Daikin Easdale 25 Manual

Other Daikin Air Handler manuals

Daikin

Daikin EBSH11P30D User manual

Daikin

Daikin Destiny VFD Series Manual

Daikin

Daikin PreciseLine Series Manual

Daikin

Daikin OAH 003G Manual

Daikin

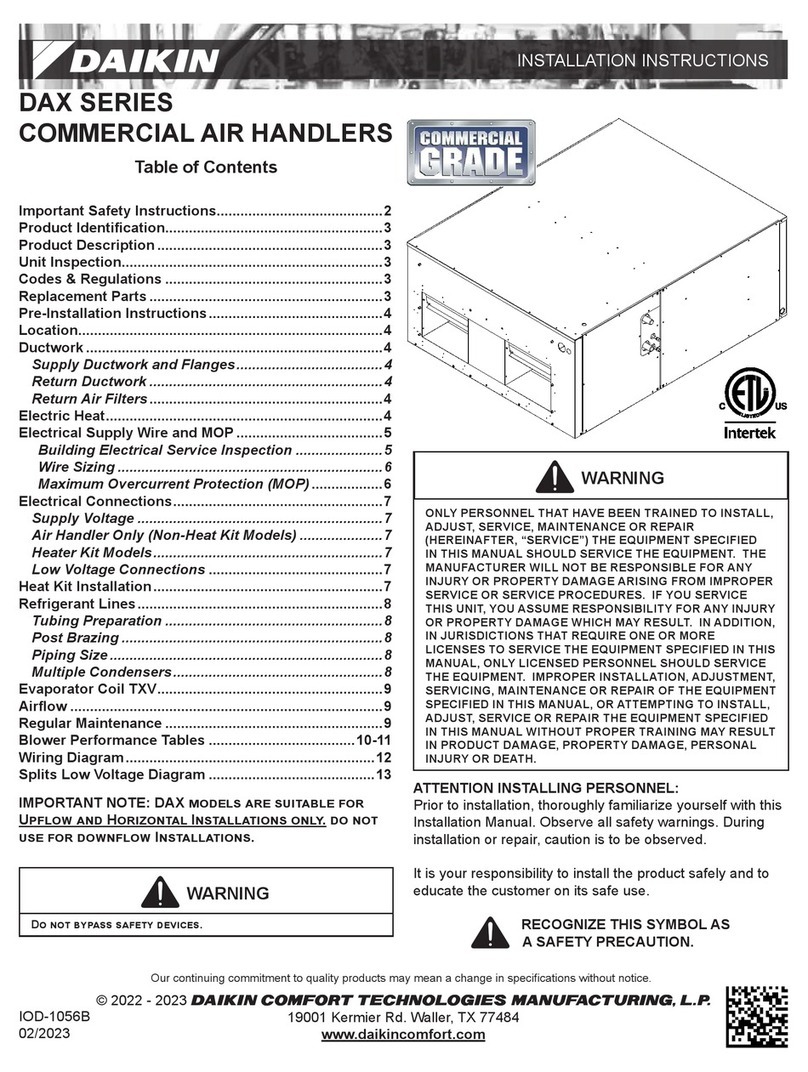

Daikin DAX Series User manual

Daikin

Daikin FWE04FF/T User manual

Daikin

Daikin RXQ12AHR User manual

Daikin

Daikin DCG090 User manual

Daikin

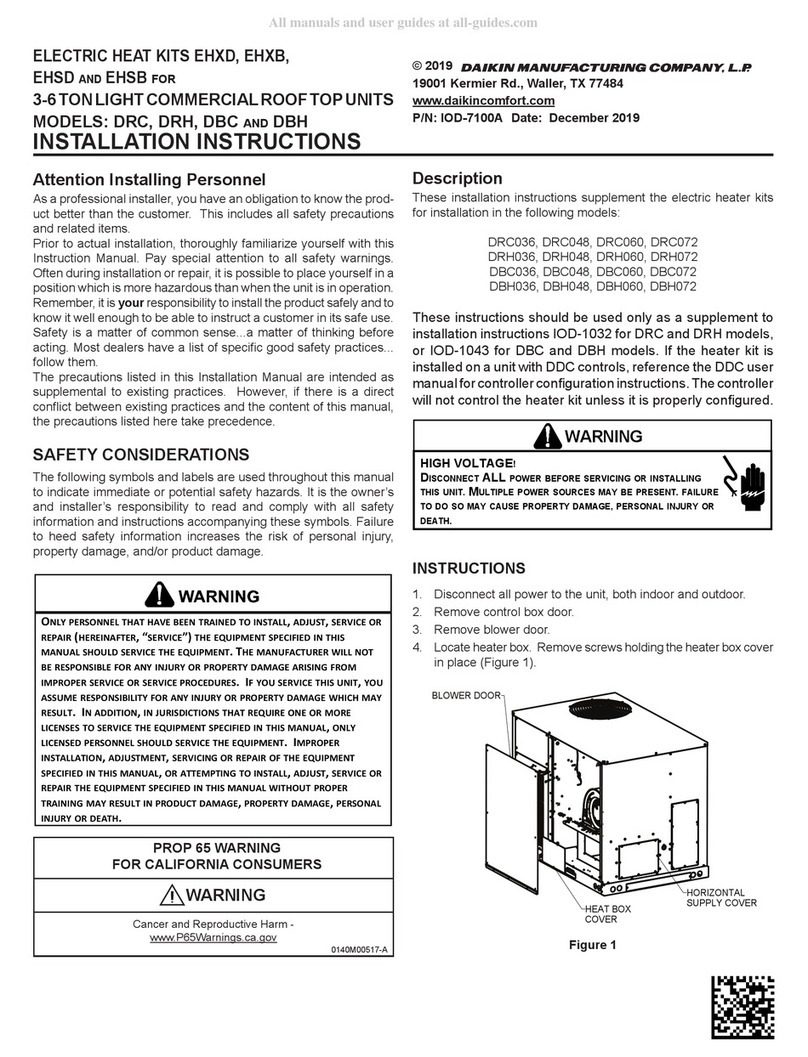

Daikin DRC036 User manual

Daikin

Daikin FXDQ-SPV1 Dimension Guide

Daikin

Daikin Vision CAC 003 C Manual

Daikin

Daikin Clima-Flex CLIFC FIXED Series User manual

Daikin

Daikin FHY71FVE User manual

Daikin

Daikin ATM18MV2S User manual

Daikin

Daikin D-AHU Professional AH-ERQ-U User manual

Daikin

Daikin DCG Series User manual

Daikin

Daikin EKEQFCBAV3-US User manual

Daikin

Daikin Altherma 3 R F How to use

Daikin

Daikin SkyAir FTQ18TAVJUA User manual

Daikin

Daikin DSC Series User manual

Popular Air Handler manuals by other brands

Klimor

Klimor EVO-S Operation and maintenance manual

Salda

Salda SMARTY XP MOUNTING AND INSTALLATION INSTRUCTION

BLAUBERG

BLAUBERG KOMFORT Roto EC S400 user manual

Trenton

Trenton TPLP Series installation instructions

Kemper

Kemper CleanAirTower operating manual

Haier

Haier HB2400VA1M20 Installation & operation manual

Webasto

Webasto BlueCool A-Series operating instructions

RDZ

RDZ DA 701 Technical installation manual

Carrier

Carrier 39T Installation, Start-Up and Service Instructions

Armstrong Air

Armstrong Air BCE5V Series installation instructions

ActronAir

ActronAir CAY500T Installation and commissioning guide

Carrier

Carrier 40MBDAQ Service manual

Allied

Allied A93UH1E Service manual

Nortek

Nortek B6VMAI installation instructions

TemperZone

TemperZone Econex Pro OPA 1410RLTM4FPQD Installation & maintenance

RDZ

RDZ WHR 200 Technical installation manual

AAON

AAON H3 Series Installation operation & maintenance

Lennox

Lennox VEOA042N432U Installation & operation instructions