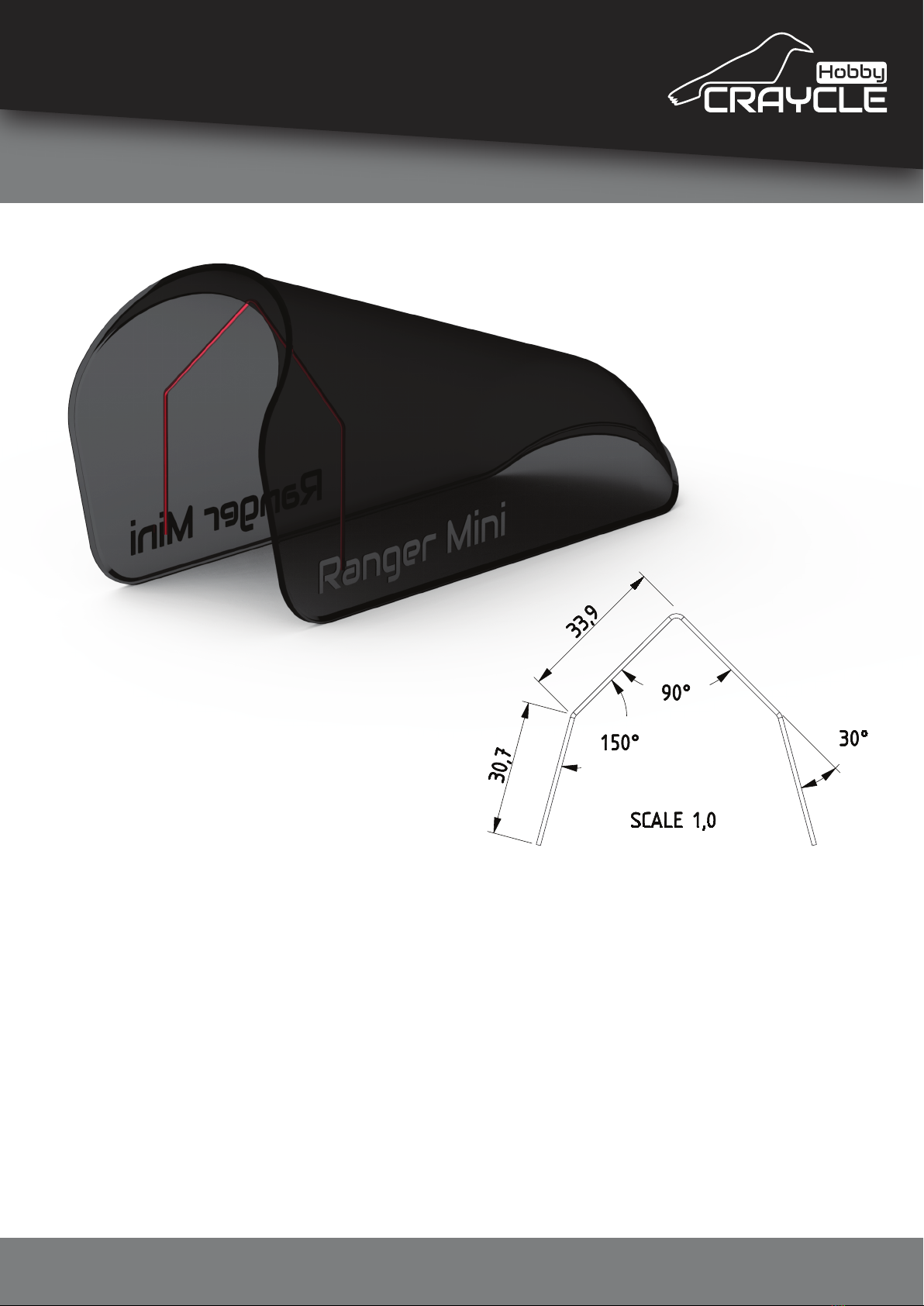

Craycle Hobby Ranger Mini User manual

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

www.craycle.com

Ranger Mini

User Guide

Designed By: Cemal ÖZÇELİK

Version: 1.0

Date: 30.07.2021

Recommended Setup

Motor

Propeller

ESC

Servo

Battery

Any FPV system if you like to use.

: 2204 2300 kv

: 5x3 - 5x2

: 20 amp

: 2 X 9 gram

: 800-1500 mAh 2s-3s

General Specifications

Length

Wingspan

Print Weight

Flying Weight

Wing Area

Wing Loading

24.2 in

31.5 in

8.3 oz.

15.8 oz.

186.6 in2

14.2 oz/ft2

: 615 mm

: 800 mm

: 235 gram

: 450 gram

: 12.04 dm2

: 37.5 g/dm2

Maker Skill

Pilot Skill

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Part List

www.craycle.com

Part NameQuantityNumber

r_fs11

r_fs22

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

2

1

2

r_fs33

r_wing1_l4

r_wing2_l5

r_wing3_l6

r_wing1_r7

r_wing2_r8

r_wing3_r9

r_canopy10

r_tail11

Part NameQuantityNumber

r_asm_parts12

spinner_113

spinner_214

9g servo15

2204 2300Kv Motor16

5x3 Propeller17

20A ESC18

Ø8x275mm Pipe19

550mm Servo Wire

800-1500mah Lipo

20

21

5x45mm O-ring

Landing Wire Front

Landing Wire Back

22

123

124

RANGER MINI PART LIST

9

8

7

12

4

10

21

12

23

12

11

11

12

12

19

12

12

11

5

6

2

3

1

14

13

12

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 1

Assemble "r_fs1", "r_fs2" and “r_fs3” using CA glue. You should

place 4 pieces of “pim parts (in asm_parts)” into the centering

holes to facilitate assembly.

Make sure the pieces fit well. If you are using CA accelerator,

you should spray on one side and wait for accelerator to dry for

20 seconds and then you can apply the glue on other side and

assemble the pieces.

Note: Avoid excessive use of glue.

1

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 2

Assemble elevator right and left pieces using CA glue. You

should place 2 pieces of “pim parts (from the asm_parts)” into

the centering holes to facilitate assembly.

Make sure the pieces fitting well on every step.

If you are using CA accelerator, you should spray on one side

and wait to dry accelerator for 20 seconds and then you can

apply the glue onto other side and assemble the pieces same

as fuselage.

2

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 3

Now you can release the flaps from the elevator by

breaking it’s tiny connections.

Reassemble the flaps using the flexible hinge pieces you

prepared. Then you can stick the control horn to the flap.

The template for the hinge is as follows. Also there is CA Hinge

Maker tool for free in the Model Library.

3

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 4

Do the same process as elevator and prepare the rudder’s flap

and then you can stick the rudder to the elevator.

4

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 5

Prepare and assemble the pieces of "r_wing2_l" and

"r_wing3_l". Apply the same process for the right wing.

Assemble the pieces of "r_wing1_l", "r_wing1_r" and

“wign support part (from the asm_parts)” together.

Assemble the parts on a flat table surface. So you can be sure

the wing and flaps are sticking in a straight line.

Make sure you use enough CA glue for this step!

Note: Avoid excessive use of glue.

5

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 6

Now you can assemble the right and left wing with the central

part.

Don't worry about the Dihedral Angle, wing support part will

guide the assembly for the necessary wing angle.

Be sure to test fit all the parts before applying the CA glue.

You can stick a piece of tape to the entire leading edge for

extra durability.

6

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 7

1-Insert the carbon pipe all the way into the fuselage and stick it.

2-Insert the wire holder (from the asm_parts) to the pipe.

3-Install the tail wing all the way to the carbon pipe and stick it.

4-Insert the wing mounting bracket (Red part) inside the fuse-

lage where the wing is going to be assembled and then stick it

into the fuselage with CA glue. In this step be careful for the

alignment of the mounting holes.

5-You can stick the m4 nut to the wing mounting bracket with

CA glue carefully before previus step.

6-Now you can assembly the wing to the fuselage with one

M4x25 imbus screw.

7

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

7- While sticking the tail wing to the carbon pipe, you can use

the tail mounting stand (from the asm_parts) for the perfect

position of the elevator.

8- Sit the fuselage on a flat table and stick the mounting stand

at a suitable location on the table with double-sided tape. Be

sure the elevator, fuselage bottom and table surface parallel

together.

8

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 8

Remove the wing to work easy on the next steps.

Now you can install all your electronics; install your Motor, ESC,

Lipo Battery, Servos and Ø1 mm Push Rods (Music Wire).

You will need to drill the fuselage from the marked points with

push rod wire from the back of the fuselage for the push rods.

Check your servo direcions on the transmitter. Setup your

EXPO and Level settings.

Flaps should move 6 mm down and 9 mm up on the elevator

and 9 mm equal right and left on the rudder for the first flight.

The 40% EXPO setting is good for easy control on all directions.

9

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 9

Prepare the landing gears using

these drawings.

Drawings are 1:1 scale in this page. So

you can print this page as %100 scale

and use as a template.

You will need Ø1.5 mm and Ø1.0 mm

music or spring wire.

Be careful in this step and use strong

bending tools.

10

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 10

Your Ranger Mini is almost Ready to Fly!

You can insert the wheels to the bended wire and then you

can install the landing gears to the place under the fuselage

and tail.

You will need 2 X 45x5 mm O-ring and 1 X 15x2 mm O-ring as

O-ring Wheels’ tires.

11

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 11

Prepare the canopy spring using these drawings.

Drawings are 1:1 scale in this page. So you can print this page

as %100 scale and use as a template.

You will need Ø1 mm music or spring wire.

Place the wire you prepared on the inside, approximately as in

the photo, and fix it with CA glue only at the ends. The wire

should be stretching the canopy outward at its ends. This is

going to fit the canopy to the fuselage strongly.

12

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Assembly

www.craycle.com

STEP 12

Assemble the wing to the fuselage. Install your canopy and

check if everything is right.

Set the Center of Gravity from the marked line under the wing

(37,5 mm behind from the leading edge).

Take your time and do the right on every step. Be in a ventilat-

ed environment or work outside when using CA glue and ac-

celerator.

Your Ranger Mini is Ready to Fly!

Take your maiden flight with an experienced person.

13

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Print Guide

www.craycle.com

You will need a printer which has a bed size at least 180x180x180.

We have optimazed the Ranger Mini for normal PLA but if you

can use the LW-PLA it’s going to be better.

There is settings table on the last page for all of the parts and

we have prepared the necessary .curaprofile files for you. You

will need to use both of them.

First of all you need to have the CURA slicer program. When

you open the program, you can find your own printer from the

list but you should define your own printer with the custom

option. Custom option is always works properly.

Open the Add Printer window, select Custom FFF printer, set

your printer name and click to the add button for the next step

1

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Print Guide

www.craycle.com

This step, you have to set your printer x, y, z dimensions. If your

printer has a heated bed then you must activate/choose this

setting. (Heated bed is necessary for the wall print.).

Nozzle size has to be 0,4 mm for the model printing process. If

you have a different size nozzle then you have to change it with

a 0,4 mm nozzle. “Compatible material diameter” is related to

your printer, this is the filament daimeter.

2

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Print Guide

www.craycle.com

Click the next button, your printer settings are ready!

Next step is importing the “craycle.curaprofile”. Follow the

instructions.

Setting - Printer - Manage Printers => Click to the

Profiles on the left.

You can see your custom and default profiles in this panel. We

have prepared the best print settings for the RC Model

printing process and you will use these settings but you will

need to check some settings.

Click to the “Import” button and go to the next step.

3

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Print Guide

www.craycle.com

Select to the “crayce.curaprofile” and click to the open button.

Now you have the craycle profile!

4

© 2021 Craycle Hobby. Copies allowed for personal use only. Not for commercial use.

Print Guide

www.craycle.com

The settings you should set according to your printer:

- Material Settings.

Printing Temperature

Buildplate Temperature

Flow (wall flow is important!)

- Travel Settings.

Retraction distance

Retraction speed

These settings are related to your printer and your filament

brand. You should print a test part (any part from the stl files). If

you can print a test part of sufficient quality and the correct

weight, you are ready to print the other parts.

Note: 0,2 mm layer height is the best settings for the

Print Quality/Printing Time. You should follow the table on the

last page.

5

Table of contents

Other Craycle Hobby Toy manuals

Popular Toy manuals by other brands

V-tech

V-tech Winnie the Pooh product manual

PLAYTIVE JUNIOR

PLAYTIVE JUNIOR 293419 Instructions for use

V-tech

V-tech CAR-BOAD RACERS CONNECTORS AND TRACK STANDS instruction manual

LaserPegs

LaserPegs 9010 SEA Model instructions

Hot Wheels

Hot Wheels COLOSSAL CRASH GFH87 instructions

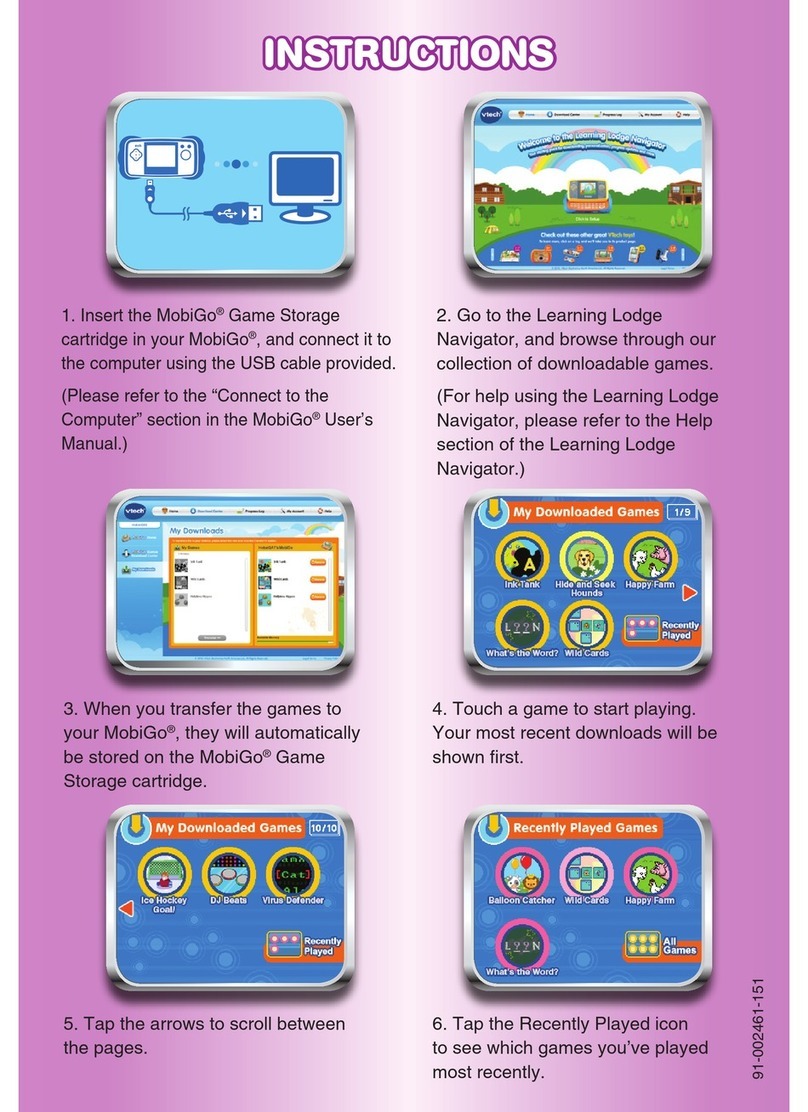

V-tech

V-tech MobiGo Game Storage instructions