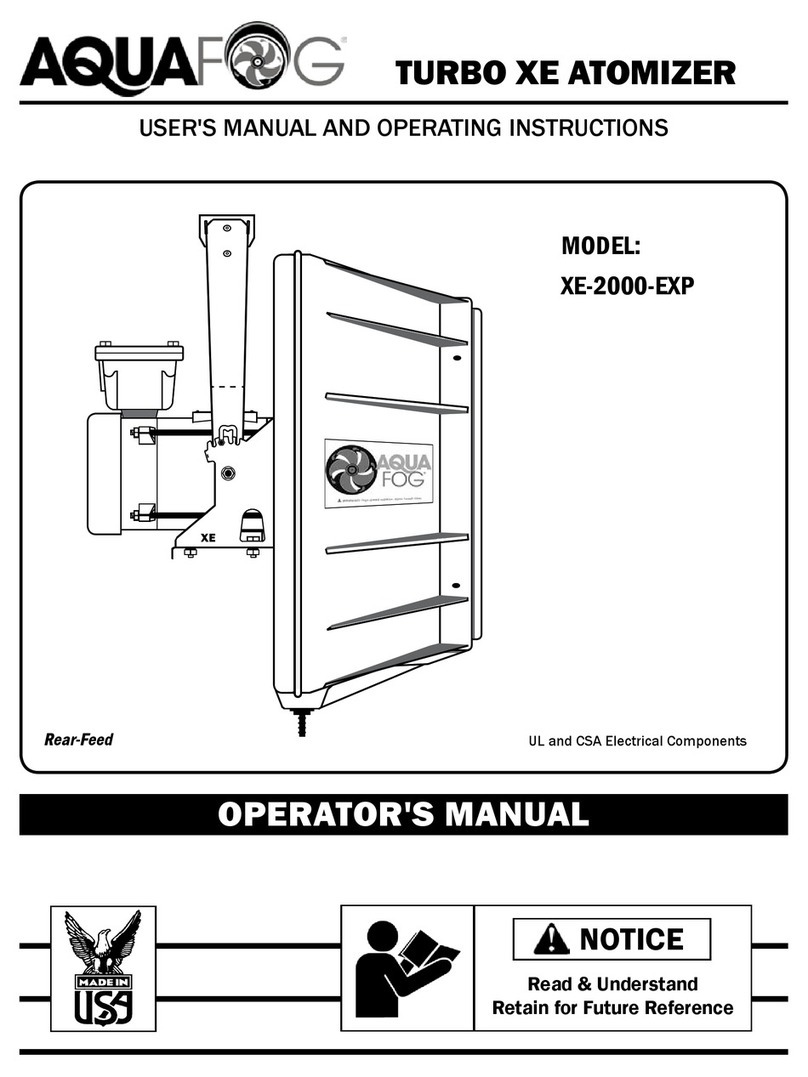

l2 SL EC - Rotating Atomizer with External Charging

Version:: 07 •As of:: 01/2020

4.2 Overview................................................................................................ 27

4.3 Functionality........................................................................................... 28

4.4 Assemblies............................................................................................. 30

4.4.1 Bell disk............................................................................................................30

4.4.2 Turbine.............................................................................................................32

4.4.2.1 Shaft detent .....................................................................................................33

4.4.2.2 Shaping air.......................................................................................................34

4.4.2.3 Rotational SpeedControl..................................................................................35

4.4.3 Valve block ......................................................................................................35

4.4.3.1 Main valve needle............................................................................................36

4.4.3.2 Valve for quick rinsing the bell disk .................................................................36

4.4.3.3 Recirculation for 1K paints...............................................................................37

4.4.4 Color tube ........................................................................................................37

4.4.5 Atomizer body and sleeve ...............................................................................38

4.4.5.1 The shaping air................................................................................................38

4.4.6 External charging.............................................................................................39

4.4.6.1 Function...........................................................................................................39

4.4.7 Clamping device (Jig)......................................................................................40

4.5 Connections........................................................................................... 41

4.5.1 Interfaces.........................................................................................................41

4.5.2 Flange assembly..............................................................................................42

4.5.2.1 Cable for potential equalization .......................................................................42

4.5.2.2 High voltage line ..............................................................................................43

4.6 Accessories and Related Parts.............................................................. 43

4.6.1 Accessories .....................................................................................................43

4.6.1.1 Case for checking high voltage shutdown.......................................................45

4.6.1.2 Atomizer attachment 60 ° (elbow) ...................................................................45

4.6.1.3 Atomizer pickup...............................................................................................45

4.6.1.4 Clamp for atomizer mount ...............................................................................45

4.6.1.5 Manual grounding rod......................................................................................45

4.6.1.6 Assembly bracket for atomizer ........................................................................45

4.6.1.7 Thread cleaner.................................................................................................45

4.6.1.8 Assembly aid for the atomizer body ................................................................46

4.6.1.9 Tool for disassembly of the atomizer body......................................................46

4.6.1.10 External mixer..................................................................................................46

4.6.1.11 Cable for potential equalization .......................................................................46

4.6.1.12 Tool set............................................................................................................46

4.6.2 Related Parts...................................................................................................46

4.6.2.1 High tension supply .........................................................................................46

4.6.2.2 R/O converter ..................................................................................................47

4.7 Tools...................................................................................................... 47

4.7.1 Tool kit .............................................................................................................47

4.7.2 Functionality of tools........................................................................................51