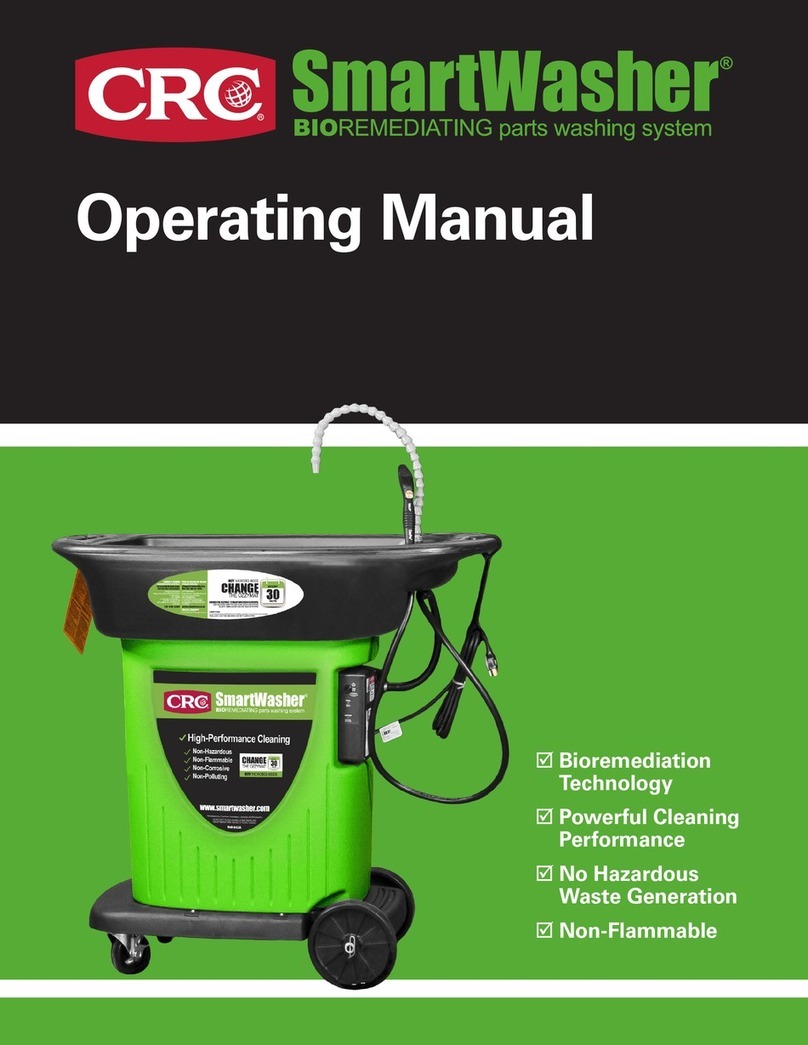

CRC SmartWasher SW-28XE Operator's manual

page 1 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

..................... P. 1

.............P.81

.............P.41

...........P.201

...........P.121

...........P.281

...........P.241

...........P.161

...........P.521

...........P.361

...........P.481

...........P.601

...........P.561

...........P.681

SL

...........P.641

...........P.441

...........P.321

...........P.401

SmartWasher®

Models:

Mobile Parts/Brake Washer

SW-23 -RGB

Signature Parts Washer

SW-25 -RGB

Mobile Heavyweight Parts

Washer SW-37 -RGB

Supersink Parts Washer

SW-28 -RGB

PLEASE READ THIS INSTRUCTION MANUAL CAREFULLY AND

COMPLETELY TO ENSURE THAT YOUR NEW SMARTWASHER®

WILL OPERATE AT ITS MAXIMUM EFFECTIVENESS

C.R.C INDUSTRIES EUROPE BV

Touwslagerstraat 1, B-9240 Zele

page 2 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

1. General

Before assembly, installation and use of this equipment, please read this user instruction manual.

Store the user instructions for later use or subsequent owners.

In case of transport damage, inform your SmartWasher®distributor or CRC Industries Europe

immediately.

2. Table of Contents

Chapter 1 General page 2 / 720

Chapter 2 Table of contents page 2 / 720

Chapter 3 Introduction page 3 / 720

Chapter 4 Description and operation page 4 / 720

Chapter 5 Safety instructions page 5 / 720

Chapter 6 Transport and storage page 7 / 720

Chapter 7 Installation and setup page 9 / 720

7.1 Mechanical installation and setup page 9 / 720

SW 23 page 9 / 720

SW 25 page 13 / 720

SW 28 page 17 / 720

SW 37 page 21 / 720

7.2 Electrical installation and setup page 25 / 720

Chapter 8 Use and application page 26 / 720

Chapter 9 Operation page 27 / 720

Chapter 10 Maintenance & repair page 29 / 720

Chapter 11 Troubleshooting page 31 / 720

Chapter 12 Environmental aspects page 33 / 720

Chapter 13 Frequently Asked Questions (FAQ) page 34 / 720

Chapter 14 Disclaimer and Warranty Page 38 / 720

Chapter 15 Declaration of Conformity Page 39 / 720

Chapter 16 Attachments Page 40 / 720

page 3 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

3. Introduction

CONGRATULATIONS !!

You have purchased the state-of-the-art SmartWasher

®

.

SmartWasher Parts Washing Systems combine a power-

ful cleaning solution with the bioremediation power of

specially-bred Ozzy

®

microbe. Once a SmartWasher

®

has

been properly installed and activated, it is literally ALIVE.

Your SmartWasher®

IS safe and easy to use

USES the latest in bioremediation technology to elim-

inate hazardous liquid waste

HELPS deregulate and detoxify your workplace and

reduce government paperwork

SAVES you money

The SmartWasher®is designed to safely and eectively

remove oil and grease from automotive and industrial

parts. It replaces hazardous solvent part washers with

aqueous-based degreasing solutions called OzzyJuice®

and microbe impregnated particulate traps called Ozzy-

MatsTM. The microbes impregnated into the OzzyMat

come to life in the OzzyJuice

®

and break down, or “eat”

the grease, oil and other contaminants in the solution

leaving by-products of harmless carbon dioxide and water

- leaving nothing hazardous to haul away. OzzyJuice®is

an award winning, pH neutral, non-caustic, non-flamma-

ble and biodegradable degreasing solution. Working in

wconcert with our microbes (Ozzy®) these superior

products help eliminate or greatly reduce your need to

dispose of hazardous waste, giving you all the perfor-

mance you are used to in a typical solvent parts washer

without all the hazard and hassles. You have made a

great decision.

page 4 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

4. Description and operation

4.1. Tecnical data

SW-23 SW-25 SW-28 SW-37

Electrical connection

Type of current V/~/Hz 220 V/AC – 50/60 Hz

Connected load pump W 45 45 45 45

Electrical fuses A 1 1 1 1

Performance data

Heating output kW 1.0

Working pressure Bar 0.3 0.3 0.3 0.3

Flow rate pump Litre/min 18 18 18 18

Adjustable thermostat °C 40 – 46 40 – 46 40 – 46 40 – 46

Container capacity Litre 60 95 95 95

Load capacity Kg 180 kg 225 kg 225 kg 450 kg

Noise emission (IEC 60704-1)

Sound pressure level dB(A) < 60

Device vibrations (ISO5349)

Washing brush m/s² < 0.62

Sizes and weights

Overall dimensions cm 109x69x107 90x67x102 119x97x107 122x89x114

Inside sink dimensions cm 69x58x20 69x44x20 104x58x20 84x69x20

Empty weight Kg 32 37 42 70

page 5 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

5. Safety instructions

a.

Use SmartWasher

®

only as described in this manual.

Use only attachments, parts and tools recommended

by the manufacturer.

b.

The equipment may only be installed, used, maintained

and repaired by adult (> 18 years), professional, trained

and/or qualified personnel

c.

The equipment must be used indoor, protected

against deleterious environmental conditions (e.g.

extreme low/high temperatures, rain, snow, wind,

lightning, …)

d. Suciently lighting and ventilation must be foreseen

by the user during use, maintenance and repair.

e.

The parts to be cleaned must have an appropriate

shape, dimension and weight in relation to the equip-

ment. Respect therefore the maximum load capacity

of the parts to be cleaned, as indicated in part 4 of

this user instruction manual.

f.

The SmartWasher®may not be used in explosive at-

mospheres (ATEX environments), confined spaces, ...

g.

The equipment may only be maintained and repaired

after the equipment has been unplugged from the

main power supply and after the equipment is cooled

down to ambient temperatures. Care must be taken

as burns can occur from touching hot parts.

h.

The SmartWasher

®

may only be used for cleaning in a

closed position, with all quick disconnect pins in firmly

place. (see chapter 7.1 of this user instruction manual).

i. The overfill protection on the SmartWasher®may

never be blocked. The overfill protection may not be

connected to the sewage system of your company.

j. Care must be taken to the ergonomic position of

the operator in relation with the dimensions of the

equipment during use.

k. Care must be taken to the environment where the

equipment is installed. It must be kept free from

surrounding obstacles and greasy underground as

this may lead to slipping, tripping or falling.

l. Do not operate SmartWasher®with damaged elec-

trical cable or if the equipment has been dropped

or damaged until it has been examined by a qualified

service person.

m.

Tools or parts, showing damage or wear, must be

instantly replaced or repaired before further use.

n. Do not let an electrical cable hang over the edge of

the table, bench, or counter or come in contact with

hot manifolds or moving fan blades.

o. If an extension electrical cable is necessary, a cable

with a current rating equal to or more than that of

page 6 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

p.

the equipment should be used. Electrical cables rated

for current lower than the equipment may overheat.

Care should be taken to arrange the cable so that it

will not be tripped over or pulled. (Must be rated a

minimum of 220 VAC))

q. Unplug the equipment from electrical outlet when

not in use for an extended period of time. Never use

the electrical cable to pull the plug from the outlet.

Grasp plug and pull to disconnect.

r.

To reduce the risk of fire, do not operate equipment

in the vicinity of open containers of flammable liquids

(gasoline).

s.

Adequate ventilation should be provided when work-

ing on operating internal combustion engines.

t.

Keep hair, loose clothing, fingers, and all parts of

body away from moving parts.

u. To reduce the risk of electric shock, do not use on

wet surfaces or expose to water.

v. The mobile models SW23 and SW37: do not move

them with high velocities (human walking speed only).

Fix the swivel wheels in blocked position prior to use.

During movement of these models of SmartWasher

®

,

be aware of obstacles, slippery floors, … as these may

cause personal harm by falling, tripping, slipping, …

These equipment can only be moved at walking speed.

w. Personal Safety Equipment

-

Always wear safety glasses to avoid eye contact

with the degreasing liquid

- Always wear safety shoes to avoid injury due to

falling objects you are busy cleaning

- It is good practice to wear gloves whenever using

industrial cleaning fluids.

x.

The equipment may ONLY BE USED for the removal

of oil and grease from automotive and industrial parts

y. The equipment may NOT BE USED for cleaning hu-

man parts (e.g. hands, …), animals, clothing, parts

which come in contact with food, painting tools, parts

containing hazardous substances (e.g. asbestos, cad-

mium, …), …

z.

For the degreasing fluids OzzyJuice

®

, consult the Safety

Data Sheet before use on the internet website of CRC

Industries Europe. If you do not have access to the

website, a paper copy can be obtained through your

local CRC distributor.

page 7 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

6. Transport and storage

6.1. Transport

• Switch of the equipment and unplug from the main

power source and avoid damage to the power cable

during transport by putting it at a safe location

• Empty and clean the equipment

•

DO NOT move the equipment when there are

cleaned parts or parts to be cleaned on the equipment

•

During movement of the equipment in the workshop,

be aware of surrounding obstacles and the proximity

of co-workers

• For internal transport:

• If not fitted with wheels : put the equipment on a

stable underground (e.g. pallet)

• If fitted with wheels : make sure the wheels are in a

good status before moving

•

For external transport: Always put the equipment

on a stable underground (e.g. pallet) and fix it

well. Appropriate packaging is required to avoid

transportation damages and to protect against

deleterious environmental conditions

•

Use appropriate equipment for lifting (check the

weight of the equipment and the lifting devices),

handling and moving the equipment

•

During transport in vehicles, secure the equipment in

an appropriate manner to avoid slipping and tipping.

6.2. Storage

• Switch of the equipment and unplug from the main

power source

• The equipment must be emptied and cleaned.

•

The equipment must be stored in a dry and clean

environment

•

Protect the equipment for adverse environmental

conditions

page 8 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

PARTS WASHER OPERATION BRAKE WASHER OPERATION

1. The pump switch is attached to a ten minute timer.

Turning the switch “ON” (upward position) will start

fluid flowing for ten minutes. To restart the flow, turn

the switch “OFF” then “ON” again and the flow will

restart for another ten minutes.

2.

Adjust the valve at the base of the nozzle to control

the flow of the fluid through the nozzle. The valve

at the base of the brush hose controls the flow of

fluid through the brush. Both outlets can be operated

independently or together.

1.

Unplug the SmartWasher

®

from the electrical outlet,

roll up the power cable and secure it with the strap

on the handle.

2. Roll the SmartWasher®to the vehicle and position

it under the brake you desire to clean.

3. Plug in the power cable and begin cleaning.

4.

When finished, unplug the power cable and secure it

with the strap on the handle. Roll the SmartWasher®

back to its original spot and plug the power cable

into the appropriate outlet.

page 9 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

7. Installation and setup

7.1. Mechanical installation and

setup

7.1.1. Model SW-23

1.

Remove the OzzyMat

®

from its package, unfold it and

lay it on the mat support grid located in the lowest

level in the sink. Make sure to lay the OzzyMat®

white side up.

2. Place the false bottom in position in the sink.

3. Form the flexible nozzle to its desired shape and be

sure that the parts brush is inside the sink

4. DO NOT PLUG UNIT IN BEFORE ADDING

OZZY JUICE®

5.

At start up, carefully add ± 60 liter of OzzyJuice®

to the SmartWasher by slowly pouring the solution

directly into the sink.

6. Plug the unit into a 220 VAC GFCI electrical outlet

7.

The SmartWasher

®

will take approximately four hours

to heat up to its selected optimal temperature of

40°C (± 1°) or 46°C (± 1°). This temperature will be

maintained as long as the SmartWasher

®

is plugged in

and full of OzzyJuice®. If the “Add Fluid” light is on,

the heater automatically shuts o.

PARTS WASHER SETUP SW-23

33076

Mat support grid

32950

Multi-Layer OzzyMat FL-4

33046

False Bottom for SW-23

32981

Plastic Basket

page 10 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

SINK DIAGRAM SW-23

32981

Plastic Basket

33046

False Bottom for SW-23

32950

Multi-Layer OzzyMat FL-4

33076

Mat support grid

33068

Angled Brush Assembly

(includes: brush, instagrip tubing

and hose clamps)

32678-AA

Angled Brush

32982

Nozzle Kit

33057

1/2” NPT Connector - Grey

33090

1/2” ball valve PVC threaded

Grey body, blue handle

33087

Velcro Strap

(for power cord)

33053

Sink Fitting Kit for SW-23 v.2

(includes : quick disconnect plug and valve)

page 11 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

POWER

ADD FLUID

ENERGIA

SECTEUR

AÑADIR FLUIDO

AJOUTER FLUIDE

Additional Parts for

Model SW-23:

32993-CF Heater Fuse; 6,3 Amp

32993-CH Pump Fuse; 1 Amp

33072 Bulkhead Fitting

BASE DIAGRAM SW-23

32987-AA

Quick Disconnect Plug

33086

Quick Release Pins

32987-AB

Quick Disconnect Base

33049

Overflow Assembly for Base

32985

Heater for SW-23

33051-AA

Heater Box Assembly

(includes: box, heater,

and probe)

33096

Dolly Kit

(includes: dolly base,

wheels, casters and

hold-down clips)

33080

4” Caster

NO BRAKE

33079

4” Caster

WITH BRAKE

33081

8" Wheel

33078

Dolly Clips - Set of 4

32986

Probe

33065

Pump Kit

(includes: pump,

liquid tight tubing,

quick connects

& tubing for plumbing)

33051-AD

5-LED Control

Box with Fuse

(includes: switch,

boot, and fuse

33095

Control Box Lid

33073

Toggle Switch

33074

Boot Seal

33082-AA

Cotter Pin

for Wheel

page 12 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

PARTS WASHER OPERATION

1. The pump switch is attached to a ten minute timer. Turning the switch “ON” (upward position) will start

fluid flowing for ten minutes. To restart the flow, turn the switch “OFF” then “ON” again and the flow will

restart for another ten minutes.

2. Adjust the valve at the base of the nozzle to control the flow of the fluid through the nozzle. The valve at

the base of the brush hose controls the flow of fluid through the brush. Both outlets can be operated inde-

pendently or together.

page 13 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

7.1.2. Model SW-25

1.

Remove the OzzyMat

®

from its package, unfold it and

lay it on the mat support grid located in the lowest

level in the sink. Make sure to lay the OzzyMat®

white side up.

2. Place the false bottom in position in the sink.

3. Form the flexible nozzle to its desired shape and be

sure that the parts brush is inside the sink

4. DO NOT PLUG UNIT IN BEFORE ADDING

OZZY JUICE®

5. At start up, carefully add ± 95 liter of OzzyJuice®to

the SmartWasher

®

by slowly pouring the solution

directly into the sink.

6. Plug the unit into a 220 VAC GFCI electrical outlet

7.

The SmartWasher

®

will take approximately four hours

to heat up to its selected optimal temperature of

40°C (± 1°) or 46°C (± 1°). This temperature will be

maintained as long as the SmartWasher®is plugged

in and full of OzzyJuice®. (If the Add Fluid Light is on,

the heater automatically shuts o)

33075

Drain Basket 3 1/2”

Stainless steel

32950

Multi-Layer OzzyMat

FL-4

33052

False Bottom With

Drain For Sink

33076

Mat Support Grid

page 14 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

SINK DIAGRAM SW-25

33052

False Bottom With Drain For Sink

32950

Multi-Layer OzzyMat FL-4

33076

Mat Support Grid

33075

Drain Basket 3 1/2”

Stainless steel

32982

Nozzle Kit

33057

1/2” NPT

Connector - Grey

33066

Brush Assembly, with 2-foothose

(includes: brush, hase & valve)

or

32678-AB

flow-through brush alone

33054

Sink Plumbing Kit

Includes: tubing, hose, clamps, tee

connectors, female hose barb,

& maile hose barb

33090

1/2” ball valve PVC

threaded - grey body,

blue handle

33090

1/2” Ball Valve PVC

threaded

grey body, blue handle

33094

90° Street Elbow

33093

Nipple 1/2"x2"

page 15 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

POWER

ADD FLUID

ENERGIA

SECTEUR

AÑADIR FLUIDO

AJOUTER FLUIDE

BASE DIAGRAM SW-25

Additional Parts for

Model SW-25:

33061

Heater Box Assembly

(includes: heater, probe,

box, fittings)

32993-CF Heater Fuse,

6,3 Amp

32993-CH Pump Fuse,

1 Amp

33072

Bulkhead Fitting

33049

Overflow Assembly

for Base

33056

Heating Element

32986

Probe

33095

Control Box Lid

33074

Boot Seal

33073

Toggle Switch

33059-AA

5-LED Control Box

with Fuse

(includes: switch,

boot & &fuse)

33064

PUMP ASSEMBLY 220V

(includes: pump, liquid tight

tubing, quick connects &

tubing for plumbing

page 16 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

SW-28

PARTS WASHER OPERATION

1. The pump switch is attached to a ten minute timer. Turning the switch “ON” (upward position) will start

fluid flowing for ten minutes. To restart the flow, turn the switch “OFF” then “ON” again and the flow will

restart for another ten minutes.

2. Adjust the valve at the base of the nozzle to control the flow of the fluid through the nozzle. The valve

at the base of the brush hose controls the flow of fluid through the brush. Both outlets can be operated

independently or together.

page 17 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

7.1.3. Model SW-28

1. Remove the OzzyMat®from its package, unfold it and

lay it on the mat support grid located in the lowest

level in the sink. Make sure to lay the OzzyMat®white

side up.

2. Place the false bottom in position in the sink.

3. Form the flexible nozzle to its desired shape and be

sure that the parts brush is inside the sink

4. DO NOT PLUG UNIT IN BEFORE ADDING

OZZY JUICE®

5.

At start up, carefully add ± 95 liter of OzzyJuice

®

to the SmartWasher®by slowly pouring the solution

directly into the sink.

6. Plug the unit into a 220 VAC GFCI electrical outlet

7.

The SmartWasher®will take approximately four hours

to heat up to its selected optimal temperature of

40°C (± 1°) or 46°C (± 1°). This temperature will be

maintained as long as the SmartWasher®is plugged

in and full of OzzyJuice®. If the “Add Fluid” light is on,

the heater automatically shuts o.

33075

Drain Basket 3 1/2”

Stainless steel

33062

False Bottom With

Drain For Sink

33076

Mat Support Grid

32950

Multi-Layer

OzzyMat FL-4

page 18 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

SINK DIAGRAM SW-28

33062

False Bottom With Drain For Sink

33075

Drain Basket 3

1/2”

Stainless steel

32950

Multi-Layer OzzyMat FL-4

33076

Mat Support Grid

33070

SuperSink Nozzle Kit

33090

1/2” Ball Valve PVC

threaded - grey body, blue handle

33094

90° Street Elbow

33093

Nipple1/2"x 2"

33088

Nozzle Clamp

33057

1/2” NPT Connector - Grey

33090

1/2” ball valve PVC

threaded

grey body, blue handle

33067-AA

4’ Brush Assembly

(includes: brush,

hose & valve)

OPTIONAL ITEM:

33071

2nd Brush Station kit

(includes: 4’Brush Assembly,

1/2” Ball Valve & Connector,

90o Street Elbow

33055

Sink Plumbing Kit

includes: tubing, hose, clamps,

tee connectors, female hose barb,

& maile hose barb

2nd Work

Station

Connection

33091

1/2” Cap

33093

Nipple 1/2" x 2"

page 19 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

POWER

ADD FLUID

ENERGIA

SECTEUR

AÑADIR FLUIDO

AJOUTER FLUIDE

BASE DIAGRAM SW-28

Additional Parts for

Model SW-28:

33067-AB

Heater Box Assembly

(includes: heater, probe,

box, fittings)

32993-CF

Heater Fuse, 6,3 Amp

32993-CH

Pump Fuse, 1 Amp

33072

Bulkhead Fitting

33064

Pump Assembly

(includes: pump, liquid

tight tubing, quick connec-

tors & tubing for plumbing)

33049

Overflow Assembly for

Base

33056

Heating Element

32986

Probe

33095

Control Box Lid

33074

Boot Seal

33073

Toggle Switch

33059-AA

5-LED Control Box

with Fuse

(includes: switch,

boot & fuse)

33064

PUMP ASSEMBLY 220V

(includes: pump, liquid

tight tubing, quick

connects

& tubing for plumbing

33086

Quick Release

Pins

page 20 of 720

BIOREMEDIATING parts washing system

SmartWasher

®

USER INSTRUCTION MANUAL

ORIGINAL INSTRUCTIONS

SW-37

PARTS WASHER OPERATION

1. The pump switch is attached to a ten minute timer. Turning the switch “ON” (upward position) will start

fluid flowing for ten minutes. To restart the flow, turn the switch “OFF” then “ON” again and the flow will

restart for another ten minutes.

2. Adjust the valve at the base of the nozzle to control the flow of the fluid through the nozzle. The valve

at the base of the brush hose controls the flow of fluid through the brush. Both outlets can be operated

independently or together.

This manual suits for next models

4

Table of contents

Languages:

Other CRC Washer manuals

CRC

CRC SmartWasher BenchtopPRO User manual

CRC

CRC Smartwasher SW-37 User manual

CRC

CRC SmartWasher SW-25 User manual

CRC

CRC Simply Go User manual

CRC

CRC SmartWasher SW-23-RGB Operator's manual

CRC

CRC SmartWasher SW-23 Operator's manual

CRC

CRC SmartWasher SW-28 User manual

CRC

CRC SnartWasher SW-23 User manual

CRC

CRC SmartWasher SW-23 User manual