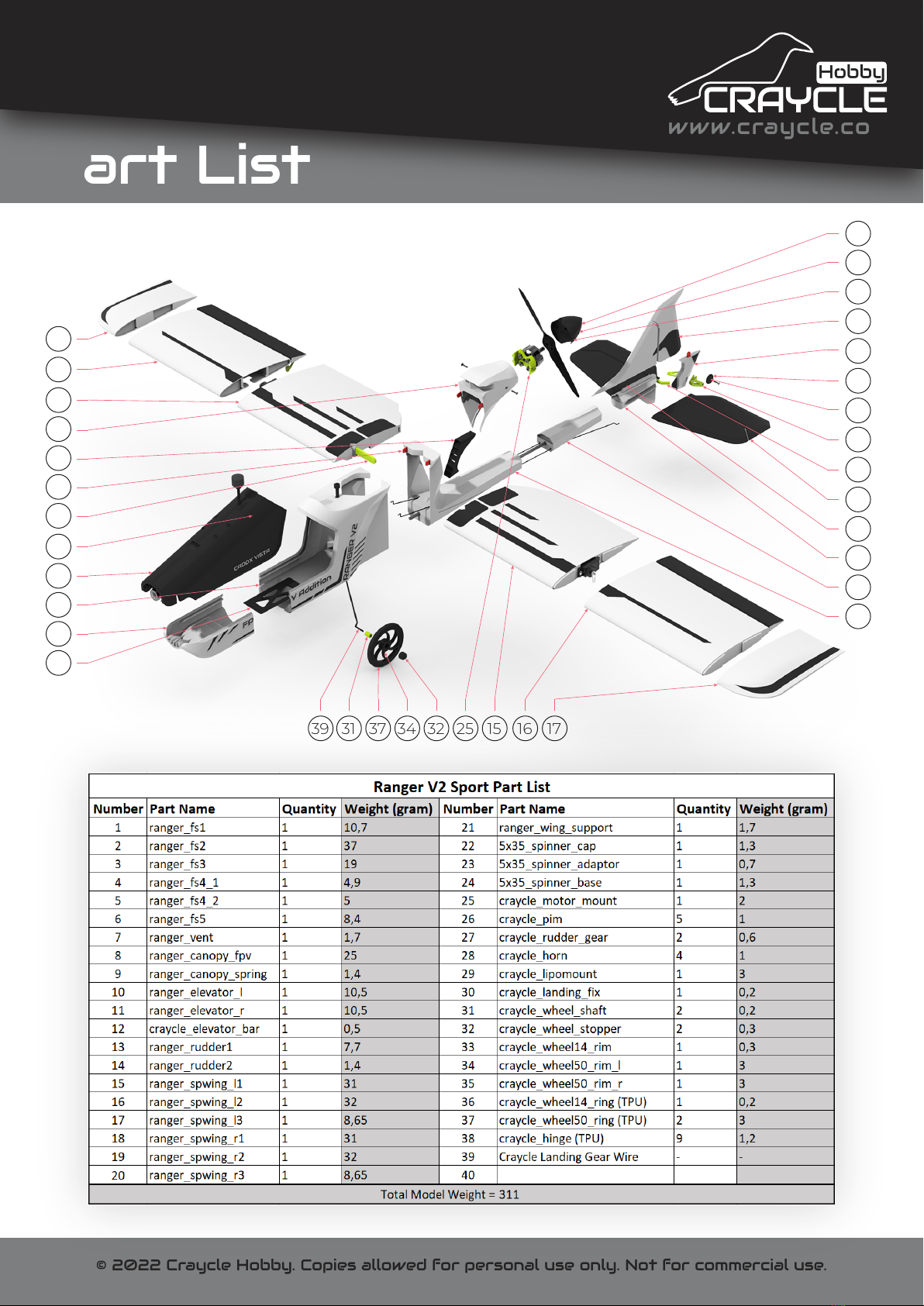

Part List

www.craycle.com

20

19

18

6

7

21

26

8

9

2

1

29

22

23

24

13

36

12

10

33

14

27

11

4

5

3

3139 37 34 32 25 15 16 17

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

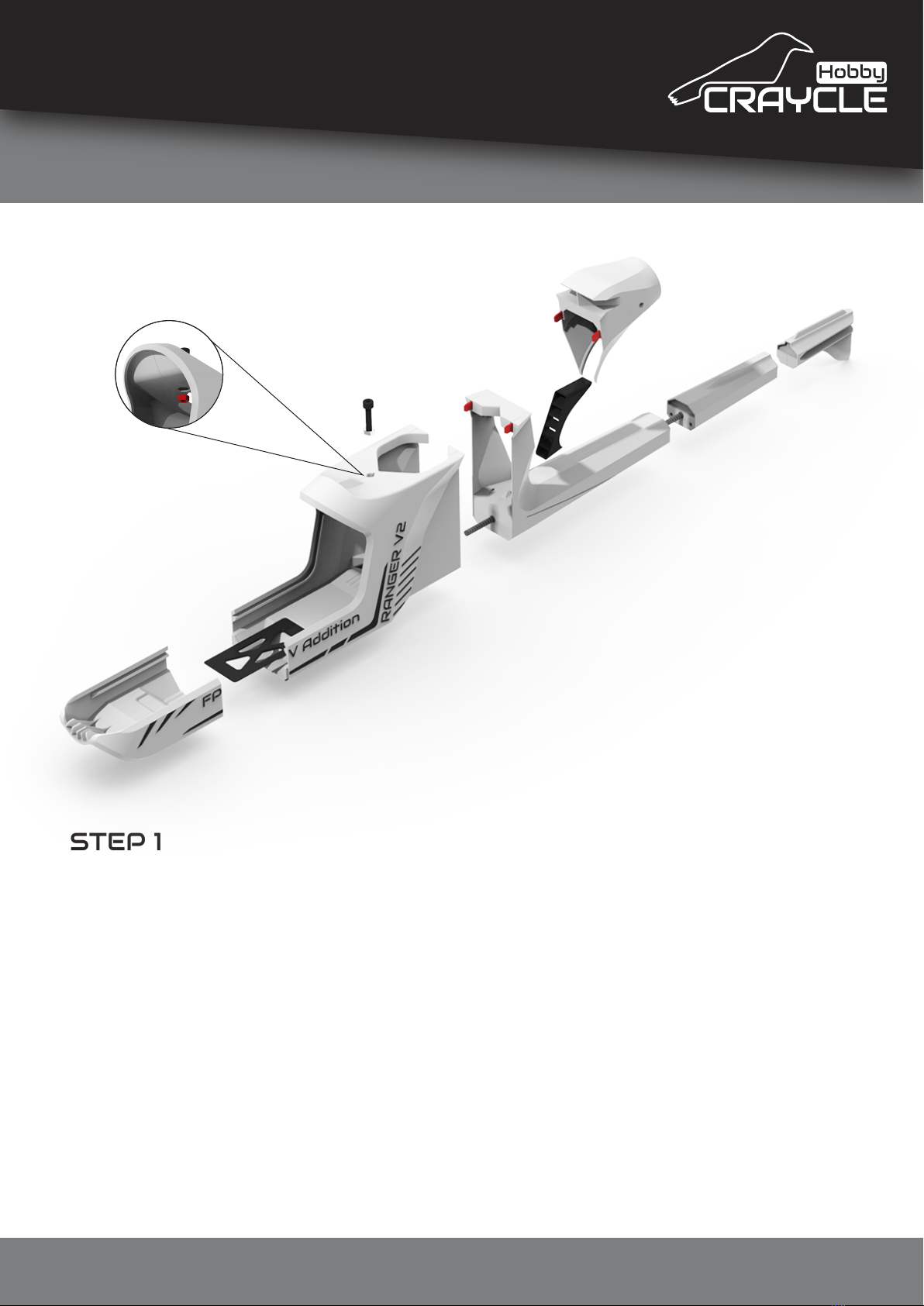

STEP 1

1) Glue the “fs3”, “fs5” parts together by inserting the “pim”

parts and then glue the “vent” part into its place.

2) Glue the m4 nut into its slot on the “fs2” and then glue the

“fs2” part to the FS3 by inserting the “pim” and Ø4x250 mm

carbon rod into its slots.

3) Glue the rest FS1, FS4_1 and FS4_2 parts together and than

glue the Lipo Mount part into its slot.

Never spray the accelerator directly onto the CA glue! Spray

onto the first part and then wait for 15 seconds to dry it. Then

you can apply glue onto the other part and put the parts

together for 5 seconds. Avoid excessive usage of glue.

1

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

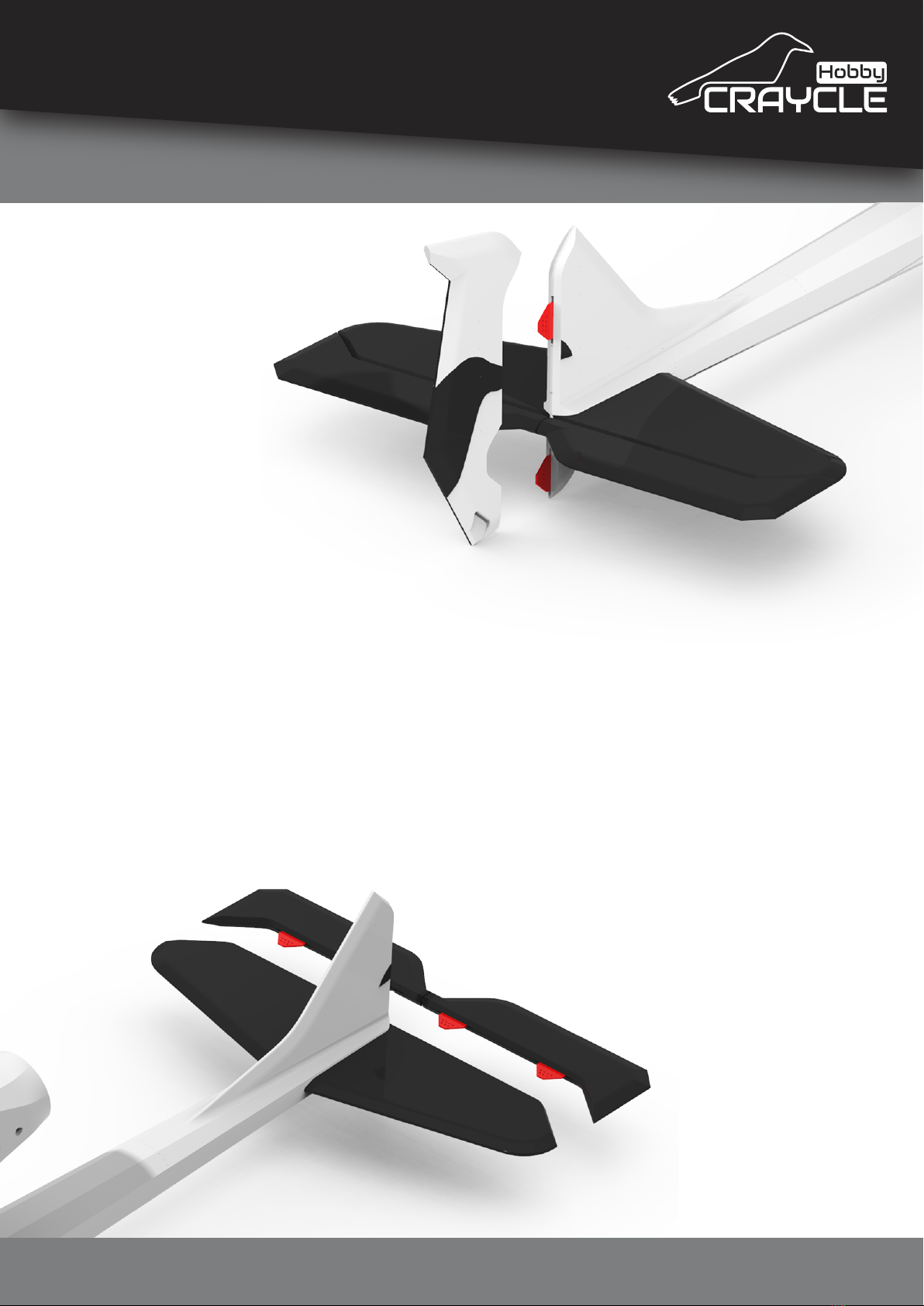

STEP 2

Glue the “rudder1” and “rudder2” parts together by

inserting the “pim”.

Glue the rudder part onto its slot on the fuselage and

breake the rudder section from its tiny connections.

Glue the “elevator_l” and “elevator_r” parts onto its

slot on the fuselage and glue the “elevator_bar” part

into its slot on the elevator. And then brake the

elevator flap from its tiny connections.

Now we are ready to install TPU hinges. You can

print “hinge” model with TPU filament or you

can build CA hinges by using CA Hinge Maker

Tool which is free on craycle.com .

Be careful using CA accelerator and

avoid to sprey onto the

Hinge Slots.

2

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 3

Reassemble and glue the Elevator using TPU or CA hinges that

you prepared and then glue the Rudder carefully into its hinge

slots.

Note: The CA accelerator sprayed to stick the elevator and

rudder parts may have contaminated the hinge slots! Take

your time, apply the glue onto the hinges in order and insert

into the hinge slots on the flaps first. (Rudder image is wrong,

elevator image is the true way to gluing hinges.)

3

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

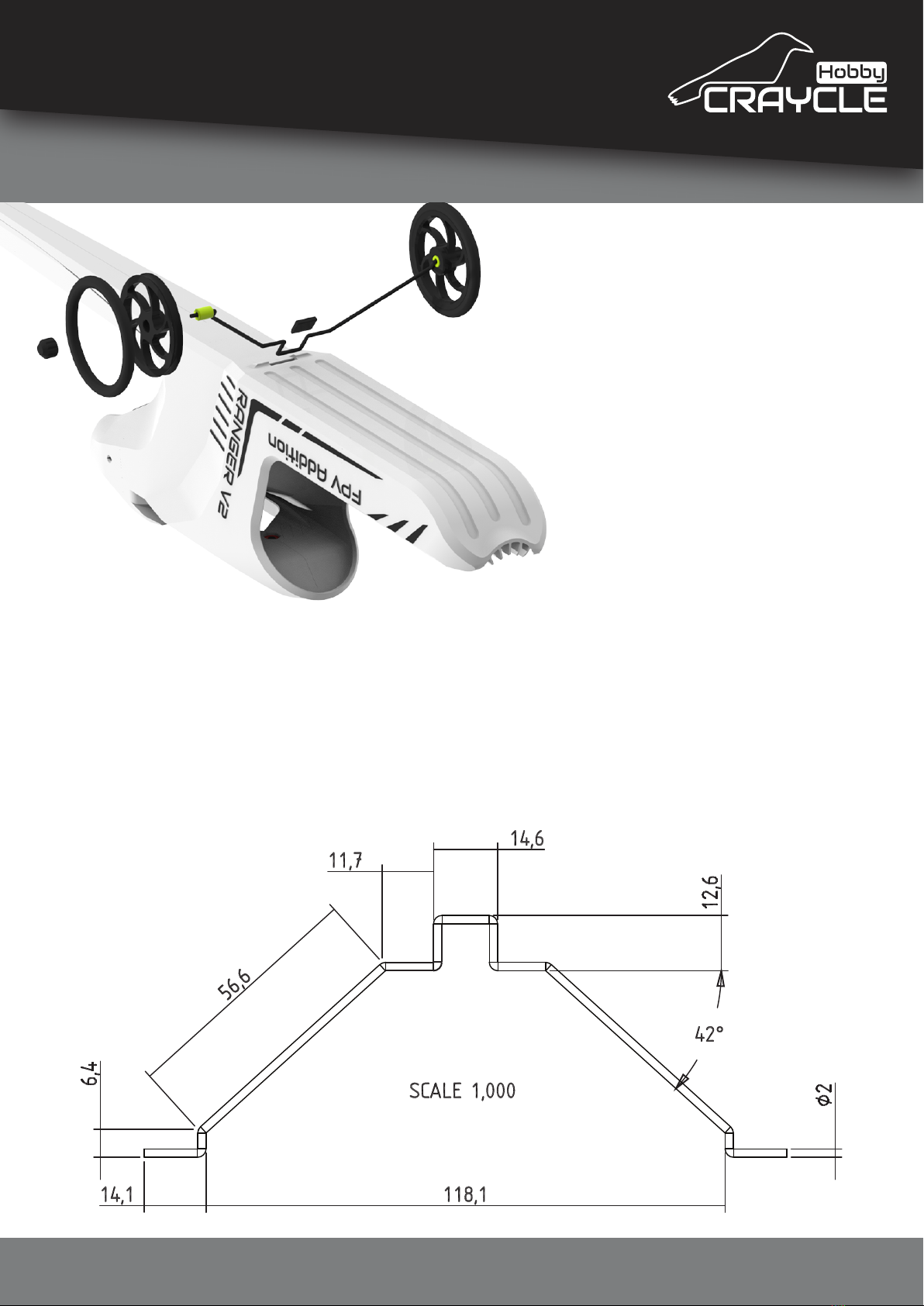

Insert the “shaft” into the “rim” and assemble the “ring” onto

the “rim” part. Shaft model should be printed with PetG

material with 90% flow in slicer settings. This way it works very

well onto the 2mm steel wire. PetG is stronger material so we

use this shaft as PetG to get more lifetime and stifness. (You

can make a clear hole in the “wheel35_rim” by drilling it with 2

mm drill bit.)

STEP 4

Prepare Craycle

Landing Gear by using

2mm steel wire. You

can use this page as a

template by printing

100% real scale or you

can also use the

dimensions below as

well.

Dimensions are in mm.

4

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

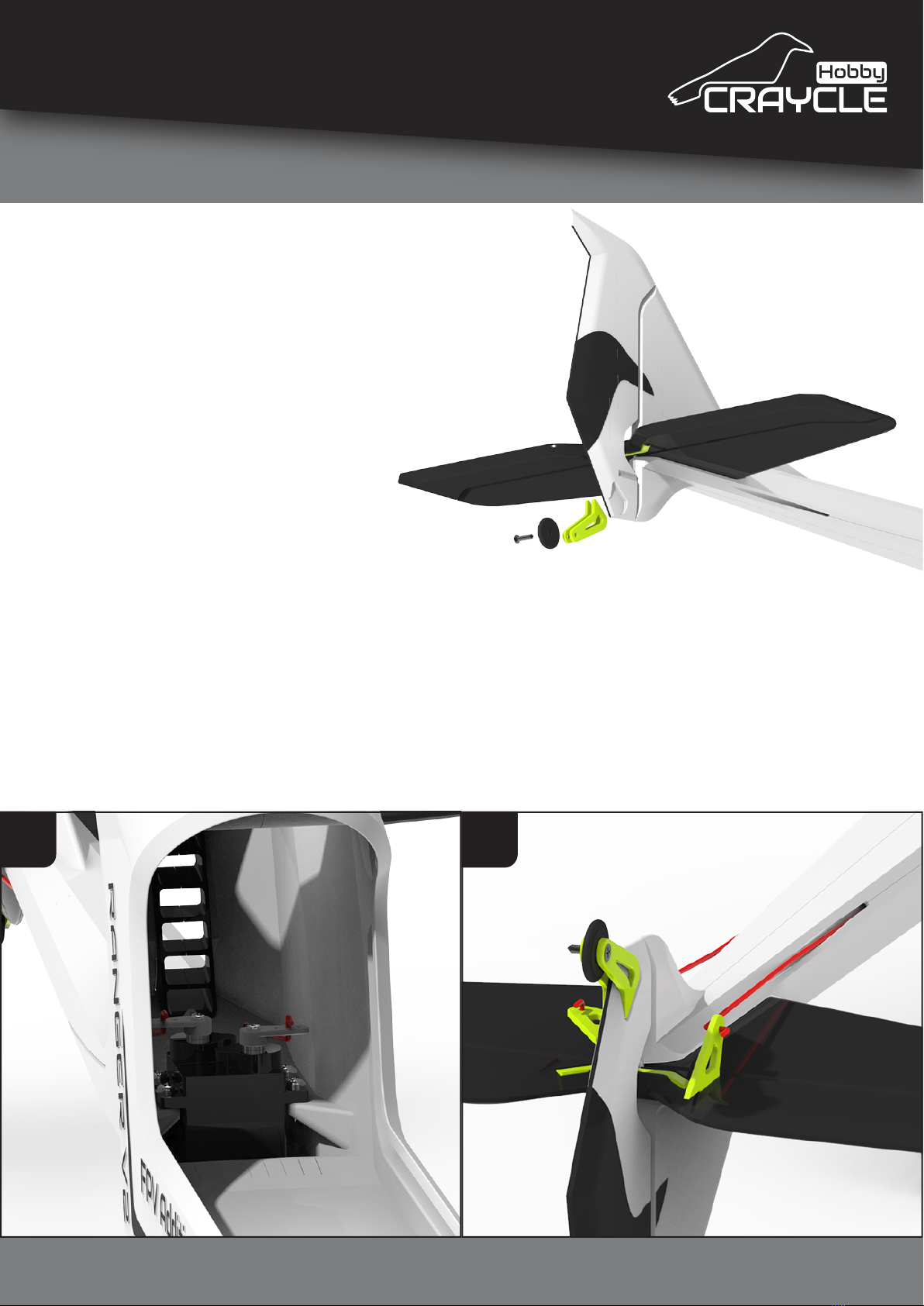

STEP 5

Glue the “rudder_gear” parts onto

its slots on the rudder. Assemble

the “rim” and “ring” parts together

and then install using 2 mm wire

to make clear shaft for

its little rear landing gear.

That's it! You have a rear landing

gear with the steering system.

Screw the Servos onto its brackets into the fuselage with its

screws. There are necessary holes in the fuselage.

Install the pushrods by sticking horns onto its slots on the flaps

for both rudder and elevator. You can also add pushrod

connectors on the servo arms to adjust flaps.

1 2

5

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 6

Now you are ready to install your electronics into the fuselage.

ESCs can pass from the motor house into the Fuselage so the

Motor and ESC can be soldered. Insert the “canopy_spring”

into its slot in the “canopy” and glue the ends of the canopy

spring. Currently 3 different FPV Canopy options are available;

Vista, AirUnit and Analog (29mm cameras). You can ask from

us for a new canopy designs for different FPV systems.

Caddx Vista DJI Air Unit Analog FPV

6

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 7

Screw the Servo Motor into its place on the “wing_l1” as shown

direction in image above. Make sure the Servo centered

connecting to a receiver or a servo tester and the servo arm is

mounted 90 degree to its body.

Now you can glue the “wing_l2” and “wing_l1” parts together.

And then glue the “wing_l3” part onto the “wing_l2”. Wings has

own inserts so you can fit the parts together well comfortably.

While assembling the wing parts together, you need to be sure

the wings are holded in a straight line (Hold the wings upside

down on the flat table). Same process goes for the right wing.

7

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 8

Prepare aileron as the same like rudder and elevator.

Install your pushrods with “craycle_horn” to its place. You can

use pushrod connectors on the horn to adjust aileron position.

Same process goes for the other wing.

Note: You can replace the Servo Motor at anytime by releasing

the Servo Hatch (Release by cutting its tiny connections).

Hatch is the Red Part in image below.

8

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 9

Now you are ready to assemble Wing Right and Left together.

Insert the “wing_support” and “pim” parts into its slots.

Pass through the Servo cables into them little gates shown as

black in image 1.

Gently apply the glue onto the wing, pim and support parts

and then bring the wings together on a flat table to make sure

the wing glued in a straigth line.

Be careful to not apply glue onto the Filament Tunnel under

the wing so you can insert the a filament piece along the wing.

Insert trough the filament piece into its tunnel all wing long

and apply the glue from the outside. This will make your wing

stronger. You can also stick the fiber tape onto the leading

edge to add more durability.

Now you can assemble the wing on the fuselage quickly using

M4x20 Imbus bolt.

1 2

9

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Epilogue

www.craycle.com

Ranger V2 is ready for the Maiden Flight!

Center of Gravity is 34,5 mm behind from the leading edge

(Filament tunnel is also the CG point of the model).

CG perfectly setted with FPV systems but if you haven’t yet,

you can add weight to make CG correct.

We are developing all our models by using Regular PLA to

provide accessibility. If you print this model with LW-PLA,

Ranger would be a Park Flyer. It’s not necessary for the sport

version but 3ch Trainer would fly easier for begginers.

Set a little trim up to elevators for the first flight.

You can also add Insta360 Go2 holder onto the wing to make

cinematic shots from the air.

10

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Free Version

www.craycle.com

What is Included?

Free version of Ranger V2 is almost the same with Sport

Version. Only the difference is 3ch Wing and Fs1, FS2 and

Canopy parts aren’t compatible with FPV gear. All other model

parts are exacly the same. Print Weight is 295 grams.

We are aiming to get more people into this hobby with our

Free Trainer model Ranger V2. So please let us know if there is

a confusing point in this guide for you. We will help you as

soon as possible and update the PDF if its necessary.

Welcome to the Craycle Community!

11

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Print Guide

www.craycle.com

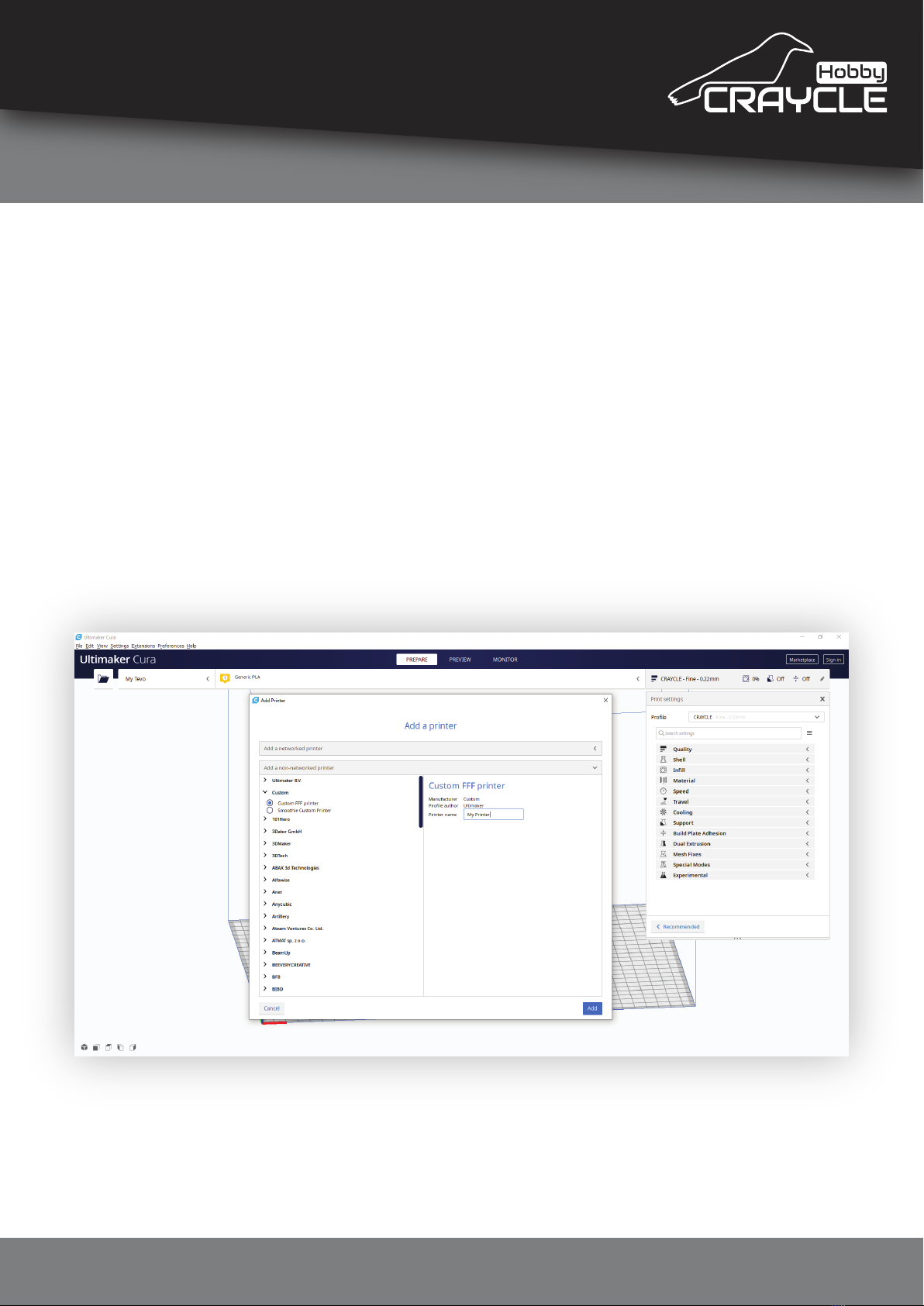

We have prepared printer profile on Cura Slicer for you. If you

have a Marlin XYZ type printer, you can print directly with

prepared gcodes as well. If you can’t use the gcodes don't

worry, just follow the instructions...

Download and install CURA Slicer on ultimaker.com.

When you open the program, you can find your own printer

from the printer list but if you are getting error on importing

curaprofile, you will need to create Custom Printer to import a

curaprofile succesfully.

Open the Add Printer window, select Custom FFF printer, type

your printer name and click to the add button for the next step

1

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Print Guide

www.craycle.com

Set your printer x, y, z dimensions. Heated Bed is necessary for

the wall printing.

Nozzle size has to be 0,4 mm. If you have a different size nozzle

then you have to change it with a 0,4 mm one.

Click the next button, your printer settings are ready!

2

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Print Guide

www.craycle.com

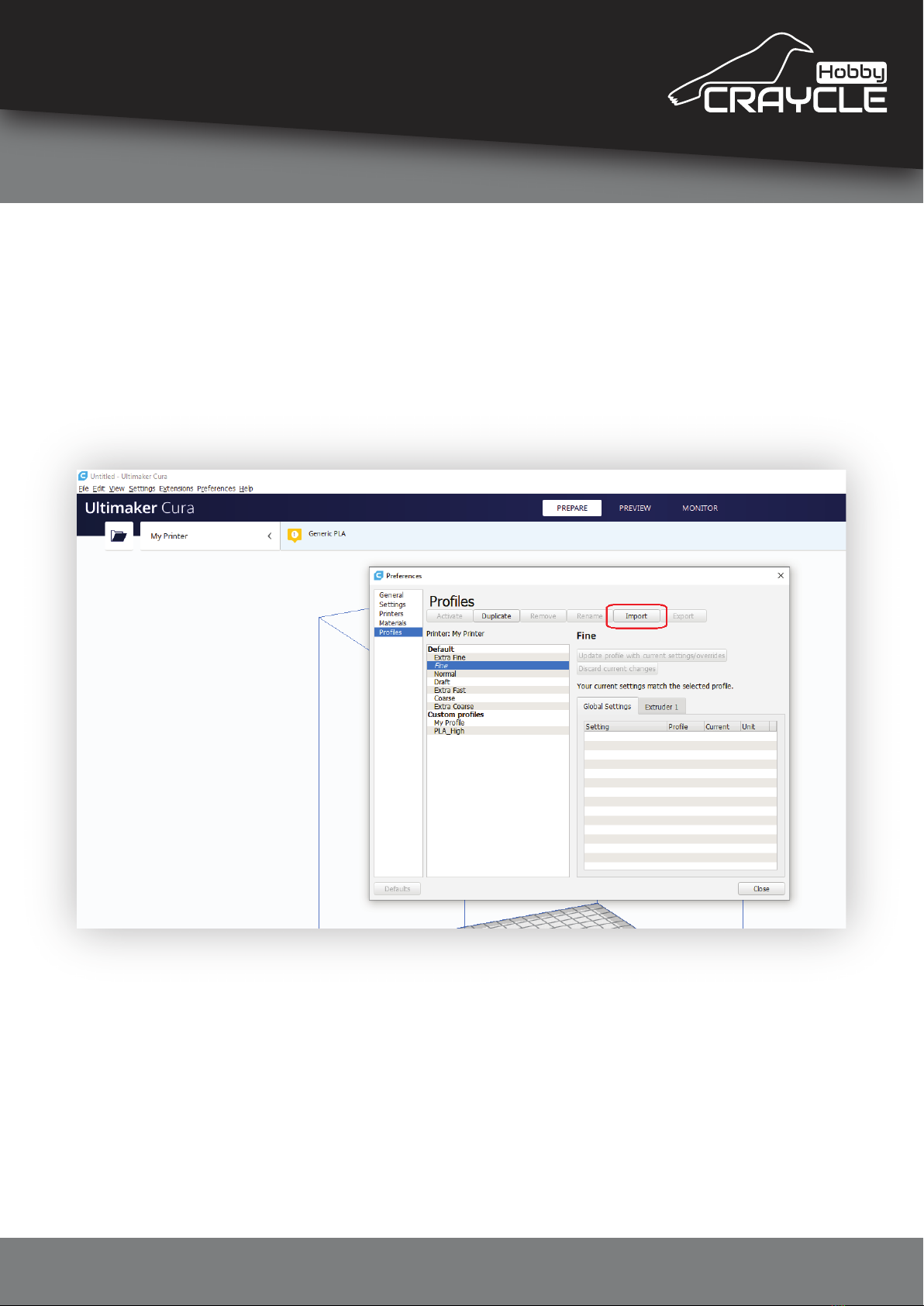

Next step is importing the “craycle.curaprofile”. Follow the

instructions.

Setting - Printer - Manage Printers => Click to the

Profiles on the left side.

You can see your custom and default profiles in this panel. We

are preparing the best print settings to our models for you and

you will be able to use these settings but you need to check

some settings for your printer first.

Click to the “Import” button and go to the next step.

3

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Print Guide

www.craycle.com

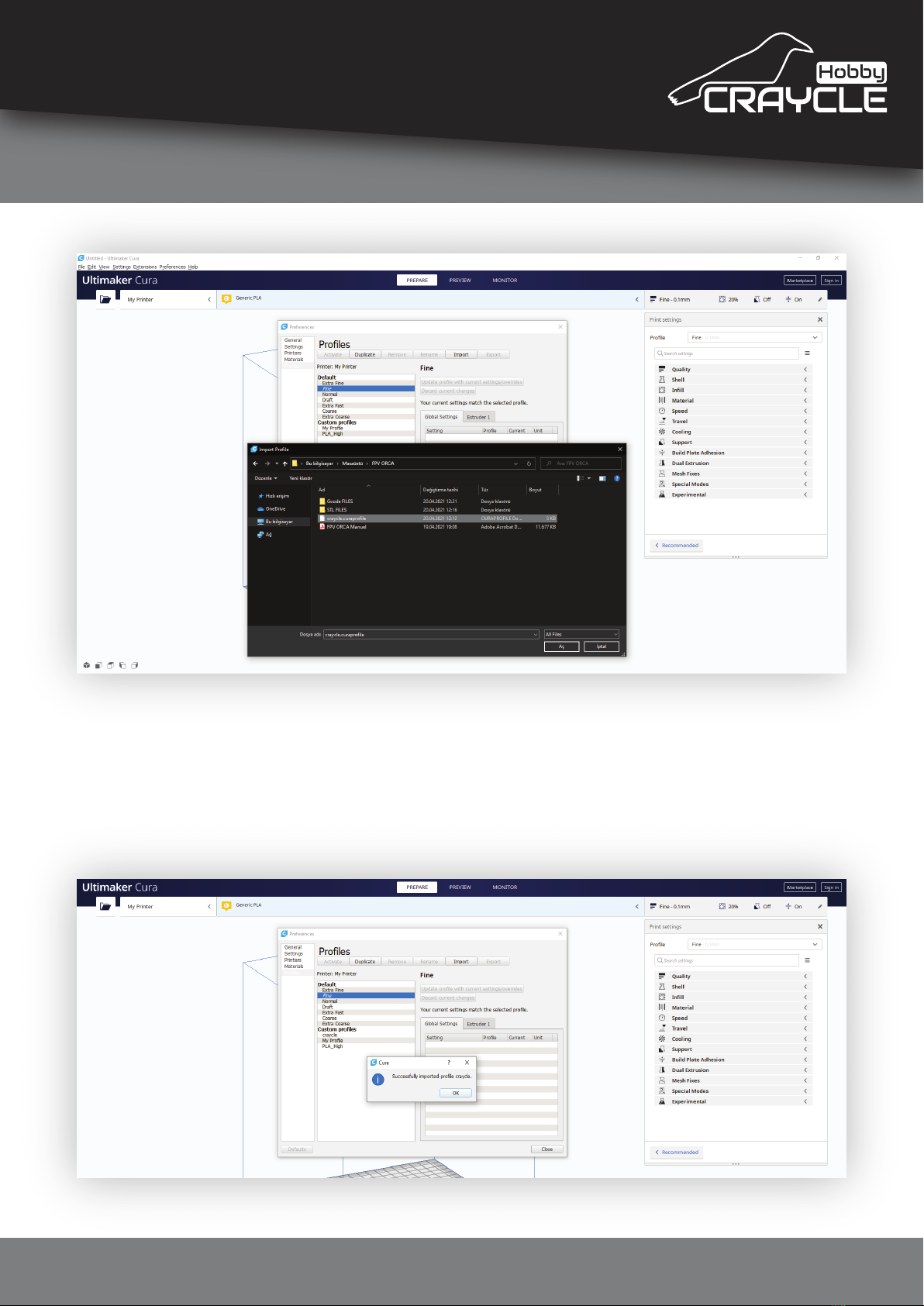

Select “crayce.curaprofile” and click to the open button. Now

you have the Craycle Profile! If you have an error in this step, you

need to create Custom Printer or update your Cura Slicer.

4

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Print Guide

www.craycle.com

The settings you should set according to your printer:

- Material Settings.

Printing Temperature

Buildplate Temperature

Flow (wall flow is important!)

- Travel Settings.

Retraction distance

Retraction speed

These settings might need adjustments according to your

printer or filament. You should print a wing part to test your

print quality. If your test print resulted in a succesful way then

you are ready to start the printing process for the rest of the

parts.

Note: 0,2 mm layer height is the best setting for the

Print Quality/Printing Time.

5

© 2022 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Print Guide

www.craycle.com

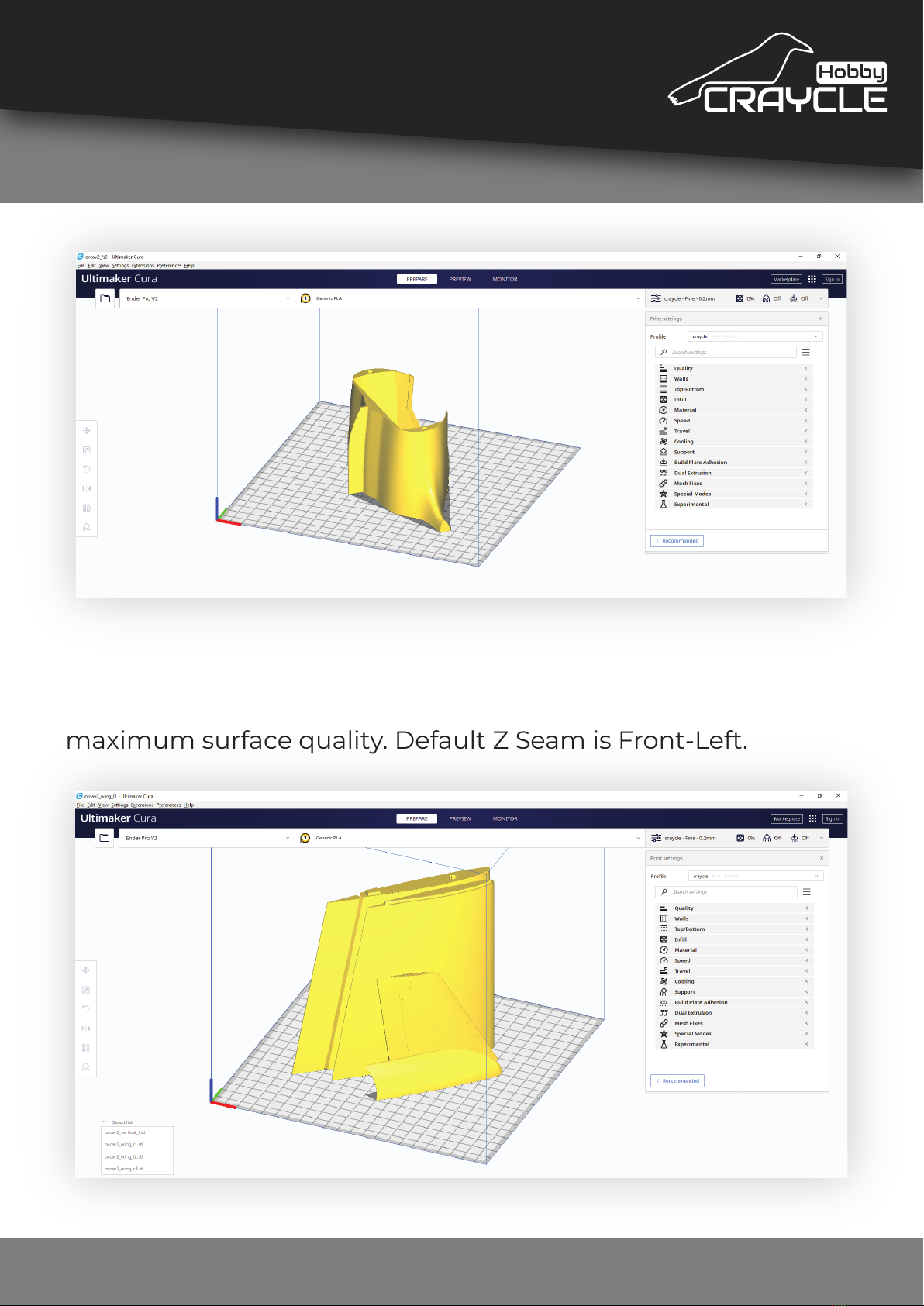

All parts are now pre-routed for Cura but if you want to print

several pieces together, orient the pieces at 45 degrees to the

bed. This way X and Y axis works coordinated and you can get

maximum surface quality. Default Z Seam is Front-Left.

6

Table of contents

Other Craycle Hobby Toy manuals

Popular Toy manuals by other brands

Mega Bloks

Mega Bloks First Builders Fast Tracks Rescue Team Assembly instructions

REVELL

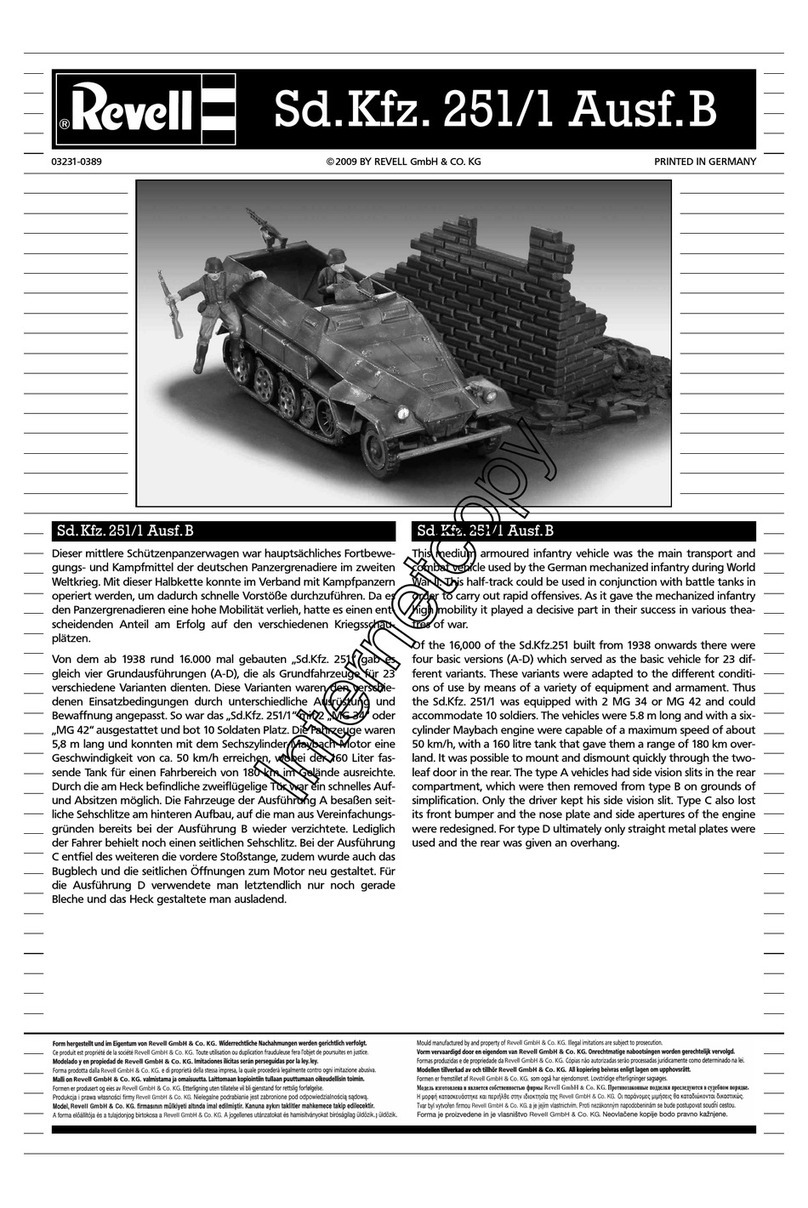

REVELL Sd.Kfz.251/1 Ausf.B Assembly manual

THUNDER TIGER

THUNDER TIGER mini Titan E325 manual

marklin

marklin 37224 user manual

LaserPegs

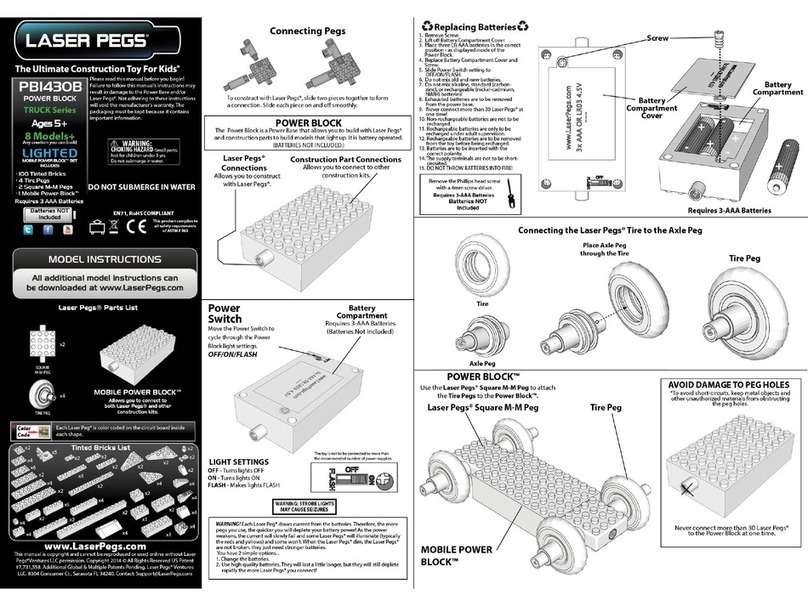

LaserPegs PBI430B Power Block Model instructions

Hot Wheels

Hot Wheels BMG68 instructions

Carson

Carson POLICE TYRANN 230 GYRO 2.4 GHz instruction manual

WOOD HEROES

WOOD HEROES Catapult II Assembly manual

Blade

Blade CX user manual

Phoenix Model

Phoenix Model AT6-TEXAN instruction manual

Fisher-Price

Fisher-Price GRAVE DIGGER Monster Truck H0436 Owner's manual & assembly instructions

Eduard

Eduard Mask B-17G Flying Fortress manual