Data Industrial 200 Series User manual

200 Series

Plastic Tee Type Flow Sensors

by Data Industrial

Owner's Manual

Introduction

Used in conjunction with any Data Industrial flow monitor or

transmitter, Data Industrial non-magnetic flow sensors provide an

accurate reading of the rate of liquid flow as well as total

accumulated flow. A number of sensor models are offered,

which cover applications for a wide range of pipe si es and

pressure/temperature specifications.

The flow sensors generate a frequency which is proportional to flow rate. An internal preamplifier allows the

pulse signal to travel up to 2000 feet without further amplification. Power to operate the sensor is provided by

the flow monitor. The impeller bearing assembly, shaft and O-rings are replaceable in the field.

Data Industrial flow sensors feature a closed, six-bladed impeller design, using a proprietary, non-magnetic

sensing technology. The forward-swept impeller shape provides higher, more constant torque than four-bladed

impeller designs, and is less prone to fouling by water-borne debris. The forward-curved shape, coupled with

the absence of magnetic drag, provides improved operation and repeatability, even at lower flow rates. As the

liquid flow turns the impeller, a low impedance signal is transmitted with a frequency proportional to the flow rate.

Sensors of similar type are interchangeable, so there is no need for recalibration after servicing or

replacement.

Electronic Types

Data Industrial provides several basic sensor configurations using the same impeller element. This allows for a

wide range of applications and pipe si es. Sensors are normally supplied with 20 feet of 2-conductor 20 AWG

shielded U.L. type PTLC 105°C cable. Optional sensors designated with the prefix "IR" feature two single

conductor 18 AWG solid copper wire leads 48 inches in length with U.L. Style 116666 direct burial insulation.

These IR models are used in below grade applications such as irrigation, municipal, and groundwater monitor-

ing. All 200 series sensor electrical components are self-contained. Pressure/temperature ratings for the

various models are contained in the Specifications section of this manual. These models can be further de-

scribed as follows:

"Standard" Sensor

Designed for indoor or protected area applications such as HVAC, pump control, and industrial process monitor-

ing where the flow rates are between 0.5-30 feet/second and temperatures are below 221°F. Standard sensors

are supplied with 20 feet of 2-conductor 20 AWG shielded U.L. type PTLC 105°C cable.

"IR" Sensor

Designed for below grade applications such as irrigation, municipal, and groundwater monitoring where the flow

rates are between 0.5-30 feet/second and temperatures are below 180°F. IR sensors are supplied with two

single conductor, 18 AWG solid copper wire leads 48 inches in length with U.L. Style 116666 direct burial

insulation.

PN# 72022

10/10/02 Rev E1

Data Industrial Plastic Tee Type Flow Sensor Manual

2

"FM/CSA" Sensor

Designed for indoor or protected area applications where intrinsic safety is required and the flow rates are

between 0.5-30 feet/second and temperatures are below 221°F. FM/CSA sensors are supplied with 20 feet of

2-conductor 20 AWG shielded U.L. type PTLC 105°C cable. These sensors must be used with an approved

safety barrier.

"Magnetic" Sensor

Designed for use with the Series 1400 battery powered flow monitor in above or below or grade applications

such as irrigation, municipal, and groundwater monitoring where the flow rates are between 1-30 feet/second

and temperatures are below 221°F.

Model 22 PV (Formerly 220P)

These models feature a modified

PVC tee with solvent weld socket

end connections, and a removable,

PPS or PVDF sensor insert. Si es of

1 1/2, 2, 3 and 4 are available.

Model 22 PD and 220PF

No longer in production - see

obsolete manuals @

www.dataindustrial.com

Mechanical Installation

General

The accuracy of flow measurement

for all flow measuring devices is

highly dependent on proper location

of the sensor in the piping system.

Irregular flow velocity profiles caused

by valves, fittings, pipe bends, etc.

can lead to inaccurate overall flow

rate indications even though local

flow velocity measurement may be

accurate. A sensor located in the

pipe where it can be affected by air

bubbles, floating debris, or sediment

may not achieve full accuracy and

could be damaged. Data Industrial

flow sensors are designed to operate

reliably under adverse conditions,

but the following recommendations

should be followed to ensure

maximum system accuracy:

1) Choose a location along the pipe where 10 pipe diameters upstream and 5 pipe diameters downstream of

the sensor provide no flow disturbance. Pipe bends, valves, other fittings, pipe enlargements and reductions

should not be present in this length of pipe.

2) The preferred location for the sensor around the circumference of a hori ontal pipe is on top. If trapped air or

debris will interfere, then the sensor should be located further around the pipe from the top but not more than

45 degrees from top dead center. The sensor should never be located at the bottom of the pipe, as sediment

may collect there. Locations off top dead center cause the impeller friction to increase, which may affect

performance at low flow rates and increase wear. Any circumferential location is correct for installation in

vertical pipes. Rising flow preferred to reduce effects of any trapped air.

200 Series Plastic Tee Sensors Matrix (1½" to 4")

Example:

2

x

x

x

x

x

-

x

x

x

x

Style

Tee Mounted

28

Material

PVC

PV

CPVC

CPV

Size

1.5"

15

2"

20

3"

30

4"

40

Electronics Housing

PPS

0

PVDF

1

ELECTRONICS

Magnetic

2

FM/CSA Approved

4

Standard

5

IR-Irrigation (not available with PVDF sensors)

6

O-RING

Viton

®

0

EPDM

1

Kalrez

®

2

Food Grade Silicone

3

Neoprene

4

Chemraz

®

5

Teflon

®

Encapsulated Viton

®

6

Teflon

®

Encapsulated Silicone

7

Buna N

8

SHAFT

Zirconia Ceramic

0

Hastalloy C

®

1

Tungsten Carbide

2

Titanium

3

Monel

®

5

316 Stainless Steel

6

Tantalum

7

IMPELLER

Nylon

1

Tefzel

®

2

BEARING

Pennlon

1

Tefzel®2

Teflon

®3

Chemraz

®

is a registered trademark of Green Tweed.

Kalrez

®

, Viton

®

, Teflon

®

, Tefzel

®

are registered trademarks of Dupont Dow Elastomers.

Monel is a registered trademark of Inco Alloys Int’l.

Hastalloy C is a registered trademark of Haynes Int’l Inc.

Data Industrial Plastic Tee Type Flow Sensor Manual

3

Mechanical Installation for 22 PV Plastic Tee Sensors

1) Note intended direction of flow as indicated by arrows on the tee. There must be free, unrestricted pipe for

at least 10 diameters upstream and 5 diameters downstream of the tee.

2) Remove the clevis pin and remove the sensor from the tee.

3) Properly clean the pipe ends and tee sockets.

4) For 228PV, solvent cement the pipe to the tee.

5) Reinstall sensor in tee as follows:

a) Align the flow arrow on the top of the sensor housing in the direction of flow.

b) Carefully press sensor straight into tee.

c) Install clevis pin through tee, sensor, and conduit cap, and install cotter ring.

Electrical Installation "Standard" sensors

1) Route the cable from the sensor to a Data Industrial flow monitor/transmitter. The cable may be extended

up to 2000 feet, using 2-conductor shielded 20 AWG or larger stranded copper wire. Be sure to leave

enough flexibility in the cable or conduit to allow for future service of sensor, if necessary.

2) When connecting to a Data Industrial flow monitor/transmitter, locate the section of terminal strip on the

monitor labeled "SENSOR INPUT" or "SENSOR". Connect the red wire to "IN", "SIGNAL(+)" OR

"SIGNAL" terminal and the black wire to "GND", "SIGNAL(-)", or "COM" terminal and the shield drain wire

(if applicable) to "SLD".

3) When interfacing with other equipment consult manufacture for input designations. The signal wave forms

and power requirements are as shown in the Specifications section. Refer to Technical Bulletin 81 @

www.dataindustrial.com

Electrical Installation "IR" sensors

The sensor leads are supplied with watertight caps over the ends.

1) DO NOT remove the plastic caps from the sensor leads until ready to splice. See Application Note 47 and

Technical Bulletin 52 @ www.dataindustrial.com

2) Use a twisted pair cable suitable for direct burial to connect the sensor to the transmitter, monitor, or

controller. Multi-pair telecommunication cable or direct burial cables may be used.

3) Make a water tight splice. Two part epoxy type waterproof kits are recommended. Be sure the epoxy seals

the ends of the cable jacket.

4) Make sure the epoxy is hardened before inverting the splice or dropping it in standing water.

5) DO NOT make an underground splice unless absolutely necessary.

6) Route the cable from the sensor to a Data Industrial flow monitor/transmitter. The cable may be extended

up to 2000 feet, using 2-conductor shielded 20 AWG or larger stranded copper wire with appropriate ratings.

Be sure to leave enough flexibility in the cable or conduit to allow for future service of sensor, if necessary.

7) When connecting to a Data Industrial flow monitor/transmitter, locate the section of terminal strip on the

monitor labeled "SENSOR INPUT" or "SENSOR". Connect the red wire to "IN", "SIGNAL(+)" OR

"SIGNAL" terminal and the black wire to "GND", "SIGNAL(-)", or "COM" terminal and the shield drain wire

(if applicable) to "SLD".

8) When interfacing with other equipment, the signal wave forms and power requirements are as shown in the

Specifications section. Refer to Technical Bulletin 81 @ www.dataindustrial.com

Data Industrial Plastic Tee Type Flow Sensor Manual

4

Electrical Installation "Magnetic" sensors

The magnetic sensor has a custom wire connector that connects to the series 1400 monitor only. The cable

may be extended up to 100 feet from the sensor. If extension cables are needed they may be ordered from

Data Industrial.

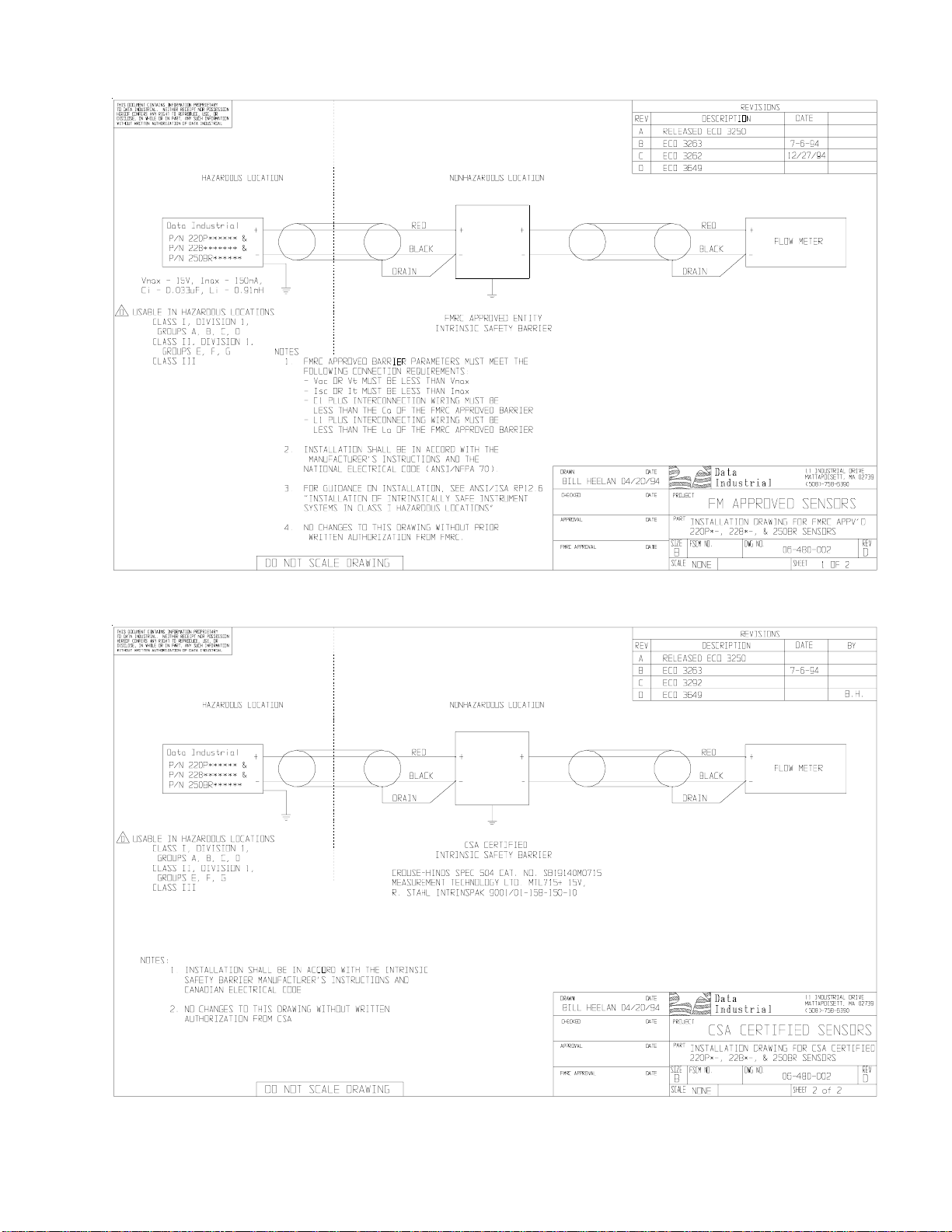

Electrical Installation (FM Sensors)

The Series 200 Sensor is approved, as an entity, as Intrinsically Safe when installed in conformance with Data

Industrial installation drawings 06-480-001 or 06-480-002 (samples shown on Page 5) as specified on the blue

label identifying an intrinsically safe sensor.

Entity approval implies that only the sensor is approved as intrinsically safe. Unless power supplies, equipment,

and instruments connected to the sensor are each rated either explosion-proof or intrinsically safe, these

devices cannot be installed in a ha ardous area. The referenced installation drawing shows such apparatus

located in a non-ha ardous location. Proper interfacing between the ha ardous and non-ha ardous areas must

be provided. It is of absolute importance that this interface be constructed and that all wiring be performed by

qualified contractors. To ensure the Intrinsic Safety of the installation, the connection of the intrinsically safe

sensor to instruments and or power supplies must take place using an approved intrinsically safe barrier located

in a non-ha ardous area. These barriers, listed below, are readily available from various suppliers.

Manufacturer: Barrier:

Crouse-Hinds Spec 504 Cat No. SB19140M0715

Measurement Technology Ltd. MTL 715+ 15 V

R Stahl Intrinspak 9001/01-158-150-10

Cable Length

Part #

5’ 7101

10’ 7108

20’ 7102

50’ 7109

Data Industrial Plastic Tee Type Flow Sensor Manual

5

Data Industrial Plastic Tee Type Flow Sensor Manual

6

Calibration Table for Series 228PV

Calibration

Data Industrial sensors use unique K and offset numbers for calibration. These numbers are derived from

calibration runs using NIST traceable instruments. Using both a K and an offset number provides higher accu-

racy than using a K factor alone. K and offset numbers for each tee configuration are listed in the following table.

Calibration Tables

The table below provides calibration and operation data for Data Industrial Plastic Tee Sensors 1.5 to 4.

Column 1 Sensor Model Number

Column 2 Apparent I.D. - For use with the Series 900 and the Series 1000

Columns 3 and 4 The K value and Offset values to use in our frequency equation:

This equation describes the frequency of the output signal of all Data Industrial flow

sensors. By substituting the appropriate K and Offset values from the table, the

sensors output frequency can be calculated for each pipe si e. This information is

required when calibrating an output board or when using the raw sensor data as

direct output to interface with a device that is not a Data Industrial product.

Column 5 This column indicates the suggested flow range of each tee sensor. Data Industrial

sensors will operate both above and below the indicated flow rates. However, good

design practice dictates the use of this range for best performance.

Sensors should be si ed for flow rather than pipe si e. To prevent disturbances to

the flow profile always connect the sensor tee to pipe nipples measuring at least 10

pipe diameters in length on the up stream (supply) side and at least 5 pipe

diameters in length on the downstream (delivery) side before making the transition

in pipe si e.If a lesser flow rate is chosen, an insufficient span exists for the proper

operation of these circuits. This can result in excessive ripple and fluctuations in

signal, which can adversely affect system performance.

)UHT *SP

.RIIVHW

Apparent I.D. Suggested

Model for Series K Offset Operating

1000, 900 Value Range

(GPM)

228PV15xx-xxxx 1.5 1.699 -0.316 5-100

228PV20xx-xxxx 1.94 2.8429 0.1435 10-200

228PV30xx-xxxx 4.02 8.309 0.227 20-300

228PV40xx-xxxx 5.15 13.74283 0.23707 40-500

Data Industrial Plastic Tee Type Flow Sensor Manual

7

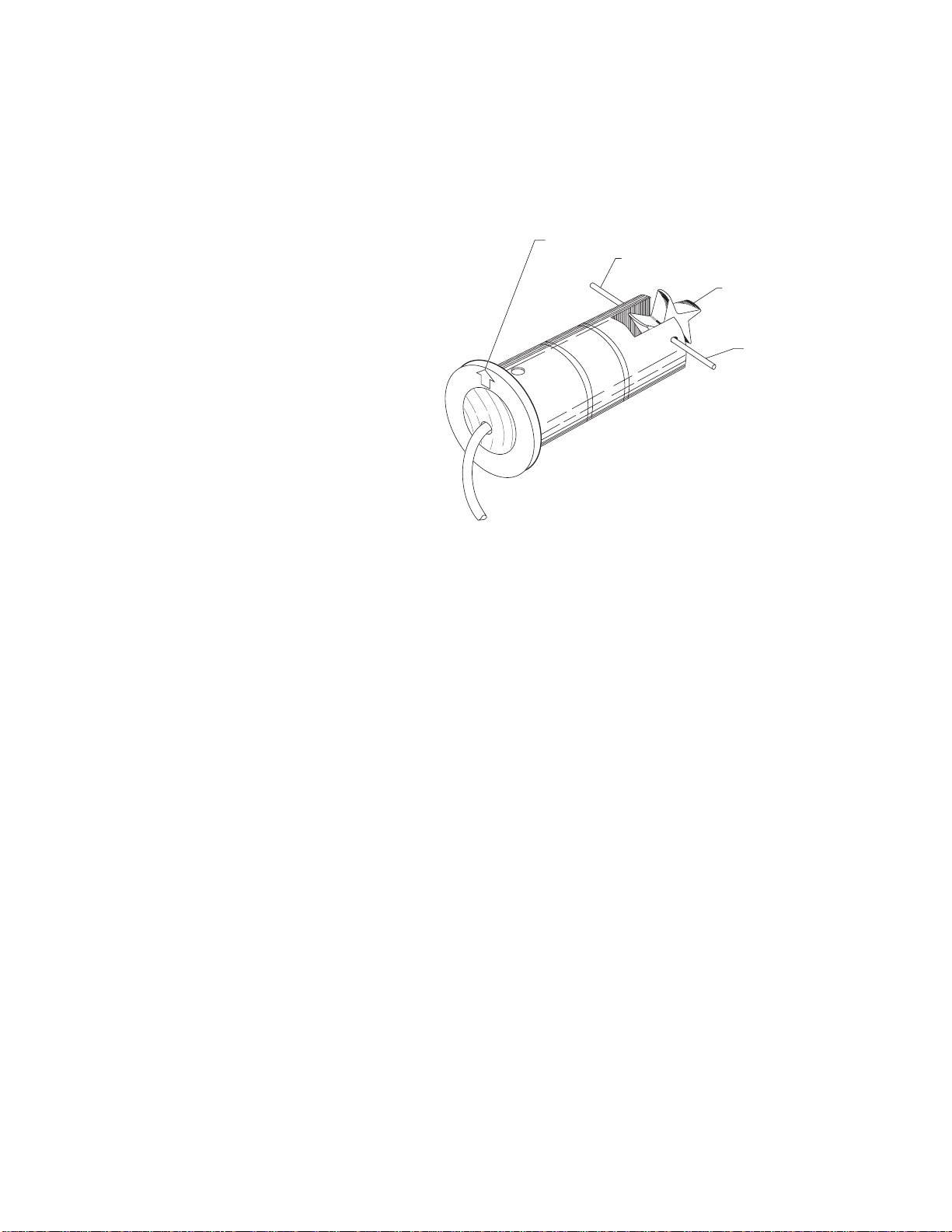

Impeller Assembly and Shaft Replacement

If you are replacing an existing Data Industrial sensor and have already calibrated your flow monitor/transmitter,

no calibration changes are necessary. For installation of a new flow monitor or for relocation of a sensor in a

new pipe si e, please refer to the calibration instructions in flow monitor manual.

1) Depressuri e pipe from which sensor is

to be removed.

2) Remove the clevis pin.

3) Remove the sensor from the tee.

4) Note the impeller blade orientation

relative to flow arrows. In order to

maintain proper calibration, the impeller

will have to be reinstalled in the same

manner with the impeller blades pointing

toward the flow source as indicated by

the flow arrows.

5) To remove the old impeller blade

assembly, push the old shaft out of the

sleeve with the new shaft (or small

diameter rod) just far enough to grab

the end with a pair of pliers and pull the

shaft completely out. The impeller assembly will now be free, and will drop out.

6) Inspect the shaft and bearings for wear, and replace as necessary.

7) Refer to Figure 1. To reinstall, position the impeller in the cavity oriented as in Step 4 so that the impeller

blades point into the flow direction. The flow direction arrow on the top of the sensor housing should point

downstream with the impeller blades pointing upstream.

8) Carefully push the shaft through the housing and impeller, taking care not to damage bearings. Make sure

that the shaft is inserted far enough so that it clears the housing on each side of the impeller housing.

NOTE: If shaft is not carefully installed, the bearing can be deformed, preventing free rotation.

9) Inspect the O-rings for damage and replace as necessary. Clean the O-rings and the sleeve and relubricate

with silicone grease from the packet provided, or use some other acceptable lubricant.

10) Install the sensor into the tee so the flow arrows points in the direction of the actual flow.

11) Install or replace the clevis pin.

13) This completes the replacement procedure. The system may now be repressuri ed and tested.

NOTE DIRECTION OF ARROW

USE PLIERS HERE

NOTE DIRECTION OF

IMPELLER

USE METAL PIN TO

REMOVE CERAMIC SHAFT

Figure 1

Impeller Assembly and Shaft Replacement

Data Industrial Plastic Tee Type Flow Sensor Manual

8

Temperature (°C)

Pressure (psi)

0

20

40

60

80

100

02560

220PV

PRESSURE/TEMPERATURE DIAGRAMS FOR

DATA INDUSTRIAL FLOW SENSORS

Specifications

Wetted Materials (except tees)

See Ordering Matrix

Tee for 22 PV

Schedule 80 PVC per ASTM D-2462 and D-2467.

Virgin, unplastici ed PVC resin, Type 1 cell classifi-

cation

12454-B. Fittings and solvent carry approval for

potable water by NSF and IAMPO.

Pressure, Temperature Ratings

Depends on hardware configurations. See Dia-

grams at end of this section.

Recommended Design Flow Range

½ to 30 ft/sec

Accuracy

± 1.0% of full scale over recommended design flow

range

Repeatability

± 0.3% of full scale over recommended design flow

range for 228PV

Linearity

± 0.2% of full scale over recommended design flow

range for 228PV

Transducer Excitation

Quiescent current 600uA@8VDC to 35VDC max.

Quiescent voltage (Vhigh)

Supply Voltage -(600uA*Supply impedance)

ON State (VLow) Max. 1.2VDC@40mA current limit

(15ohm+0.7VDC)

Output Frequency

3.2 H to 200 H for all except 228PF

Output Pulse Width

5 msec ±25%

Electrical Cable for Standard Sensor Electronics

20 feet of 2-conductor 20 AWG shielded U.L. type

PTLC wire provided for connection to display or

analog transmitter unit. Rated to 105°C. May be

extended to a maximum of 2000 feet with similar

cable and insulation appropriate for application.

Electrical Cable for IR Sensor Electronics

48 inches of U.L. Style 116666 copper solid AWG

18 wire w/direct burial insulation. Rated to 105°C.

Data Industrial Plastic Tee Type Flow Sensor Manual

9

Troubleshooting

1) If the voltage at the sensor input is less than 7 VDC in a No Flow situation, disconnect the sensor from the

barrier strip and measure the voltage at the sensor input terminals of the barrier strip again. It should be

between 8 VDC and 20 VDC. If the voltage at the sensor input is still below 7 VDC or 3 VDC, the problem

may be with the monitor (hardware or programming).

2) If you suspect that the sensor is bad, you can test the monitor circuitry by connecting a piece of wire to

one of the sensor input terminals and tap the other side of the wire to the other sensor input terminal.

Shorting across the sensor input terminals ON and OFF repeatedly allows the display to respond by trying

to calculate a flow rate for the frequency of your shorting action. If the display does not show a change

from 0.00, it indicates a problem with the monitor.

3) If the monitor tests ok and there are any splices in the cable, break the sensor cable at the splice closest

to the sensor and retry the shorting test in step 2.

4) If the cable tests ok, drain the pipe line, verify the pressure is off, and pill the clevis pin holding the sensor

electronics. Spin the impeller by hand. If flows are noted on the display, and impeller spins freely then the

flow rates may have been below our design minimums or the line was full of air. Try again. If the sensor

fails to respond then replace sensor.

Data Industrial Plastic Tee Type Flow Sensor Manual

10

All rights reserved. No part of this work covered by the copyrights hereon may be reproduced or copied in any

form or by any means - graphic, electronic, or mechanical, including photocopying, recording, taping, or informa-

tion and retrieval systems - without written permission of Data Industrial.

Copyright © 2002

Data Industrial Corporation

11 Industrial Drive

Mattapoisett, MA 02739

TEL: 508-758-6390 FAX: 508-758-4057

www.dataindustrial.com

email: [email protected]

Warranty

Data Industrial Corporation (Seller) of 11 Industrial Drive, Mattapoisett, Massachusetts 02739-0740, U.S.A.,

warrants to the original purchaser of its product that such product manufactured by Data Industrial Corporation shall

be free from defects in materials or workmanship when installed, serviced and operated according to Data Industrial

corporation instructions or in other such normal use. This warranty is effective for a period of 12 months from the

date of installation by the Purchaser or 18 months from the date of shipment by the Seller whichever occurs or

terminates first. This limited warranty does not cover damage or loss resulting from corrosion or erosion caused by

acids or other chemicals or by severe environmental conditions or negligent or improper installation or improper

operation, misuse, accident, unauthori ed repair or substitution of components other than those provided by the

Seller, and does not cover limited life components such as bearings, shafts, impellers where wear rate is a function

of application and environment. Any component not manufactured by the Seller but included in its products shall

not be covered by this warranty and is sold only under such warranty as the manufacturer may provide.

If Buyer or Purchaser wishes to make a claim hereunder, he shall send written notice of any defect within the warranty

period, to Seller at the above address. Seller may at its sole option instruct Buyer to ship subject part, postage

prepaid, to the Seller at above address or authori e a representative to inspect the part on site. Seller will at its

sole option repair or replace any defective product covered by this warranty. If Buyer makes repairs or alterations

to any product or part covered by this warranty without Sellers prior written approval, this warranty shall be null and

void.

The foregoing shall constitute Buyers or Purchasers sole and exclusive remedy against Seller, and no other

remedy, including but not limited to, incidental or consequential damages for personal injury, loss of fluids, gases

or other substances or for loss of profits or injury to property or person shall be available to the Buyer or Purchaser.

The warranty extended herein shall be in lieu of any other implied warranty of merchantability or fitness for a particular

purpose, and seller shall bear no liability for representatives or retail sellers. In no event shall Data Industrial

Corporation be liable for any contingent, incidental, or consequential damage or expenses due to partial or complete

inoperability of its product.

This manual suits for next models

4

Table of contents