Operating manual EMGZ307

3

Table of Contents

1Safety Instructions ....................................................................................2

1.1 Description conditions 2

1.2 List of safety instructions 2

2Definitions..................................................................................................3

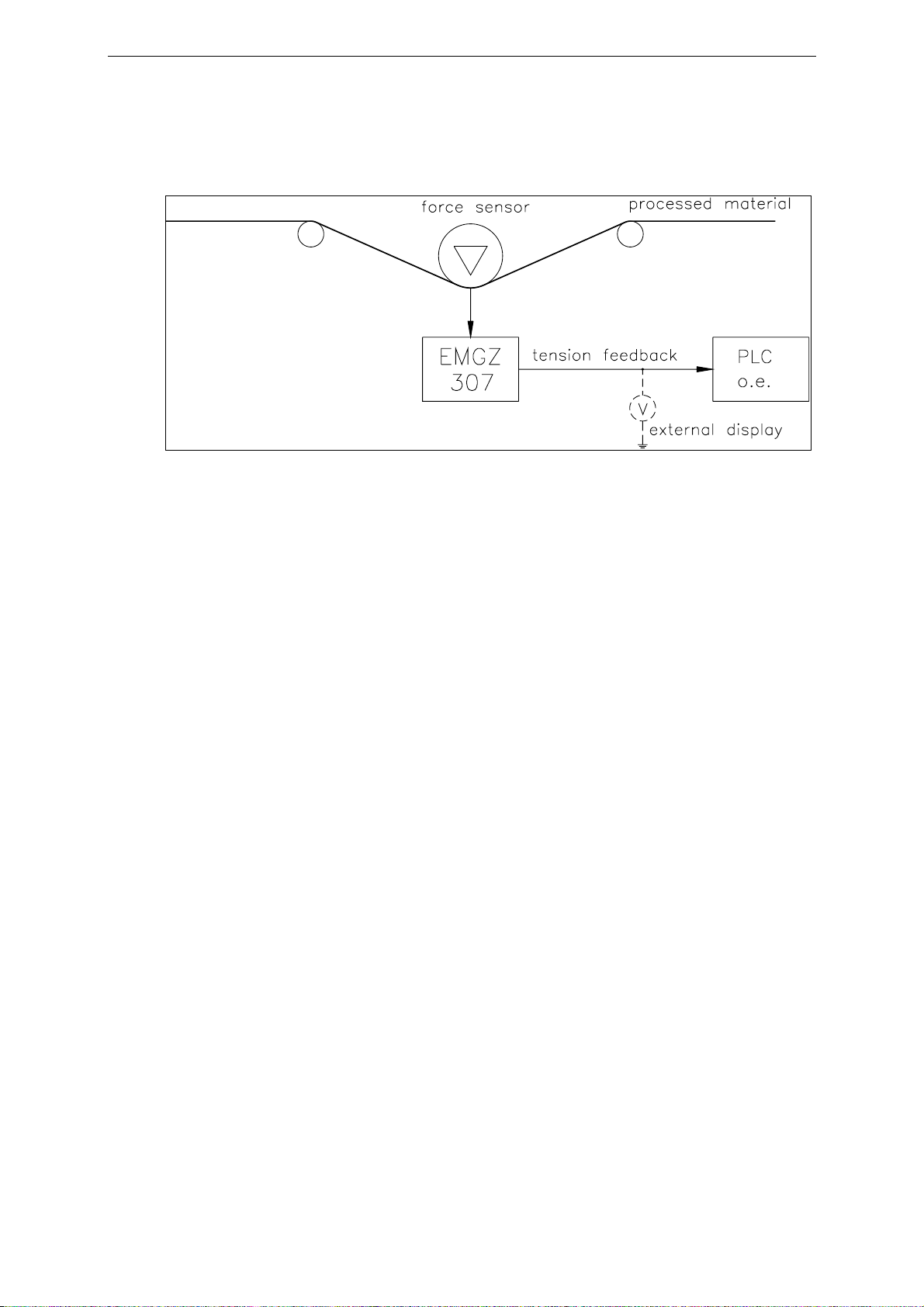

3System components...................................................................................4

3.1 Different EMGZ307 Variants 4

4System Description....................................................................................5

4.1 Functional description 5

4.2 Force sensors 5

4.3 Measuring amplifier EMGZ307 5

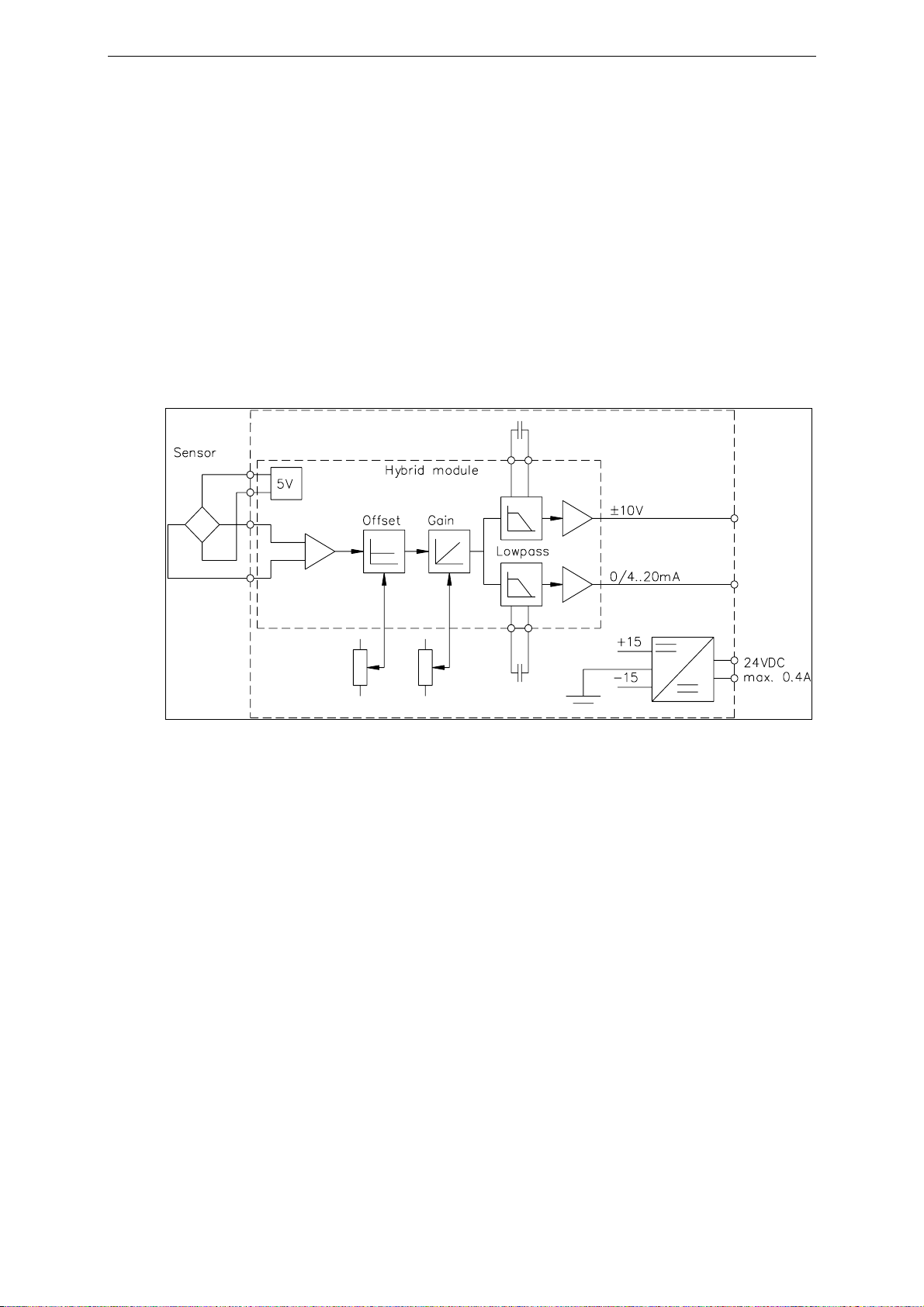

4.4 Block Diagram 6

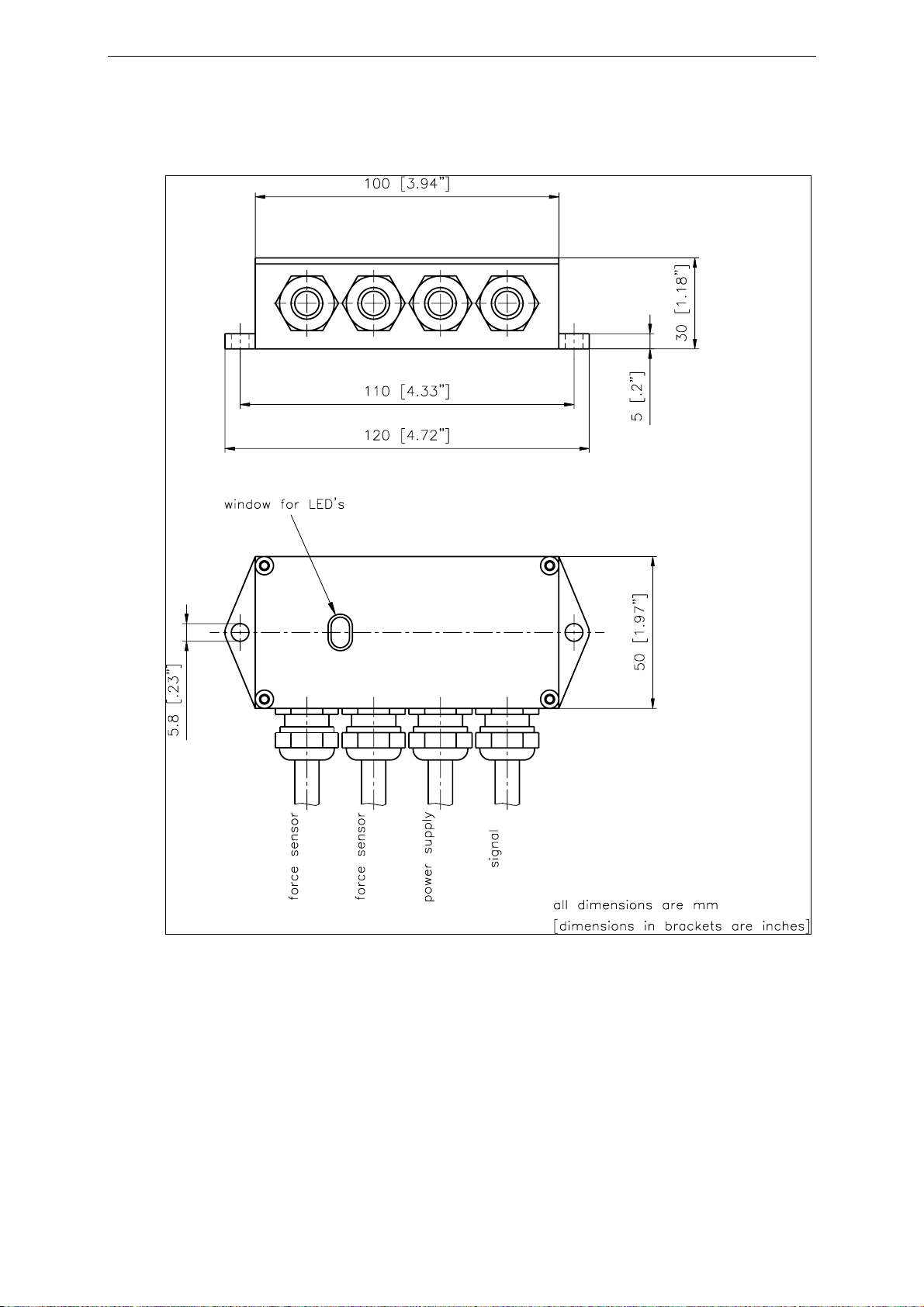

5Dimensions.................................................................................................7

6Installation and Wiring ............................................................................8

6.1 Mounting and Wiring of the Electronic Unit 8

6.2 Mounting the Force Sensors 8

6.3 Wiring 9

7Setting into Operation.............................................................................10

7.1 View of the Setting Elements 10

7.2 Settings for EMGZ307.582388 10

7.3 Configuring Gain and Offset 11

7.4 Configuring the Outputs 12

7.5 Configuring the Lowpass Filters 13

7.6 Calibrating the Measuring Amplifier 14

8Trouble shooting......................................................................................15

9Technical Specification...........................................................................15

2Definitions

Offset:

Correction value for compensation of the zero point difference. Thanks to the offset, it

is ensured that a force of 0N will generate a signal of 0V exactly.

Gain:

Amplification factor for the measuring signal. Use of proper value will set the

measuring range of the sensor exactly corresponding to the signal output range

(0...10V).

Strain gauge:

Electronic component that changes its resistance when its length changes. Strain

gauges are used in the FMS force sensors for acquisition of the feedback value.