CRS 5AHPR0 User manual

Electronic Crimping Tool HPS

With External Activation

Model 5AHPR0

Crimping tools with interchangeable jaws and

dedicated power supply

Operation Guide

2 Chromatography Research Supplies, Inc.

Notices

© Chromatography Research Supplies, Inc.

Part No: 995217

Printed in USA

January 2017

Chromatography Research Supplies, Inc.

2601 Technology Drive

Louisville, Kentucky

USA

Safety Notices

A CAUTION notice warns of a hazard. It calls

attention to an operating procedure, practice,

or the like that, if not correctly performed or

adhered to, could result in damage to the

product or loss of important data. Do not

proceed beyond a CAUTION notice until the

indicated conditions are fully understood and

met.

WARNING

A WARNING notice warns of a hazard. It

calls attention to an operating procedure,

practice, or the like that, if not correctly

performed or adhered to, could result in

personal injury or death. Do not proceed

beyond a WARNING notice until the

indicated conditions are fully understood

and met.

Recycling

For recycling contact CRS or

your local CRS distributor.

Sound Pressure

Sound pressure LpA = 79 dB(A)

Electronic Crimping Tool 5AHPR0 3

Electronic Crimping Tool HPS with RS485 Serial Interface

Operations Guide

Contents

Warnings, Intended Use, Limits 4

Background, Warnings, Description,

Mechanical Connections 5

Electrical Connections 6

Full Serial Control 6

Demonstration Interface 7

Power Supply Information 8

Support/Repair 8

Appendix A - Accessory Base for Electronic Crimpers 9

This operation manual applies to the following products:

Model Number

Electronic Crimping Tool HPS with RS485 Serial Interface

5AHPR0

Related Items

Item Number

Accessory Base for Electronic Crimpers

5ABAS0

11 mm Crimper Jaw Set

311955

20 mm Crimper Jaw Set

320955

20 mm Flip-Off Crimper Jaw Set

320956

8 mm Crimper Jaw Set

308955

13 mm Crimper Jaw Set

313955

13 mm Flip-Off Crimper Jaw Set

313956

11 mm Decapper Jaw Set

311965

20 mm Decapper Jaw Set

320965

13 mm Decapper Jaw Set

313965

4 Chromatography Research Supplies, Inc.

Warnings

Remember to wear safety glasses when crimping or decapping.

The crimper or decapper jaws can pinch severely.

Only change jaws after the power supply has been disconnected or the tool has

been locked.

Never insert fingers into the crimping tool jaws.

Use only the 12 volt DC Power Supply supplied with the crimping tool.

Intended Use

Electronic Crimping Tools are intended for use in a laboratory environment.

Prohibited Use

All other uses are prohibited.

Limits

Temperature 15ºC to 35ºC

Humidity not more than 75%

Pressure 0.75 to 1 bar

Electronic Crimping Tool 5AHPR0 5

Background

The CRS 5AHPR0 High Power Crimping Tool can be adapted for use as a crimping

head in automatic equipment. This guide serves to outline the mechanical and electrical

connections necessary to do so.

The designer of the device incorporating this tool will

need to issue a new Declaration of Conformity after

doing a risk analysis and studying the DoC Supplied.

While the interface is straightforward, the designer

must to enough testing to verify that the tool is

suitable for the application intended.

Warnings

All of the warnings stated in the Instruction Manual apply to the tool when in remote

operation, but additional considerations apply.

When the crimper is activated remotely the pinch danger from the crimper jaws is

increased considerably. The purpose of remote activation is to allow the crimper to be

built into an automatic machine or used with special guarding, for example in a glove

box, in which case an additional risk assessment needs to be carried out.

A user with 2-hand access to the crimping head when remote operation is employed is

exposed to the action of the jaws during crimping and additional guarding should be

provided.

Description of 5AHPR0

1. The tool includes a 12 volt universal external

power supply with an IEC-320 connection for

a power cord in the country of use. The

supply carries appropriate markings for the

US and Canada, the European Union, -

Japan, China and Taiwan.

2. Interchangeable crimping heads are

available for most standard crimp caps and

seals.

3. The crimping action may be adjusted by a

keypad on top of the unit.

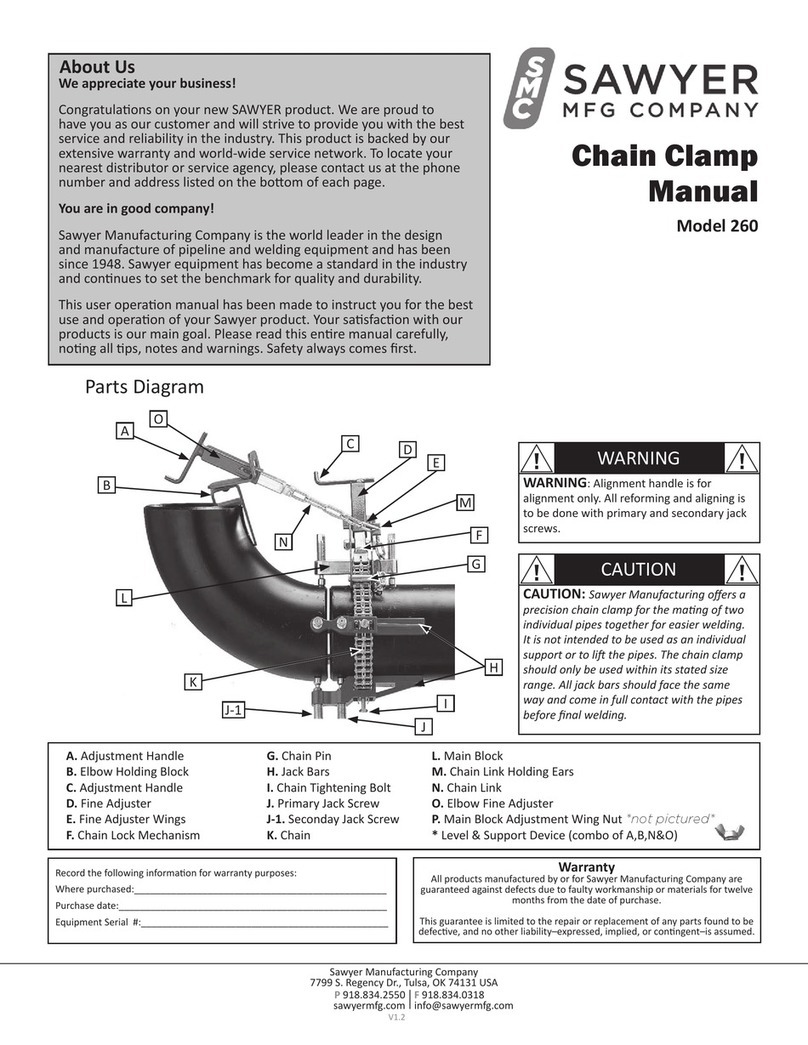

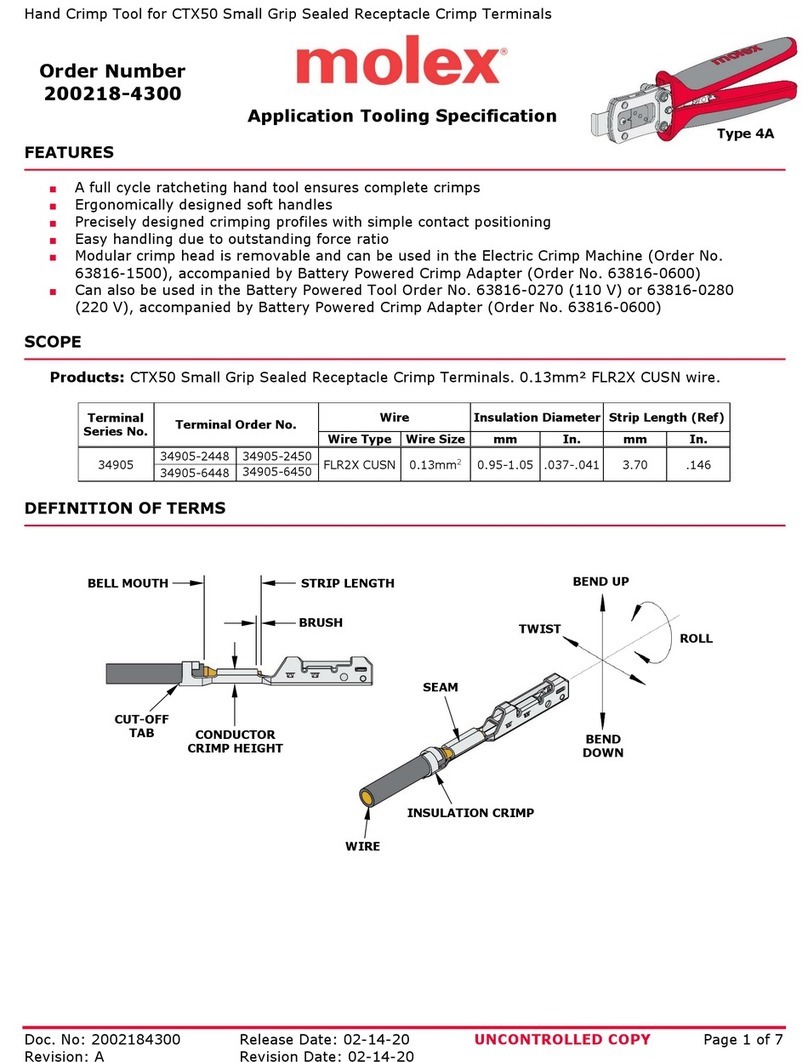

Mechanical Connection

There are two M3x.5 threaded inserts in the side of the crimping case. These inserts

should be used to attach the crimping tool to a mounting bracket or support.

6 Chromatography Research Supplies, Inc.

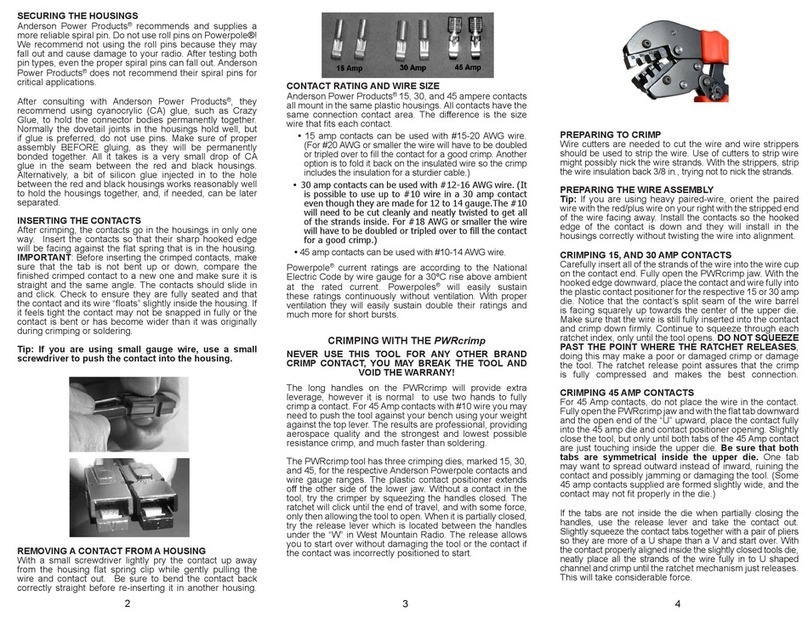

Electrical Connection (Active Crimp or Serial Control)

For remote activation (to activate the crimp cycle with a simple

contactor) a connection can be made through the case wall of

the crimping tool to the power supply adapter circuit board.

There is a two-pin connector (P6, the lower white connector in

the photo below) on this board that is wired in parallel to the

activation button on the crimping tool itself. If these pins are

shorted together the crimper will cycle.

Full Serial Control

The power supply adapter board also has provision for a serial interface that can allow a

greater degree of external control, for example to change the crimper setting, to reset

the tool, to receive error messages for logging, to acquire cycle data, etc. An RS485

connection (19.2 BAUD, 8 bits, no stop bit) is available through a DIN connector, which

can be added to the top of the unit next to the power connection.

The serial connection can be tested with a sample C# Windows program. The actual

machine control would be effected by the machine designer, directly from a PLC or

through an OPC driver (for example).

The following instructions are implemented in the serial interface:

Instruction

Notes

Purpose

ANSWERME

Verify connectivity

MOVETOxx

“xx” is percent of the maximum stroke for the

selected jaw set.

Move the plunger to a selected position.

RETRACT

Moves the plunger back to the top

position.

REZERO

Moves the plunger up to the hard stop

past the top position to establish a zero

point.

JAWSETxxa

Sets the selected jawset. “xx” = 8, 11, 13 or 20. “a”

= C or D. JAWSET with no size parameter will

cause the crimping tool to answer with the

information as to the currently selected jaw set, in

the format “JAWSETxxa”.

Select a jawset, or request the jawset

information from the tool.

Caution:

The motor/gearbox

assembly must

remain in its seat

when the top case is

removed and

replaced in order to

avoid damage to the

main circuit board.

Electronic Crimping Tool 5AHPR0 7

PROGRAMNOx

Sets the program to one of the preset programs, 0-

9.

TARGETxx

Sets the Stop Position as a % of maximum, or if xx

is omitted requests the stop position.

CRIMP

Executes the crimping (or decapping) cycle

Demonstration Interface

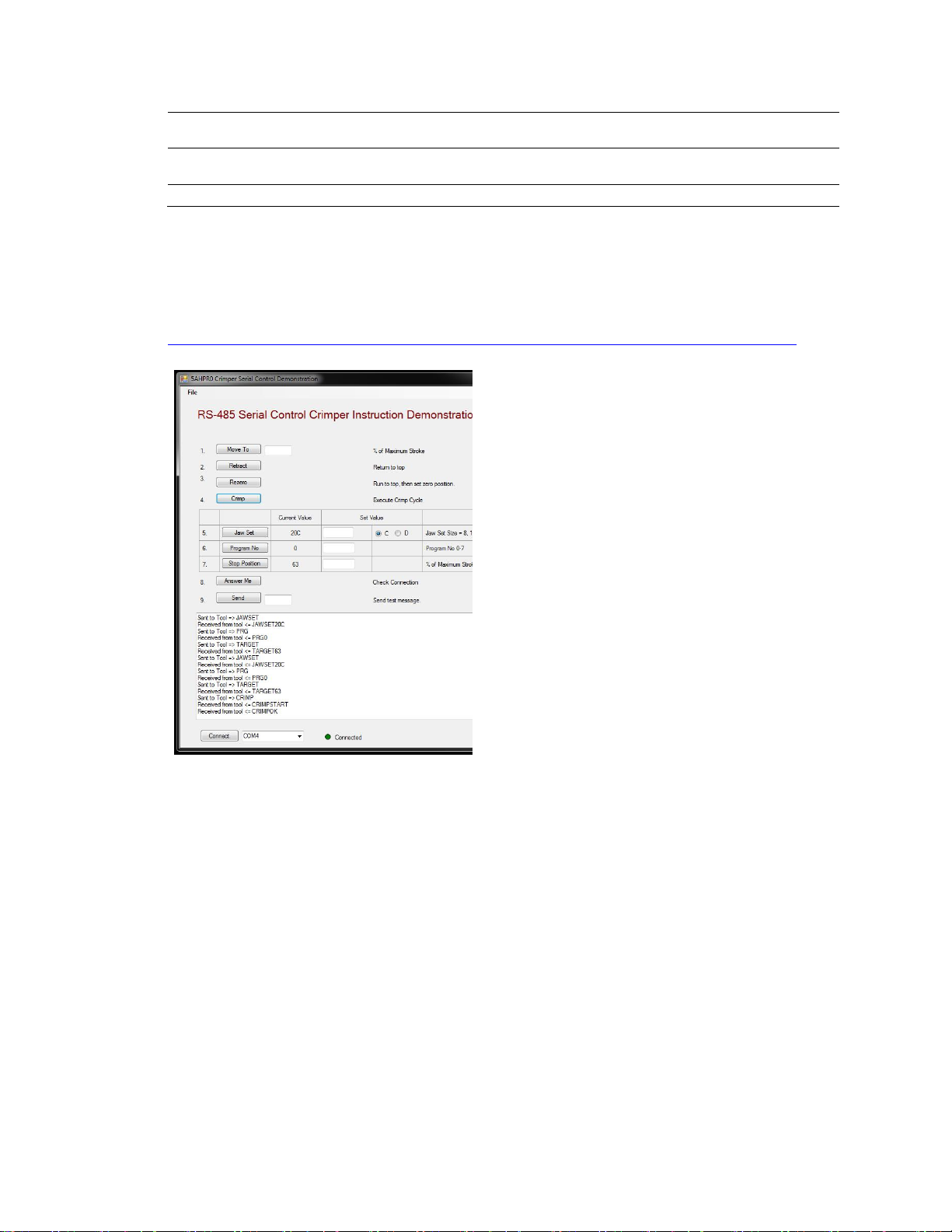

A simple C# program is available to test the crimper interface and to aid in development.

This program can be downloaded from:

https://www.ChromRes.com/media/catalog/product/5/A/HPR%20Demonstration.zip

Instructions:

1. Connect the RS485 port on the crimper to a serial

port of the crimper. (It might be helpful to use a USB <=>

RS485 converter, such as the B&B Electronics

USPTL4).

2. Start the demonstration program, select the correct

COM port and click the “Connect” button.

3. The log window should start to show the

communications between the crimper and the computer.

4. The various commands and the available can be

tested using the buttons.

5.The log window shows the communication between

the tool and the test program. Note that the program

queries the tool setting continuously to keep up with any

manual changes to the tool settings, with a lag time of

several seconds.

Electronic Crimping Tool 5AHPR0 9

Appendix A

Accessory Base for Electronic Crimpers

Table of contents

Popular Crimping Tools manuals by other brands

Gazelle

Gazelle G9622 user manual

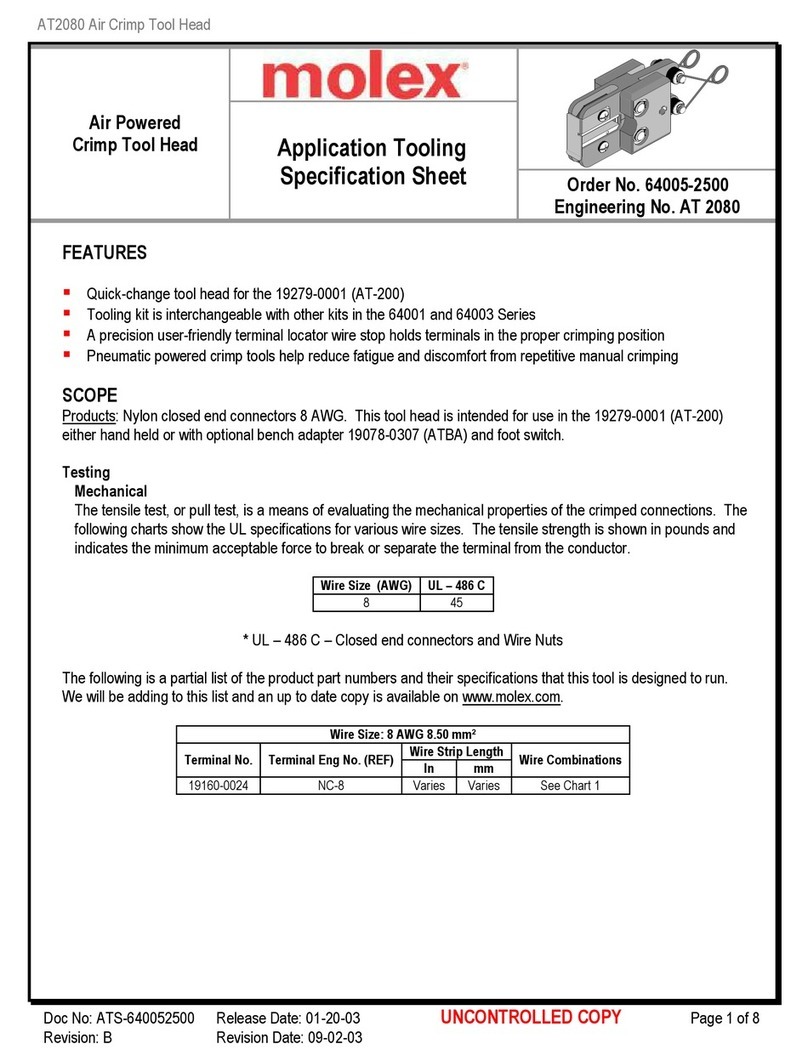

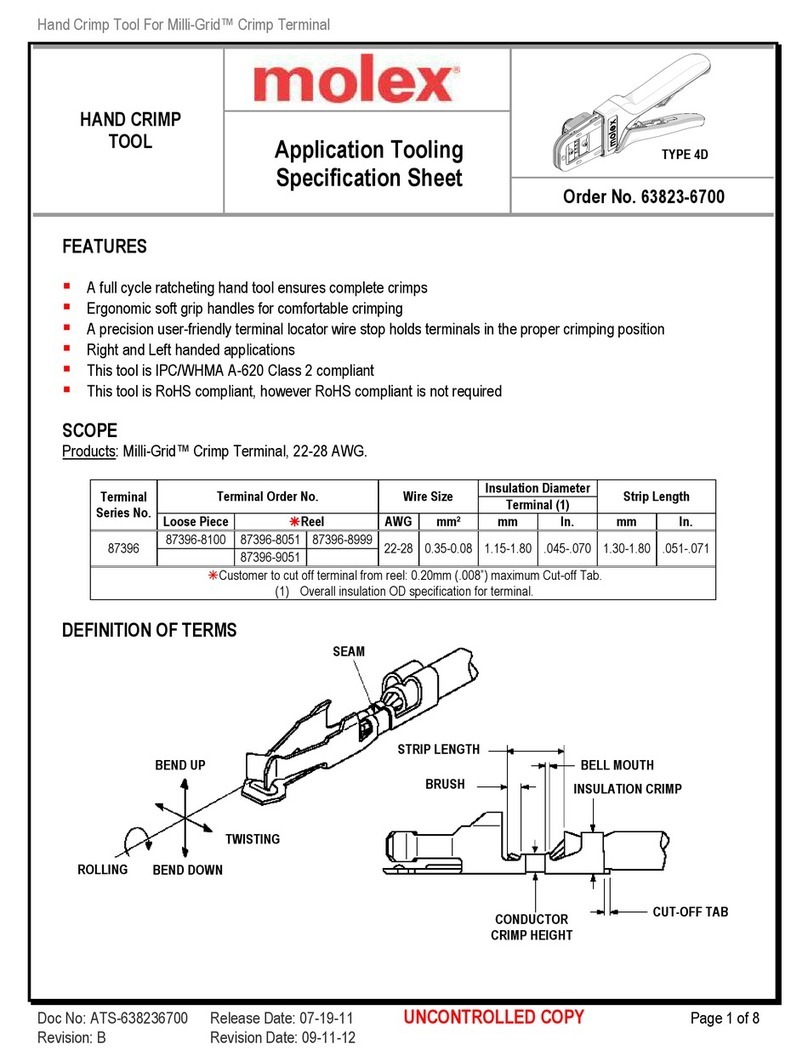

molex

molex 207129 Series specification

Tyco Electronics

Tyco Electronics 408-10050 instruction sheet

TE Connectivity

TE Connectivity PRO-CRIMPER III instruction sheet

Textron

Textron EK1240CL Operation manual

TE Connectivity

TE Connectivity CERTI- CRIMP Series instruction sheet

Panduit

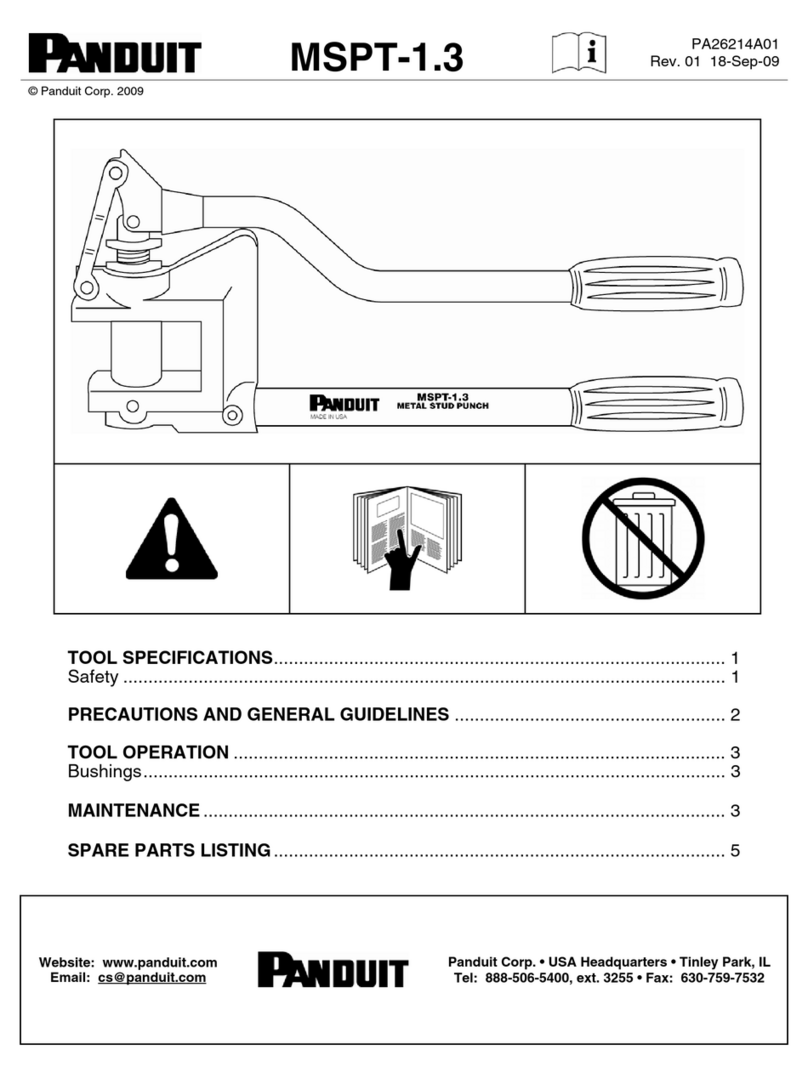

Panduit MSPT-1.3 quick start guide

Deutsch

Deutsch DTT-16-01 Instruction guide

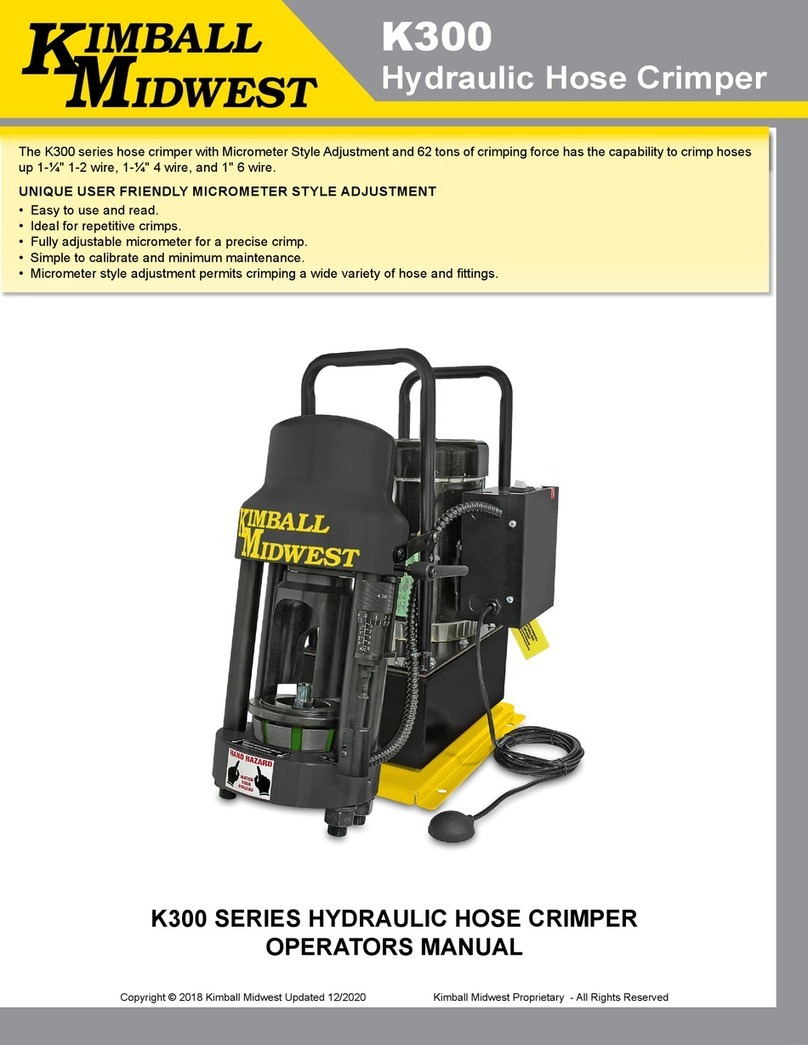

KIMBALL MIDWEST

KIMBALL MIDWEST K300 Series Operator's manual

molex

molex 63825-9400 Application Tooling Specification Sheet

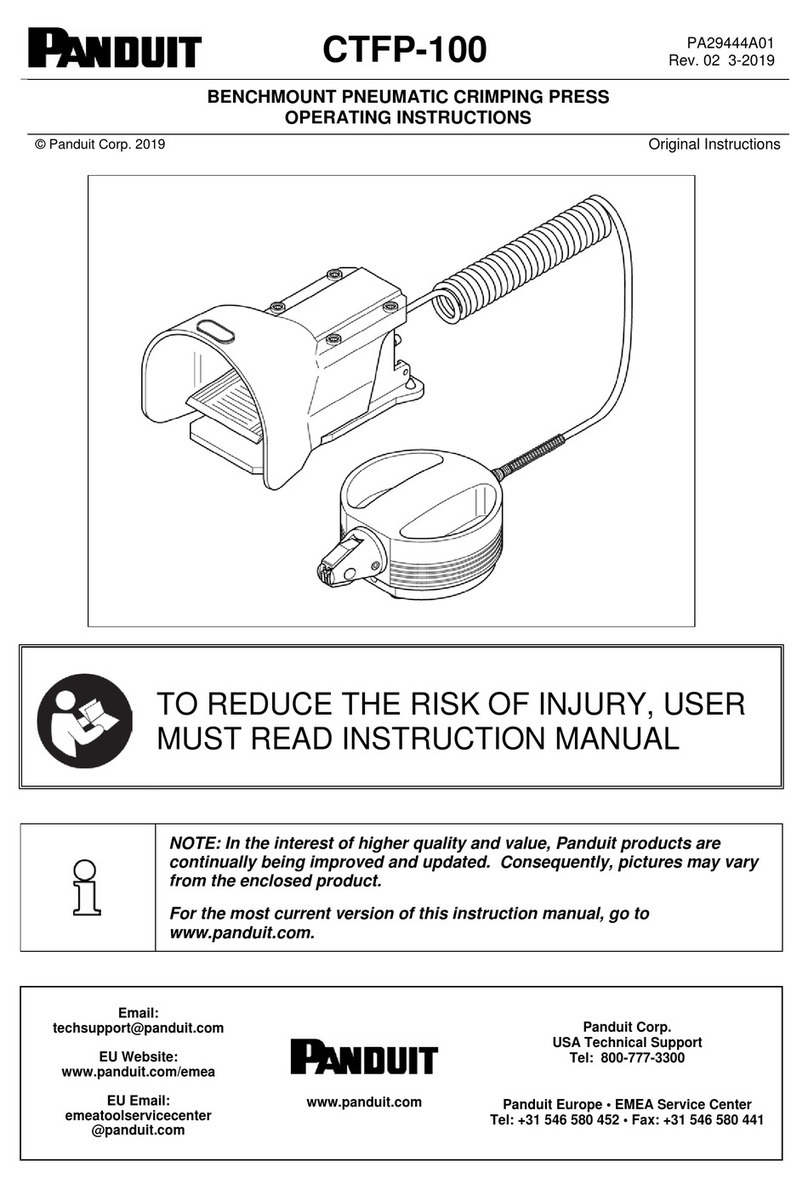

Panduit

Panduit CTFP-100 operating instructions

Textron

Textron Greenlee GATOR EK12IDLT Operation manual