Crystal Mountain Storm Cafe User manual

Service Manual

Storm Café

Hot, Cold and Coffee Dispenser

2

Notes

3

SECTION 1: Product Specification 4

Dimensional Drawing 5

Description of Product Model Number 6

SECTION 2: Parts Listing and Exploded Views 7

Parts Listing 7

Exploded Views 8

Fluid Path Diagram 9

Wiring Diagram 9

SECTION 3: Water Bottle Installation and Replacement 10

SECTION 4: Replacement of SmartFlo™ System 14

SECTION 5: Electrical Diagnosis and Replacement 17

Cold Control Replacement 17

Cold Control Adjustment 19

Hot Thermostat/Limiter Replacement 20

Hot Tank Replacement 21

Compressor Relay/Overload Replacement 24

SECTION 6: Cleaning & Sanitization 26

Cleaning and Sanitizing the Water Cooler 26

Monthly Cleaning and Sanitizing of the Brewer 31

Clearing the Inlet or Outlet Needle 32

SECTION 7: Displaying and Clearing Fault Codes 34

SECTION 8: Purging Water from System 35

SECTION 9: Troubleshooting 36

CAUTION: Optimum Operating Range 50°F-90°F (10°C-32°C)

Table of Contents

4

The Storm Café water dispenser with coffee brewer is the latest model

in the Storm family of coolers. The Café combines the convenience of

the original Storm bottom load cooler with a single serve coffee cup

type brewer. This generation of the Storm has an upgraded fascia with

lighting over each faucet handle.

Specifications

Storm Café

Power Rating Single Phase

100-115VAC 60Hz

Standard Current 8.9~9.5A

Power Cold 70W

Consumption Hot 1000W

Cold

Compressor Single Phase Compressor

Refrigerant Type R134a (32g)

Temperature Range 4-10°C(39.2-50°F)

Hot/Coffee

Heater Internal Heater

Temperature Range 73.9°C -85°C (165°F -185°F)

Temp. Range for Coffee 91.5°C (196.7°F)

Safety Device Bimetal (Limiter115°C (239°F) OFF)

Temperature Control Bimetal 95°C (203°F)

NTC Control Electronic

Net Weight 15.1kg (33.1 lb.)

Loading Quantity 20’ Container: 204 Units

40’ container: 420 Units

5

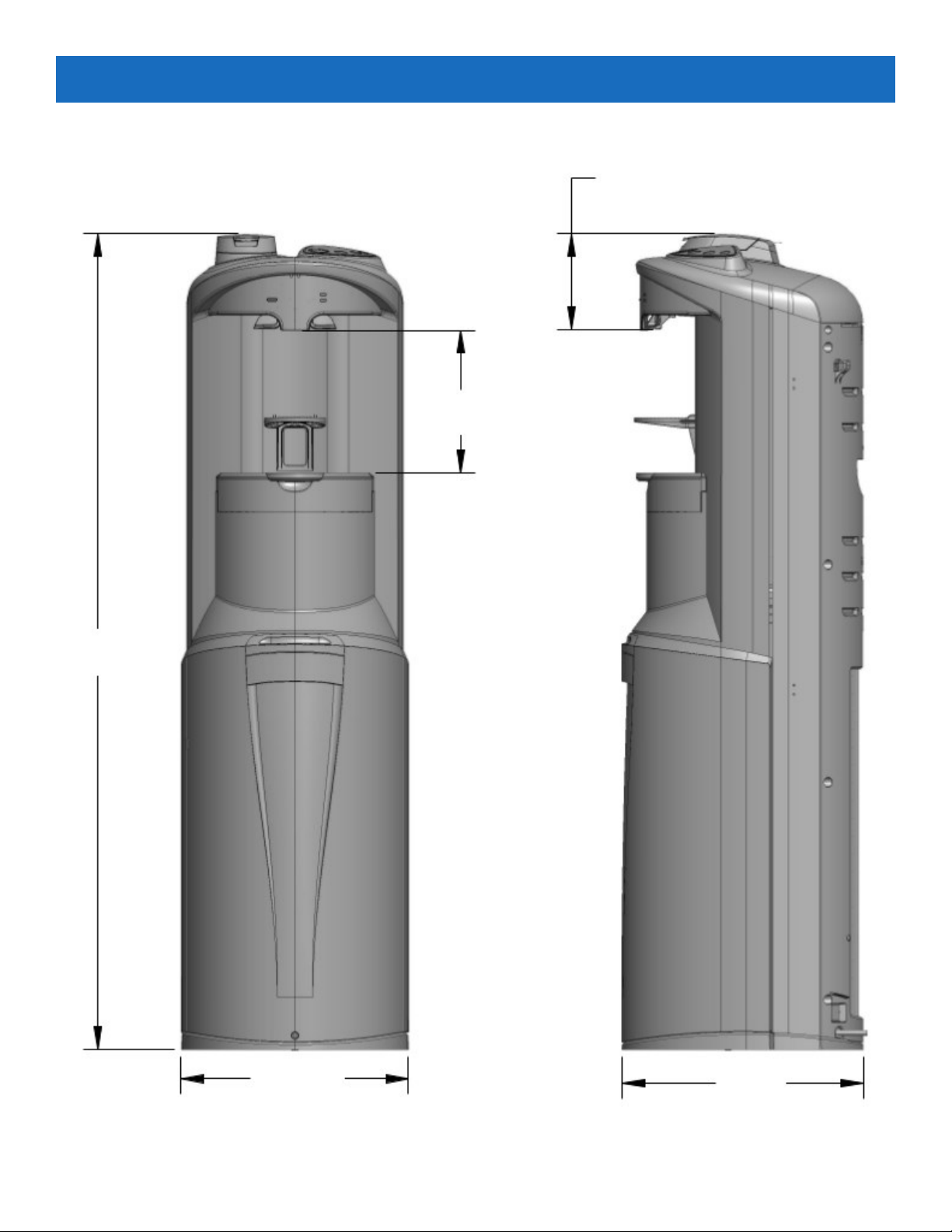

Dimensional Drawing

45.172 (1147.37)

7.904 (200.76)

5.273 (133.93)

12.598

(319.99)

13.386

(340)

Dimensions are shown in Inches (mm)

6

The model and serial number can be found on the rear of the cooler.

See the example to right.

AB FM2KHK 1

Cooler Shape Reservoir Type Type of Lid # of

Faucets

Body Color Temp.

Option

Insert Color Voltage Option

AB=

Storm Coffee

Brewer

F=

SmartFlo™

Water

Cartridge

M=

Manifold

2K=

Black

H=

Hot & Cold

K=

Black

1=

115V

CF=

Café

Description of Product Model Number

7

DESCRIPTION ABFM2KHK1CF

1. Tube Guide, Hot PLC-C150176

2. Handle Assembly (contains hot & cold handles) SUB-G300001

3. Spring, SS, Faucet FAS-C100104

4. Pin, Handle 76mm FAS-C100199

5. Flow Meter ELE-C100489

6. Tube, Silicone, Flow Meter SIL-C150043

7. Connector, Water, Female PLC-C150167

8. Valve, One Way POU-C100100

9. Cover, Pump PLC-C150174

10. Tube, Silicone, Air Pump SIL-C150032

11. Pump, Air, DC12V ELE-C100436

12. Cover, RJ11 PLC-C150177

13. Upper Shelf Assembly SUB-C200632

14. Cold Control REF-C100035

15. Motor, 12V DC, 1600 RPM ELE-C100204

16. Bushing, Motor PLC-C150052

17. Door Rail, Cap PLC-C150033

18. Latch, SmartFlo, Cafe PLC-C150166

19. Spring, SS, Safety Button FAS-C100116

20. Safety Button, Red PLC-C150126

21. PCB Switch Board ELE-C100421

22. Top Cover Assembly (8, 10, 12 oz brew size) SUB-C200722

Top Cover Assembly (6, 8, 10 oz brew size) SUB-C200839

23. Pod Holder PLC-C150162

24. Housing, Rear Café Assy SUB-C200640

25. Housing, Front, Café Assy SUB-C200642

26. Steam Valve, Café SUB-C200634

27. Solenoid Valve SUB-C200638

28. Base, Café Module Assy SUB-C200639

29. Cover, Power PCBA PLC-C150188

30. SmartFlo, Single Pack SUB-C200724

31. Hot Tank Assembly SUB-C200628

32. NTC, White ELE-C100457

33. NTC, Red ELE-C100452

34. Limiter ELE-C100459

35. Thermostat, Sealed ELE-C100458

36. Drain Cover PLC-C150216

37. Plug, Drain, Yellow SIL-C100154

38. Drain Cap PLC-C100399

39. Drain Fitting PLC-C150121

40. Spring Clip FAS-C000029

41. Tube, Drain SIL-C150002

Parts Listing

8

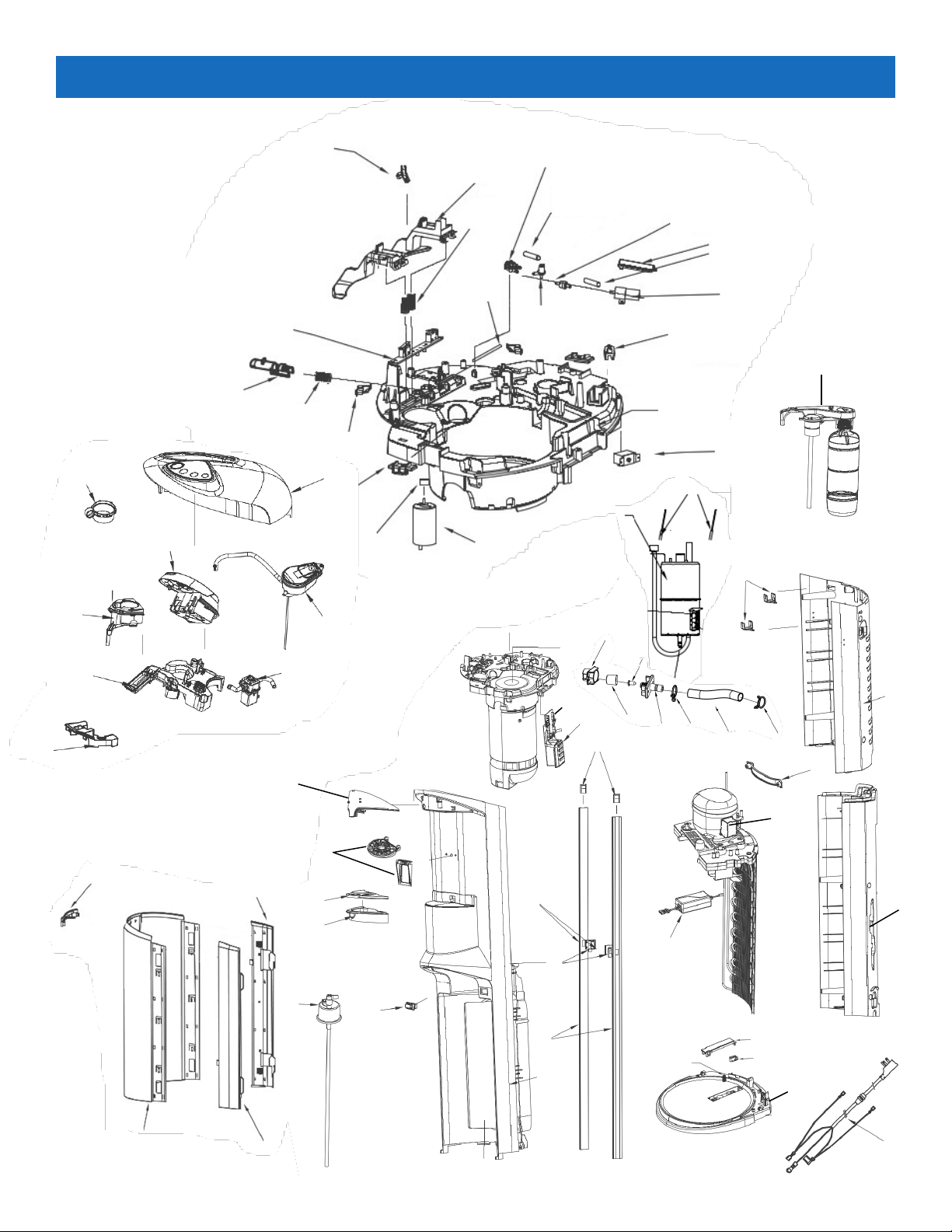

Exploded View

1

2

3

47

5

68

9

10

11

12

13

14

15

16

17

18

19

20

21

22

25

24

23

26

2728

29

30

31

32, 33

31

34, 35

36

37

38 39 40 41 42

43

44

45

47, 48

46

49

50

51

52, 53

54 55

56

58

57

59 60

61

62

63

64

65

66, 67

68

69

70

73

71

72

9

Fluid Path Diagram

Electrical Diagram

SmartFlo

Water

Pump

Cold Water

Dispense

Hot Water

Dispense Coee

Dispense

Bole

Pinch

Valve

Pinch Valve

Hot

Tank

Solenoid

Coee Pod

Brewer Head Brewer

Housing

Air Pump

One-Way

Valve

Flow

Meter

Steam Valve

Cold

Reservoir

Brewer

Lid

Switch

Connector

Blk

Hot Switch

Coee UI PCBA

Power Cord

Hot

Tank

Limiter

Hot Thermostat

Cold Control

Heater Control

PCBA

Blk

Blk

White

G/Y

G/Y White

White

White

Transformer To Overload

To Relay

Compressor

Flow Sensor

Lid Switch

LED FPC

LED Panel

MAIN PCBA

Switch PCB

Switch PCBA

Intensity SW

Water Pump

Solenoid

Air Pump

Bole SW

BK

Yellow

Blue Thermistor Dispense

Thermistor Control

Red

White

NTC

Red

NTC

10

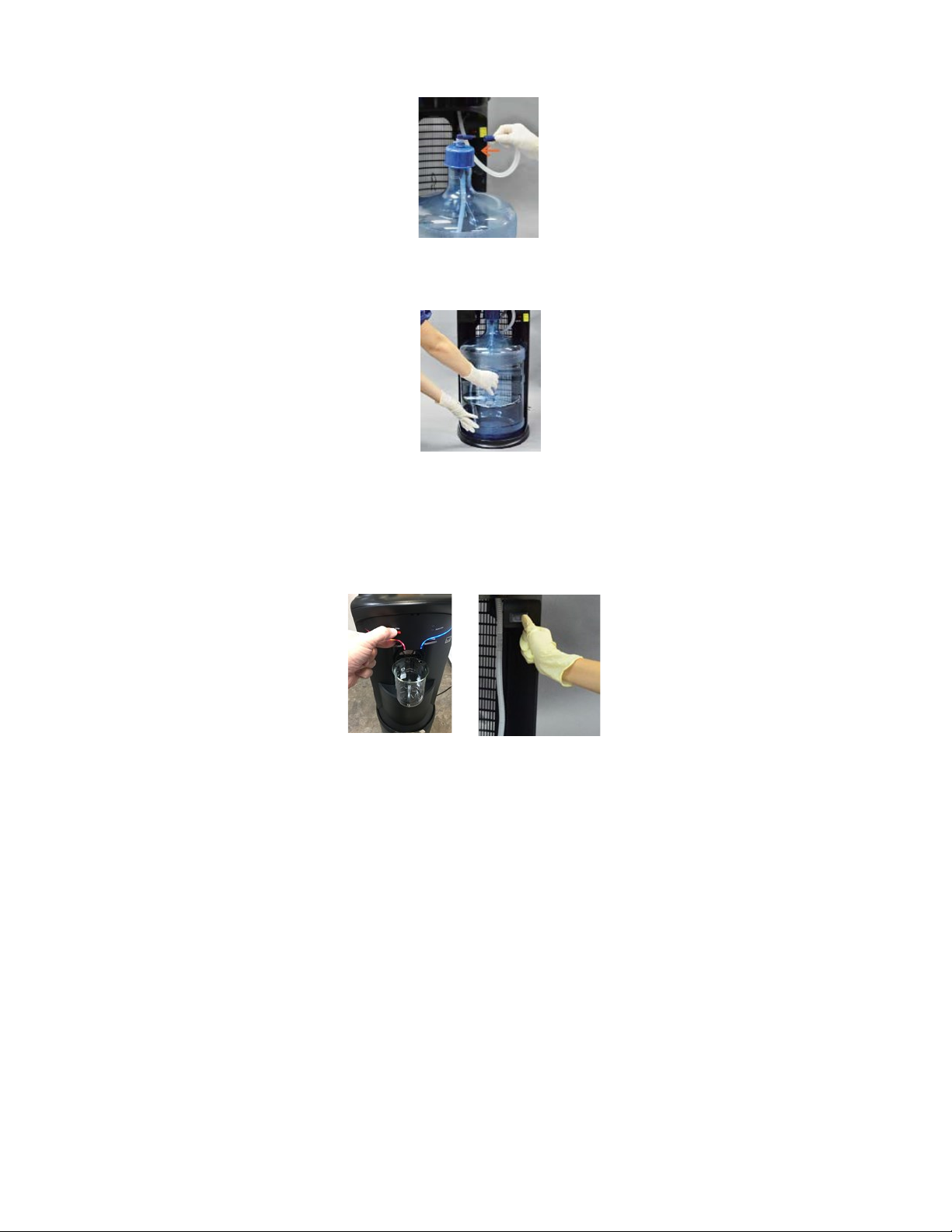

1. Open Dispenser door (Fig.1). Slide door upward to access bottle area.

2. Place fresh bottle outside of the cabinet.

3. Clean the outside of new bottle with a cloth (Fig. 2).

4. Remove label/seal from the bottle cap (if applicable) and insert spike cap through the bottle cap (do not remove bottle cap)

and press down to secure (Fig. 3 & 4).

5. Insert the bottle adapter assembly through spike cap until tube hits bottom of the bottle (Fig. 5 & 6).

Fig. 1

Fig. 2

Fig. 3 Fig. 4

Fig. 5 Fig. 6

Water Bottle Installation and Replacement

11

6. Remove the red protective cap from the blue tube of the SmartFlo and install onto the bottle adapter assembly

(Fig. 7).

7. Slide bottle into cabinet (Fig. 8) and close the door. Push down to close.

8. Depress the cold lever to fill the cold water tank (Fig. 9). When water begins to flow in a steady stream from the cold faucet,

the tank has been filled (approximately 1 minute although it may be less time). Repeat the process with the hot lever until the

flow out of the hot faucet is a steady stream. Lift the door to the bottle area and turn on the hot tank switch (Fig. 10) and

close the door by lowering back into place.

Fig. 7

Fig. 8

Fig. 10

Fig. 9

12

A blinking blue light above the cold water lever and a blinking “Replace Bottle” on the brew selection panel will alert you when

your water bottle is getting low. Water may be dispensed normally until empty (no water flows from the water outlets when lev-

ers are depressed).

Note: A flashing blue light above the cold water lever will alert you to when the SmartFlo Water Cartridge should be replaced.

The system has been pre-set to provide indication after a period of 12 months of use. User may operate the cooler as normal until

the bottle has been emptied. Note: To reset the life timer system, the SmartFlo is required to be removed from the dispenser for a

minimum of 15 seconds while the unit is connected to the mains power supply.

1. Open Dispenser door (Fig. 11). Slide door upward to access bottle area.

2. Slide empty bottle out of cabinet (Fig. 12).

3. Place a fresh bottle outside of the cabinet.

4. Clean the outside of new bottle with a cloth (Fig. 13). Remove the security label/seal from the bottle cap (if

applicable).

5. Remove bottle adaptor from the empty bottle (Fig.14) and remove the cap from the Hose Assembly (Fig.15).

Note: to maintain sanitization of the system, refrain from touching the section of the bottle adapter tube that

is inserted into the bottle.

Fig. 11

Fig. 12

Fig. 13

Fig. 14 Fig. 15

Changing the Water Bottle

13

6. Install Spike Cap through the bottle cap (do not remove bottle cap) and press down to secure (Fig. 16 & 17)

7. Insert the Bottle adaptor assembly through Spike cap until tube hits bottom of the bottle (Fig. 18 & 19).

8. Slide bottle into cabinet and close the door (Fig. 20 to Fig. 22). Push door down to close.

9. Place a container under faucet and dispense cold water until a smooth stream of water is dispensed. This may

take up to 1 minute.

Fig. 16 Fig. 17

Fig. 18

Fig. 20 Fig. 21 Fig. 22

Fig. 19

14

Notice:

The information and/or procedures presented in the following demonstration(s) should be performed by a trained Water Cooler

Service Technician only. Never attempt to service or repair a water cooler while it is plugged into any power supply. Prior to

any service or repair of the water cooler, ensure that the water has been completely drained from the system.

For the best tasting and highest quality water, it is recommended to change the SmartFlo™ Water Cartridge every 12 months.

Follow the steps below to replace the SmartFlo™. It is recommended to empty the bottle prior to replacement of the SmartFlo™

and bottle adaptor.

Note: A blue light above the cold water lever will alert you when the SmartFlo™ Water Cartridge should be replaced. The sys-

tem has been pre-set to provide indication after a period of 12 months of use. Users may operate the cooler as normal until the

bottle has been emptied.

Note: To reset the timer system, the SmartFlo™ must be removed from the dispenser for a minimum of 15 seconds while the unit

is connected to the mains power supply.

1. Open Dispenser door (Fig. 1). Slide door upward to access bottle area. Turn off the hot tank power switch (Fig. 2) and unplug

the water cooler (Fig. 3).

CAUTION: WATER IN HOT TANK IS VERY HOT AND CAN CAUSE SEVERE BURNS. ALLOW SUFFICIENT TIME FOR

THE HOT WATER TO COOL BEFORE DRAINING (1-2 HOURS)

2. Take bottle out from the base. (Caution: don’t break the corrugated tube.) Remove the connecter from adapter. Fig. 4).

3. Place a glass or other container below the water outlets (to catch drips) and unlatch the blue locking clip located

near the front of the cooler to release the water tubing (Fig. 5).

Fig. 1 Fig. 2 Fig. 3

Fig. 4

Fig. 5

Replacing the SmartFlo™

15

Fig. 12 Fig. 13 Fig. 14

4. Using the top cover key (Fig. 6), insert into the two holes (on the front, approximately 2 inches above and to the right of

hot water safety button), push key inward to open top cover (Fig. 7 & 8).

5. Squeeze the latch’s end to open (Fig. 9 & 10). Turn counterclockwise to release the two blue knobs (Fig. 11 & 12).

Pull to remove the SmartFlo™ Water Cartridge and discard in recycling bin (Fig. 13 & 14).

6. Install a new SmartFlo™ Water Cartridge. Install the connector and corrugated tube into the inlet through cooler to bot-

tom (Fig. 15 & 16). Insert the reservoir into evaporator (Fig. 17). Ensure the SmartFlo™ is installed properly. Turn the

two blue knobs to lock into place (Fig. 18 & 19).

Fig.11

Fig. 9 Fig. 10

Fig. 6 Fig. 7 Fig. 8

Fig. 15 Fig. 16 Fig. 17

Fig. 18 Fig. 19

16

Fig. 20

7. Close and latch the locking arm (Fig. 20).

8. Install the hose connecter to bottle adapter (Fig. 21). Put the water bottle into the bottom of the cooler.

9. Close the top cover and lower the door to close. Plug the cooler into the electrical outlet. Pull the cold faucet lever

until a steady stream of water comes out. Then, push the hot safety button and press the hot water faucet lever to

activate water flow. Keep pressing the hot water faucet lever until water comes out (Fig. 22).

10. Lift the door to open. Turn the hot tank power switch ON. Push downward to close the door.

CAUTION: TO PREVENT DAMAGE TO THE HOT TANK, DO NOT SWITCH ON IF HOT TANK IS EMPTY.

Fig. 21

Fig. 22

17

Fig. 1

Notice:

The information and/or procedures presented in the following demonstration(s) should be performed by a

trained Water Cooler Service Technician only.

Never attempt to service or repair a water cooler while it is plugged into any power supply.

Prior to any service or repair of the water cooler, ensure that the water has been completely drained from the system.

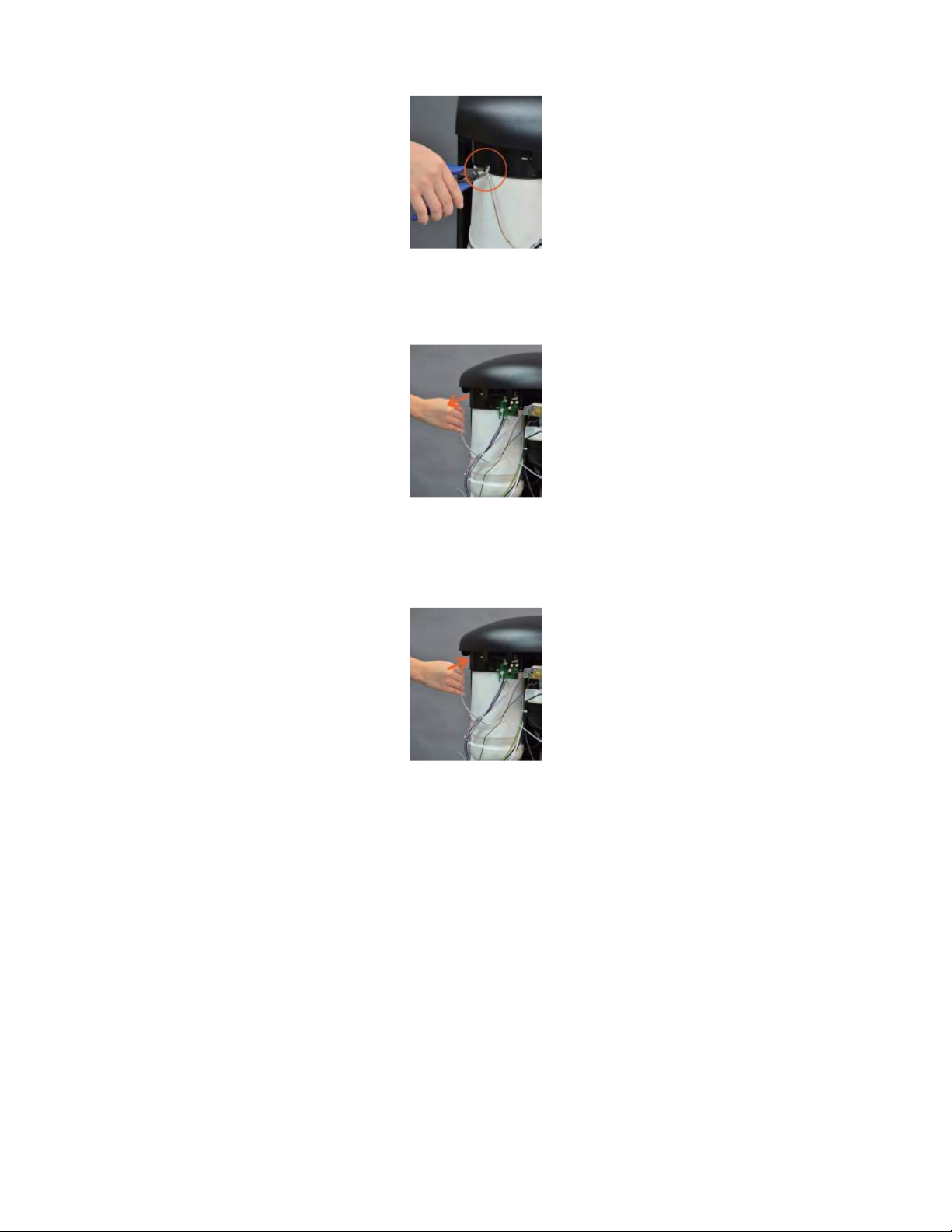

1. Turn off hot tank power switch (located on the front panel, inside the door) (Fig. 1) and unplug the water cooler.

2. Remove the upper back panel from the water cooler.

3. Remove both mounting screws from the cold control. (Fig. 2 & 3).

4. Remove the cold control from the plastic shelf (Fig. 4).

5. Remove the terminals from the thermostat, taking care to identify where each terminal is installed (Fig. 5 - 7).

Fig. 2 Fig. 3

Fig. 5 Fig. 6 Fig. 7

Fig. 4

Cold Control Replacement

18

6. Cut the small plastic zip tie holding the cold control sensor bulb to the evaporator insulation (Fig. 8).

7. Pull the sensor tube out from the evaporator insulation to remove (Fig. 9). Note: If required, install the Sensor tube cover onto

the replacement cold control.

8. Install the replacement cold control into the evaporator insulation until it bottoms out—approximately 5 inches (Fig. 10). Note:

Care should be taken while installing the sensor tube that the protective cover within the evaporator insulation is in the proper

position.

8. Install a replacement zip tie to hold the sensor within the evaporator insulation.

9. Reinstall the wire terminals onto the cold control taking care to place in original position.

10. Install the cold control to the plastic shelf, re-using the original screws.

11. Reinstall the upper back panel.

12. Re-connect the cooler to the power supply. Note: Ensure proper thermostat setting (see section for Cold Control Adjustment).

Fig. 8

Fig. 9

Fig. 10

19

Note:

The Cold Control can be adjusted without the removal of any panel. The adjustment screw is on the top rear (when viewed

from the rear, see Fig. 1).

To make the water colder, rotate the screw in the clockwise direction approximately 1 hour position. Allow the cooler to

stabilize for 2-3 hours to ensure proper temperature of the cold water. (Note: do not change the setting by more than 1 hour

setting at a time to prevent freezing).

To make the water warmer, rotate the screw in the counterclockwise direction approximately 1 hour position. Allow the

cooler to stabilize for 2-3 hours to ensure the proper temperature of the cold water.

Fig. 1

Cold Control Adjustment

20

Notice:

The information and/or procedures presented in the following demonstration(s) should be performed by a trained Water Cooler

Service Technician only.

Never attempt to service or repair a water cooler while it is plugged into any power supply.

Prior to any service or repair of the water cooler, ensure that the water has been completely drained from the system.

Note: Begin with the unit unplugged, the water drained, and the upper back panel removed.

Tip: Use a plier or flathead screwdriver to pry wire connecters off (Fig. 1).

1. Remove the wire terminals from the thermostat or limiter and identify.

2. Remove the two screws. Remove the thermostat (or limiter) from its bracket (Fig. 2).

3. There is enough heat transfer paste on the tank and old control to simply wipe the bottom of the new con-

trol against the old one (Fig. 3). Place into position and evenly tighten the two screws.

4. Reconnect the wires onto the thermostat (or limiter) as identified.

Fig. 3

Fig. 2

Fig. 1

Thermostat and/or Limiter Replacement

Other manuals for Storm Cafe

1

Table of contents