with air conditioning ................................................... 19-9

Diagnostic – failures interpretation

at vehicles with air conditioning ............................... 19-10

Water pump ............................................................... 19-11

Exhaust Assembly...................................................... 19-13

Fuel tank .................................................................... 19-15

Fuel pump ................................................................. 19-22

Fuel filter ................................................................... 19-24

Engine suspension ..................................................... 19-25

CLUTCH

Identification ............................................................. 20-1

Diagnostic .................................................................. 20-2

Clutch disk – Mechanism ......................................... 20-5

Pressure bearing – Clutch releasing fork ................ 20-7

Engine flywheel ................................................. 20-8

MECHANICAL GEARBOX

Sectional view .................................................... 21-1

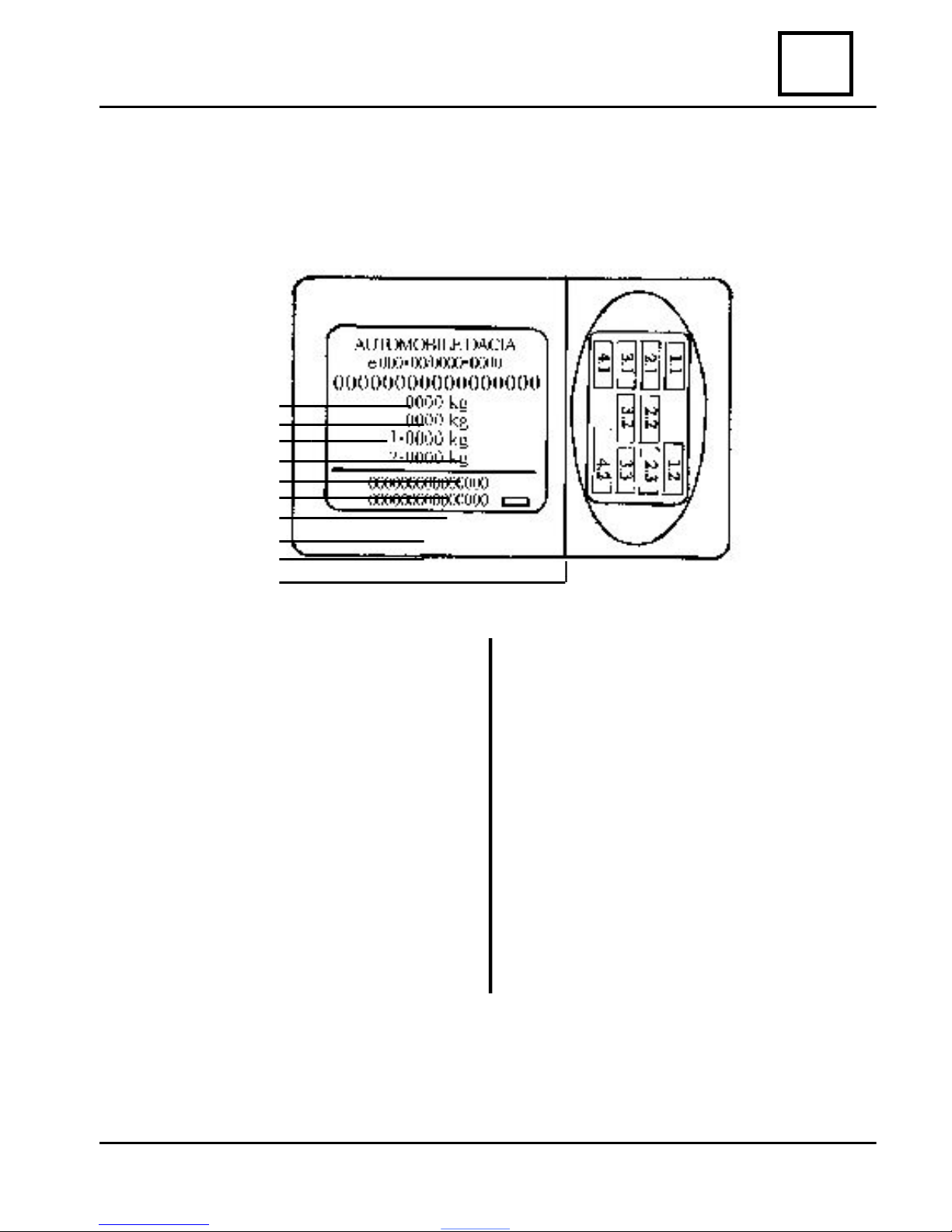

Identification ...................................................... 21-2

Tightening moments in daNm .......................... 21-3

Particurarities .................................................... 21-4

Ratios .................................................................. 21-5

Ingredients .......................................................... 21-6

Capacity, lubricants .......................................... 21-7

Parts that are replaced after

each dismonting ................................................. 21-8

Necessary special tools ...................................... 21-9

Gearbox dismounting ........................................ 21-10

Replacement of the planetary sealing

gasket (on the vehicle) ....................................... 21-30

Replacement of the 5-th gear synchroniser

and pinion (on the vehicle) .................................. 21-32

TRANSMISSION

Front transversal transmission ........................ 29-1

Bellows - Bearing assembly to

the gearbox (left) ............................................... 29-4

Bellows to wheel (left) ....................................... 29-7

Bellows to gearbox (right) ................................. 29-12

Bellows to wheel (right) .................................... 29-15

GENERAL

General principle schedule

of the brake circuit ............................................ 30-1

Tightening moments (in daNm) ....................... 30-2

Composition and dimensions

of the main braking system elements ............... 30-6

Braking system diagnostic ................................ 30-7

Brake connections and ducts ............................ 30-12

Brake fluid ......................................................... 30-13

Braking system purging .................................... 30-14

The influence of angles ...................................... 30-16

Angles checking principle ................................. 30-17

Front axles checking and adjustment ............. 30-18

FRONT AXLESELEMENTS

Characteristics ..................................................... 31-1

Suspension arm ................................................. 31-2

Elastic bushings of the suspension arm ........... 31-5

Suspension ball joint .......................................... 31-6

Brake lining (pads) ............................................ 31-7

Checking the brake pads wear ......................... 31-9

Brake caliper ...................................................... 31-10

Brake disk ........................................................... 31-12

Steering knuckle ................................................. 31-13

Steering knuckle bearing (35 x 65 x 35) ......... 31-15

Front suspension ................................................ 31-16

Shock absorber, Spring ...................................... 31-17

Spring – shock absorber assembly ................... 31-18

Anti roll bar ........................................................ 31-20

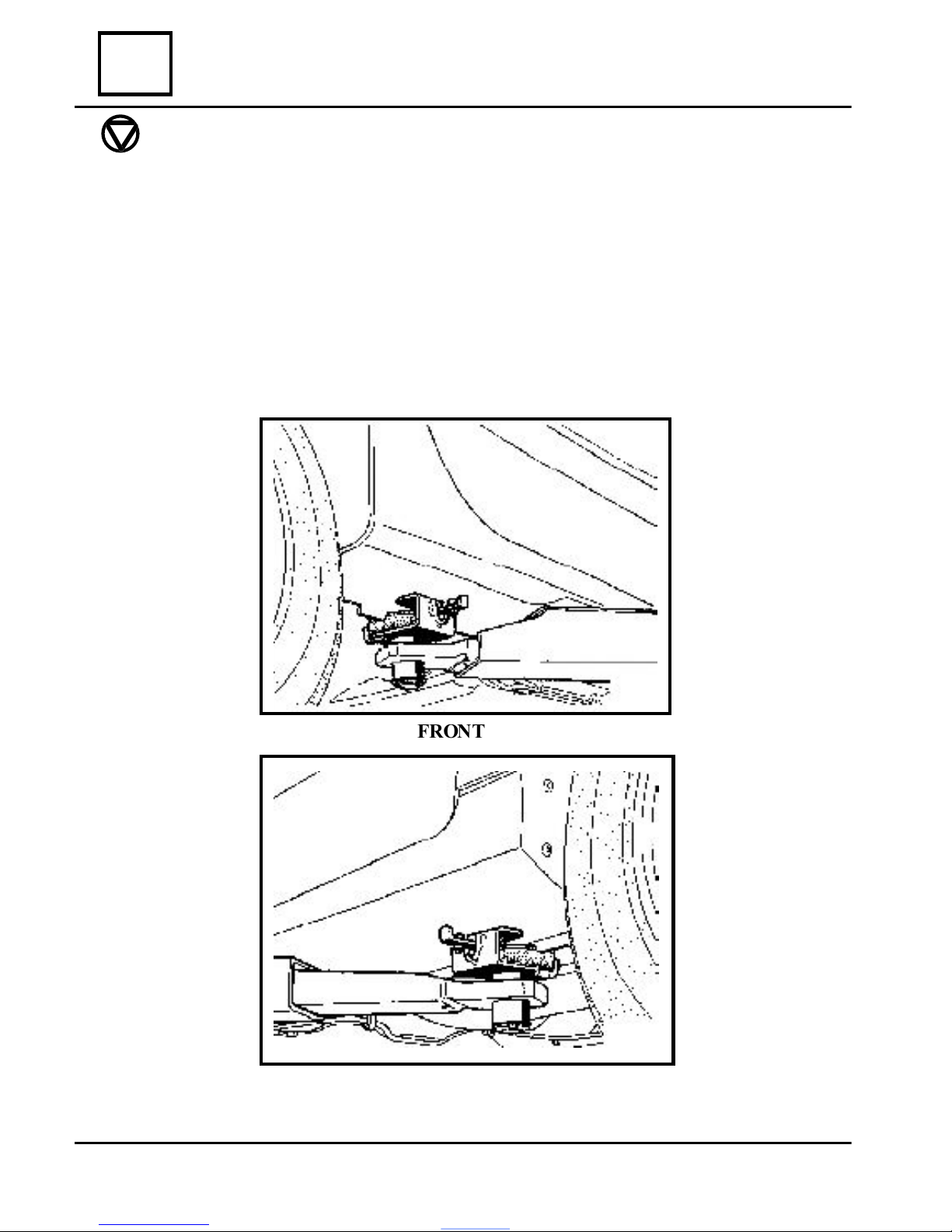

Power train support .......................................... 31-21

REAR AXLES ELEMENTS

Characteristics ................................................... 33-1

Rear axle ............................................................. 33-2

Rear suspension ................................................. 33-4

Shock absorber ................................................... 33-5

Spring ................................................................. 33-6

Brake drum ........................................................ 33-7

Brake cylinder .................................................... 33-8

Brake shoes ......................................................... 33-10

Bearing ................................................................ 33-13

WHEELS AND TIRES

Characteristics ................................................... 35-1

Wheels balancing ............................................... 35-4

STEERING ASSEMBLY

Steering connecting rods .................................. 36-1

Manual steering box .......................................... 36-3

Steering box pusher ........................................... 36-4

Noise absorbant bushing .................................. 36-5

Bellows................................................................ 36-6

General .............................................................. 36-7

Power steering box ............................................ 36-8

Power steering box pusher ............................... 36-11

Power steering pump ......................................... 36-12

Steering column ................................................. 36-14

THE MECHANICAL ELEMENTS CONTROLS

Brake pump........................................................ 37-1

Servobrake ......................................................... 37-3

Air filter – servobrake retainer valve .............. 37-6

Handbrake - adjustment ................................... 37-7

Handbrake control lever ................................... 37-8

Handbrake secondary cables ............................ 37-10

Brake flexible hoses ........................................... 37-11

Brake pressure controller .................................. 37-13

Gears control ..................................................... 37-15

Clutch and brake pedals ................................... 37-17

Clutch cable ........................................................ 37-18

Pedals support ................................................... 37-20

Acceleration control .......................................... 37-21

20

21

29

30

31

33

35

36

37

Transmission

2

Chasis

3