INTRODUCTION

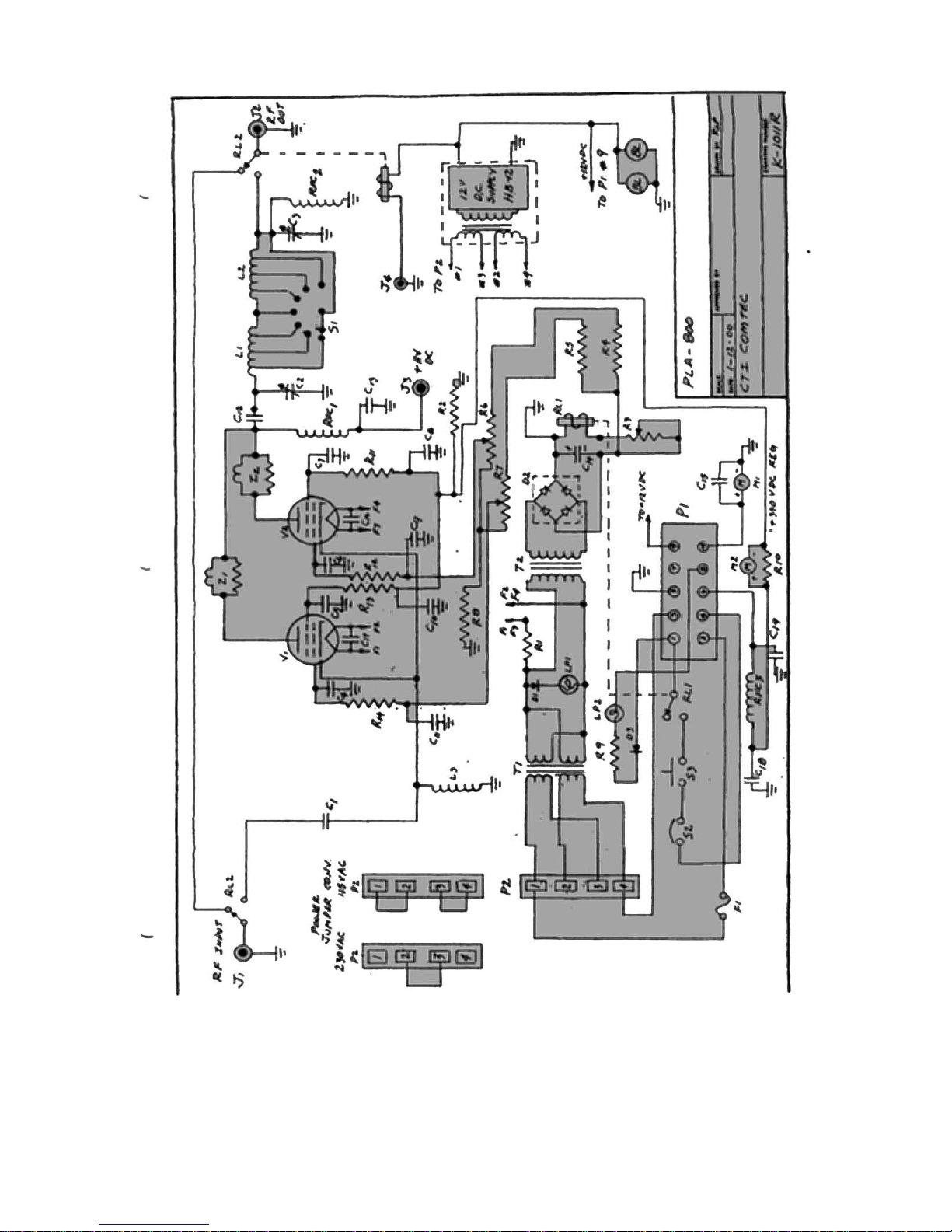

The PLA-800 Linear Amplifier uses a pair of 4CX250’s tetrodes as final amplifier tubes.

These tubes have been used and are still used today by the military because of its compact

size and ability to put out power ina compact space. They also have the ability to amplify

signal from .1 MHz to 500 MHz. Therefore their power bandwidth is approximately 500

MHz.

The 4CX250B’s have a control screen grid. The voltage and regulated current for the

screens are supplied by the PSL 1000 Power Supply. Using screen voltage regulation, the

grids have the advantage of self-limiting the current flow to the plates of the tubes. As a

result, the tubes cannot be driven into saturation causing distortion. The maximum

allowable screen current is regulated by the power supply. Once that point of current

demand is reached, the screen limits the plate current flow to it’s maximum. Therefore,

and ALC circuit, to prevent driver overload, is not required.

The maximum plate and cathode current flow is measured by the 0-500 ma. meter on the

front panel. The screen current only, is measured by the 0-50 ma. meter located also on the

front panel.

The band switch and plate and loading capacitors are also located on the front panel. The

capacitors use a 6:1 vernier ball drive to give smooth, easy tuning. Also located on the

front panel are the two lights indicating filament voltage on and plate current on. The

filament supply is contained in the PLA-800 and is protected by the 3 AG fuse next to the

indicator light. These bulbs are tungsten elements, with a life of 50,000 hours. The plate

on and off switch is located in the middle of both lamps.

Both the amplifier and power supply are inter-locked for your safety. The removal of the

FOUR (4) thumbscrews will allow you to slide the units forward and out of their respective

enclosures. NEVER open either unit with the AC and DC power applied. As an added

safety feature, the power supply has a mechanical shorting rod, which, upon sliding the

unit out of the enclosure beyond 1/4 of an inch, will ground the high voltage capacitor

bank. This is done for your safety and should NOT be defeated.

Built into the PSL 1000 power supply is a maximum current overload circuit. If more than

600 ma. is delivered to the load, the circuit will activate, opening the plate relay and

removing the high voltage. At the same time, the current overload indicator lamp on the

front panel of the power supply will light and an audible alarm will sound. To reset the

high voltage back, simply push the reset button on the panel. The power supply is also

equipped with a voltmeter allowing you to monitor the high voltage (0-500 vdc) and the

screen voltage (0-500 vdc).

Under normal loading conditions, the PLA-800 will deliver 600 watts key down or 1200

watts PEP output. However, the key down power level should not be maintained for more

than 10 seconds. In cases where RTTY or AM is used, the amplifier should be operated at

one-half power level. 1200 watts PEP can be operated at any time.