Data Aire DAC Series User manual

DATAAIRE SERIES

Operation and Maintenance Manual

Chilled Water 7-50 ton

INSTALLATION

OPERATION

MAINTENANCE

2

CONGRATULATIONS ON THE SELECTION OF A DATAAIRE PRECISION

ENVIRONMENTAL CONTROL SYSTEM. PROPER INSTALLATION, OPERATION

AND MAINTENANCE OF THIS EQUIPMENT WILL ENSURE YEARS OF OPTIMAL

PERFORMANCE.

This manual is intended to assist trained service personnel by providing

necessary guidelines for this particular equipment. Service to Data Aire units

should be done by qualified individuals with an adequate background in

areas such as HVAC, electrical, plumbing and electronics, as applicable.

Service performed by unauthorized or unqualified technicians may void

manufacturers’ warranties and could result in property damage and/or

personal injury.

Special care should be given to those area where these symbols appear.

Data Aire, Inc. reserves the right to make design changes for the purposes

of product improvement, or to withdraw any design without notice.

3

Table of Contents

1.0 INSTALLATION ................................................................................................... 5

1.1 Room Considerations........................................................................................... 5

1.2 Inspection............................................................................................................. 5

1.3 Rigging................................................................................................................. 5

1.4 Locating the Unit.................................................................................................. 6

1.4.1 Downflow Units .................................................................................................... 6

1.4.2 Upflow Units ......................................................................................................... 7

1.5 Paperwork ............................................................................................................ 7

1.6 Storage................................................................................................................. 7

2.0 PIPING ................................................................................................................. 8

2.1 Chilled Water Piping ............................................................................................ 8

2.1.1 Connection sizes, Chilled Water unit................................................................... 8

2.2 Chilled Water Valve Ratings ................................................................................ 8

2.2.1 3-Way Chilled Water Valves ................................................................................. 9

2.2.2 2-Way Chilled Water Valves ................................................................................. 9

2.3 Condensate Drain Piping..................................................................................... 9

2.4 Humidifier Piping................................................................................................ 10

2.4.1 Steam Generator Humidifier ............................................................................... 10

2.4.2 Dry Steam Humidifier.......................................................................................... 10

2.5 Leak Testing....................................................................................................... 10

3.0 ELECTRICAL CONNECTIONS ..........................................................................11

3.1 Electrical Service. . .............................................................................................11

3.2 Nameplate Ratings..............................................................................................11

3.3 Grounding ...........................................................................................................11

3.4 Voltage Tolerance ...............................................................................................11

3.5 Remote Shutdown...............................................................................................11

3.6 RemoteAlarm Contacts ......................................................................................11

3.7 Remote Sensors ................................................................................................ 12

3.8 Condensate Pumps............................................................................................ 12

3.9 Condensate Probe ............................................................................................. 12

3.10 Water Sensing Cable......................................................................................... 12

4.0 CONTROLS....................................................................................................... 13

4.1 DAPIII Microprocessor ControlPanel ................................................................. 13

4.2 Wiring Diagrams................................................................................................. 13

5.0 REGULAR MAINTENANCE ITEMS .................................................................. 14

5.1 Filters ................................................................................................................. 15

5.2 Belts ................................................................................................................... 14

5.3 Bearings............................................................................................................. 14

4

Table of Contents, cont’d

5.4 Humidifier Canisters ........................................................................................... 14

5.5 Fuses ................................................................................................................. 14

5.6 HeatingElements................................................................................................ 15

6.0 WARRANTY....................................................................................................... 16

7.0 CONTACT DATAAIRE ...................................................................................... 17

MONTHLY MAINTENANCE INSPECTION CHECKLIST ................................... 19

QUARTERLY MAINTENANCE INSPECTION CHECKLIST............................... 21

INDEX ................................................................................................................ 22

5

1.0 INSTALLATION

There is no intent on the part of DataAire, Inc. to define local codes or statutes which may

supercede common trade practices. The manufacturer assumes no responsibility for their

interpretation. Consult local building codes and the National Electrical Code for special

installation requirements.

1.1 Room Considerations

Precision air conditioning equipment is designed to control spaces within close tolerances

of temperature and humidity. However, the room must be built with a proper vapor barrier. Afilm of

polyethylene is often used on walls and ceilings. Walls and floors must also be painted with a

vapor-seal paint. Failure to provide a vapor barrier can compromise space conditions.

Introduction of outside air into the space should be minimized. Outside air in excess of 5% of

the total circulated air volume can have a significant effect on the overall space conditions and

result in poor space control.

1.2 Inspection

This Data Aire unit has been factory run-tested and has gone through a comprehensive

inspectionprior to itspackagingandshipment to ensurethatit arrives inexcellentcondition. However,

shipping damage can occur and a visual inspection of the outer crating immediately upon delivery

should be performed.

Noteany externaldamageor other transportationdamageonthe freightcarrier’sforms. Inspect

the unit itself for internal damage. Aclaim should be filed with the shipping company if the equipment

is damaged or incomplete.

Loose items such as remote control panels, disconnect switch handles, spare belts and spare

filters are packed inside the unit. Refer to the yellow shipping tag located on the unit door for

details.

Freight damage claims are the responsibility of the purchaser. Action to recover losses

should be filed immediately. Please notify factory personnel of any claims.

1.3 Rigging

Move the unit in its upright position to the installation site. It is recommended that the unit be

protected from damage to the decorative doors during any storage or moving. Removal of the

decorative doors is easily accomplished and may be done when moving equipment.

The shipping skid should be left in place if the unit is being moved with a forklift. If the unit is

being lifted, use spreader bars to prevent damage to the doors and panels.

The unit has 3/4" holes in the shipping skid to which casters with 3/4" stems can be attached.

This allows easy movement down halls, into elevators and through doorways. If clearance is a

6

problem the casters may be inserted directly into the bottom of the 1" tubular steel corner posts at

the bottom of the unit.

Warning: Improper lifting or moving of equipment may result in damage to decorative

doors, panels or frame members.

1.4 Locating the Unit

When installing the unit, sufficient space must be allowed for airflow clearance, wiring,

plumbing, and service access. It is recommended that each side and front have a clearance of at

least 30" to allow the doors to swing open and for servicing the unit.

The doors on some sides may not require as much service clearance. Refer to the particular

unit component breakdown drawings for assistance. Rear clearance is not required, but 1" to 2" of

clearance is suggested.

For the best air distribution, the unit should be centered against the longest wall, as close to

the heat load as possible, unless the unit is ducted. The unit should not be placed near any corner

of the room or at the end of a long, narrow room. Multiple units should be evenly spaced, as far

apart as possible.

Note to Installing Contractor: Condensation formation and frequent humidifier flushing

are normal functions of this equipment. Proper drain connections must be made to ensure

proper removal. Unit will require water connections for condensate removal and possibly

for humidifier makeup water, chilled water and/or hot water. Installation of units above

equipment that could sustain water damage should be avoided.

1.4.1 Downflow Units

Downflow units will typically sit on an elevated flooring system known as a raised floor. The

unit discharges air downward which pressurizes the raised floor and channels upward through

perforated floor tiles. Location and quantity of perforated tiles will dictate proper air distribution. If

the raised floor is strong enough to support the unit and local codes permit, the unit can be placed

directly on top with cutouts made for the discharge openings.

There may be additional support required in the form of adjustable jackstands. These are

adjustable, threaded leveling rods which support the unit in each of the corners and in the center on

longer length units. Tighten the locknuts provided with each jackstand. The baseplate can rest on

the floor or on vibration isolation pads.

Floorstands are also a way of supporting the unit. These are ordered to the height of the floor

with leveling rods to allow adjustment. The floorstand has lips in each corner to align with the unit

which is placed on top. It is recommended that the unit frame be bolted or screwed to the floorstand

from below. Local building codes may dictate this procedure. After installation, the raised floor is

typically built around the unit.

The raised floor serves as the distribution plenum for air on downflow units. Cables,

piping,wiring raceways, inadequate floor heightandany other restrictions can inhibitproper

airflow. Care should be taken to avoid restrictions.

7

1.4.2 Upflow Units

Upflow units will typically be supported by vibration isolation pads and/or floorstands which

and may also include leveling screws. An air discharge plenum may be factory provided which

ships loose and must be attached at the top of the unit frame.

Alternately, an air distribution plenum must be field fabricated with supply grilles to distribute

the air. Units are shipped with a drive package to overcome external static pressure. Adjustments

to the blower speed may be required to adjust to actual conditions.

1.5 Paperwork

Each Data Aire unit ships with a start-up sheet that should be completed during installation.

Also included in the paperwork is a warranty/information packet that provides important wiring

diagrams, specific component literature, warranty registrations cards and other valuable paperwork,

including a copy of this Installation/Operation and Maintenance manual.

A yellow tag is attached to the outside decorative door to indicate articles that may have

been packaged and shipped loose within the unit cabinet. Typically this would be jackstands,

condensate pumps and other loose components that are not factory mounted.

1.6 Storage

Your DataAire equipment comes ready for immediate installation. In some instances in may

be necessary to store the equipment for a period of time. If you must store the equipment it should

be done in a dry area, out of the weather, protected from damage by other equipment in storage or

transportation equipment, never stacked, and avoid frequent relocation.

If equipment is stored for longer than 30 days special precautions must be taken to avoid coil

damage. All coils should be charged and sealed with a low pressure (1-25 psig) inert gas, such as

nitrogen. This prevents contaminates from entering the coils; then when the seal is broken at

installation, the rush of escaping gas verifies the coil is still leak free. If coils are not charged and

sealed condensation mixes with air pollutants forming a weak acid and over time can cause pin hole

leaks to develop in the coil tubes.

When equipment is installed after storage caution should be taken to inspect and replace, if

required, rubber hoses and belts. All moving parts, such as blowers and motors, should be hand

tested to ensure that they are free and clear prior to start-up. Finally, verify that all lubrication is

fresh and full.

It is the responsibility of the installing contractor to return the start-up sheet and warranty

registration card to Data Aire for proper activation of the unit warranty. Failure to do so

may cause delays and in some cases void the warranty.

8

2.0 PIPING

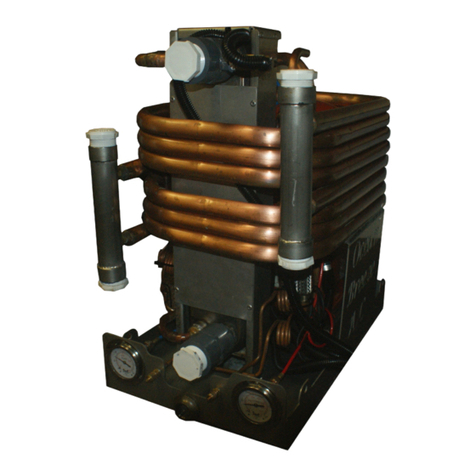

2.1 Chilled Water Unit Piping

The required field installed water pipe sizes may or may not be the same as the connection

sizesattheunit. Thiswill depend on the length of pipe and the calculated pressure drop of peripheral

components.

Shutoff valves should be installed within a few feet of the inlet and outlet connections of the

unit to allow the unit to be isolated for service. Afill valve with a hose bib connection should also be

used on the supply line or return line at the unit to allow the unit to be drained.

Water temperature and worst-case room temperature and humidity conditions should be

used to determine whether external piping should be insulated. Typical water temperature is 45° F

which is usually cold enough to cause pipes to sweat.

Field pipe connections are topically made at the bottom of the unit. Punching holes in the

back panel and making a 90° turn out the back of the unit is also acceptable. In some cases

provisions have been made to route the pipes out the right or left side or out the top of the unit.

Openings should not be made in the hinged decorative doors as this could prevent the door from

swinging open.

Standard chilled water units have a 3-way chilled water valve. An option for a 2-way valve is

also available. In either case the water connections to the unit should be made so there is a

counterflow between the water and air. Field water pipe connections are labelled but the counterflow

should also be verified before making field connections.

One of the most common problems in a Chilled Water system is the presence of air in the

chilled water water loop. Air vents must be installed in various locations in the piping system to

purge the air.

2.1.1 Connection sizes, Chilled Water units

Water In and Out Water In and Out

Evaporator Model Connections, OD Evaporator Model Connections, OD

DACx 07 1 1/8” DACx 22 2 1/8”

DACx 09 1 1/8” DACx 26 2 1/8”

DACx 11 1 5/8” DACx 30 2 1/8”

DACx 13 1 5/8” DACx 40 2 5/8”

DACx 15 1 5/8” DACx 45 2 5/8”

DACx 18 2 1/8” DACx 50 2 5/8”

2.2 Chilled Water Valve Ratings

All chilled water valves used on DataAire Series models 7 to 50 tons use chilled water valves

that are rated at 400 psi operating pressure. The chart on the next page gives the valve size and Cv

rating on 3-way valves for all unit models. The same information plus maximum close off pressure

for optional 2-way valves is also indicated

9

2.2.1 3-Way Chilled Water Valves

Unit Model Valve Size Valve CV

DACx 07 1” 10.0

DACx 09 1” 10.0

DACx 11 1-1/4” 10.0

DACx 13 1-1/2” 19.0

DACx 15 1-1/2” 19.0

DACx 18 2” 46.0

DACx 22 2” 46.0

DACx 26 2” 46.0

DACx 30 2” 46.0

DACx 40 2” 46.0

DACx 45 2” 46.0

DACx 50 2” 46.0

2.2.2 2-Way Chilled Water Valves Close-off

Unit Model Valve Size Valve CV Pressure, psi

DACx 07 1” 10.0 200

DACx 09 1” 10.0 200

DACx 11 1 1/4” 10.0 200

DAC x 13 1 1/2” 19.0 200

DACx 15 1 1/2” 19.0 200

DACx 18 2” 46.0 200

DACx 22 2” 46.0 200

DACx 26 2” 46.0 200

DACx 30 2” 46.0 200

DACx 40 2” 46.0 200

DACx 45 2” 46.0 200

DACx 50 2” 46.0 200

2.3 Condensate Drain Piping

Every indoor unit has a 3/4" copper stub provided for condensate removal. A union is

recommended at the field connection which will permit easy disconnection from the unit for cleaning.

A trap should be built into the drain line to prevent air from backing up into the unit. Drain

lines should be pitched downward not less than 1/4" for each ten feet of horizontal run. Do not

reduce the size of the drain line.

Some applications have no convenient means of allowing a gravity drain. In this case, a

condensate pump can be used. These come either factory mounted or shipped loose. Factory

mounted condensate pumps do not require a separate power source.

Condensate pumps shipped loose (or field provided) typically require a dedicated 110 volt power

source. Field pipe connections must be made to the pump discharge connection. A check valve

must be installed to prevent short cycling. See also condensate pump electrical requirements in

Section 3.9.

10

2.4 Humidifier Piping

2.4.1 Steam Generator Humidifier

Thestandardhumidifier on DataAiresystemsisa steam generatortypewith a disposablecylinder.

Thehumidifier makeup water shouldbebrought to the humidifierthroughthe field connection opening

using 1/4" copper tubing. A compression fitting is provided at the humidifier.

A shutoff valve should be provided outside the air conditioner to allow disconnection for service.

An in-line water pressure regulator and strainer should be installed. Water pressure should be set

between 20 and 50 PSI.

The humidifier has a drain at the bottom which is factory piped to the main condensate drain line.

The dispersion tube also has a drain line. No additional field piping is required.

2.4.2 Dry Steam Humidifier

The optional dry steam type humidifier requires a strainer on the inlet steam line. An outlet

connection with a field-provided steam trap is also required. Steam pressure is typically 10-15 psi.

2.5 Leak Testing

No installation is complete until the entire system has been thoroughly checked for leaks. This

includes water lines, flare fittings, pressure controls, and Shrader fittings.

Check all humidifier water makeup lines, condensate lines, condensate pumps, chilled water

lines.

Tightening of fittings and valves is the responsibility of the installing contractor.

11

3.0 ELECTRICALCONNECTIONS

Beforeproceedingwiththeelectricalconnections,makecertainthatthevolts,hertz,andphase

correspondto that specified on theunitelectrical nameplate. Use copper conductors only.

3.1 Electrical Service

Checktobesurethe serviceprovided bythe utilityis sufficientto handlethe additionalload imposed

bythis equipment.

3.2 Nameplate Ratings

Refertotheunitelectricalnameplateforequipmentelectricalrequirements. Minimumcircuitampacity,

(MCA) also known as wire sizing amps, will dictate the minimum required wire gauge. Maximum

overcurrentprotection (MOP) device amps willdictatethe maximum circuit breaker orfusesize.

3.3 Grounding

Theunitcabinetmusthaveanuninterruptedtrueearthground. Anelectricalgroundwireofadequate

sizemust be connected to the groundlugprovidedinside the main electrical box.

3.4 Voltage Tolerance

The supply voltage to the unit must be within 10% of the voltage indicated on the unit electrical

nameplate. Phase to phase imbalance must not exceed 3%. The local utility company should be

contactedfor correction of improper line voltage. Deviationfromvoltageratings can cause premature

failuresand possibly voidunitwarranties.

Check the wiring connections in the unit control panel to ensure they are tight. Screw

terminalsmaybecomelooseintransit. Tighteningofwiringconnectionsistheresponsibility

oftheinstallingcontractor.

3.5 Remote Shutdown

Every Data Aire chilled water unit has remote shutdown contacts. These are intended for a field

supplieddry contactorswitch to bewiredacross two terminals. Whenthecontact orswitchopens, the

control circuit power is interrupted and the unit shuts down, including the control panel. The control

circuit is 24 VAC and the field provided contact or switch should have a minimum rating of 10 amps.

The remote shutdown contacts are always terminals #1 and #2 on the terminal block designated

TB1. Theunit will ship with afactory wired metal jumper clip thatconnects terminal #1 to terminal #2.

Removethis clip prior to installing the field wires.

3.6 Remote Alarm Contacts

TheDAPIII,microprocessor control panel providesaremotealarm output contact that can befield

accessed on terminals #11 and #13 of terminal block TB1. This is a Normally Open, Close onAlarm,

dry contact, intended to be used in a control circuit not exceeding 5 amps at 24 VAC.

This programmable output contact will close on a failure and remain closed until the alarm is no

longerpresent. Threeadditionalalarmoutputcontactscomewiththeoptionalrelaymodule. Theterminal

designations for these alarm output contact pairs are #40 and #42; #43 and #45; and #48 and #50.

12

3.7 Remote Sensors

Remotesensorsare optional. Although existing unit mounted sensors can be removed for remote

mounting, the remote sensor option provides a more convenient means of field installation. This is

becausethesensorsare alreadyconnected toapredeterminedlengthof cableand comemountedin a

remote sensor enclosure. The temperature and humidity sensors require a total of five wires, these

shouldbe a twisted, shielded cable.

3.8 Condensate Pumps

Condensatepumps which ship loosenormallyrequirea separatesource of 110volt power. Always

check the pump power requirements before connecting power. Condensate pumps are available in

othervoltages.

Condensatepumpsmayalsocomeunitmountedandpowered. Whilenooutsidepowersourceis

required,fieldpipingisstillarequirement.

Condensatepumps arewired to displaya “HighCondensateWaterLevel” alarm. Thewiringfor this

mustbe done in the field on pumps that shiploose. Factorymountedpumpscomepre-wired.

3.9 Condensate Probe

A condensate probe for sensing underfloor water is included with this unit. This comes in a plastic

bag,with about 15 feet ofcoiled-upwire. The probe is a flatplatethatis typically placed below theunit

ina location where waterislikelyto accumulate.

Placetheprobeflatontheflooron topof athin layerof nonconductivesilicone. Secure theattached

wireswhere necessary. Alonger length ofwiremaybeused if required.

Note: Failure to uncoil the length of wire attached to the condensate probe can result in a

nuisancewater-detectedalarm. Iftheprobeisnotgoingtobeuseditshouldbedisconnected.

3.10 Water Sensing Cable

Anotheroption for watersensingis the WaterDetection Cable. This is alongcable that can sense

moisture anywhere along its length. It is typically placed below the unit in a rectangular pattern that

matchesthe perimeterofthe unit.

13

4.0 CONTROLS

4.1 DAP III Microprocessor Control Panel

Thestandardcontrolson allDataAireSeriesequipmentistheDAPIIImicroprocessorcontrolpanel.

This state-of-the-art control panel has a separate manual that goes into extensive detail regarding

functions,features,programming,andtroubleshooting.

The DAP III microprocessor control panel has an entire manual dedicated to its use and

operation. Thismanualmustbereferencedtocompleteathoroughunitinstallation. Start-

upis not complete until theDAPIII controlpanel settings areestablished.

4.2 Wiring Diagrams

Every DataAire unit comes with a wiring diagram. These diagrams are ‘ladder’- type schematics

intended for service personnel. The intent is to allow the technician to understand the wiring details

associated withthe electricalcomponents and howthey interfacewiththe DAP IIIcontrol panelaswell

asperipheral equipment.

DataAire’schilled water unitwiringdiagrams will have a drawing number whichstartsoutwith the

three letter designation, “DAC”. An example of a typical diagram, DAC-S-813, is shown on page 18.

14

5.0 REGULARMAINTENANCEITEMS

5.1 Filters

Filtersshould bechecked onaregular basisand changedwhenthey becomedirty. Thiswill ensure

efficientoperationofthe unit. Althoughthe unithas adirtyfilteralarm,thisshouldnot berelied onas the

only determinant for replacing filters. Amaladjusted filter differential pressure switch may not give a

proper indication of a clogged filter.

Tocheckthefilterdifferentialpressure switchfor properadjustment,temporarilycoverabout 75%of

thereturnairopeningusingheavy cardboardor similarmaterial. The alarmshould energizewhen75%

ofthe air is blocked, simulating dirty filters. If the alarm energizesprematurelyordoesnot energize at

all,thepressureswitchshouldbeadjusted. Doorsmustremainclosedwhendeterminingifanadjustment

isnecessary.

Spare filters should be kept in stock as these tend to be a frequently replaced maintenance item.

Filtersmay requirechangingas oftenasmonthly. Notealsothatconstruction dust onnewinstallations

willquickly clognew filters.

Filters that require changing can restrict airflow and create problems such as poor air

distribution.

5.2 Belts

Belttensionshouldbecheckedregularly(monthly)toensurepropertension. Iftighteningisrequired,

loosen the four motor mounting bolts. Turn the adjustment screw on the end of the motor mounting

channeluntil the proper belt tension is attained. Retighten the four mounting bolts. Damage can also

occurto belts that areovertightened. Theamountof play in a typicaldriveset should be 1/2 inch.

5.3 Bearings

Pillowblock bearings used on many models havezirktype grease fittings. These will only require

grease once annually. Care should be taken to avoid over-greasing. Only one or two pumps from a

manual gun are required. All other blower bearings are permanently lubricated and do not require

maintenance.

Mostblower motors have sealed bearingsandaremaintenance free. Some motors have zirktype

greasefittingsonthe bearings. Ifsothemotorshould begreasedonceannually. Careshouldbe taken

toavoid over-greasing. Only one ortwopumpsfrom a manual gun arerequired.

5.4 Humidifier Canisters

SteamgeneratortypehumidifierisstandardonDataAireSeriesequipment. Thereisnomaintenance

requiredother thanto replacethecanister asrequired. Thisfrequency willdependon usageand water

type. A set of manufacturer’s instructions for the humidifier is sent as part of the paperwork placed

insidethe unit whenitships.

5.5 Fuses

Fuses may occasionally require changing especially with installations where the voltage is not

consistent. Drops involtagecancreatebriefperiods of high amp draw, causing fuses toblow. Always

replacefuseswiththoseoftheequivalentratingwithregardto: 1)amperage, 2)voltage,and 3)speed.

15

Forinstance motorsare inductiveloadswhich requiretimedelay fuses. Electricreheatand humidifiers

areresistiveloads requiring fast acting fuses.

5.6 Heating Elements

Heatingelementsdonotnormallyrequiremaintenance. Howeversometimesthey mayaccumulate

afilmofdustordirtwhenunused forextended periodsof time. Whenenergized, theburning debriscan

createsmokeorunpleasantodor. Tohelp avoid this, periodic cleaning is recommended.

16

6.0 WarrantyPolicy

Seller warrants its equipment to Buyer to be free from defects in material and workmanship for a

period of eighteen (18) months from date of shipment, as long as equipment is utilized under normal

conditionsand service andisproperly installed;however,thewarranty shall notbeapplicable toanyof

thefollowingitems:refrigerant,belts,filters,humidifier, heaters not regularly cleaned, light bulbs, and

anyother itemseitherconsumed orwornout bynormalwear andtear, orbyconditions beyondSeller’s

control,including (withoutlimitationastogenerally) polluted orcontaminatedairor water.

The Seller’s obligation under this warranty is limited solely to the repair or replacement, at Seller’s

options,ofanypartorparts thereofwhichshall, withineighteen(18)monthsfromdateofshipment ofthe

equipment to the original purchaser be returned to the factory, transportation charges prepaid, which

upon examination shall disclose to the Seller’s satisfaction to have been defective under normal use

andservice.Thisagreementtorepairorreplacedefectivepartsisexpresslyinlieuofallotherwarranties,

expressedorimpliedandallotherobligationsorliabilitiesonthepartofSellerandSellerneitherassumes

norauthorizesanyother personto assumeforit anyliability orobligationin connectionwith thesalesor

serviceofitsequipment,except said repair or replacement of defective parts set forth above.

Thiswarranty does not include any labor charges forworkdoneoutsideofthefactoryfor replacement

of parts, adjustments, repairs, or any other work. Seller’s liability does not include any resulting

damage to persons, property, equipment, goods or merchandise arising out of any defect in or

failure of any equipment of its manufacture and Buyer hereby waives any claim against Seller arising

out of such claim. This warranty shall not cover the repair or replacement of any equipment which

hasbeen repairedor alteredoutsideofthe factory inanyway or whichhasbeen subject tonegligence,

misuse, or abuse, or to pressures in excess of stated limits.

This warranty applies only to the original purchaser of the equipment and does not extend, expressly

or by implication, to the third parties or others without the specific written approval and

acknowledgment of Seller. Buyer’s exclusive remedy and Seller’s maximum liability for any and all

loss, injury, damage, costs, or expense arising from any defect covered by this warranty shall be

limited to the repair or replacement, but not the installation of any defective material, F.O.B., Seller’s

plant; provided however, that Seller shall not be required to replace any part or component (a) which

can be repaired, or (b) unless Buyer has given Seller immediate written notice that replacement or

repair.Inaddition, Seller shallnotbe liable for anycostor expense of replacementorrepaircontracted

for by Buyer with any third person, unless, and then only to the extent that Seller authorizes in

writing, such costs or expense.

Seller shall not be liable for any direct, indirect incidental, consequential, or other form of loss,

injury,damage,cost, orexpense,whethercausedbydelay,failure,orperformance,breach ofwarranty,

or by any cause whatsoever.

Seller’s obligation under this warranty shall be void if Buyer fails: (a) without legal justification to pay

Seller, when due, the full purchase price for the equipment sold hereunder; or (b) to have the

equipment sold hereunder installed, maintained, and serviced by competent personnel and in

accordance with Seller’s instructions.

17

7.0 Contact Data Aire

Address:Data Aire Inc.

230 W. BlueRidge Avenue

Orange, CA 92865

Phone 714-921-6000

800-347-AIRE (2473) Toll Free

Fax: 714-921-6010 Main

714-921-6011 Engineering

714-921-6022 Part Sales

E-mail:[email protected] Service

[email protected] TechnicalSupport

[email protected] Engineering

[email protected] Sales

Web site:www.dataaire.com

Job information:

Model Number: DA__ __ - __ __ __ __ - __ __

Serial Number: __ __ __ __ - __ __ __ __ - __

Job number: _______________________________________

Date installed: ___ / ___ / 20____

Installing Contractor: ________________________________

18

19

Data Aire, Inc.

Monthly Maintenance Inspection Checklist

Model No. _________________ Serial No. ____________________

Preparedby: _______________ Date: ___ / ___/ 20___

AirFilters

___ Check for restricted air flow

Blower Section

___ Blower wheel free of debris moves freely

___ Check belt tension and condition

___ Bearings in good condition

___ Check pulleys and motor mounts

Air Distribution Section

___ Check for restriction in grille(s)

Condensate Drain and Pump (if applicable)

___ Check for water leaks

___ Check for restricted air flow

___ Pump operation

Steam Generating Humidifier

___ Checkcanister fordepositsand waterlevel

___ Checkcondition ofsteam hoseandclamps

Infrared Humidifier (if applicable)

___ Check humidifier lamps

___ Check pan for mineral deposits

Electrical Panel

___ Check contactor operation

___ DAPIIIcontrolpanel operations

Equipment Runtimes

Blower _________ hrs

Reheat No. 1 _________ hrs

Reheat No. 2 _________ hrs

Reheat No. 3 _________ hrs

Humidifier _________ hrs

Dehumidification _________ hrs

Chilled Water Cooling _________ hrs

__ Reset all to read zero runtimes

Temperature/Humidity set at: ___° ___% RH

Notes: ________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

20

Table of contents

Other Data Aire Chiller manuals

Popular Chiller manuals by other brands

Ocean Breeze

Ocean Breeze Micro Series instructions

Zanussi

Zanussi ZANUSSI easyChill 110043 Brochure & specs

Liebert

Liebert CBH 025 Service manual

Accu

Accu EQ Series Installation, operation and maintenance manual

Daikin

Daikin REYQ-AATJA Service manual

Arctica

Arctica HEF967 Installation, operation & maintenance manual