GENERAL INFORMATION 0B – 9

DAEWOO V–121 BL4

Fuel Micro–Filter Replacement

Replace the engine fuel filter every 48,000 km (30,000

miles).

The engine fuel filter is located on the center dash panel

near the brake booster.

Air Cleaner Element Replacement

Replace the air cleaner element every 48 000 km (30,000

miles).

Replace the air cleaner more often under dusty conditions.

Throttle Body Mounting Bolt Torque

Check the torque of the throttle body mounting bolts.

Tighten the throttle body mounting bolts to 17 NSm (13 lb–

ft) if necessary.

Spark Plug Replacement

Replace spark plugs with the same type.

– Type: AC Type FR8LDC4 (2.0L DOHC)

– Gap: 0.8 mm (0.031 in.) (2.0L DOHC)

Spark Plug Wire Replacement

Clean the wires and inspect them for burns, cracks, or oth-

er damage. Check the wire boot fit at the direct ignition

system (DIS) module and at the spark plugs. Replace the

wires, as needed.

Brake System Service

Check the disc brake pads or the drum brake linings every

9,600 km (6,000 mi) or 6 months. Check the pad and the

lining thickness carefully. If the pads or the linings are not

expected to last another 9,600 km (6,000 mi), replace the

pads or the linings. Check the breather hole in the brake

fluid reservoir cap to be sure it is free from dirt and the pas-

sage is open.

Transaxle Service

The manual transaxle fluid does not require changing. For

automatic transaxles, refer to ”Scheduled Maintenance

Charts”in this section.

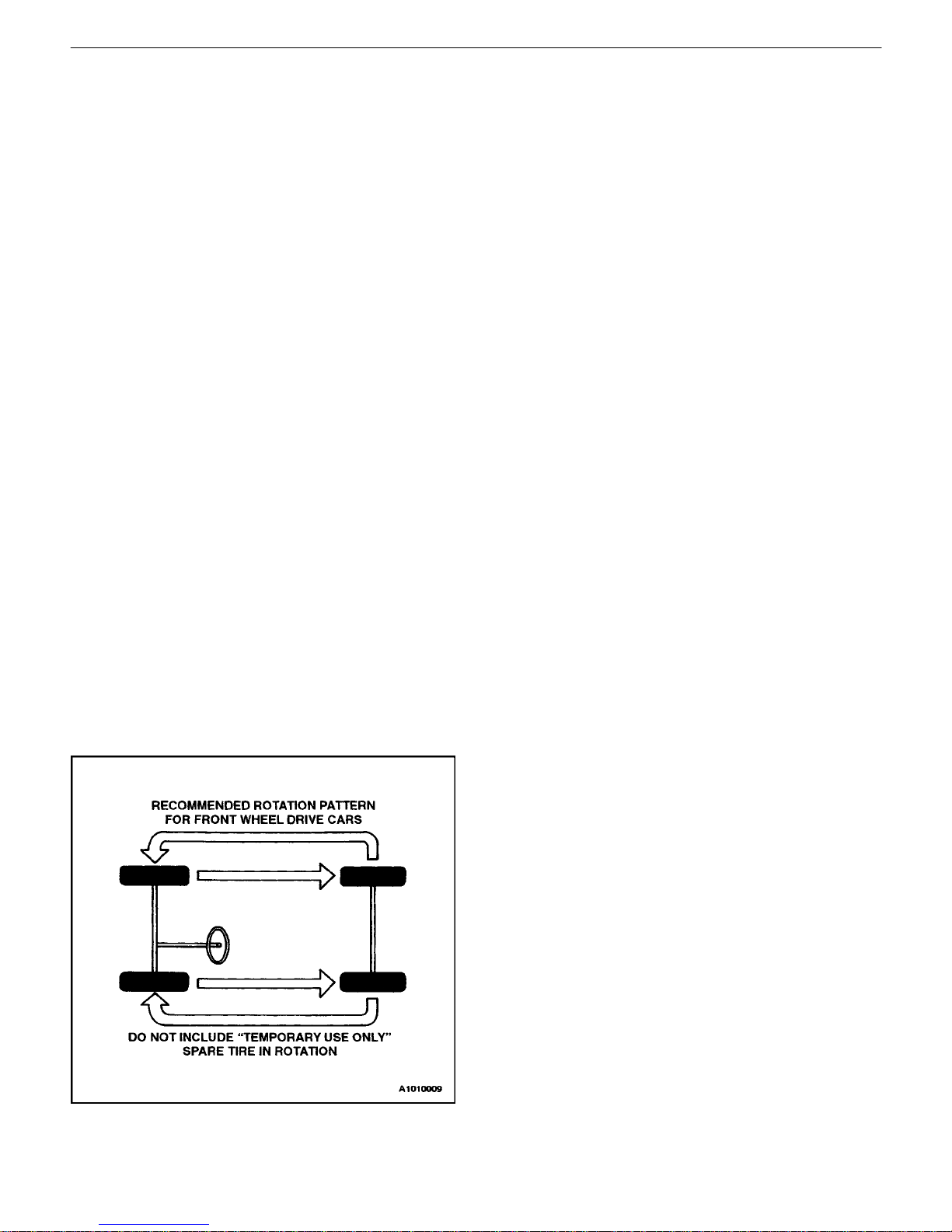

Tire and Wheel Inspection and Rotation

Check the tires for abnormal wear or damage. To equalize

wear and obtain maximum tire life, rotate the tires. If irreg-

ular or premature wear exists, check the wheel alignment

and check for damaged wheels. While the tires and

wheels are removed, inspect the brakes. Refer to ”Each

Time The Oil Is Changed”in this section.