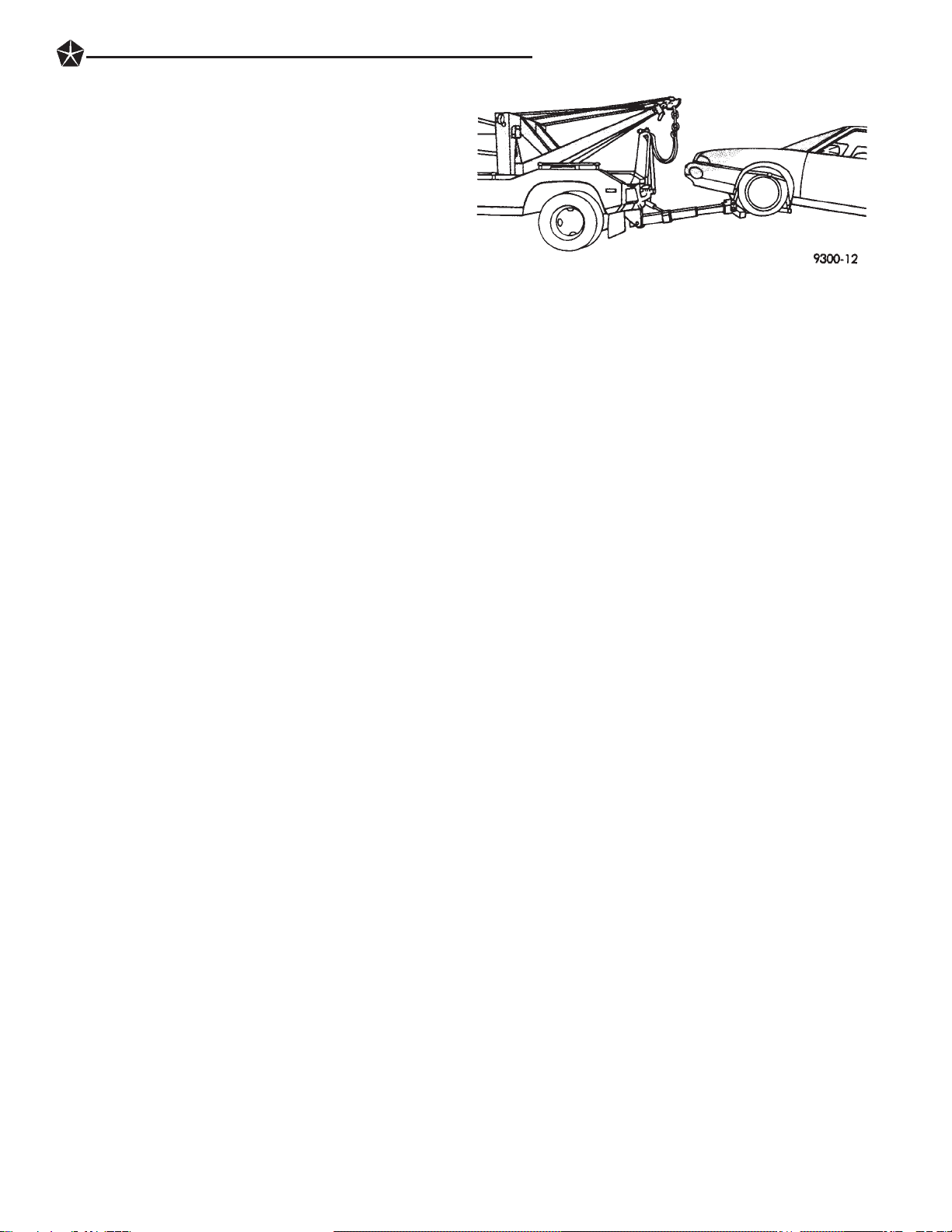

JUMP STARTING, HOISTING AND TOWING

JUMP STARTING PROCEDURE

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN GROUP 8A, BATTERY/START-

ING/CHARGING SYSTEMS DIAGNOSTICS.

DO NOT JUMP START A FROZEN BATTERY, PER-

SONAL INJURY CAN RESULT.

DO NOT JUMP START WHEN BATTERY INDICA-

TOR DOT IS YELLOW OR BRIGHT COLOR.

DO NOT ALLOW JUMPER CABLE CLAMPS TO

TOUCH EACH OTHER WHEN CONNECTED TO A

BOOSTER SOURCE.

DO NOT USE OPEN FLAME NEAR BATTERY.

REMOVE METALLIC JEWELRY WORN ON HANDS

OR WRISTS TO AVOID INJURY BY ACCIDENTAL

ARCHING OF BATTERY CURRENT.

WARNING:

WHEN USING A HIGH OUTPUT BOOST-

ING DEVICE, DO NOT ALLOW DISABLED VEHICLE’S

BATTERY TO EXCEED 16 VOLTS. PERSONAL INJURY

OR DAMAGE TO ELECTRICAL SYSTEM CAN RESULT.

CAUTION: When using another vehicle as a booster,

do not allow vehicles to touch. Electrical systems

can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually in-

spect engine compartment for:

•Battery cable clamp condition, clean if necessary.

•Frozen battery.

•Yellow or bright color test indicator, if equipped.

•Low battery fluid level.

•Generator drive belt condition and tension.

•Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster source,

turn off all accessories, place gear selector in park or

neutral, set park brake or equivalent and operate

engine at 1200 rpm.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake or equivalent. Turn

OFF all accessories (Keyless Entry system must be

turned OFF manually).

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to nega-

tive terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result (Fig.

1). Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 1).

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(6) Allow battery in disabled vehicle to charge to at

least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

•Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

•When using a Booster vehicle, disconnect BLACK

cable clamp from battery negative terminal. Discon-

nect RED cable clamp from battery positive terminal.

•Disconnect RED cable clamp from battery positive

terminal on disabled vehicle.

HOISTING RECOMMENDATIONS

Refer to Owner’s Manual provided with vehicle for

proper emergency jacking procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VE-

HICLE. WHEN THE ENGINE OR REAR SUSPENSION

IS REMOVED FROM A VEHICLE, THE CENTER OF

GRAVITY IS ALTERED MAKING SOME HOISTING

CONDITIONS UNSTABLE. PROPERLY SUPPORT OR

SECURE VEHICLE TO HOISTING DEVICE WHEN

THESE CONDITIONS EXIST.

Fig. 1 Jumper Cable Clamp Connections

LUBRICATION AND MAINTENANCE 0 - 5