9T – 2IIMMOBILIZER ANTI–THEFT SYSTEM

DAEWOO V–121 BL4

DIAGNOSIS

IMMOBILIZERANTI–THEFTSYSTEM

The immobilizer anti–theft system requires diagnosis

when it is not possible to start the engine. If the no–start

condition occurs because of the immobilizer system, a

diagnostic trouble code (DTC) 53 should be set.

The immobilizer anti–theft system requires diagnosis

when it is not possible to start the engine. If the no–start

condition occurs because of the immobilizer system, a

diagnostic trouble code (DTC) 53 should be set.

Unauthorized use of a scan tool could be a method of de-

feating the immobilizer anti–theft system. Therefore, cer-

tain scan tool procedures require the use of a password.

The following functions are password protected:

SCoding of an additional key.

SDeleting all key codes.

SDeletion of the immobilizer identification (ID) code.

SDeletion of the powertrain control module

(PCM)/engine control module (ECM) ID code.

The following functions do not require a password:

SReading an ignition key to determine if the trans-

ponder is working or if a key is authorized.

SReading the immobilizer ID code to verify that it

matches the PCM/ECM ID code.

DTC 53 – PCM/ECM Immobilized Error

Step Action Value(s) Yes No

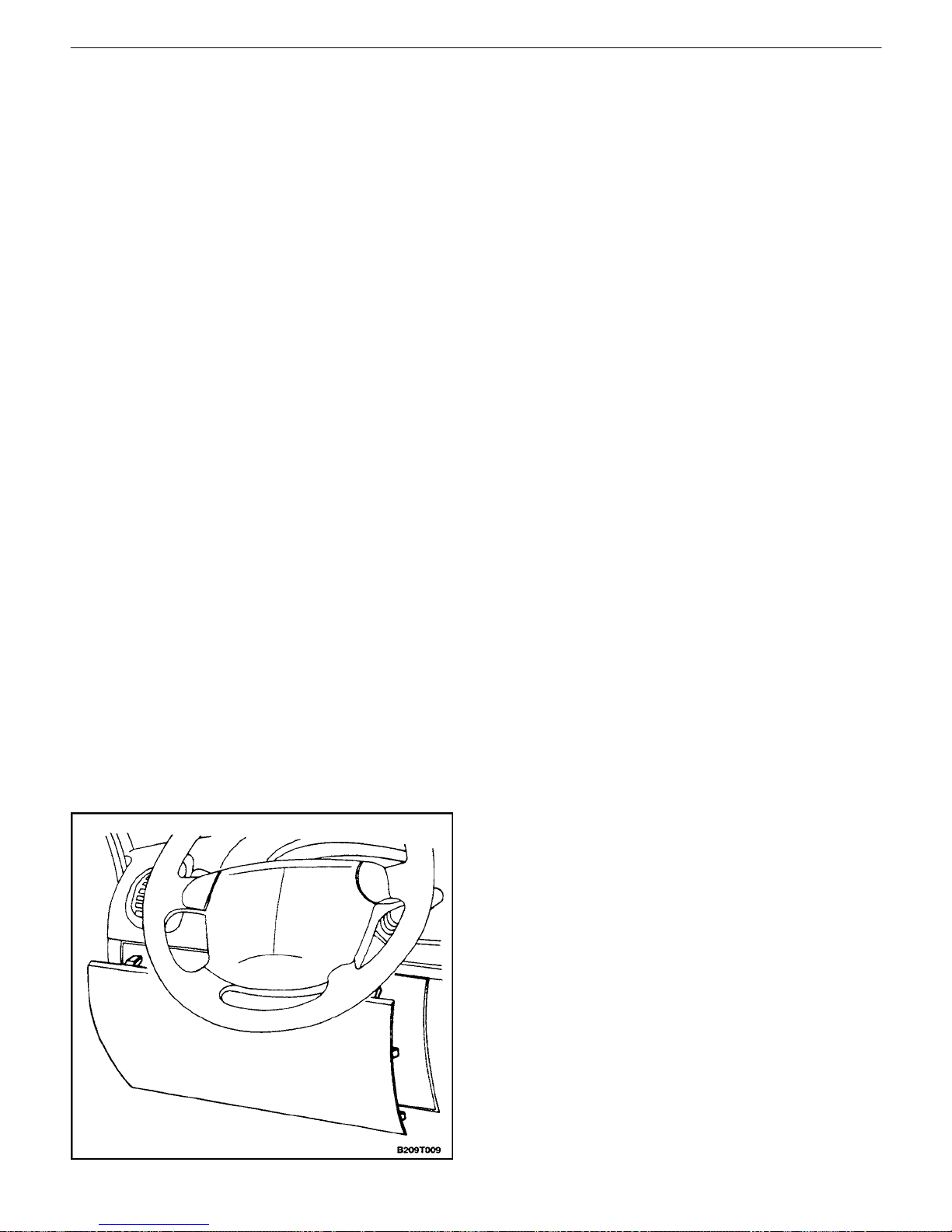

1Connect the scan tool using the following procedure:

1. Insert the immobilizer data cartridge into the

scan tool.

2. Turn the ignition OFF.

3. Connect the scan tool to the data link connec-

tor DLC).

4. Turn the ignition ON, but do not start the en-

gine.

Is communication established between the scan tool

and the immobilizer control unit?

Go to Step 2 Go to ”Commu-

nication Be-

tween Immobi-

lizer and Test

Equipment”

2Select SYSTEM DIAGNOSIS from the scan tool

menu.

Does the KEY STATUS message indicate POS NR

(position number) 00?

Go to ’Key

Status Errors” Go to Step 3

3Read the IMMO & PCM/ECM ID–CODE message

that is displayed after requesting SYSTEM DIAG-

NOSIS.

Does the message ID–CODE DIFFERENT appear?

Go to ”ID

Code Repro-

gramming”

Go to Step 4

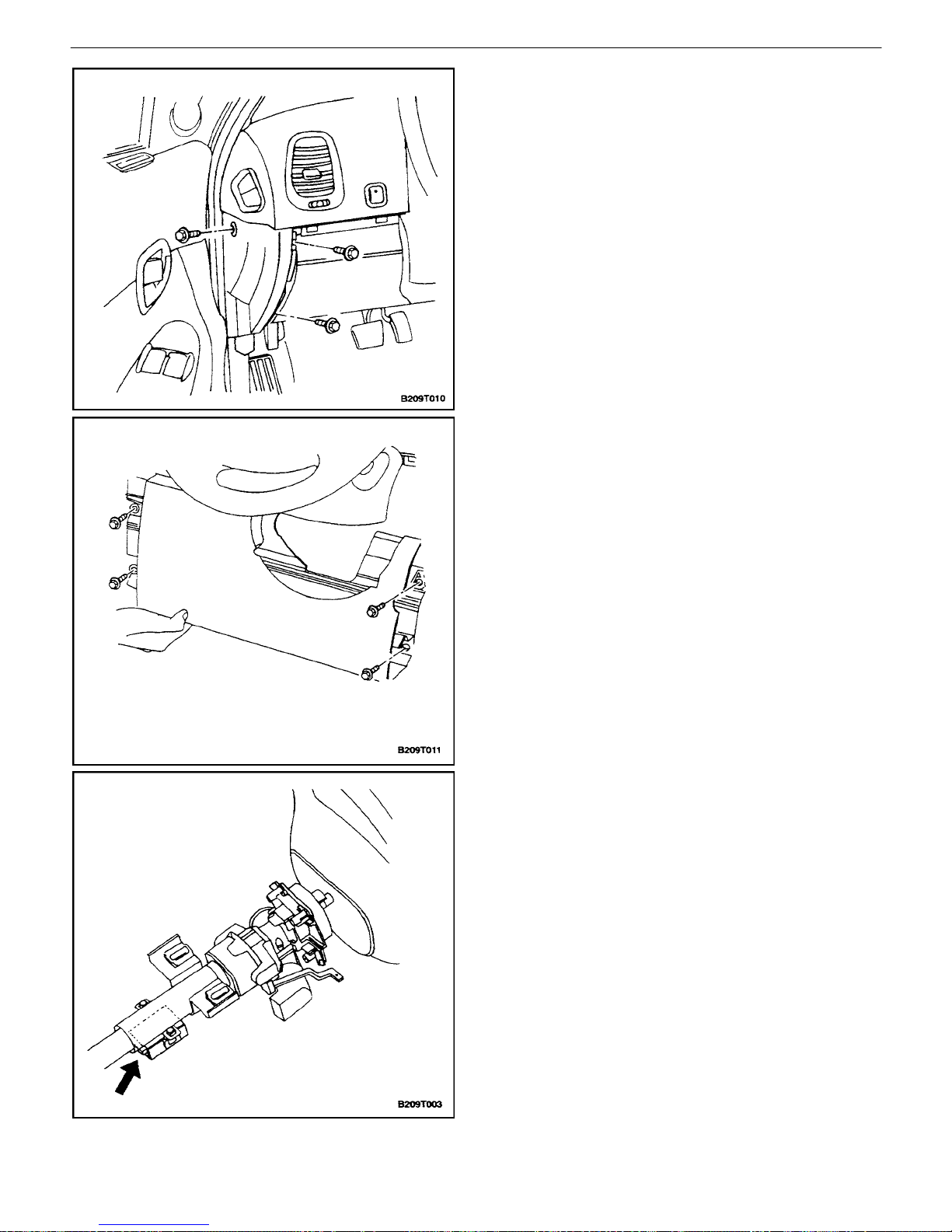

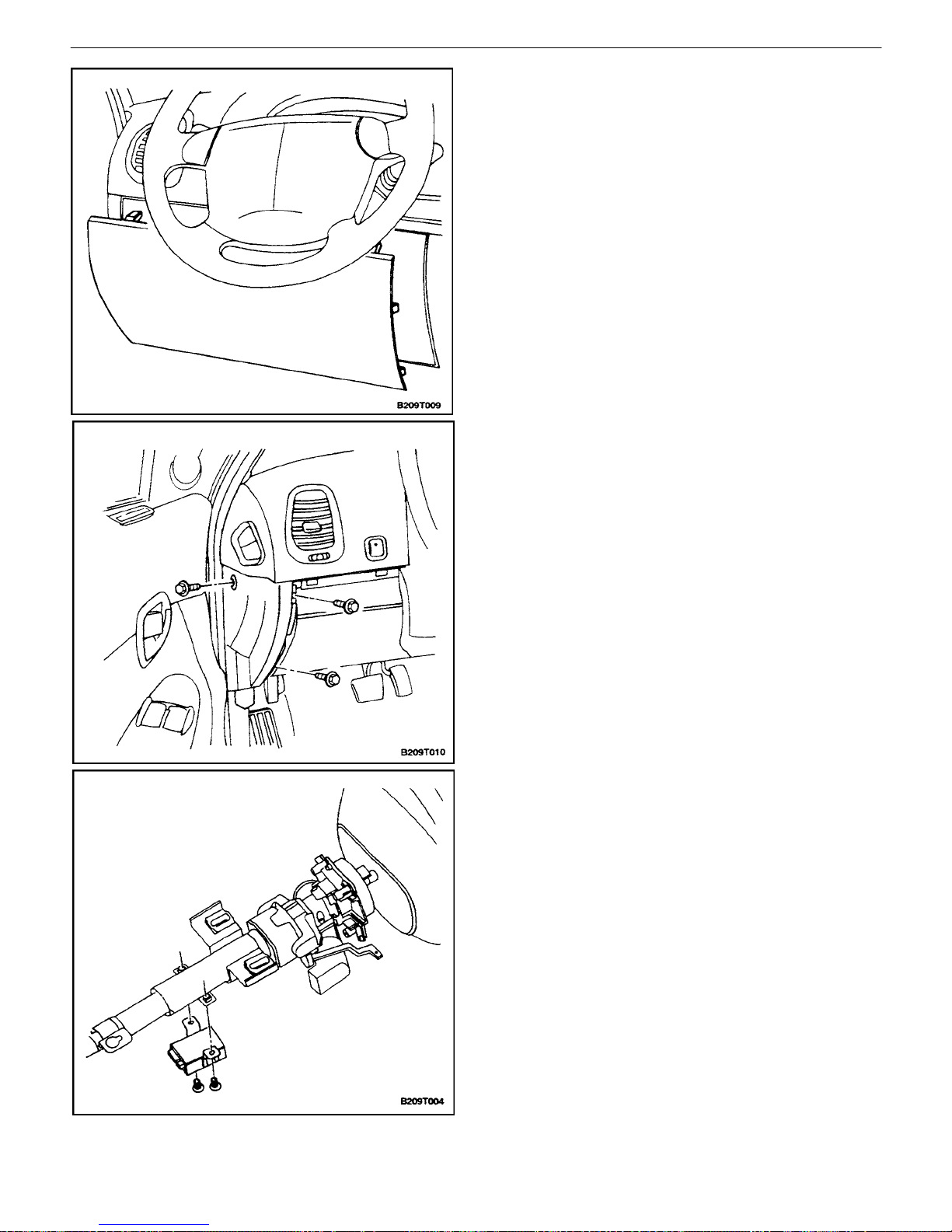

4Check for an open serial data wire between the im-

mobilizer control unit and the powertrain control

module (PCM)/engine control module (ECM).

Is the circuit open?

Go to Step 5 Go to Step 6

5Repair the open serial data wire between the PCM/

ECM and the immobilizer control unit.

Is the repair complete?

System OK

61. Replace the ECM.

2. Reprogram the identification (ID) code. Refer

to”ID Code Reprogramming” in this section.

Is the repair complete?

System OK

KEY STATUS ERRORS

The following KEY STATUS messages may be shown on

the scan tool after commanding SYSTEM DIAGNOSIS:

SIGNITION OFF STATUS. This message informs

the technician that the ignition is OFF during the

key coding process. Turn the ignition ON during key

coding, but do not start the engine.