1

CUES Inc.,WTR III User Manual | TX920 CUES Inc., WTR III User Manual | TX920

www.cuesinc.com,| salesinfo@cuesinc.com www.cuesinc.com,| salesinfo@cuesinc.com

INTRODUCTION

Features & Benets:

• WTR III can inspect dead-end lines or lines without accessible exits.

• WTR III has a proven transmission mechanism with the capability of power forward, power reverse,

and freewheel for easy back-out of a dropped manhole and high speed retrieval without running

over the cable.

• Existing CUES 12-pin conguration truck systems can operate the WTR III transporter system

directly; CUES trucks with 5/4 cable ends can operate the WTR III transporter system with a 5/4-to-

12 pin adapter.

• WTR III can be used with any 3-pin single-conductor system.

• WTR III operates most eciently with the new CUES platinum lightweight and high-strength video

cable. The auto-payout reel system is recommended to optimize inspection distance when operating

with gold-cable setups.

• WTR III transporter includes a built-in locking connector and protective housing for direct insertion

of the OZ III camera — no additional camera interface cables are required and the camera retention

locking mechanism securely attaches the camera to the main body.

• With a small cross prole and reduced length with an OZ III camera, WTR III in the tracked mode

(TX351-1) can t into 5 inch diameter pipe. In 6 inch pipe, the TX351-1 with OZ III camera has

a large bottom clearance; it can travel through inverts with limited space and traverse 22, 45, and 90

degree sweeps. With the OZ III camera, it can inspect 6 inch diameter relined pipe with full pan,

tilt, and zoom capability.

• In tracked mode (TX351-1), WTR III can travel at maximum speed of ~35fpm with the standard

motor transmission module, P/N TX320; with the optional high-speed motor transmission module,

TX320-1 (sold separately), WTR III can travel at maximum speed of ~60fpm.

The WTR III Transporter Highlights:

• The WTR III is designed to be a component of a multi-conductor or single-conductor CCTV

pipeline inspection system.

• The WTR III is a wheeled or optional tracked transporter that’s designed to carry the OZ III

camera through the pipeline during CCTV inspections.

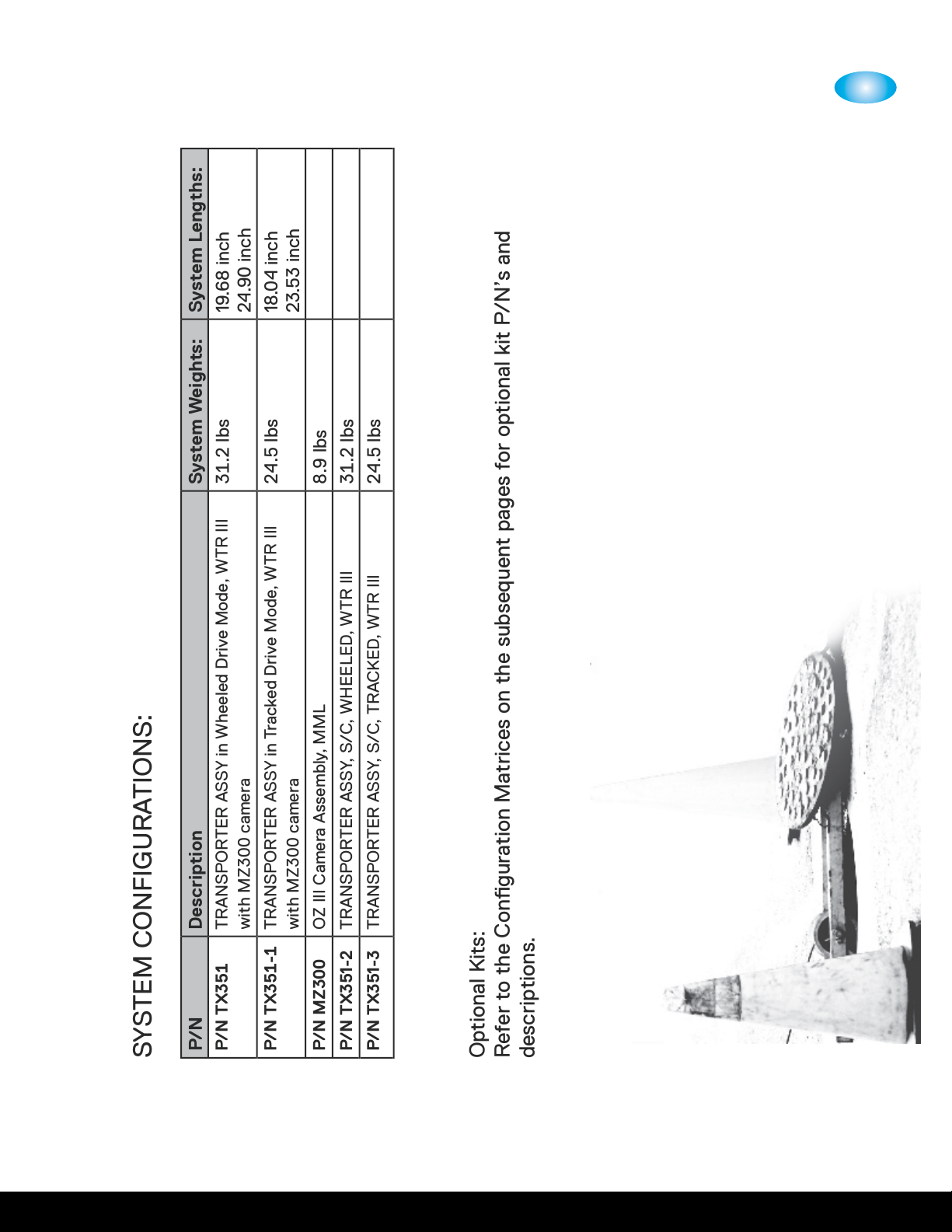

• The WTR III features a “modular” design. It can travel either as a:

- wheeled transporter, P/N TX351, with wheel module P/N’s TX322 and P/N TX323

- or as a tracked transporter, P/N TX351-1, with track module P/N’s TX324 and P/N TX325,

to adapt to various pipe conditions.

• The unit can easily switch between wheeled and tracked drive mode with only a few screw

changes.

• Can inspect 6 inch through 24 inch pipelines, in either wheeled or tracked mode, without prior

stringing or other setup procedures.