11.3 PERFORMING A FIELD CALIBRATION ................................................................................ 109

CHAPTER TWELVE MEASUREMENT & WAVEFORM DISPLAY ............... 123

12.1 QUANTITIES OF MEASUREMENT ...................................................................................... 123

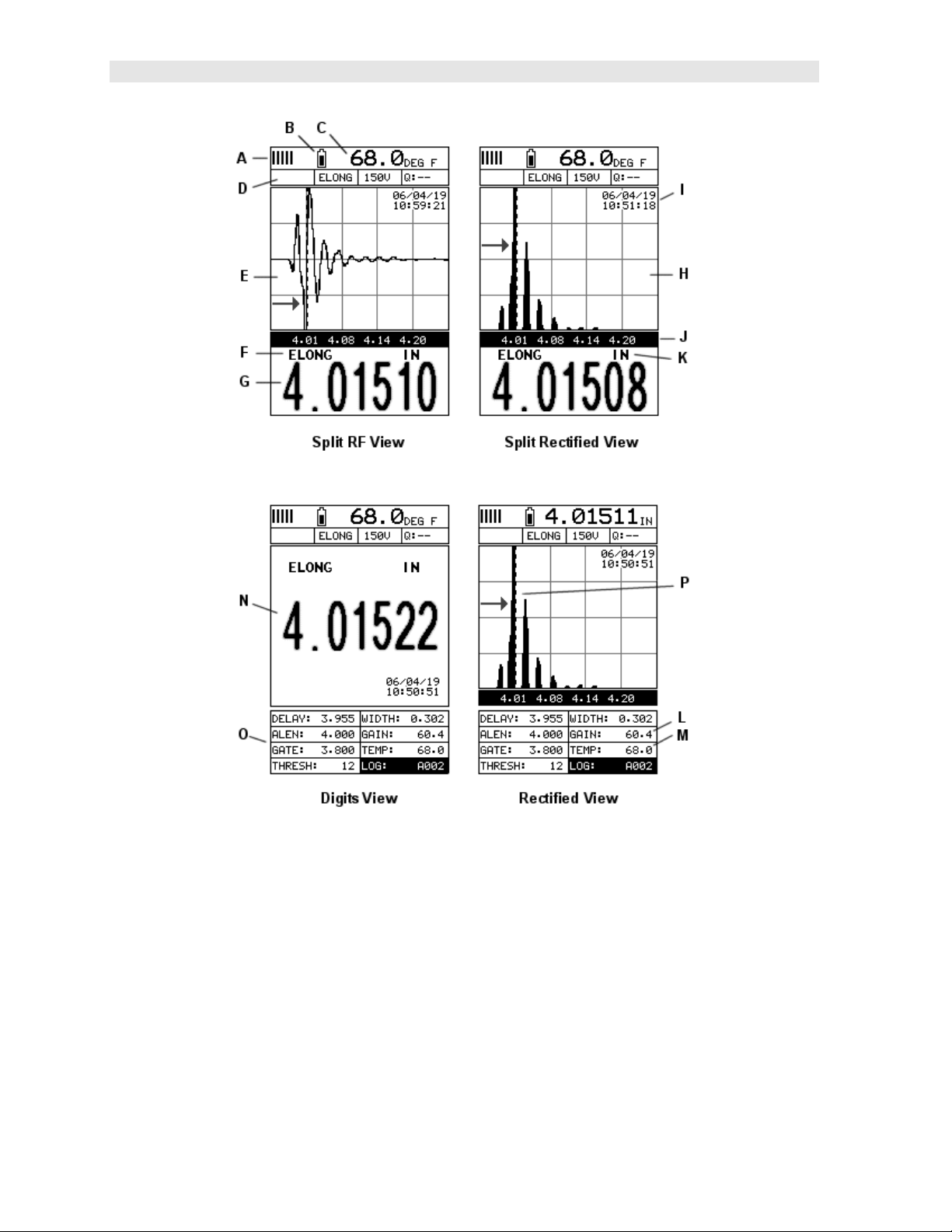

12.2 DISPLAY VIEW OPTIONS ................................................................................................. 124

12.3 ADJUSTING THE DISPLAY ................................................................................................ 128

12.4 GAIN .............................................................................................................................. 132

12.5 GATE ............................................................................................................................. 135

12.6 THRESHOLD ................................................................................................................... 138

12.7 INTERPRETING THE WAVEFORM ...................................................................................... 141

12.8 MANUALLY LOCATING THE ECHO .................................................................................... 142

12.9 AUTOMATIC ECHO OPTIMIZATION (AUTO SET) ................................................................. 144

12.10 UNLOADED LENGTH AND ELONGATION MEASUREMENTS ................................................ 147

CHAPTER THIRTEEN ADDITIONAL FEATURES ........................................ 148

13.1 QUALITY/CORRELATION (TRANSDUCER PLACEMENT) ...................................................... 148

13.2 CONTRAST ..................................................................................................................... 148

13.3 BACKLIGHT .................................................................................................................... 149

13.4 GRAPHICS OPTIONS (LOOK & FEEL) ................................................................................ 150

13.5 PULSE ........................................................................................................................... 152

13.6 PULSER VOLTAGE .......................................................................................................... 153

13.7 DAMPING ....................................................................................................................... 154

13.8 DIGITIZER ...................................................................................................................... 155

13.9 POLARITY ...................................................................................................................... 156

13.10 ALARM MODE ............................................................................................................... 157

13.11 KEY CLICK ................................................................................................................... 160

13.12 DATE & TIME ................................................................................................................ 160

13.13 UPGRADE GAUGE ........................................................................................................ 162

13.14 FREEZE & CAPTURE ..................................................................................................... 163

CHAPTER FOURTEEN DATA STORAGE – SETUP, EDIT, & VIEW FILES 165

14.1 INTRODUCTION TO GROUP (SPREADSHEET) FORMAT ....................................................... 165

14.2 CREATING A NEW GROUP ............................................................................................... 165

14.3 STORING A READING ....................................................................................................... 168

14.4 VIEWING STORED READINGS ........................................................................................... 169

14.5 DELETING GROUPS (FILES) ............................................................................................ 170

14.6 EDITING A GROUP (FILE) ................................................................................................ 173

14.7 CHANGING THE ACTIVE FILE - OPEN ................................................................................ 175

14.8 CLOSING AN ACTIVE FILE - CLOSE ................................................................................... 177

CHAPTER FIFTEEN SETUPS – CREATE, STORE, EDIT, & RECALL ....... 178

15.1 INTRODUCTION TO SETUPS ............................................................................................. 178