Crazy Monkey Creations 2 Yard Electric Skein Winder Quick setup guide

2 Yard Electric

Skein Winder

Assembly and Use

Package Contents

• 1 - Triangular Base (w/ motor)

• 1 - Cross Arm

• 1 - Left Foot (w/ yarn guide)

• 1 - Right Foot

• 2 - Adjustable Fingers (w/ yarn clip)

• 2 - Adjustable Fingers (no clip)

• 4 - Slider Pads

• 1 - Drive Pulley

• 1 - Variable Speed Control

(w/ power cord)

• 1 - V-Belt

• 4 - Plastic Knobs

• 1 - 3/8 x 7” Hex Head Bolt

(w/ washer & roll pin)

• 1 - 3/8 x 2” Fender Washer

• 2 - Ball Bearings

• 1 - 1/2” Aluminum Spacer

• 1 - 5/16” Aluminum Spacer

• 1 - Roll Pin

• 2 - 3/8” Washers

• 1 - Lock Nut

• 4 - 1-1/2” Flat Head Wood Screws

• 4 - 5/16 x 1-3/4” Carriage Bolts

• 4 - 5/16” Washers

Tools Required

• #2 Phillips or #2 Square Drive Screwdriver

• 9/16” Open End Wrench, Socket Wrench or

Adjustable Wrench

• 11/32” Open End Wrench or Adjustable

Wrench (if needed to adjust belt tension)

Assembling the Winder

Inspect the contents of your package.

If any parts are missing or damaged,

call or e-mail us so we can send you

replacement parts immediately.

Main Body:

Screw left foot (with yarn guide) and right

foot (without yarn guide) to the bottom

of the triangular winder base using the

provided 1-1/2” long at head wood

screws and either a #2 square drive or

#2 Phillips screw driver.

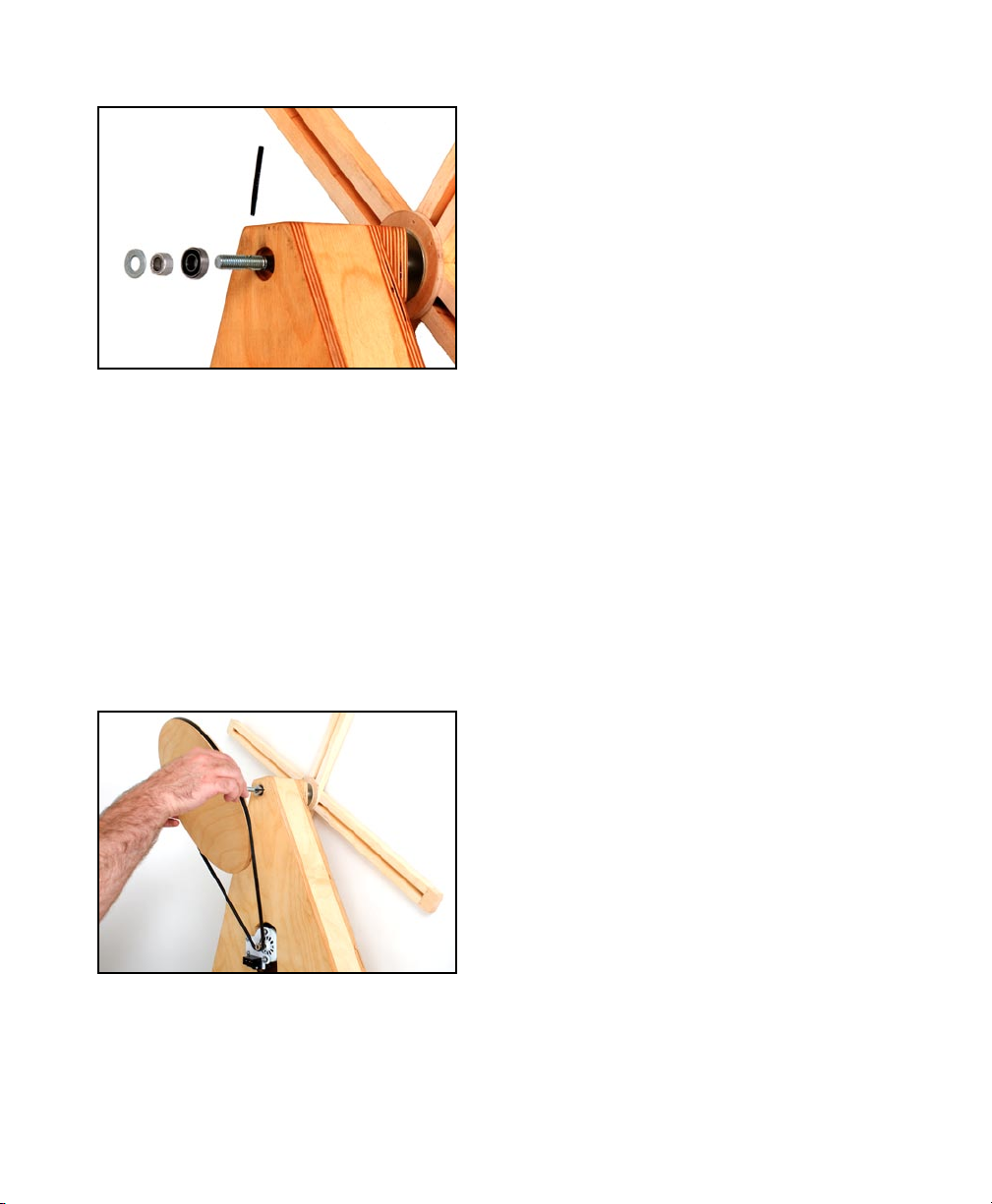

Cross Arms:

Insert 3/8 x 6-1/2” bolt with washer and

roll pin through the hole in the center of

the cross arms. Be sure the slot and

engraved size markings are facing

forward. The pin should t snugly in the

slot on the front of the arms, you may

have to tap the bolt with a hammer to

fully insert it. If the roll pin does not line

up with the slot, rotate 180º. The washer

should sit at against the surface of the

cross arms.

Place the 3/8 x 2” fender washer on the

bolt, against the back side of the cross

arms, followed by the 1/2” aluminum

spacer. Note, there are two aluminum

spacers, this is the larger of the two.

Place one of the ball bearings on the

bolt behind the spacer.

Insert the entire arm and bolt assembly

into the front of the winder base, through

the hole at the top. The bearing should

seat nearly ush inside the hole.

Pulley & Belt:

Place the second ball bearing on the

bolt on the back side of the wider. The

bearing should seat in the large hole

on the back side of the winder base.

Followed by the 5/16” (the smaller)

aluminum spacer and a 3/8” washer.

Insert the roll pin through the hole in

the back of the bolt, just behind the

washer. Turn the arms so that the hole

is horizontal, this will keep the pin from

falling out while you install the pulley.

Loop the v-belt around the large wooden

pulley and hold with one hand on each

side to keep the belt from slipping. Insure

that the slot on the front of the pulley is

facing towards the winder body. Hook the

extra length of the belt under the small

pulley on the motor shaft. Carefully lift

the wooden pulley until you can slip it on

the end of the bolt, while being sure not

to drop the belt. Push the pulley onto

the bolt and align the slot with the roll

pin. The pin should t snugly in the slot

on the pulley, and the pulley should be

at against the washer.

Place a 3/8” washer on the bolt, followed

by the 3/8” lock nut. Hold the cross arms

steady with one hand while using a 9/16”

wrench to tighten the nut. Tighten the

nut just until the cross arms and pulley

feel solid. Do not over tighten as this

will put undue pressure on the bearings

and make the winder turn slower.

Belt Tension:

The drive belt tension is adjusted to

the correct tension before shipping.

However should the motor move during

shipping or assembly readjustment may

be necessary.

The drive belt should appear slightly

loose, but be tight enough that it can not

be easily removed from the lower drive

pulley. To check the tension grasp one

side of the belt half way between the

two pulleys and move it back and forth.

There should be approximately 2 inches

of play. If the belt is too tight it will put

more load on the motor, if too loose it

may slip off the pulley.

If adjustment is necessary, use an

11/32” wrench or adjustable wrench

to hold the nuts inside the base and

slightly loosen the two screws securing

the motor bracket to the base using a

Phillips screwdriver. Tilt the motor up

or down to achieve the correct tension,

then retighten the mounting screws.

Adjustable Fingers:

Insert a 5/16 x 1-3/4” carriage bolt

through the wooden slider pad, so that

the square neck of the carriage bolt seats

in the square hole in the pad. Hold an

adjustable nger on the front of one arm

of the crass arms, so that the tongue

on the back side of the nger ts in the

groove on the arm. Insert the carriage

bolt/slider assembly through the back

of the arm, and through the hole in the

nger, so that the tongue on slider ts

into the groove in the arm.

Place a 5/16” washer on the end of the

carriage bolt, followed by the plastic

knob. Tighten the knob until the head of

the carriage bolt seats fully.

Repeat for the other 3 nger assemblies.

For best operation and balance, the

two ngers with yarn clips should be

opposite of each other.

Danger: The winder arms

are very solid and spin

at very high speed. Keep

hands, arms, head and other

appendages clear of spinning winder.

Severe injury can occur.

Danger: The yarn moves

extremely fast. Do not

touch the yarn or attempt to

guide it with your hand while

winding. The yarn may cause a severe

and painful cut.

Warning: Do not leave the skein winder

unattended while in use. If yarn catches

on the swift or other object the yarn,

swift or winder may be damaged.

Warning: Keep pets and children clear

of the winder and yarn.

Using the Winder

Adjusting Skein Size:

The winder arms can be adjusted for any

circumference from 36 inches up to 89

inches. Each arm is marked at 1 yard,

1-1/2 yard, and 2 yard circumferences

for convenience.

To adjust, loosen the knob on one slider

and slide to desired position, re-tighten

the knob. For a 1 yard, 1-1/2 yard or

2 yard skein position the slider with the

outside edge aligned with the respective

line marked on the arm. Repeat for

the other 3 arms. The sliders should

be positioned equally on each arm for

proper balance during use. Do not set

the arms to their smallest size, or it will

not be possible to remove the skein

later.

Winding a Skein:

Pass the yarn through guide loop on

the left foot and under the arms. Bring

the yarn up an around the arms in a

counter-clockwise motion. Wrap the

warn counter-clockwise around a nger

which has a clip and secure it with

the clip. Rotate the winder counter-

clockwise by hand for a few revolutions

to be sure that yarn feeds smoothly.

This will also help further secure the

yarn before starting powered operation.

Make sure yarn is taut and not caught

on any obstructions.

Turn the control knob to it’s lowest

setting (counter-clockwise) then press

the knob to turn on the power. Rotate the

knob clockwise until the desired speed

is reached. Continue winding until the

skein is the desired size. Press the

knob to stop the winder. When winding

thin yarn which is easily broken, or yarn

which tangles easily it is best to use a

slower speed.

Winding From a Swift:

Securely attach your swift to a table or

solid object. The winder winds very fast

causing strong vibrations in the swift.

Be sure that the yarn is not tangled on

the swift. If the yarn gets stuck it could

break or damage the swift. If the swift

is not secured if could be pulled toward

the winder, causing personal injury or

damage to the swift or winder.

Tuck the loose end of the yarn on the

swift under the coil of yarn. If left to ap

about, the loose end can wrap around

the yarn as you are winding, causing

the yarn to break.

Removing the Skein:

Tie off the skein. Remove the end of the

yarn from the clip. Loosen the knob on

any slider and move it toward the center.

If the yarn is very tight the slider may not

move easily. Pinching the outside end

of the slider to the arm will usually free

the slider. If the skein does not easily

come off the winder, it may be necessary

to loosen another slider. Remove the

skein and return the slider to the desired

position. Re-tighten the knob. You are

now ready to wind your next skein.

Warranty

We produce our skein winders to the highest standards

of quality and performance. Your skein winder is backed

by a one year warranty against defect in material or

workmanship. If your winder breaks or becomes non

functional for any reason, within one year from the date

of delivery we will repair or replace it free of charge.

arrange for the repair of your winder.

Table of contents

Popular Toy manuals by other brands

Phoenix Model

Phoenix Model EXTRA 260-EP instruction manual

Hasbro

Hasbro Buzz Lightyears Rolling Rescue Station 03102 instruction manual

Turnigy

Turnigy Nitro Rumble instruction manual

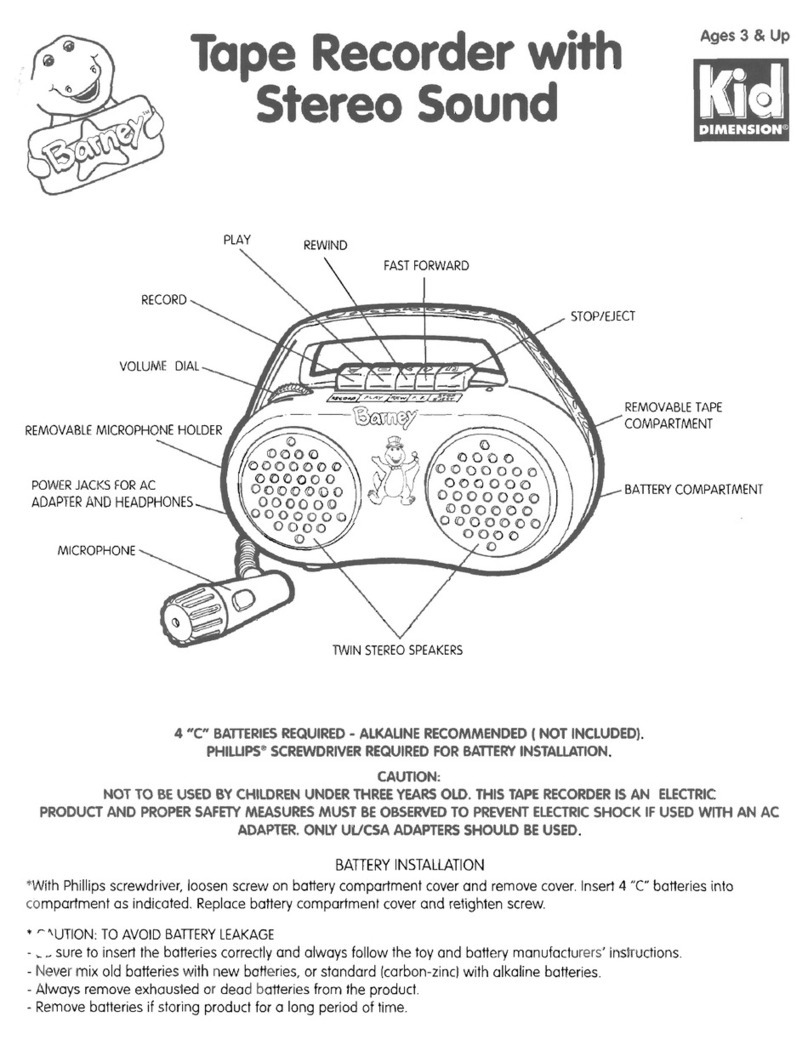

Kid Dimension

Kid Dimension Barney Tape Recorder with Stereo Sound instructions

Fisher-Price

Fisher-Price B0322 manual

JR ProPo

JR ProPo JR Ergo Assembly instructions

Giant Leap Rocketry

Giant Leap Rocketry Elipse manual

Black Horse Model

Black Horse Model dornier DO335 Instruction manual book

REVELL

REVELL Junkers Ju 88 A-1 "Battle of Britain" Assembly manual

Henseleit Helicopters

Henseleit Helicopters Three-Dee-Fun TDR-II user manual

Fisher-Price

Fisher-Price W9750 instructions

Faller

Faller GOLDBECK 130890 instructions