HELIX ONE Mk2 INSTALLATION & OPERATION GUIDE

10

DA-MAN-H1-001 www.dohmanna dio.com

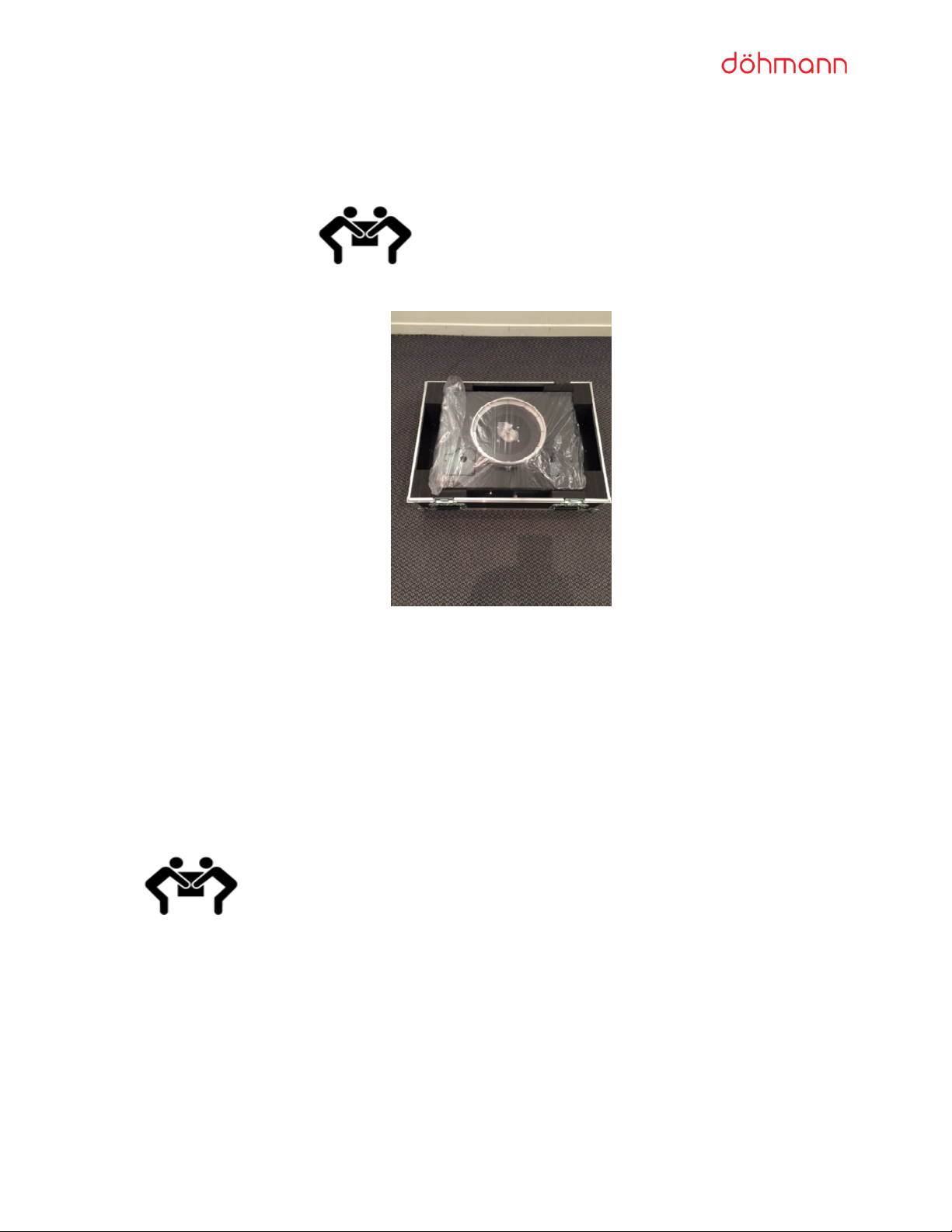

STEP 4

Please note the 4 x LONG M6 transport sec ring screws sed to lock the table chassis to the s spension

system (vibration isolation platform) d ring shipping. They are located near the inner edge of the Platter Ring

shown below.

BEARING

TRANSPORT SCREWS

4 off M6 x 120MM Long

Once the t rntable is in its final operating position, remove the 4 x LONG M6 transport sec ring screws with

an Allen wrench (Hex key).

* VERY IMPORTANT

* VERY IMPORTANT* VERY IMPORTANT

* VERY IMPORTANT

–

––

–

T

TT

The

he he

he transport screws m st be

transport screws m st be transport screws m st be

transport screws m st be nscrewed even

nscrewed evennscrewed even

nscrewed evenly. Start with one screw and

ly. Start with one screw and ly. Start with one screw and

ly. Start with one screw and nscrew it

nscrew it nscrew it

nscrew it

for a few rotations, then move to the next screw and

for a few rotations, then move to the next screw and for a few rotations, then move to the next screw and

for a few rotations, then move to the next screw and nscrew

nscrew nscrew

nscrew it

it it

it for the same amo nt of rotations, then the

for the same amo nt of rotations, then the for the same amo nt of rotations, then the

for the same amo nt of rotations, then the

same for the third screw

same for the third screwsame for the third screw

same for the third screw

and then the same for the fo rth screw.

and then the same for the fo rth screw. and then the same for the fo rth screw.

and then the same for the fo rth screw. Ret rn to the first screw and then repeat

Ret rn to the first screw and then repeat Ret rn to the first screw and then repeat

Ret rn to the first screw and then repeat

this process so that the

this process so that the this process so that the

this process so that the top of the t rntable rises evenly and is not lo

top of the t rntable rises evenly and is not lotop of the t rntable rises evenly and is not lo

top of the t rntable rises evenly and is not lop

pp

psided. To make this easier, it is

sided. To make this easier, it is sided. To make this easier, it is

sided. To make this easier, it is

recommended that

recommended that recommended that

recommended that yo place one hand on the s rface and gently p sh down while nscrewing each of the

yo place one hand on the s rface and gently p sh down while nscrewing each of the yo place one hand on the s rface and gently p sh down while nscrewing each of the

yo place one hand on the s rface and gently p sh down while nscrewing each of the

screws

screws screws

screws so that yo avoid the mechanism

so that yo avoid the mechanism so that yo avoid the mechanism

so that yo avoid the mechanism p shing p nevenly as the screws are nscrewed and event ally

p shing p nevenly as the screws are nscrewed and event ally p shing p nevenly as the screws are nscrewed and event ally

p shing p nevenly as the screws are nscrewed and event ally

removed.

removed.removed.

removed.

If the two

If the twoIf the two

If the two

screws

screws screws

screws on one side are nscrewed and removed prior to the other screws on the other

on one side are nscrewed and removed prior to the other screws on the other on one side are nscrewed and removed prior to the other screws on the other

on one side are nscrewed and removed prior to the other screws on the other

side being nscrewed and removed, the

side being nscrewed and removed, the side being nscrewed and removed, the

side being nscrewed and removed, the internal mechanism may ‘snap p’ nevenly and this can damage the

internal mechanism may ‘snap p’ nevenly and this can damage the internal mechanism may ‘snap p’ nevenly and this can damage the

internal mechanism may ‘snap p’ nevenly and this can damage the

internal mechanism

internal mechanisminternal mechanism

internal mechanism. PLEASE AVOID THIS POSSIBILITY BY FOLLOWING

. PLEASE AVOID THIS POSSIBILITY BY FOLLOWING. PLEASE AVOID THIS POSSIBILITY BY FOLLOWING

. PLEASE AVOID THIS POSSIBILITY BY FOLLOWING

THE

THE THE

THE ABOVE INSTRUCTIONS CAREFULLY.

ABOVE INSTRUCTIONS CAREFULLY.ABOVE INSTRUCTIONS CAREFULLY.

ABOVE INSTRUCTIONS CAREFULLY.