10

Appendix A – Command Reference

Command Abbreviations:

• ID: Device ID, with a value range of 07, default is set to 0

using DIP switches

• TD: Target density of encoder, with the default set to 128.

• RD: Roller diameter, taking into account no screen material

(mm)

• SL: Length of slack wrap (screen material that remains on

the roller when the screen is fully lowered). Length of slack

wrap (roller wrap of material + amount of top black drop).

• ST: Screen thickness (mm)

• SW: Viewing Area Width (mm)

• SH: Viewing Area Height (mm)

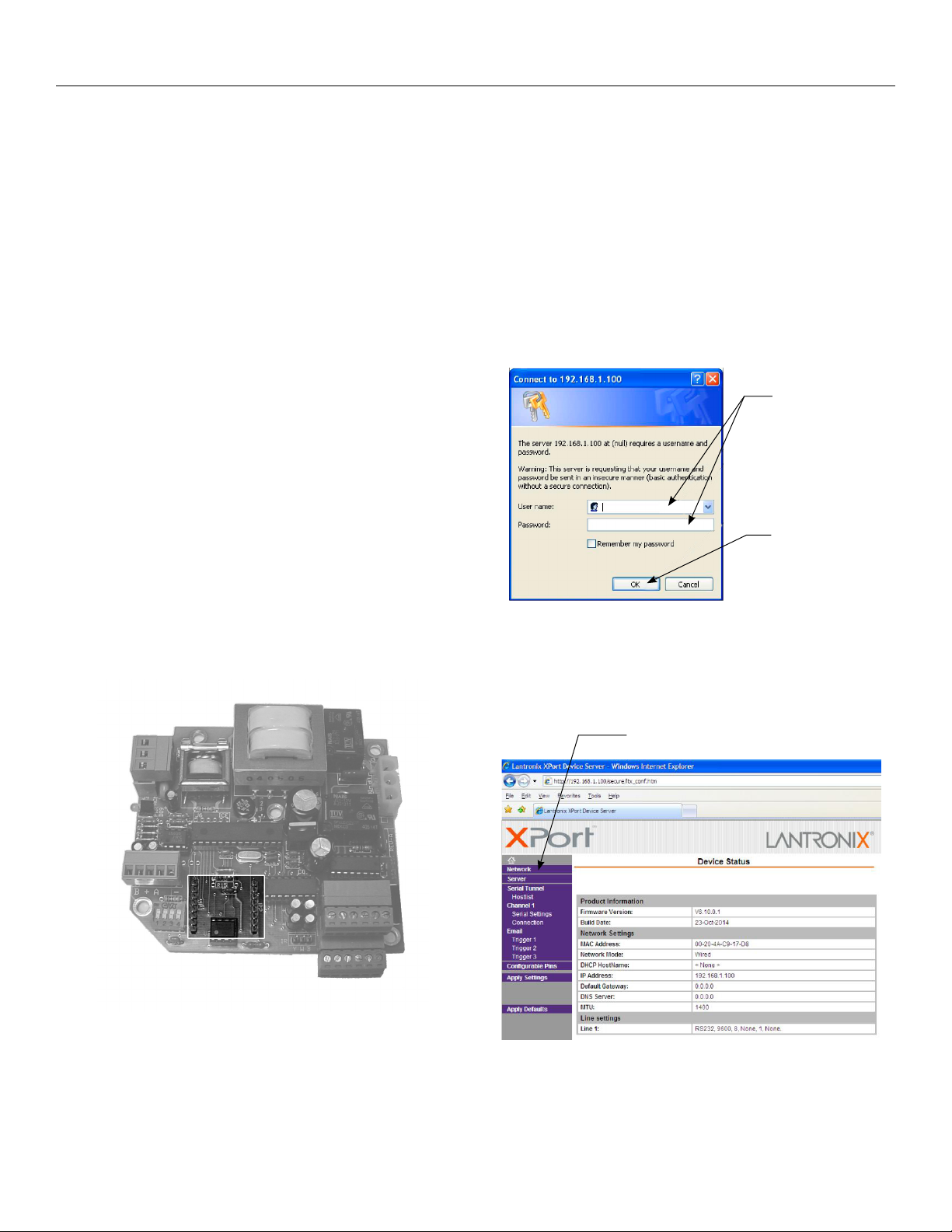

• MA: MAC address of the NET200

• DH: DHCP NET200 support on or of, default is set to ON

(ON, OF)

• SE: Rotary sensor support on or of, default is set to ON

(ON, OF)

• RE: Relay status, where UP indicates position 1 is shorted,

DN indicates position 2 is shorted, and ST indicates both

positions are open. (This unit is not designed for contact

closure operation.)

• AC: AC Current consumed through relay, in AC amps,

resolution to tenths of an amp.

• UL: Mechanical and electronic upper limit position, with a

counter value of 0

• LL: Mechanical and electronic lower limit position, with a

counter value of LL

• TA: Screen position to the nearest target, with a counter

value between 0 and LL

• IN: Screen position to the nearest inch, resolution to

hundredths of an inch

• MM: Screen position to the nearest mm

• A1: SP using aspect ratio of 1:1, where width = SW

• A2: SP using aspect ratio of 1.25:1, where width = SW

• A3: SP using aspect ratio of 1.33:1, where width = SW

• A4: SP using aspect ratio of 1:66, where width = SW

• A5: SP using aspect ratio of 1.78:1, where width = SW

• A6: SP using custom aspect ratio or amount of screen drop

(user deinable and accessible through NET200 or RS232)

• A7: SP using custom aspect ratio or amount of screen drop

(user deinable and accessible through TCP/IP or RS232)

• A8: SP using custom aspect ratio or amount of screen drop

(user deinable and accessible through TCP/IP or RS232)

• A9: SP using custom aspect ratio or amount of screen drop

(user deinable and accessible through TCP/IP or RS232)

• A0: SP using custom aspect ratio or amount of screen drop

(user deinable and accessible through TCP/IP or RS232)

• IP: IP address of NET200, whether DHCP or statically

assigned

• SN: Subnet of the NET200, whether DHCP or statically

assigned

• AL: Device status, providing complete settings information

• RS: Reset the SCB200 (Equivalent to a power cycle.)

Basic command rules:

• All commands shall begin with a “#” symbol.

• All values in the command shall be separated by a single

ASCII space “ “.

• All commands shall end with an ASCII carriage return “<CR>”.

• Any spaces immediately prior to the <CR> shall be ignored.

• Any invalid commands should result in an ACK of

“# ID ERR” and the appropriate error code, as deined

below. Commands issued to an invalid master / slave ID

shall be ignored.

• Position setting values can be set as FIXed, INCrement,

or DECrement. All numeric values following shall be

positive integers.

SCB200 Error Codes:

13: Command Timed Out

14: Busy Calibrating

15: Requires Rotary Sensor

16: Requires Calibration

17: Already Calibrated

18: Motor OverCurrent Fault

19: Motor Encoder Fault

20: Supported Only From NET200

21: Requires NET200

22: Supported Only At Master