5. Handling.

The pump must be packaged properly during transport, to avoid damage to the pump or surroundings.

It can be transported and stored in vertical or horizontal position.

Always place the pump on a stable surface, so it cannot tip over during service, transport, testing and

installation.

For storage for long periods of time the pump must be checked again before use. Before electrical

connection, the impeller shall be turned by hand to ensure the parts do not bind.

Accidents in relation to installation can be minimized by taking care.

Be especially careful with the pump’s weight and the risk of electrical accidents.

When lifting with hoisting equipment, these must always be of the correct dimensions with regard

to the lifted weight. Secure pallet and lift the pump using motor eye-bolts.

Never walk under hanging pump.Then lift high enough only to clear pallet, and gently place on a

flat floor surface in a stable upright position.

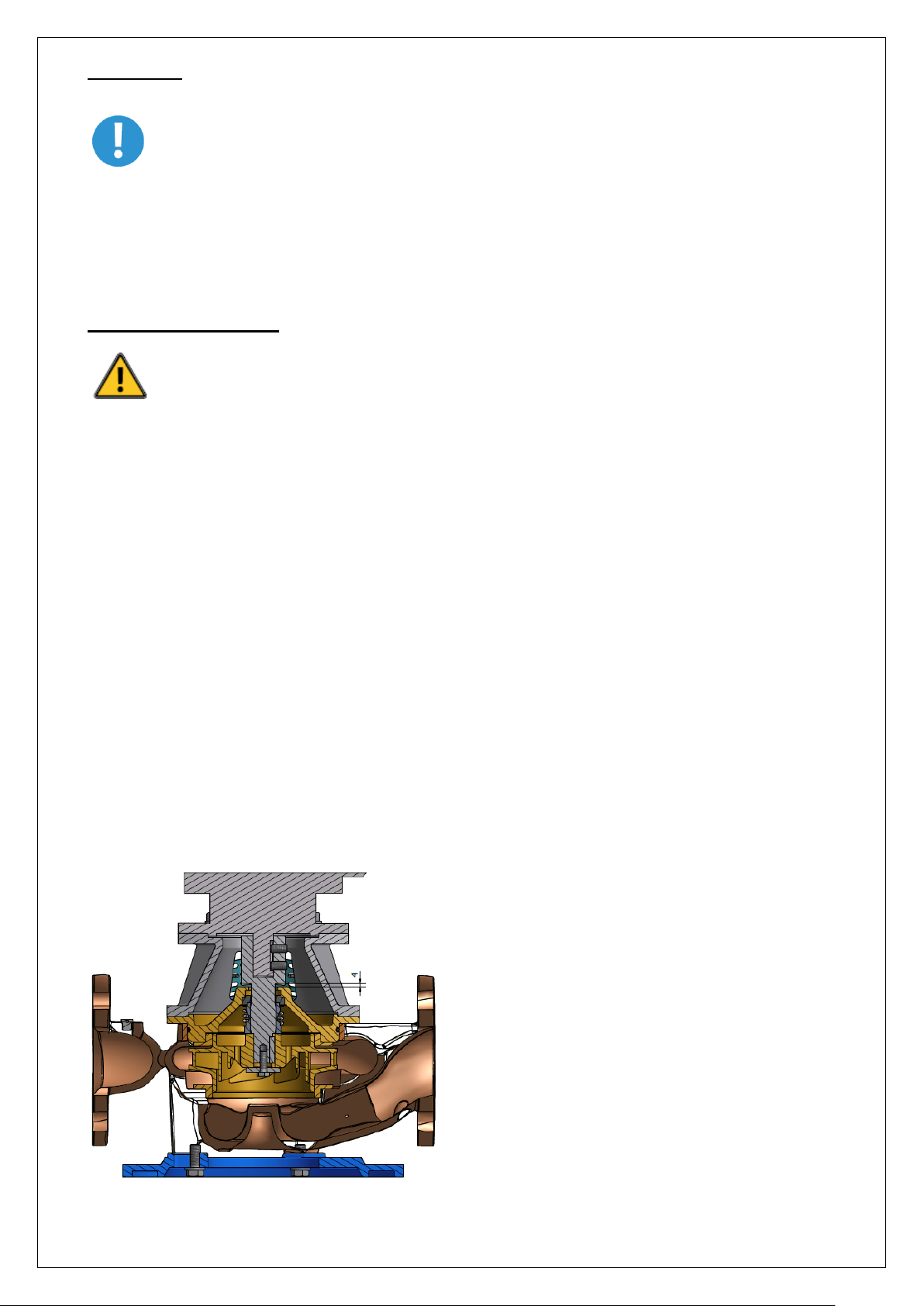

6. Pump installation.

The pipe system must have at least the same section (DN) as the pump connections.

The pump unit is designed to be installed in the pipeline. Standard piping supports on either side of the

pump should be used, to eliminate pipe and flange stresses.

The suction and discharge pipes must be in line, and the pump must not be used to pull the piping into

place by tightening the flange bolts.

Pipes should be supported near the pump

Never run the pump with suction side and discharge side blocked simultaneously.

Only shunt the pump on the discharge side.

Cavitation in the pump volute may occur, if the pump's suction becomes obstructed.

Cavitation can cause damage to the internal elements of the pump, especially on the impeller.

Always provide the right suction conditions.

Suction.

Connection elements that may cause air pockets, should not be used under any circumstances.

User larger pipes whenever needed, to maintain the water speed in the pipe below 1.2 m/s (4 feet per

second).The suction pipe must be one continuous run from its starting point to the pump.

In order to prevent air pockets and the intake pipe must never be positioned higher than the water level or

the level of the pump.

Whenever, if reducers are required to be used on the pump, then we recommend the use of concentric

reducers.

All pipe systems containing water, must be equipped with valves to prevent flooding during pump

maintenance.

Discharge.

All pipe systems containing water must be equipped with valves to prevent flooding during pump

maintenance.

In order to reduce power and flow losses, we recommend the use of pipes of same (DN) or larger diameter

than the pump discharge.

Elements that may cause air pockets should not be used under any circumstances.

The diameter of the pipes ought to be such, the water speed in the pipe remains below

2 m/s (7 feet per second).