7

7. Eletrical Installation

Work is only permitted to be carried out by qualied specialists and must to be carried out in accordance

with local regulations. Before work commences, ensure that all power is switched o and cannot be switched

on again accidental. This also applies to the auxiliary power circuits, e.g. anti-condense heaters.

Check that supply voltage and frequency are the same as rated data.

Motors can be used with a supply deviation of ± 5% voltage and ± 2% frequency, according to IEC60034-1

Connection diagrams for main supply and accessory as PTC or heater are located inside the terminal box.

Connections must be made in such a way as to ensure that a permanently safe electrical connection is

maintained, both for the main supply and the earth connection. We recommend that crimped connections

are made in accordance with IEC 60352-2. Use always overload switch.

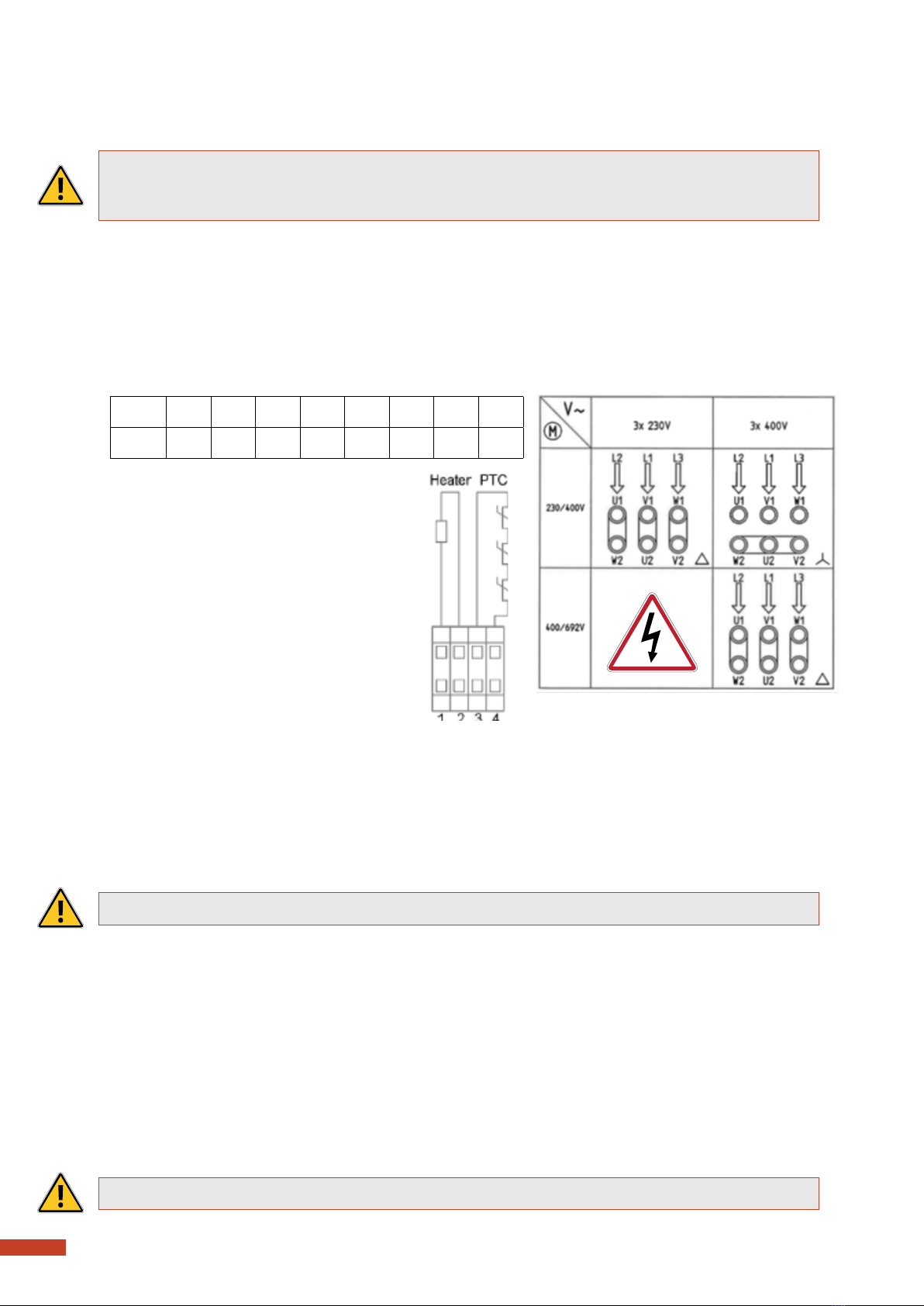

Tightening torques for terminal board screws:

Thread M5 M6 M8 M10 M12 M16 M20 M24

T.(Nm) 2.5 3.5 7 12 18 35 55 80

Ensure that the terminal box is clean and dry.

Unused glands must be closed with blind caps.

Check the terminal box gasket before it

is remounted.

The pump must be mounted with a motor

guard and a ground fault circuit breaker.

PTC terminals: No. 3 - 4

Motor space heater: No. 1 - 2

See also motor label inside the

motor terminal box.

8. Operation

Before the pump is started, the rotation direction must be checked. At start the motors starting torque will

cause the pump to jerk, and therefore has the pump to be mounted rm to the base.

Before start, the pump must be fully assembled and ready for operation.

At wrong start reaction, two phases must be switched. See the connection diagram.

NOTE: Wrong rotation or cavitation in the pump can make a loud noise.

9. Service and Maintenance

Before any inspection, service or repair of the pump, it has to be physically disconnected from the power

supply. Remove connectors or dismount the wires on the electric board. An emergency stop can be released

or be defective and start the pump by mistake.

All pumps require regular control and preventive maintenance to operate economically and reliably.

The pump should be checked every 6 months and during possible extreme operating conditions more often.

For complete overhaul of the pump contact an authorised Sondex Pumps workshop or your local Sondex

Pumps dealer. Clean the pump carefully before dismantling it. Follow local and national safety instructions.

NOTE: Make sure the fan cover are clean for dust and ect., so fan wing are able to cool the motor.