3

093683• Version 1.4• 19.04.2017

Introduction

Overview

Introduction This is the service manual for the Dantherm Air Handling A/S

home ventilation unit type HCV300.

Table of contents This manual covers the following topics:

Introduction ..................................................................................................................3

Overview ................................................................................................................3

General information ...............................................................................................4

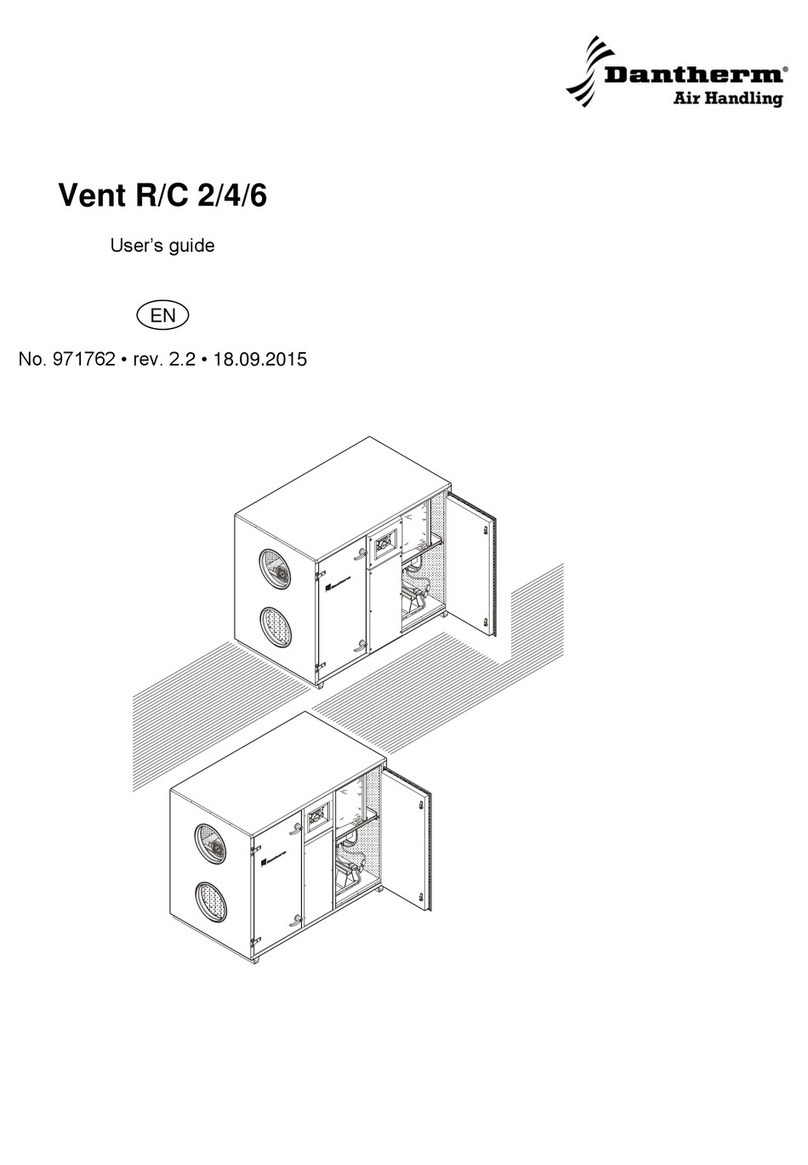

Product description .......................................................................................................5

General description ................................................................................................5

Description of parts ...............................................................................................8

Description of additional equipment ....................................................................10

Electronic control .................................................................................................11

System operation strategy....................................................................................14

Installation ..................................................................................................................15

Wall mounting......................................................................................................16

Drain....................................................................................................................17

Duct positioning ..................................................................................................18

External connections............................................................................................20

Changing the air flow path...................................................................................21

Calibration ...........................................................................................................23

Setting operating parameters ...............................................................................24

Firmware update ..................................................................................................25

User's guide ................................................................................................................26

General ventilation functions................................................................................27

Use of control panel. ............................................................................................28

Use of LAN interface.............................................................................................30

Service guide...............................................................................................................31

Overview ..............................................................................................................31

Preventative maintenance.....................................................................................32

Troubleshooting...................................................................................................35

Spare parts list .....................................................................................................37

Wiring Diagram ....................................................................................................41

Contact Dantherm................................................................................................43