2

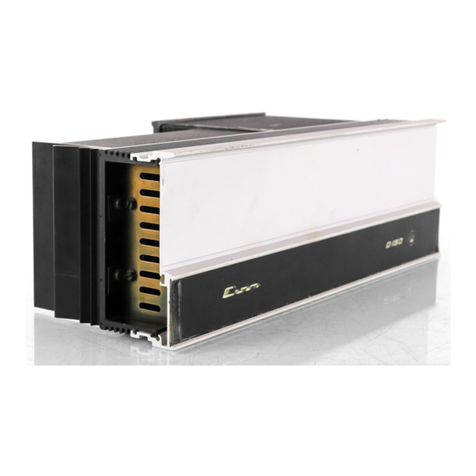

Sometimes a product fits an application so well, it

is deemed a classic. The term is synonymous with

the Crown®Macro-Tech Series of power amplifiers.

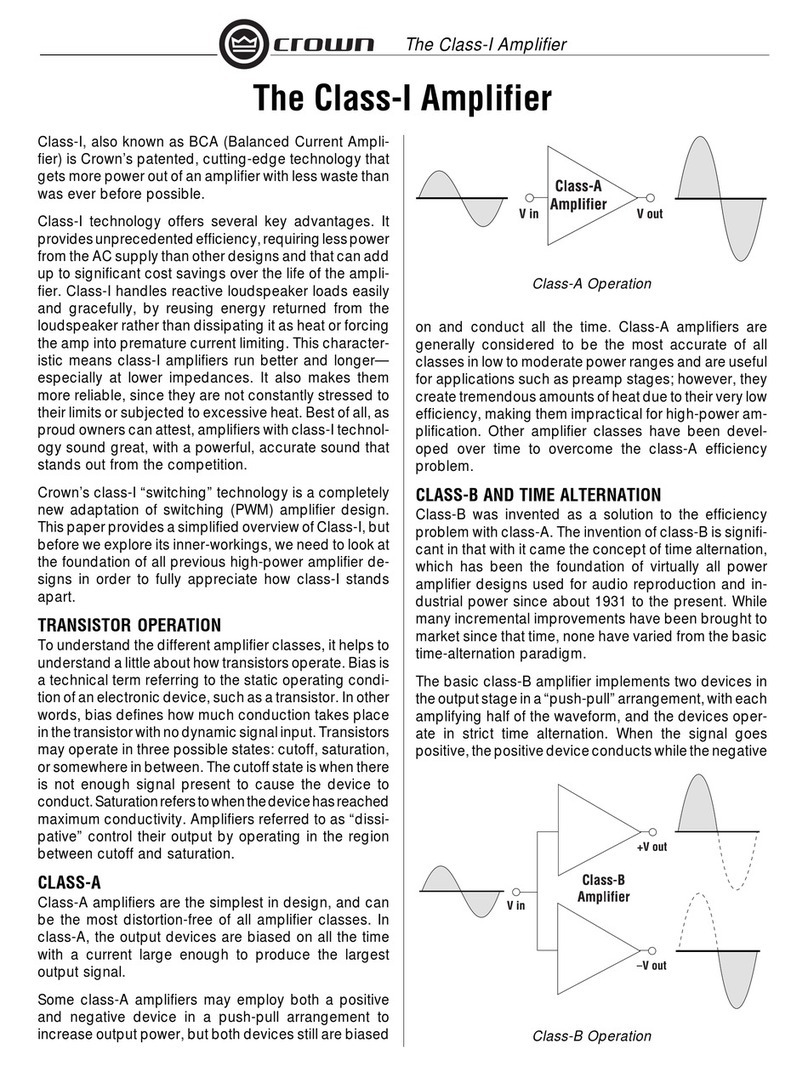

That product line, and its predecessor Micro-Tech®, sparked

innovative technologies that provided lower distortion, less

thermal stress, higher output power, greater reliability, more

power density and superior audio quality.

No compromises, no gimmicks. Just brilliant engineering

backed by superior manufacturing, support and an

unsurpassed commitment to quality.

Like all Crown amps, the defining characteristic of the Macro-

Tech Series is sonic accuracy. A tight, rock-solid low end, with

smooth, detailed highs and a well-defined midrange. In short,

Crown Macro-Tech Series

Enjoy!

the most accurate reproduction of an audio signal you’ve ever

heard. And because we put the quality of sound above all else,

Crown amplifiers are the most coveted in the business.

When it comes to manufacturing amps, our work is based on

one simple fact: there are no shortcuts to quality. And our Macro-

Techs have proven this time and time again in some of the most

demanding applications in the world.

For this special, limited Macro-Tech release, we wanted to bring

you more than just the typical operation manual. This brochure

goes much further, delving into the Macro-Tech’s development,

design philosophy, and advanced technical features. We’ve also

included some brochures from the past, a bio of Crown’s chief R&D

engineer Gerald Stanley, customer statistics, anecdotes and more.

Since 1984, Crown has shipped

approximately 272,625 MT and MA

amplifiers to date. That’s approximately

54 million watts into 4 ohms or 65

million watts into 2 ohms!