4

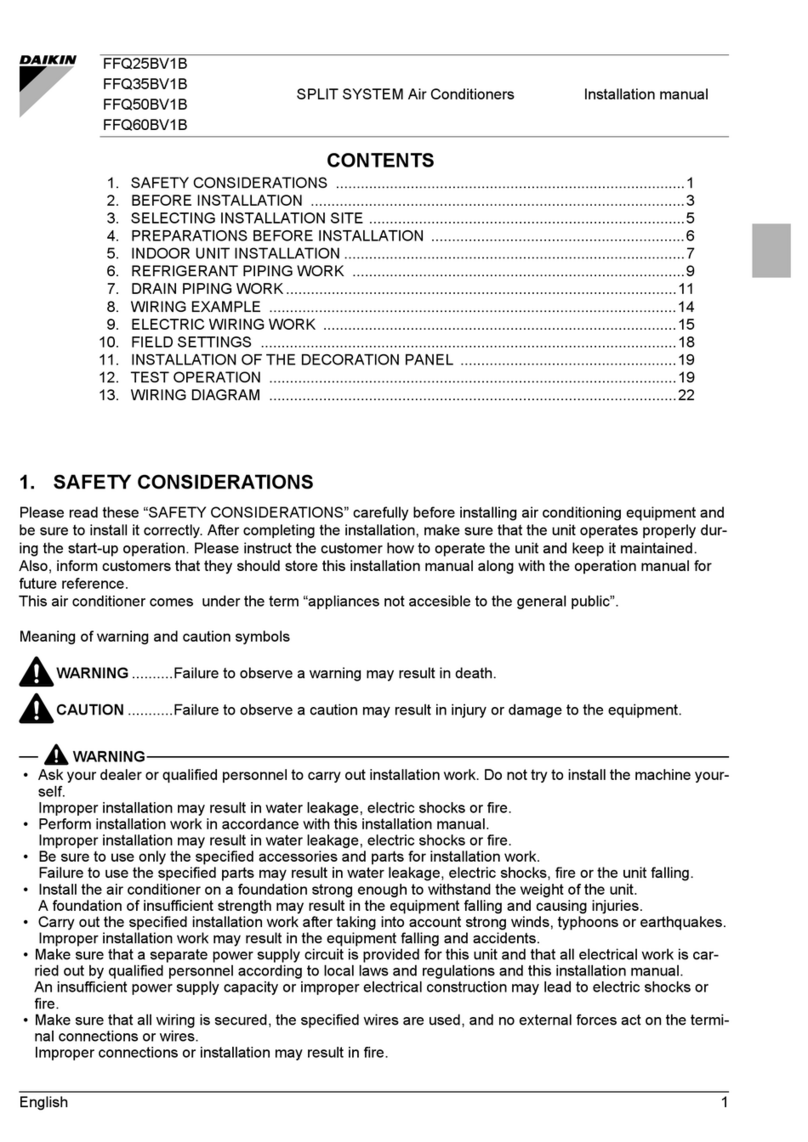

SAFETY PRECAUTIONS

!WARNING !CAUTION

Installation and maintenance should be performed by qualified persons

who are familiar with local code and regulation, and experienced with

this type of appliance.

All field wiring must be installed in accordance with the national

wiring regulation.

Ensure that the rated voltage of the unit corresponds to that of the

name plate before commencing wiring work according to the wiring

diagram.

The unit must be GROUNDED to prevent possible hazard due to

insulation failure.

All electrical wiring must not touch the water piping or any moving

parts of the fan motors.

Confirm that the unit has been switched OFF before installing or

servicing the unit.

Risk of electric shock, can cause injury or death. Disconnect all remain

electric power supplies before servicing.

DO NOT pull out the power cord when the power is ON. This may

cause serious electrical shocks which may result in the fire hazards.

Keep the indoor and outdoor units, power cable and transmission

wiring, at least 1m from TVs and radios, to prevent distorted pictures

and static. {Depending on the type and source of the electrical waves,

static may be heard even when more than 1m away}.

•

•

•

•

•

•

•

•

•

Please take note of the following important points when

installing.

Do not install the unit where leakage of flammable gas may

occur.

If gas leaks and accumulates around the unit, it may cause

fire ignition.

Ensure that drainage piping is connected properly.

If the drainage piping is not connected properly, it may cause

water leakage which will dampen the furniture.

Do not overcharge the unit.

This unit is factory pre-charged. Overcharge will cause

over-current or damage to the compressor.

Ensure that the unit’s panel is closed after service or

installation.

Unsecured panels will cause the unit to operate noisily.

Sharp edges and coil surfaces are potential locations which may

cause injury hazards. Avoid from being in contact with these

places.

Before turning off the power supply set the remote controller’s

ON/OFF switch to the “OFF” position to prevent the nuisance

tripping of the unit. If this is not done, the unit’s fans will start turning

automatically when power resumes, posing a hazard to service personnel

or the user.

Do not install the units at or near doorway.

Do not operate any heating apparatus too close to the air conditioner

unit or use in room where mineral oil, oil vapour or oil steam exist,

this may cause plastic part to melt or deform as a result of excessive

heat or chemical reaction.

When the unit is used in kitchen, keep flour away from going into

suction of the unit.

This unit is not suitable for factory used where cutting oil mist or

iron powder exist or voltage fluctuates greatly.

Do not install the units at area like hot spring or oil refinery plant

where sulphide gas exists.

Ensure the color of wires of the outdoor unit and the terminal

markings are same to the indoors respectively.

IMPORTANT : DO NOT INSTALL OR USE THE AIR

CONDITIONER UNIT IN A LAUNDRY ROOM.

Don’t use joined and twisted wires for incoming power supply.

The equipment is not intended for use in a potentially explosive

atmosphere.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

INSTALLATION MANUAL

NOTICE

Disposal requirement

Your air conditioning product is marked with this symbol. This means that electrical and electronic products shall not be mixed with unsorted household

waste.

Do not try to dismantle the system yourself: the dismantling of the air conditioning system, treatment of the refrigerant, of oil and of other parts must be

done by a qualified installer in accordance with relevant local and national legislation.

Air conditioners must be treated at a specialized treatment facility for re-use, recycling and recovery. By ensuring this product is disposed of correctly,

you will help to prevent potential negative consequences for the environment and human health. Please contact the installer or local authority for more

information.

Batteries must be removed from the remote controller and disposed of separately in accordance with relevant local and national legislation.

This manual provides the procedures of installation to ensure a safe and good standard of operation for the air conditioner unit.

Special adjustment may be necessary to suit local requirements.

Before using your air conditioner, please read this instruction manual carefully and keep it for future reference.

This appliance is intended to be used by expert or trained users in shops, in light industry and on farms, or for commercial use by lay persons.

This appliance is not intended for use by persons, including children, with reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

1-IM-5WMJ(R)-0714(2)DAIKIN(SASO)4 41-IM-5WMJ(R)-0714(2)DAIKIN(SASO)4 4 5/22/15 4:27:15 PM5/22/15 4:27:15 PM