DAEWOO

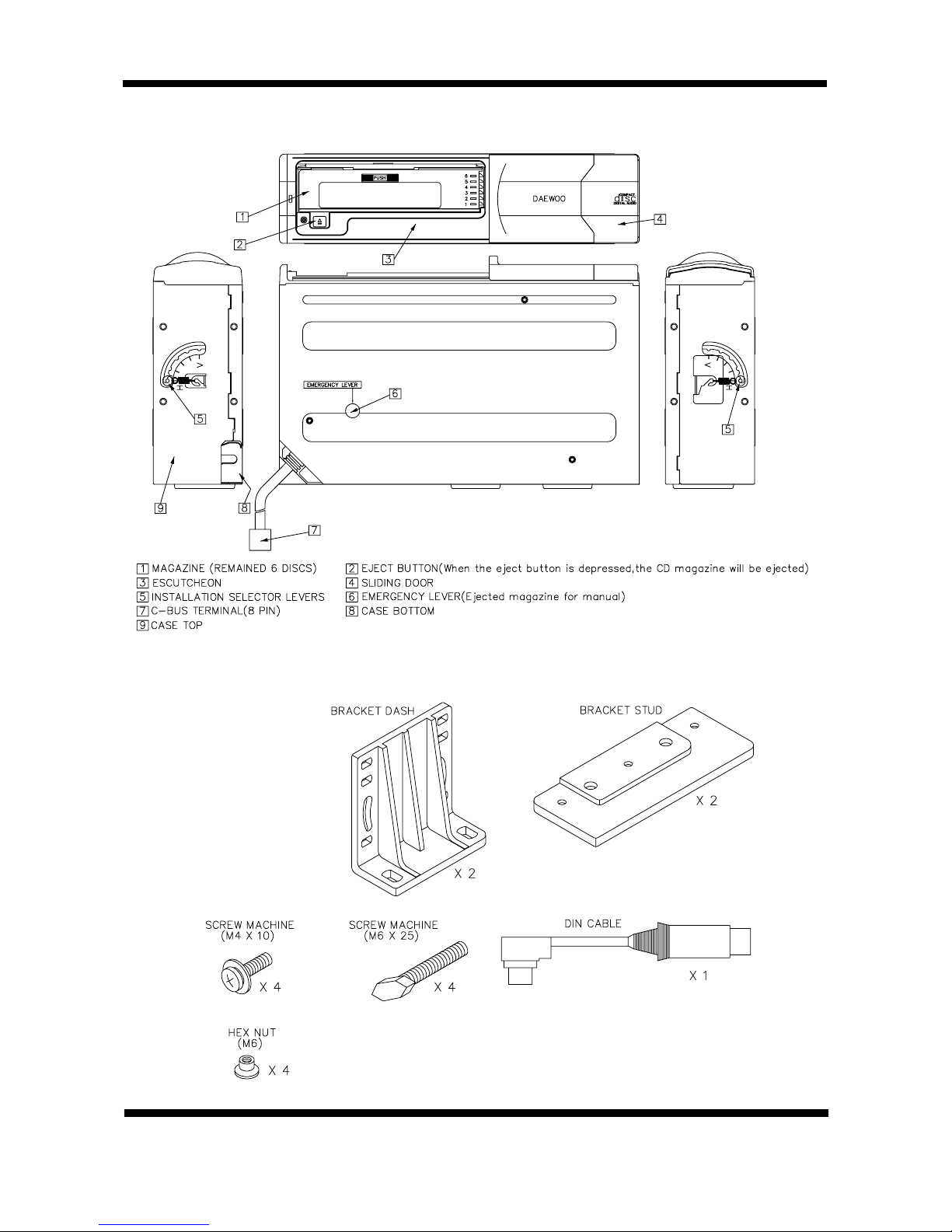

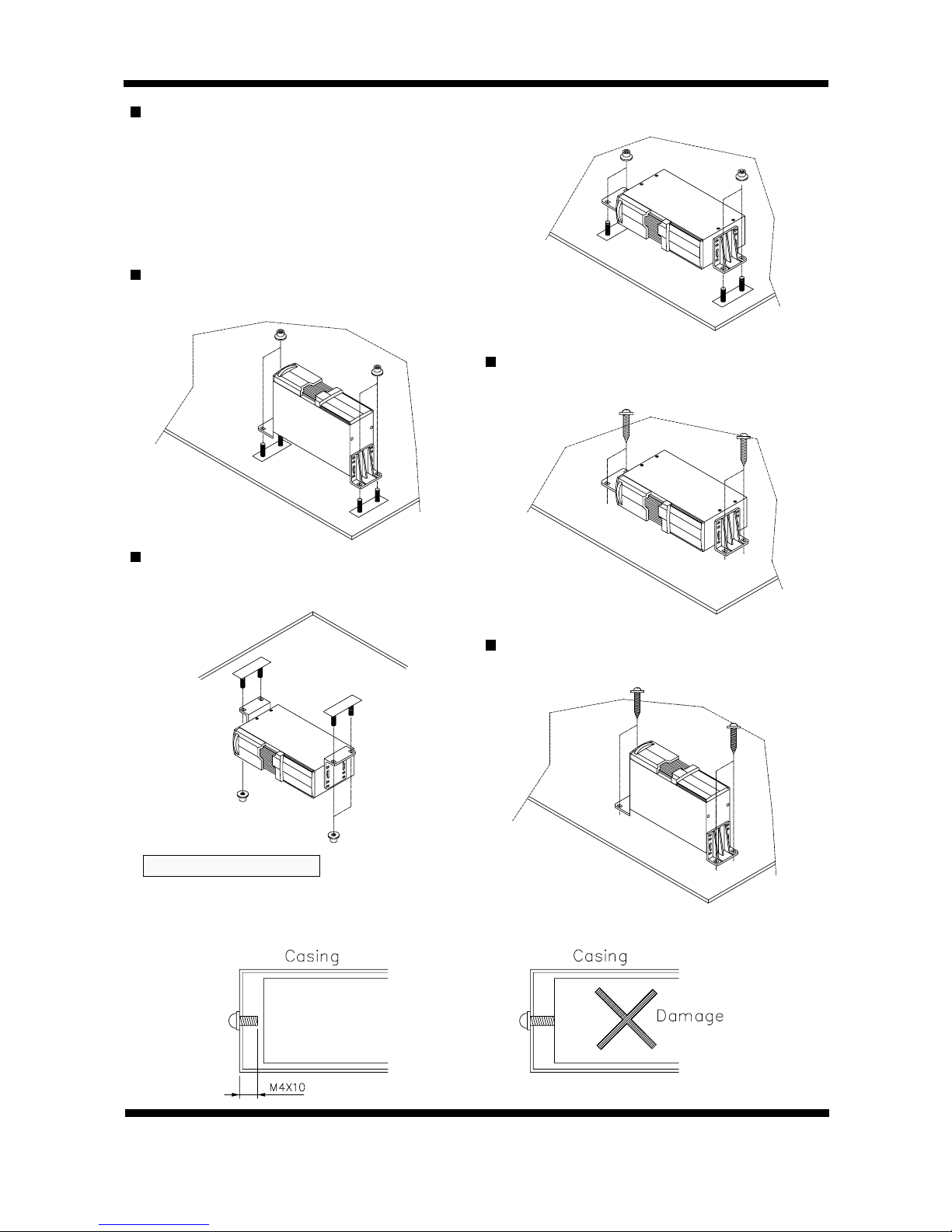

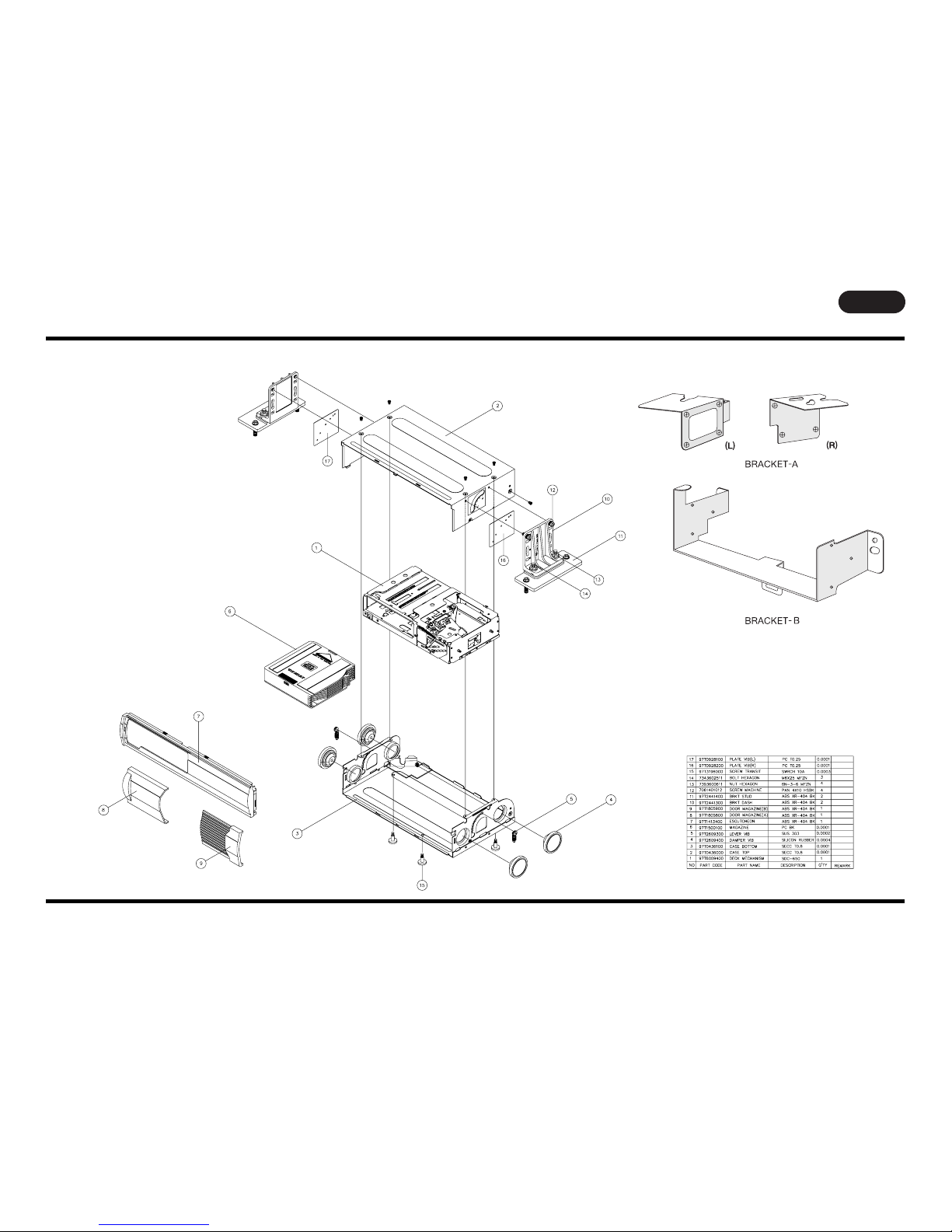

4.INSTALLATION METHOD

(HOW TO INSTALL THE VEHICLE)

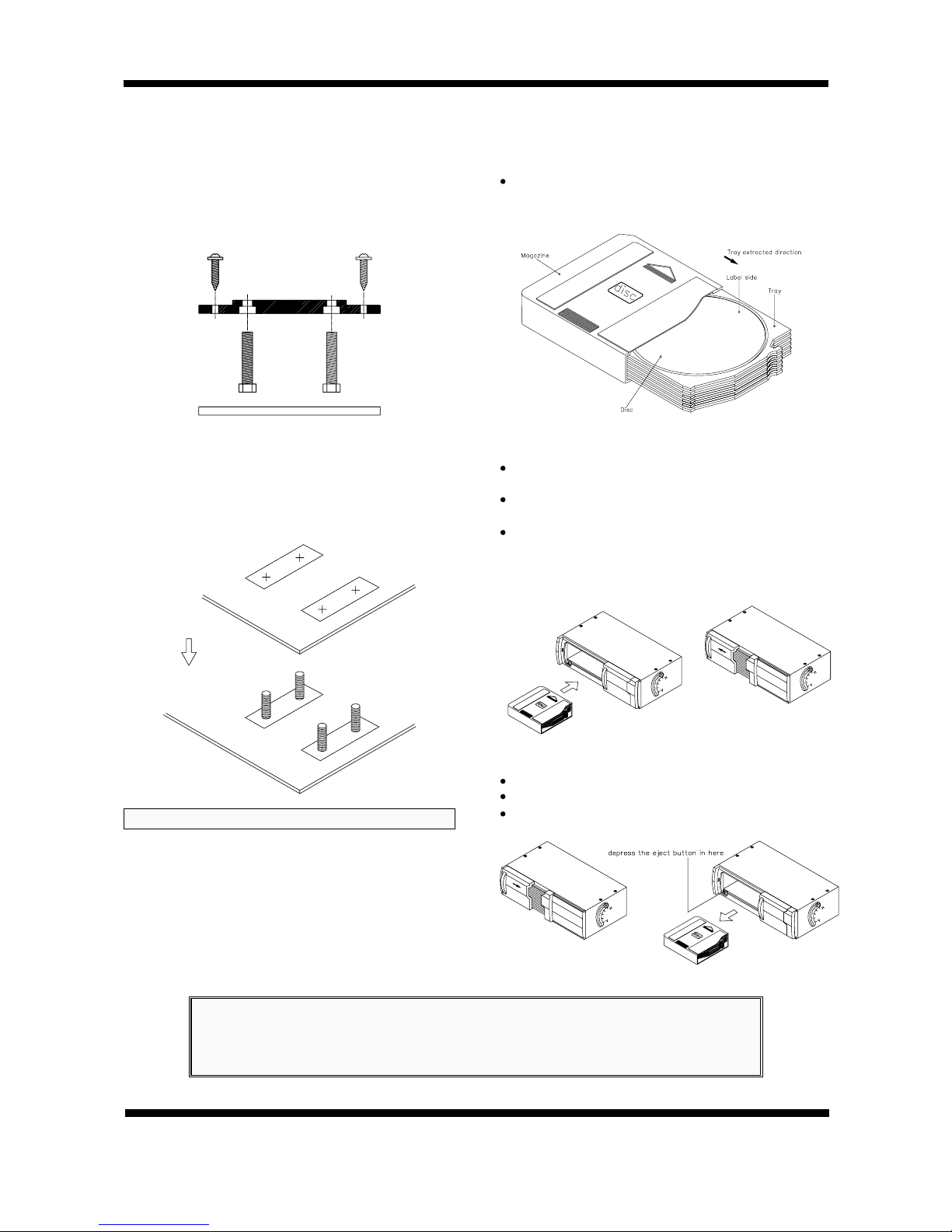

5.PREPARATIONS

- 6 -

Should be determined before the unit install under

carpet.

Adjust the installation bracket with bolts to suit the place

of installation.

1.Remove the floor carpet and decide on the place to

install.

2.Remove the separator of the cushion rubber that is

attached to the installation bracket with bolt and install

accordingly.

3.Align the unit with the bolts and secure it with the wing

nuts.

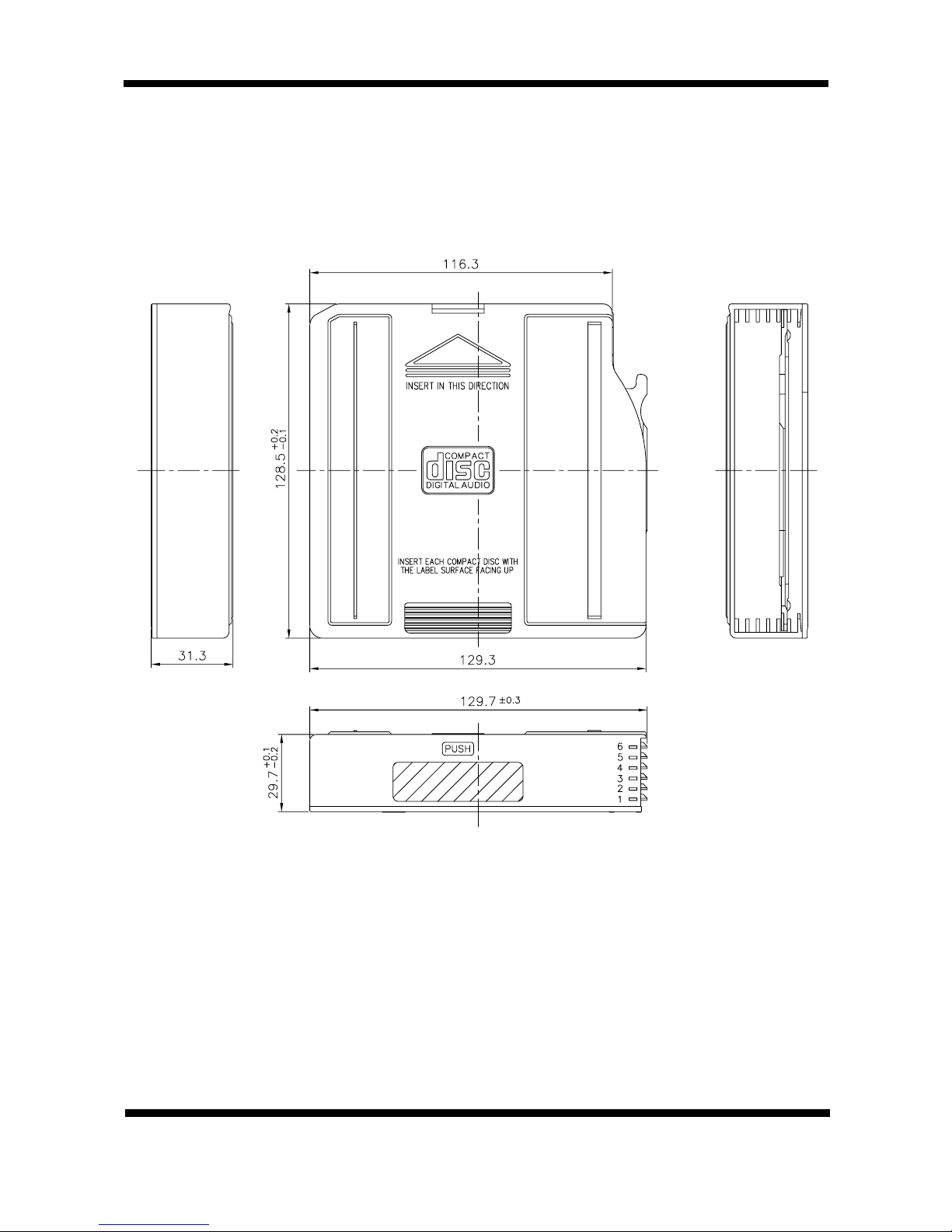

1.USAGE OF MAGAZINE (To load the discs)

Load the discs with the labels facing upwards, as

shown in the diagram.

2.TO LOAD THE MAGAZINE

Slide the sliding door to the right until it is completely

latched on.

Load the magazine in the direction as shown in the

diagram. push it in until is locked into the unit.

After the magazine has been loaded, close the sliding

door.

(If not close sliding door, Dirt or dust entering it will

cause damage)

3.TO REMOVE THE MAGAZINE

Open the sliding door and depress the eject button.

Remove the magazine when it has been ejected.

Close the sliding door.

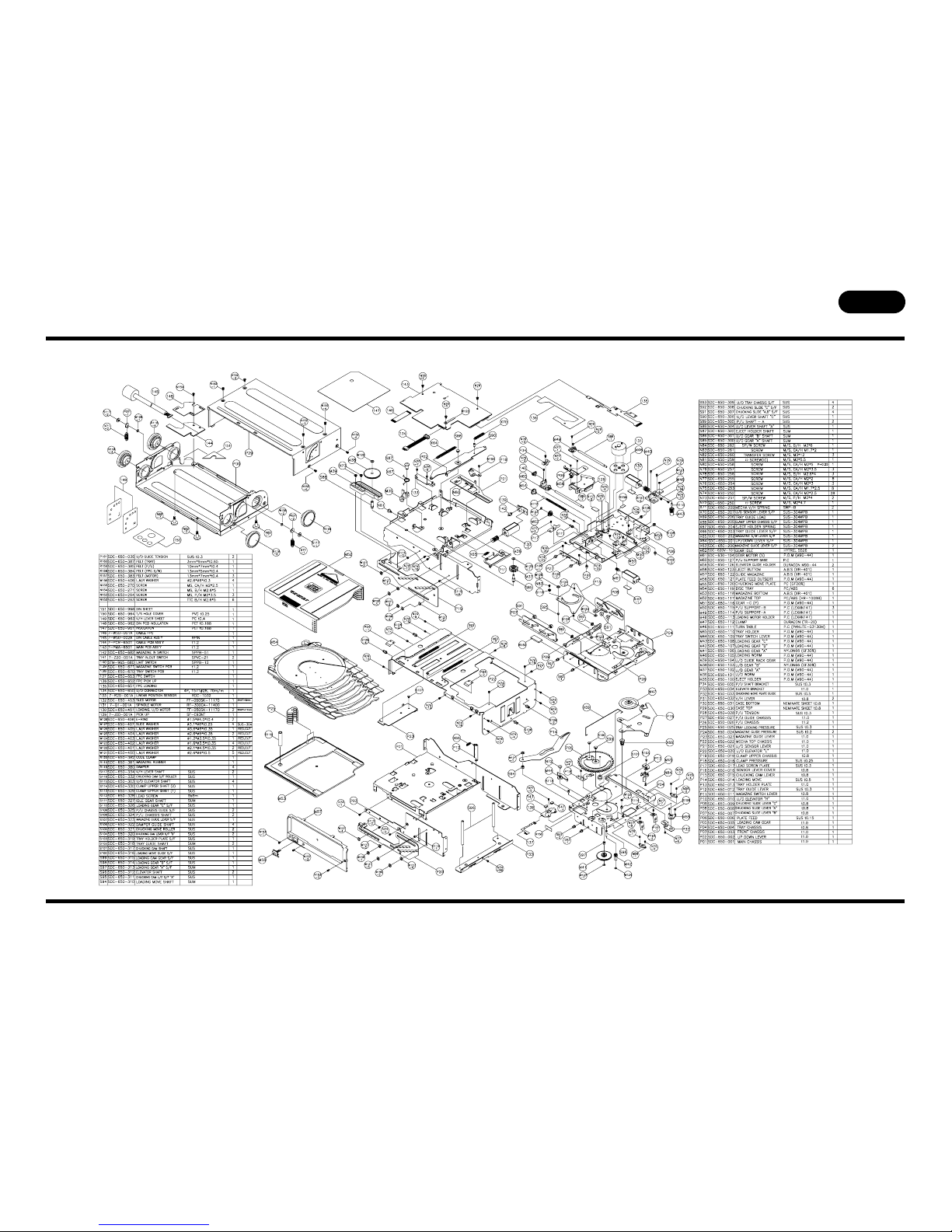

Notes on handling the optical pick-up block or base unit

1.The laser diode in the optical pick-up block may suffer

electrostatic breakdown because of the potential

difference generated by the charged electrostatic

load,etc. on clothing and the human body.

2.During repair, pay attention to electrostatic breakdown

and also use the procedure in the printed matter which

is included in the repair parts.

3.The flexible board is easily damaged and should be

handled with care.

CAUTION:

USE OF CONTROLS, ADJUSTMENTS, OR PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN, MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

THE COMPACT DISC PLAYER SHOULD NOT BE ADJUSTED OR REPAIRED BY ANYONE

EXCEPT PROPERLY QUALIFIED SERVICE PERSONNEL.